Plastic surface antibacterial grease-resistant coating and preparation method thereof

A surface antibacterial and oil paint technology, applied in the field of paint, can solve the problems of low construction efficiency, not easy to obtain, slow drying rate, etc., to achieve the effect of convenient construction, strong paint adaptability, and rapid drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

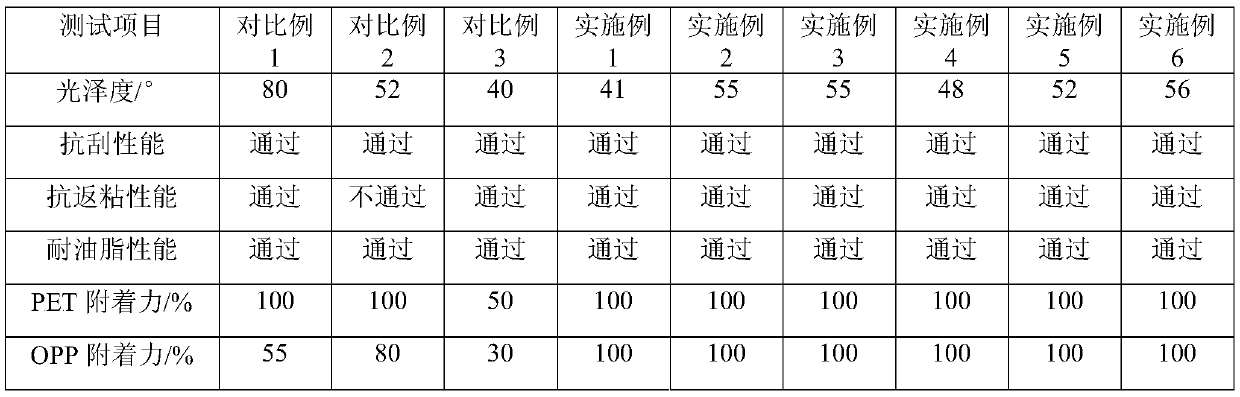

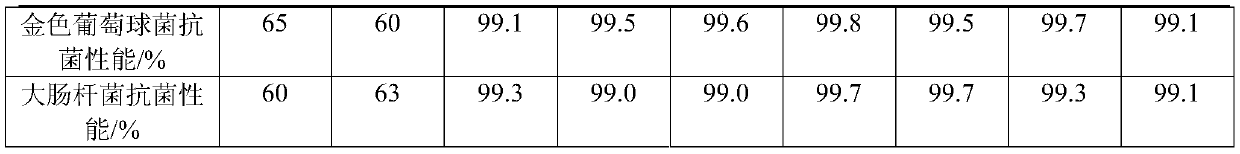

Examples

preparation example Construction

[0045] Preparation of main PU resin:

[0046] Method 1: Put 200g of PTMG with a molecular weight of 2000 into the reactor, vacuumize at 120°C for 1 hour, cool down to 60°C, put in 16.7g of IPDI, heat up to 90°C for 2 hours, add 144.5g of butyl acetate and 72g of ethanol , to obtain the main PU resin a, with a solid content of 50%, and R=0.75.

[0047] Method 2: Put 200g of PPG with a molecular weight of 2000 and 18g of 1,4-butanediol into the reactor, vacuumize at 120°C for 1 hour, cool down to 60°C, put in 90.3g of MDI, heat up to 90°C and react for 2 hours , adding 100g of ethyl acetate and 32g of isopropanol to obtain the main PU resin b with a solid content of 70% and R=1.2.

Embodiment 1

[0055] Adhesion promoter 814S (Nippon Paper) 1.5g, matte powder (Degussa OK420) 3.5g, silicate-loaded elemental silver antibacterial agent 1.0g, and the rest are the same as Comparative Example 1.

Embodiment 2

[0057] 4g of nitrocellulose, 6g of dammar resin, 1.5g of isothiazolinone antibacterial agent, and the rest are the same as in comparative example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com