Patents

Literature

35results about How to "Guaranteed crosslink density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-toughness, anti-impact and high-flexibility epoxy pouring sealant and preparation method thereof

ActiveCN106281174AGuaranteed crosslink densityGuaranteed heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesTO-18Diluent

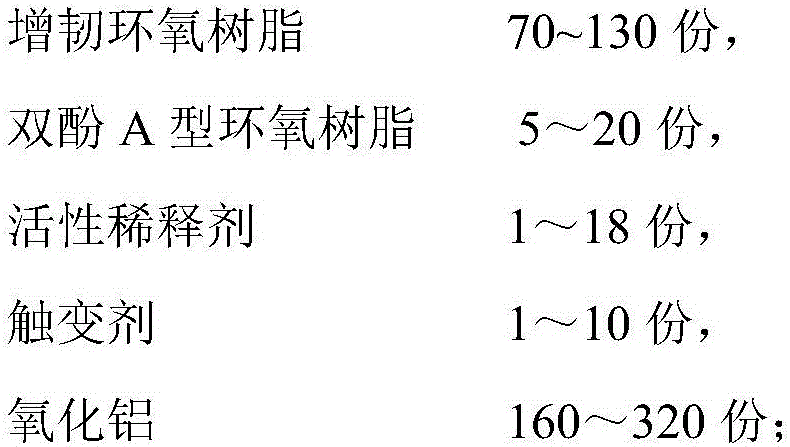

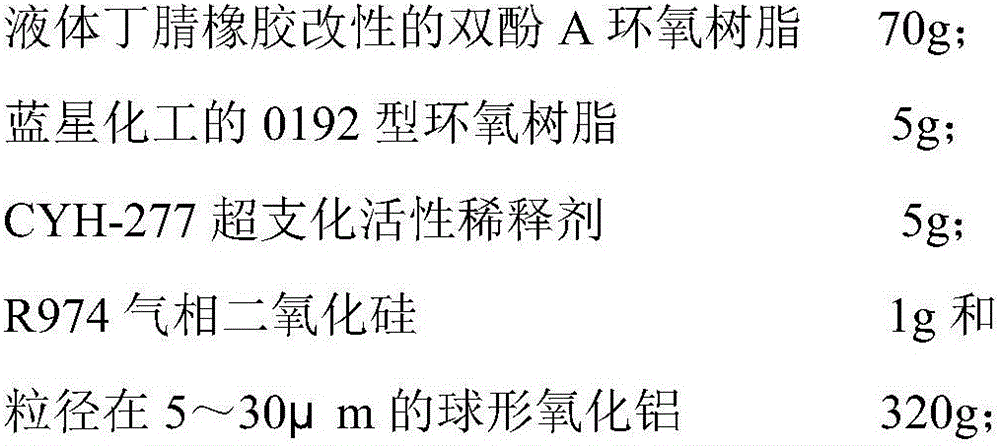

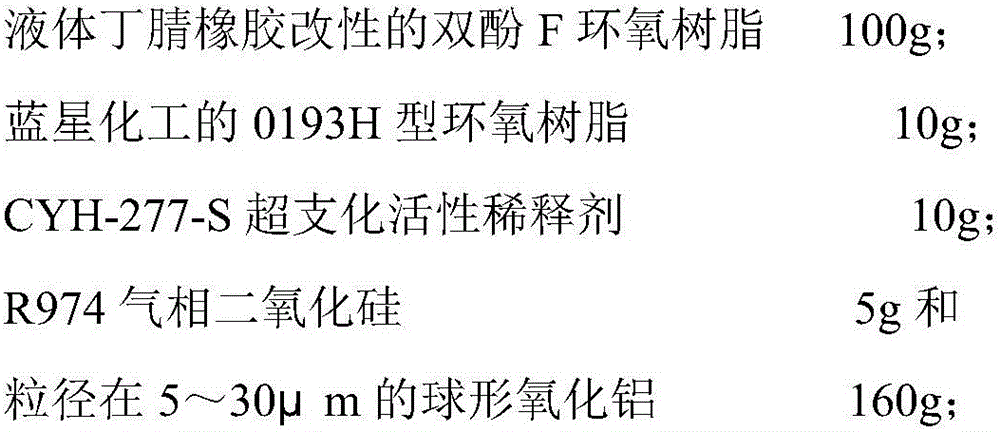

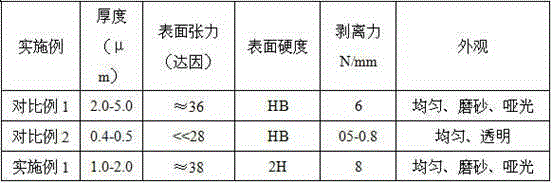

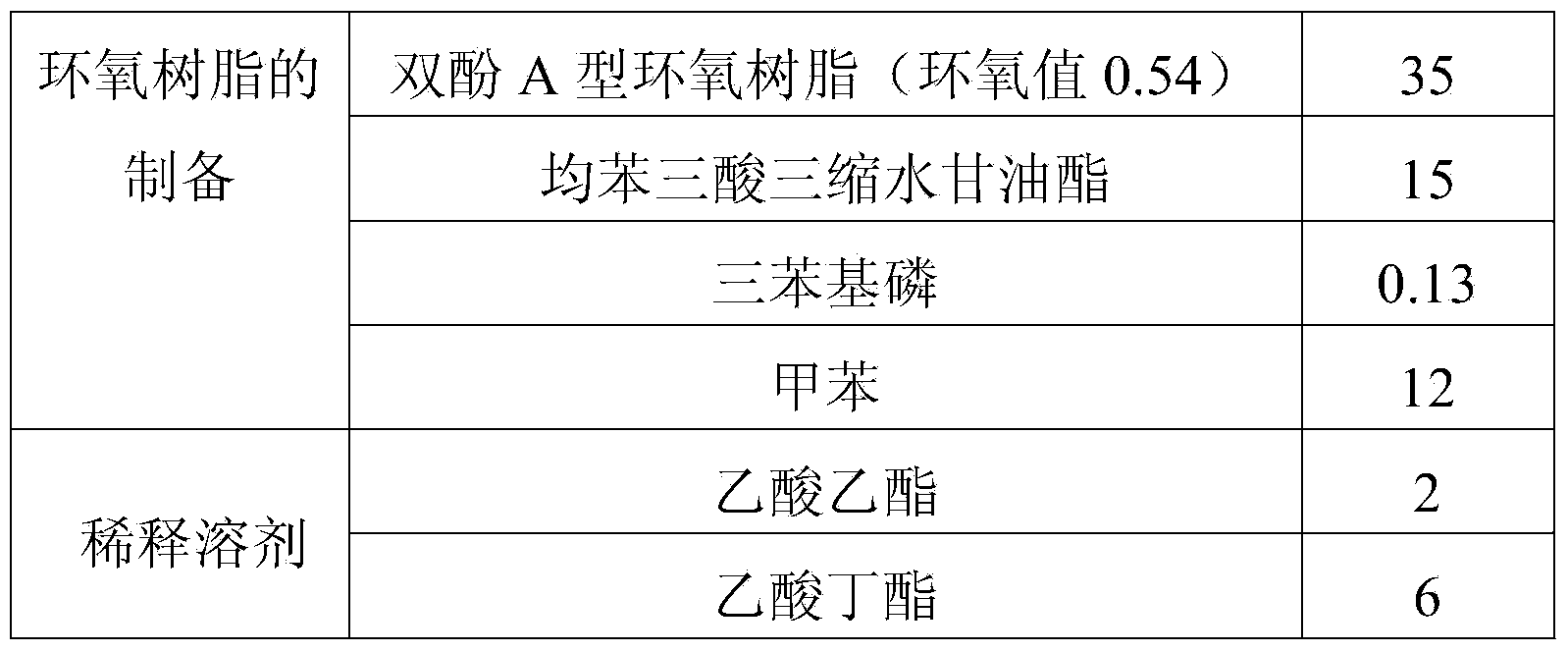

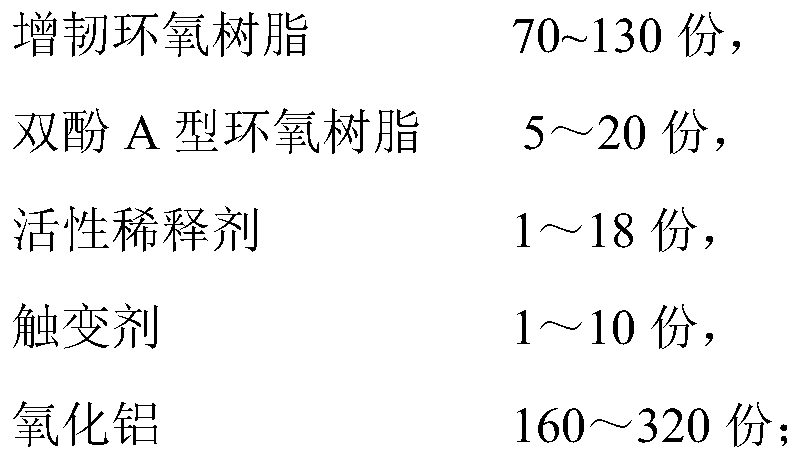

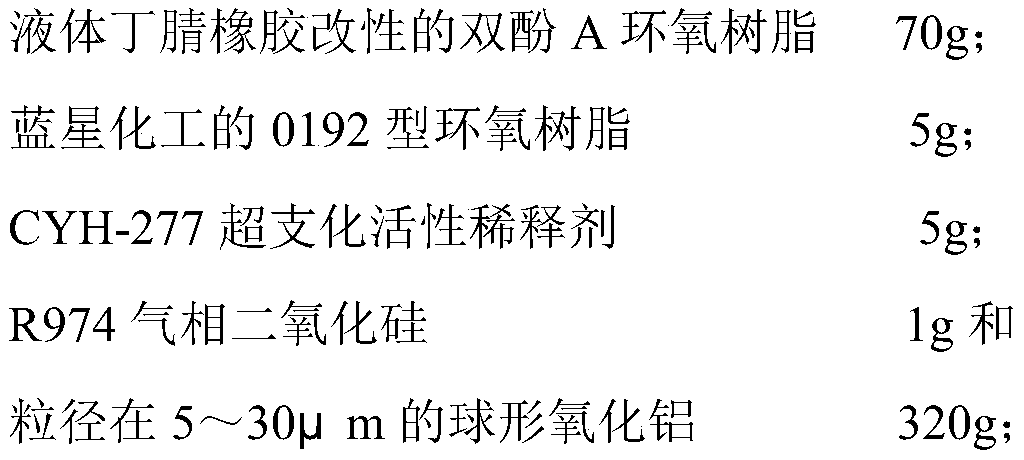

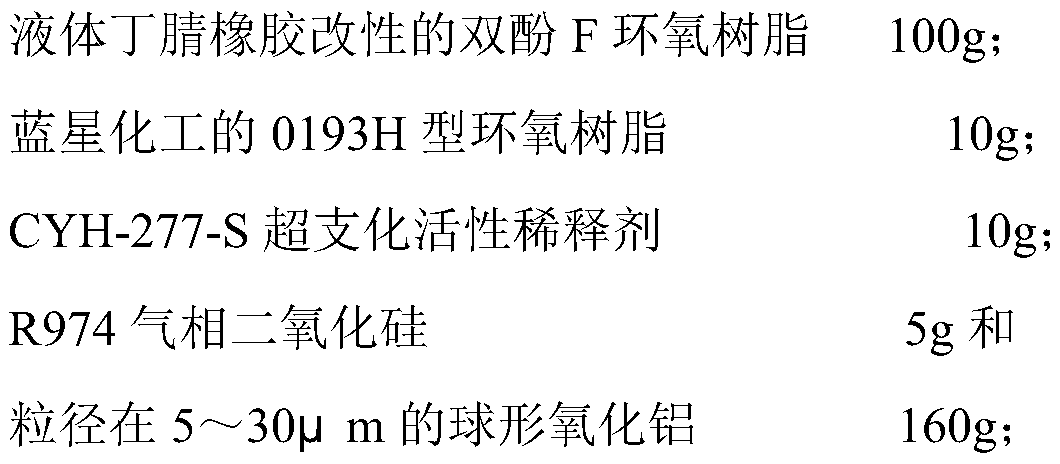

The invention discloses a high-toughness, anti-impact and high-flexibility epoxy pouring sealant. The high-toughness, anti-impact and high-flexibility epoxy pouring sealant is composed of a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 0 to 130 parts of toughening epoxy resin, 5 to 20 parts of bisphenol A type epoxy resin, 1 to 18 parts of an active diluent, 1 to 10 parts of a thixotropic agent and 160 to 320 parts of aluminum oxide; the component B is prepared from the following raw materials in parts by weight: 20 to 50 parts of a flexible curing agent, 25 to 50 parts of a hyperbranched curing agent and 1 to 5 parts of an accelerant; the mass ratio of the component A to the component B ranges from (10 to 1) to (20 to 1). According to a preparation method provided by the invention, the materials are prepared and mixed according to formulas of the component A and the component B respectively. The epoxy resin provided by the invention not only has rubber flexibility, but also has excellent heat-resisting performance and rigidity.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

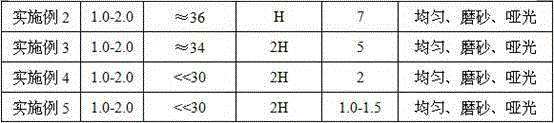

Matt release film

ActiveCN105348946ASolve technical problems caused by residuesHigh residual adhesionCoatingsPolymer scienceAcrylic resin

The invention relates to a matt release film. The matt release film comprises a base film and a matt release coating layer arranged at one side of the base film; and the matt release coating layer is formed by coating a fluorine-containing thermosetting coating, and the coating comprises fluorine series resin, acrylic resin, aldehyde ketone resin, a curing agent system, an assistant, a delustering agent and a mixed solvent. The matt release film has the advantages of low surface tension, good adhesiveness and overcoatability, excellent heat and solvent resistance, and high residual adhesion rate and excellent matt effect after peeling when the matt release film is used in the field of electron manufacturing.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

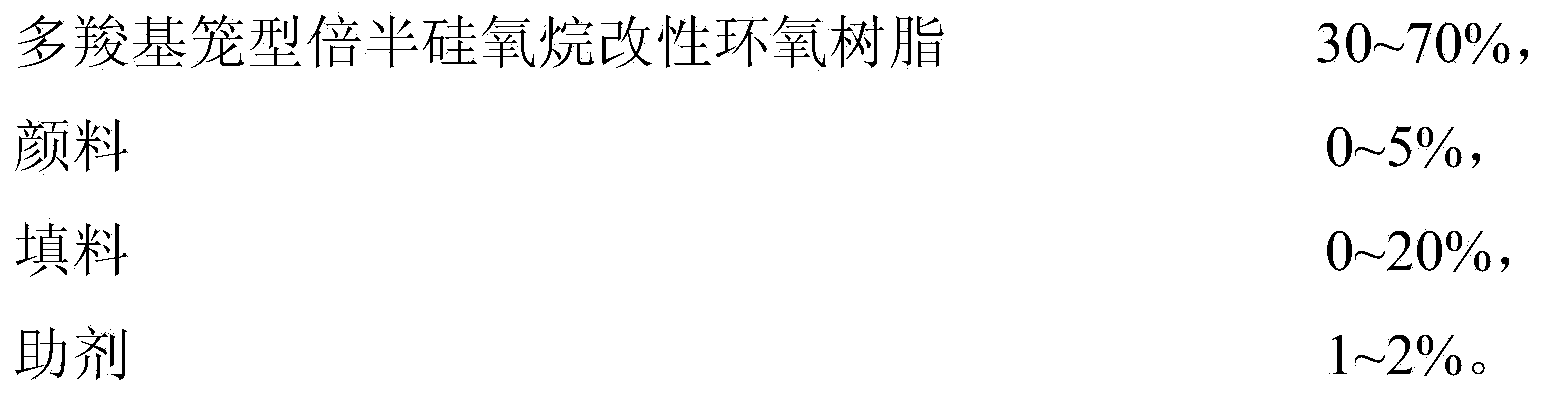

Low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and preparation method thereof

InactiveCN106833503AImprove adhesionImprove mechanical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationALUMINUM STEARATES

The invention discloses a low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant and a preparation method thereof. The silicon sealant is prepared from hydroxyl end-blocked dimethylsiloxane, a plasticizer, white mineral oil, gas phase method silica aerogel, a reinforcing filler, aluminum stearate, pigment, a crosslinking agent, a vulcanization accelerator, a silane coupling agent and a catalyst. The preparation method comprises the following steps: 1) uniformly mixing the hydroxyl end-blocked dimethylsiloxane, the plasticizer, the white mineral oil, the gas phase method silica aerogel, the reinforcing filler, the aluminum stearate and the pigment, and drying the mixture fully to obtain a premix compound; 2) performing vacuum full kneading on the premix compound to obtain base; 3) adding the crosslinking agent, the vulcanization accelerator and the silane coupling agent into the base, performing vacuum stirring uniformly;4) adding the catalyst into the base, performing vacuum stirring uniformly, discharging the mixture, and performing filling and sealing. The low-modulus monocomponent de-ketoxime type room temperature sulfurized silicone sealant provided by the invention has the advantages of neutral solidification, strong bonding power, excellent mechanical property, and good heat resistance and oil resistance.

Owner:GUANGDONG RES INSTITITUTE OF PETROCHEM & FINE CHEM ENG

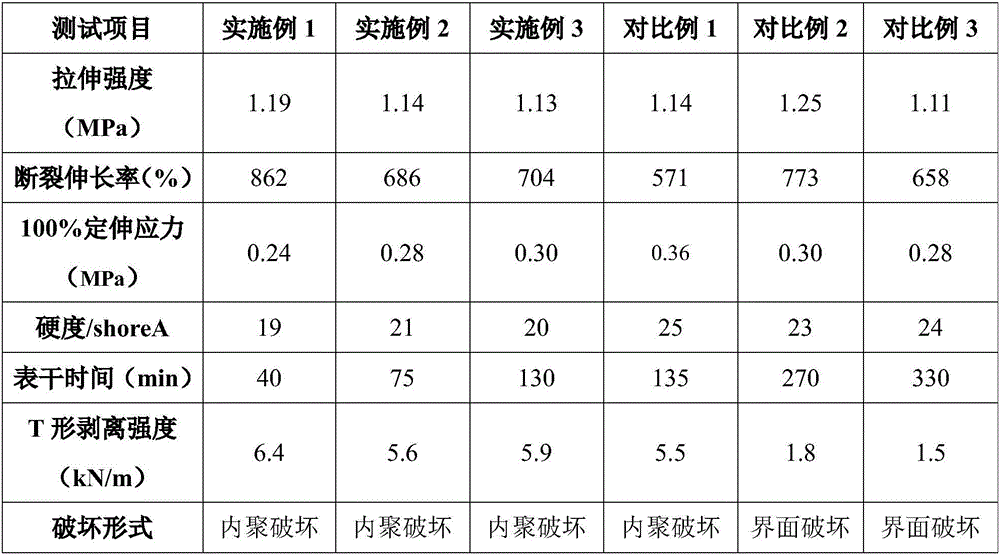

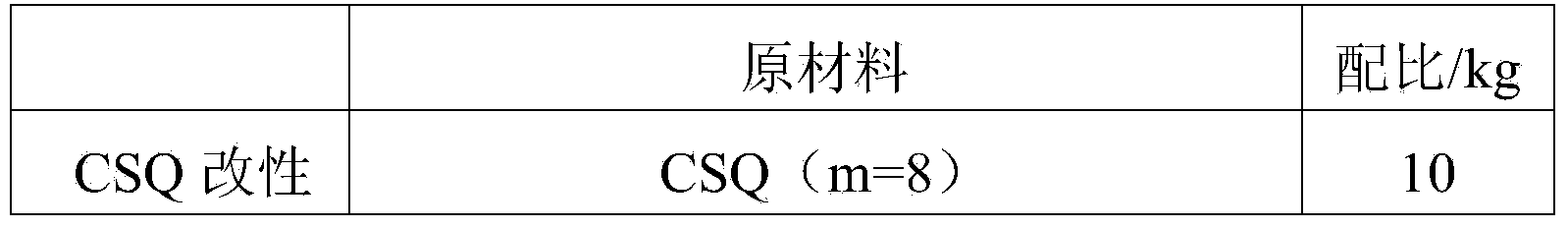

Multi-carboxyl cage silsesquioxane modified epoxy resin and application thereof in coating

InactiveCN103865033AImprove adhesionImprove fullnessPolyurea/polyurethane coatingsEpoxyResin coating

The invention belongs to the field of epoxy resin coating, and discloses a multi-carboxyl cage silsesquioxane (CSQ) modified epoxy resin and an application thereof in coating. The CSQ modified epoxy resin is prepared by following steps of throwing CSQ and epoxy resin into a reaction kettle according to the mass ratio of (1:4)-(1:7), adding a catalyst and an organic solvent, and mixing uniformly; reacting for 2-4 hours at 105-115DEG C, filtering and discharging, so as to obtain CSQ modified epoxy resin containing high activity hydroxyl; and then carrying out curing reaction on the hydroxyl and polyisocyanate group so as to prepare a high hardness quick curing coating, wherein the mass ratio of the organic coating to the curing agent is (30:50)-(70:25). The CSQ modified epoxy resin has high hardness, good abrasion performance and fast drying speed, so that the coating prepared based on the modified epoxy resin has advantages of high hardness, good toughness, fast drying speed, good shock resistance and good corrosion resistance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

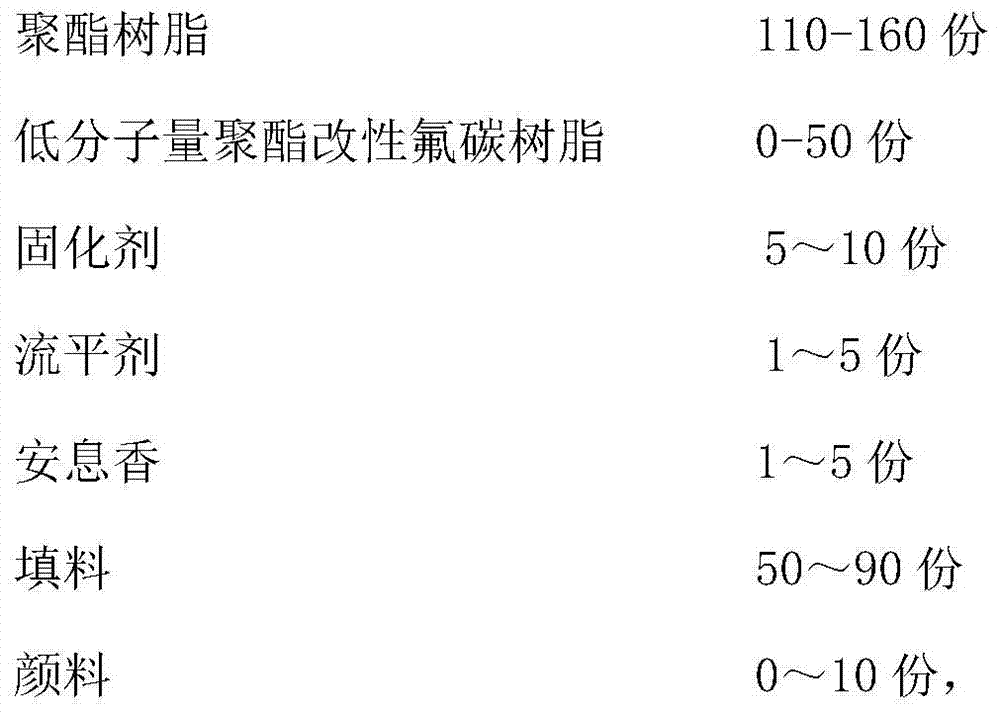

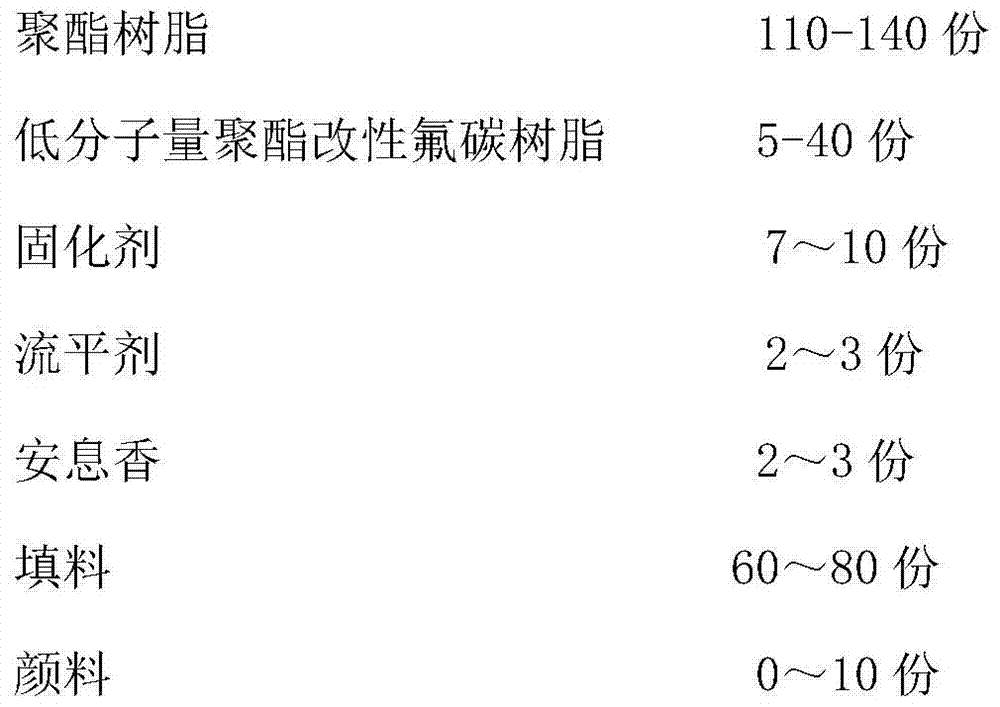

High-infrared rapid-curing powder paint for coil steel and preparation method thereof

ActiveCN105273581AGood compatibilityImprove the disadvantage of poor compatibilityPowdery paintsPolyester coatingsEnergy conservationCoating adhesion

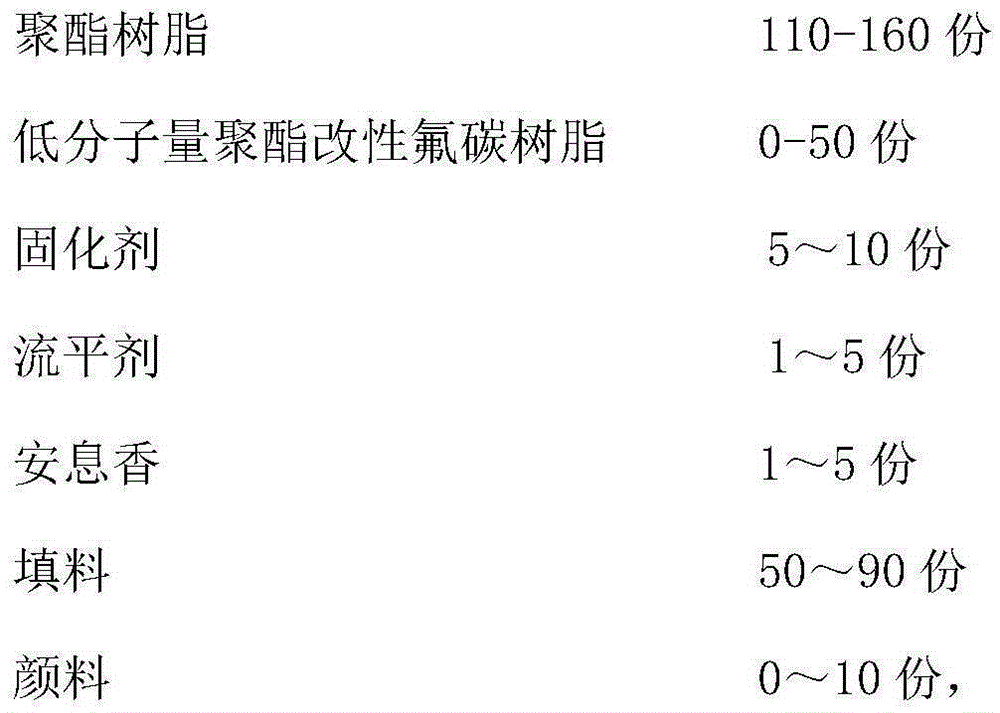

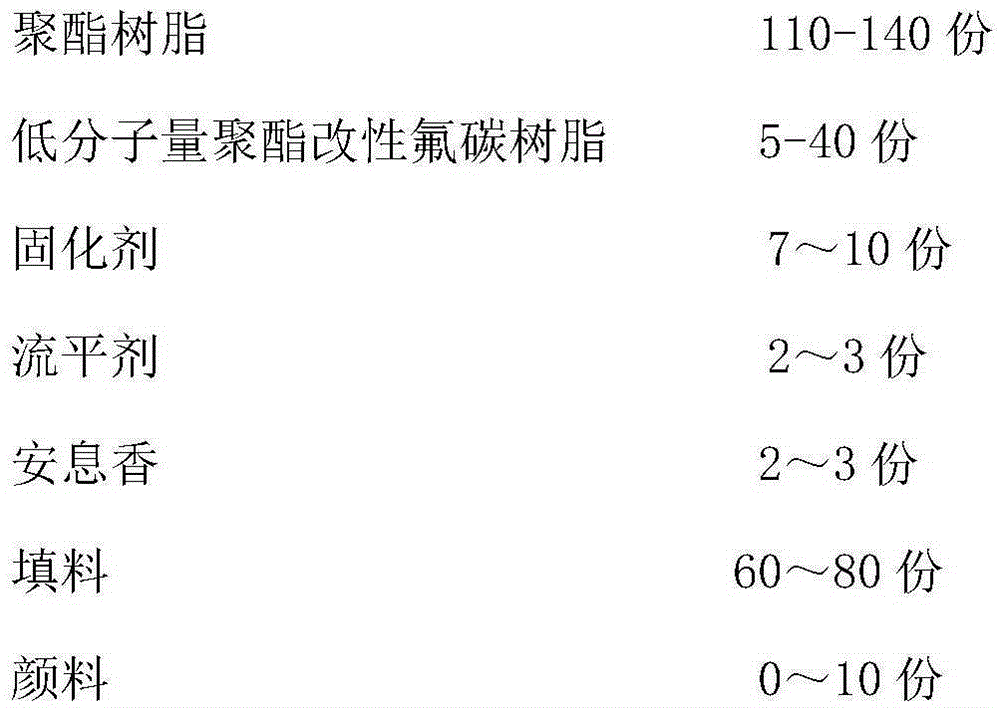

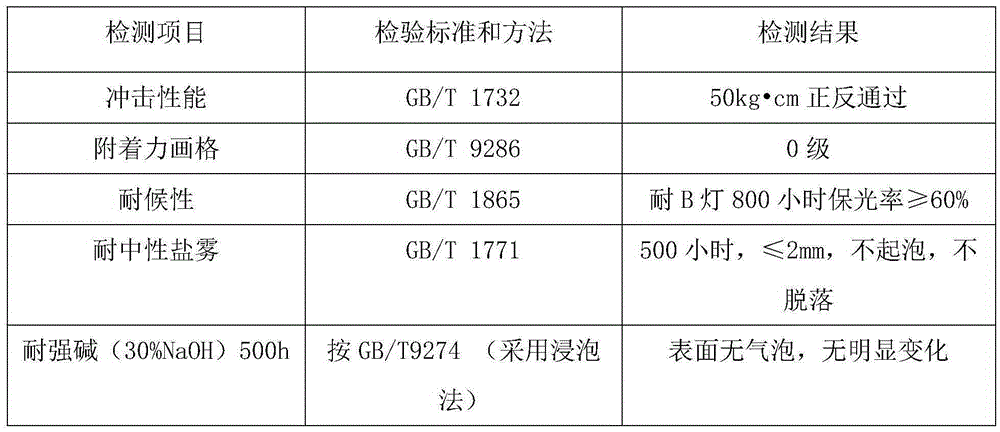

The invention discloses high-infrared rapid-curing powder paint for coil steel. The high-infrared rapid-curing powder paint for the coil steel is prepared from, by weight, polyester resin, polyester-modified fluorocarbon resin with low molecular weight, a curing agent, a flatting agent, benzoin, packing and pigments. According to the powder paint, by adopting the polyester resin with the moderate viscosity and acid value to be compounded with the polyester-modified fluorocarbon resin with the low molecular weight, the coating surface condition and performance requirements are improved; curing can be achieved by performing high-infrared heating for 15-30 s, a cured powder coating is good in adhesive force and has the excellent weather resistance and alkali resistance. The powder paint has the advantages of being short in curing time, excellent in comprehensive performance and the like and can achieve energy conservation and environment protection.

Owner:GUANGZHOU KINTE IND

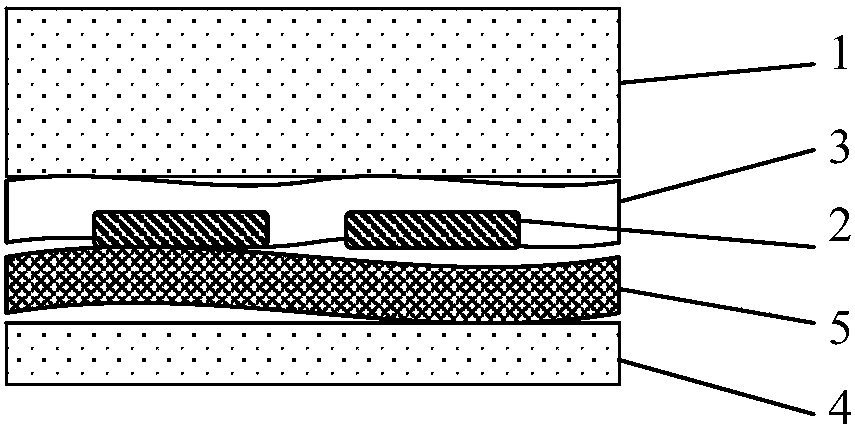

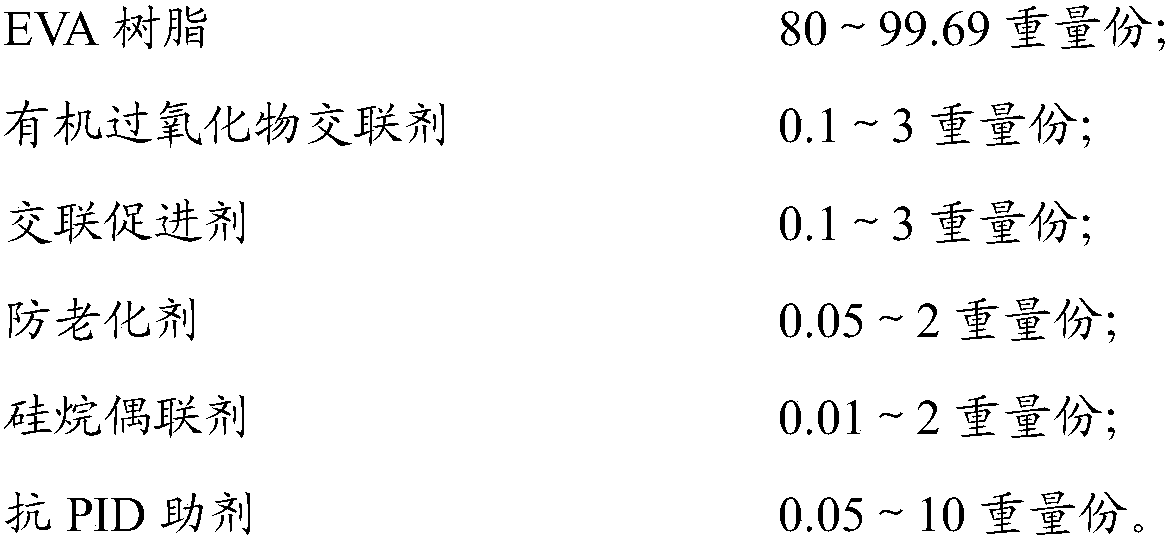

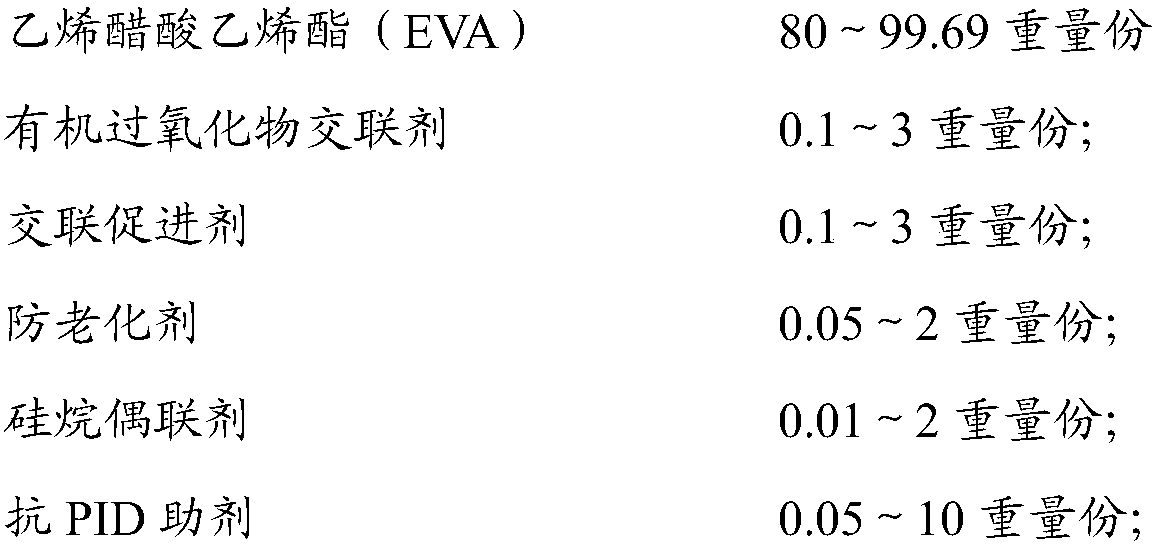

Anti-PID ethylene vinyl acetate film, package assembly and packaging method

ActiveCN109554141AReduce hydrolysisInhibition of hydrolysis reactionNon-macromolecular adhesive additivesMacromolecular adhesive additivesCarbon chainHydrolysis

The invention relates to an anti-PID ethylene vinyl acetate film comprising the following components: 80-99.69 parts by weight of EVA resin; 0.1-3 parts by weight of an organic peroxide crosslinking agent; 0.1 to 3 parts by weight of a cross-linking accelerator; 0.05 to 2 parts by weight of an anti-aging agent; 0.01 to 2 parts by weight of a silane coupling agent; and 0.05 to 10 parts by weight ofan anti-PID auxiliary agent. The invention also provides a package assembly and a packaging method thereof. The anti-PID auxiliary agent of the anti-PID film is resin having a carbon chain and a branched chain containing a plurality of hydroxyl groups, the structure of the resin is similar to the structure of a hydrolyzed product of the EVA resin, progress of EVA hydrolysis reaction can be suppressed, the EVA hydrolysis reaction can be effectively reduced, the crosslink density of the EVA film can be ensured, ions on the surface of the EVA and glass can be effectively blocked from accumulating on the surface of a battery, and the PID phenomenon of the assembly can be suppressed.

Owner:SHANGHAI HIUV NEW MATERIALS

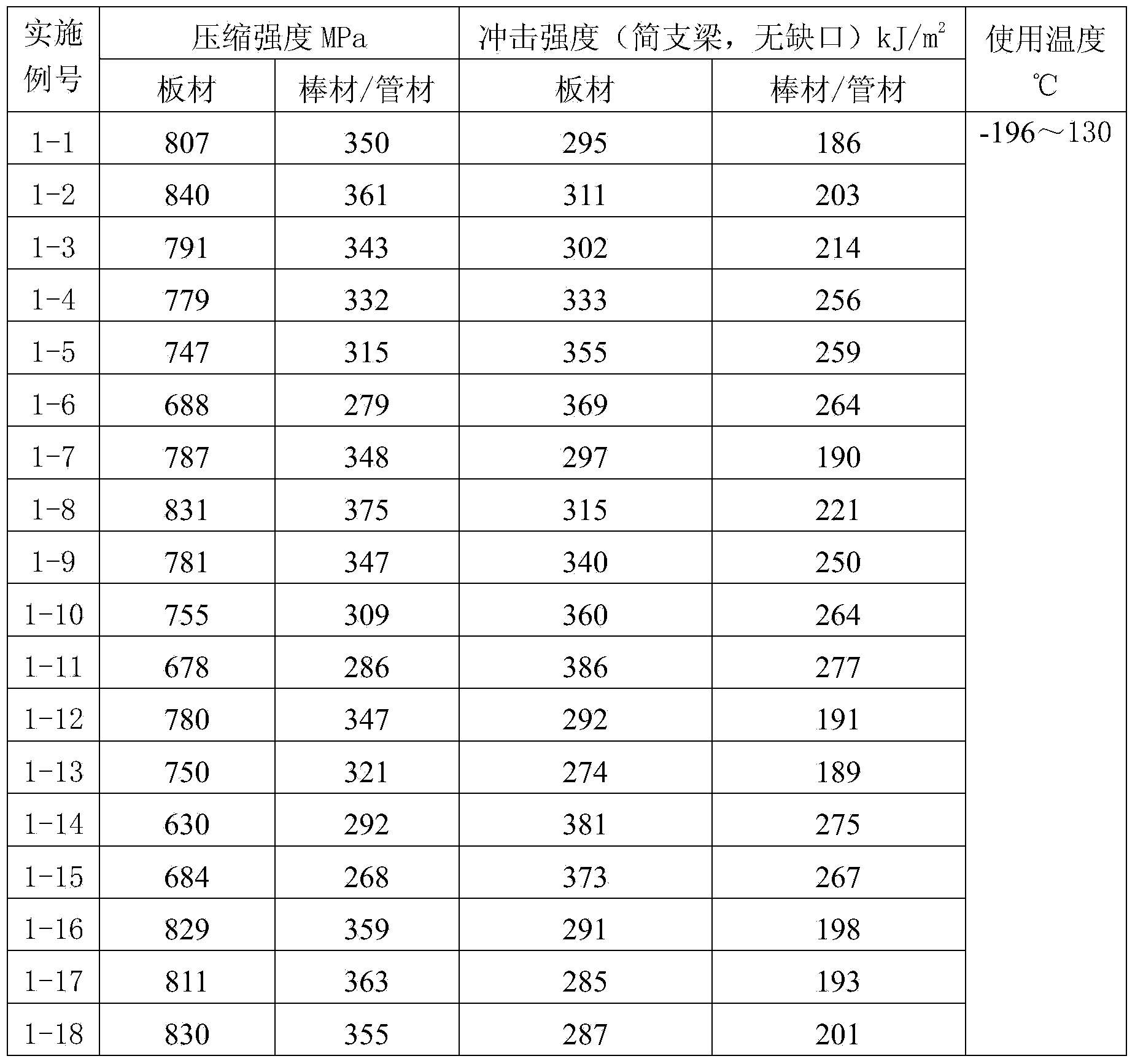

Low-temperature resin composition and preparation method thereof

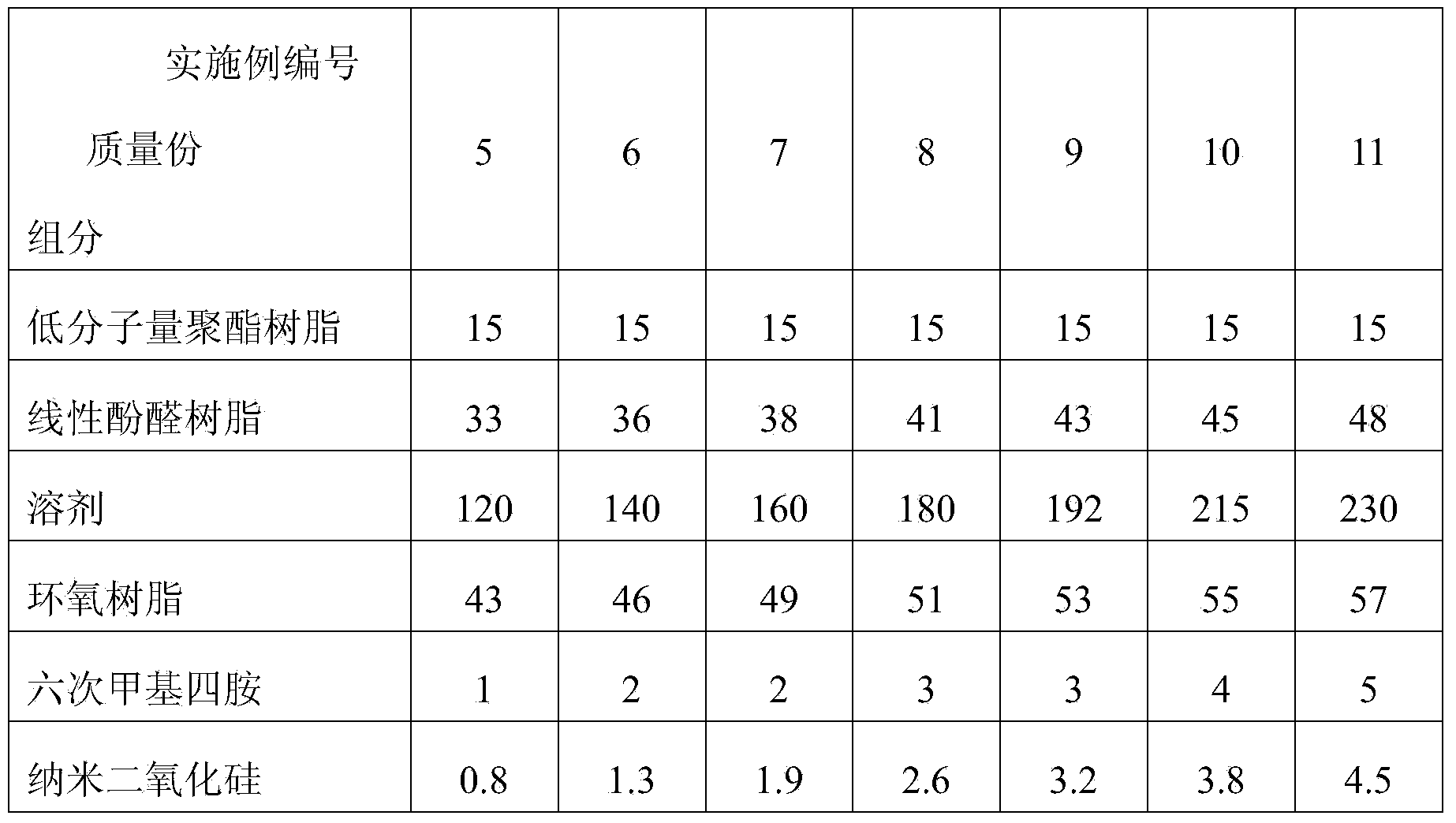

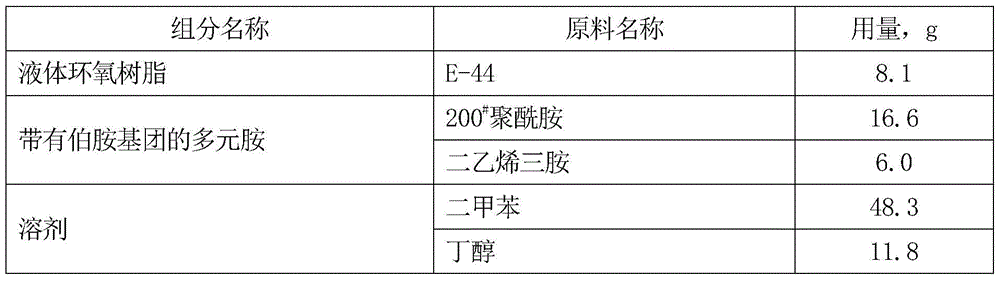

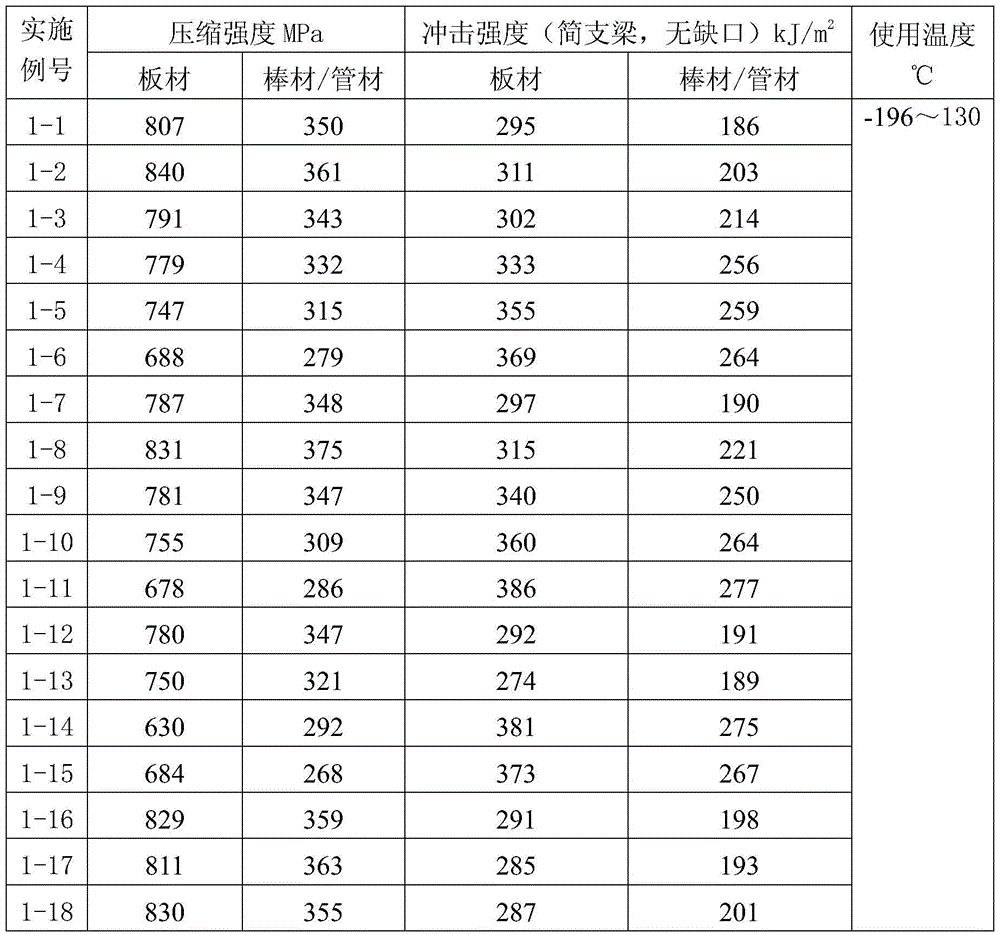

The invention discloses a low-temperature resin composition and a preparation method thereof. The preparation method of the low-temperature resin composition comprises the steps of adding 15 parts by weight of low-molecular weight polyester resin, 30-50 parts by weight of phenolic novolac resin, 0-15 parts by weight of polyvinyl butyral resin and 100-240 parts by weight of solvent to a reactor, stirring for 1-2 hours at 40-60 DEG C, cooling to a room temperature, next, adding 40-60 parts by weight of epoxy resin and 1-5 parts by weight of hexamethylenetetramine, stirring thoroughly for dissolving, and finally, adding 0.5-5 parts by weight of nano silicon dioxide, and thoroughly dispersing and evenly stirring to obtain the low-temperature resin composition. The invention provides a low-temperature resin mixture which can be used as a support structure at minus 196 to 130 DEG C for a glass fiber cloth reinforcing material; the low-temperature resin mixture is especially applicable to low temperatures, has the characteristics of high strength, good toughness, not easy cracking and the like at low temperatures, and is excellent in product properties and high in practicability.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

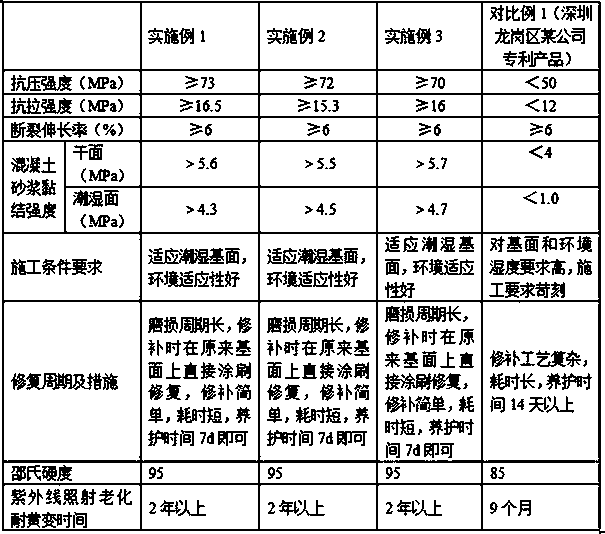

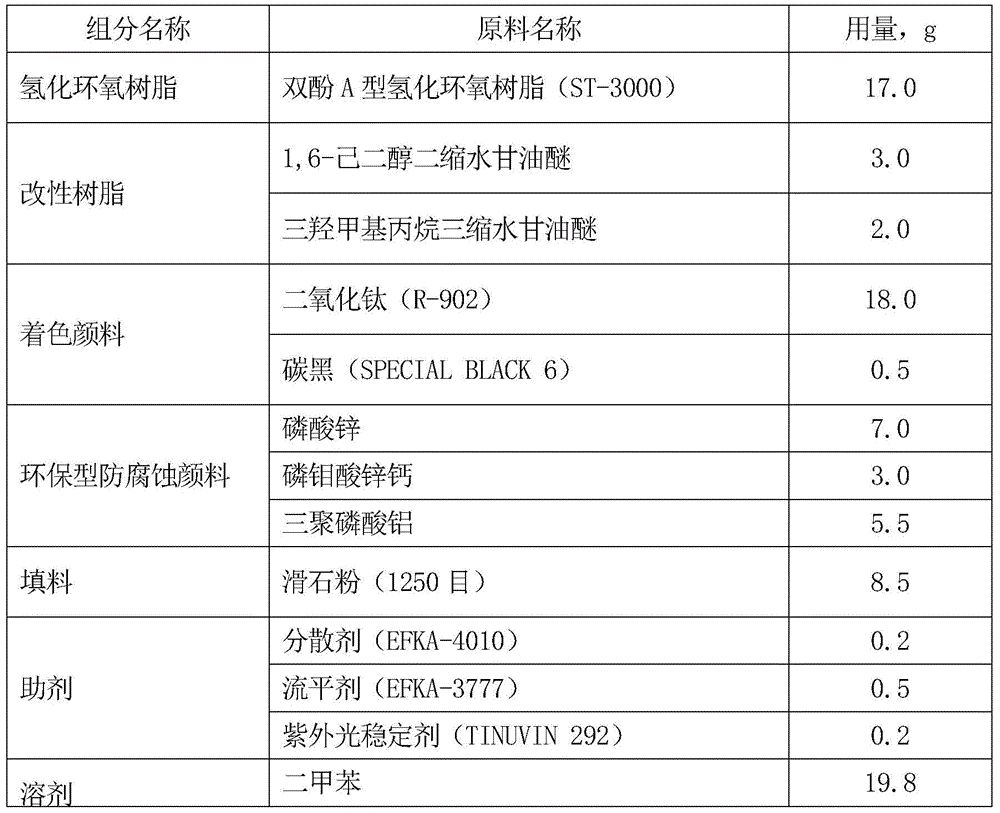

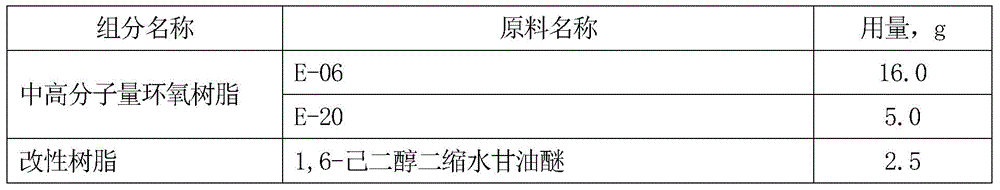

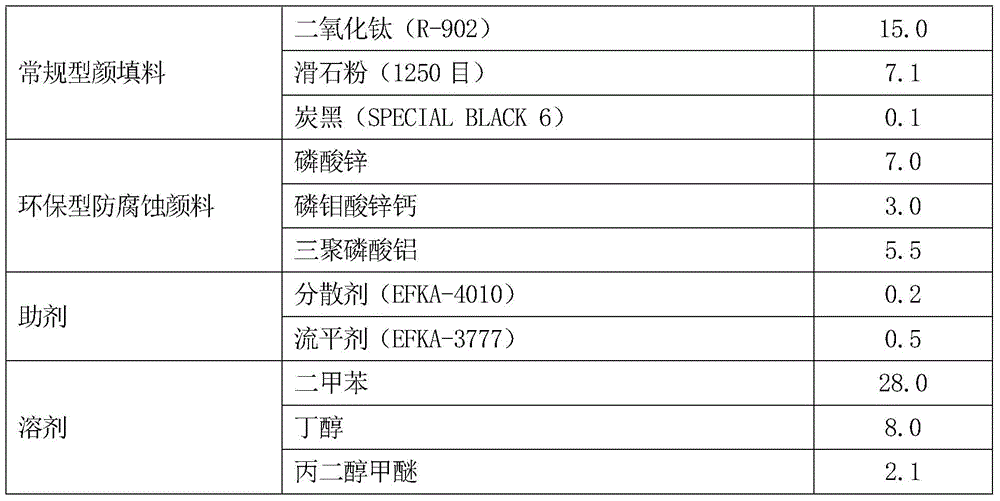

Coating composition for rapidly repairing damaged skin coat of spacecraft

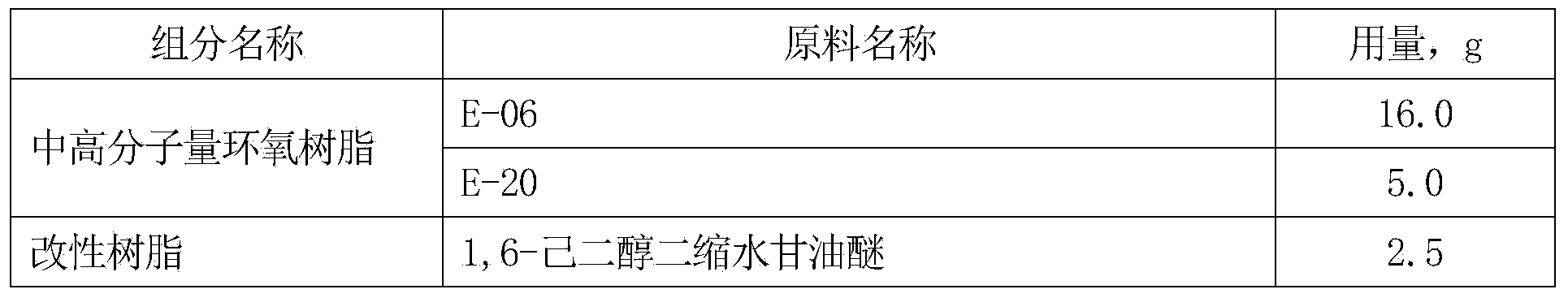

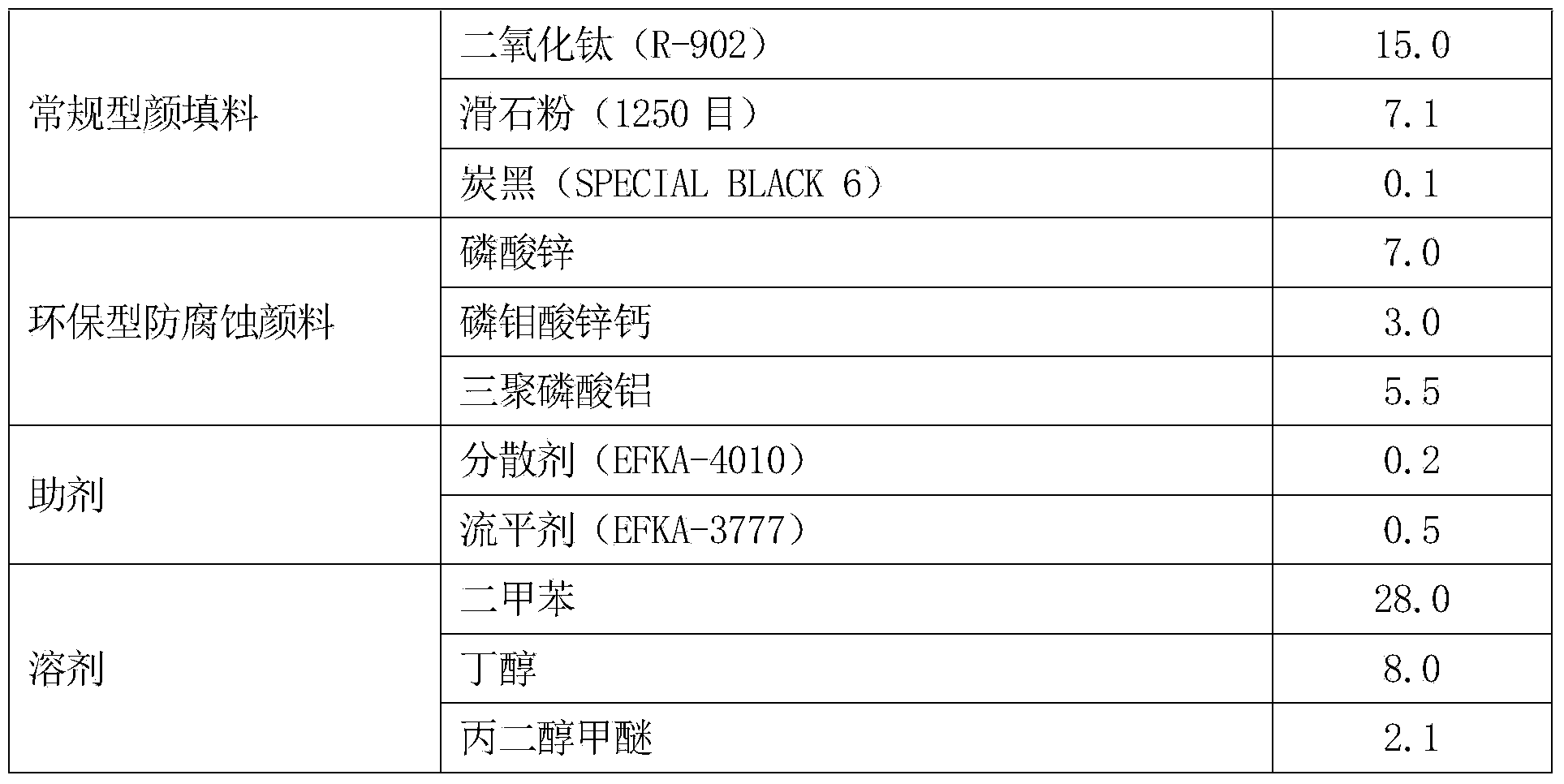

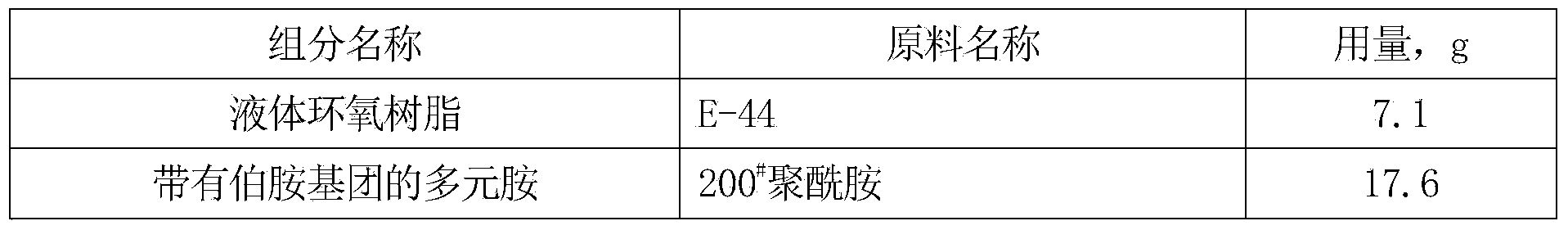

ActiveCN104387916AGuaranteed crosslink densityImprove flexibilityAnti-corrosive paintsEpoxy resin coatingsSolventCoating system

The invention relates to a coating composition for rapidly repairing a damaged skin coat of a spacecraft. The coating composition comprises a component A and a component B, wherein the component A comprises the following components in percentages by mass: 15%-25% of medium-high molecular weight epoxy resin, 2%-12% of modified resin, 15%-30% of conventional-type pigment and filler, 15%-30% of environment-friendly anti-corrosion paint, 0.5%-1% of additive and the balance of the solvent; the component B comprises the following components in percentages by mass: 60%-90% of epoxy-amine adduct, 10%-40% of epoxy-polyaminoalkoxysilane adduct, and the sum of epoxy-amine adduct and epoxy-polyaminoalkoxysilane adduct is 100%; before construction, the component A and the component B are evenly mixed at a mass ratio of (4 to 6): 1. The coating composition has excellent comprehensive performance which is comparable to that of the novel coating system, the repair time is shortened, the repair efficiency is increased, the wastes of energy and resources are decreased and the labor intensity of workers is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Environment-friendly organosilicon ''three-prevention'' coating and preparation method thereof

ActiveCN110628326ASmall volume shrinkageImprove thermal shock resistanceCoatingsElastomerReactive diluent

The invention discloses an environment-friendly organosilicon ''three-prevention'' coating and a preparation method thereof. The environment-friendly organosilicon ''three-prevention'' coating comprises the following components: (A) 80-100 parts by weight of vinyl silicone oil, (B) 0.1-10 parts by weight of a crosslinking agent, (C) 1-10 parts by weight of a reactive diluent, (D) 1-10 parts by weight of MQ silicone resin, (E) 1-10 parts by weight of hydrophobically modified white carbon black, (F) 0.1-0.5 part by weight of a reaction inhibitor, (G) 0.1-0.5 part by weight of a silicon hydrogenaddition reaction catalyst, (H) 0.1-0.5 part by weight of a photopolymerization initiator, and (I) 0.1-2 parts by weight of a tackifier. The environment-friendly organosilicon ''three-prevention'' coating provided by the invention effectively solves the problems that an existing organosilicon elastomer ''three-prevention'' coating is slow in curing speed and poor in adhesion and is not environmentally friendly.

Owner:广州玖盈化工材料有限公司

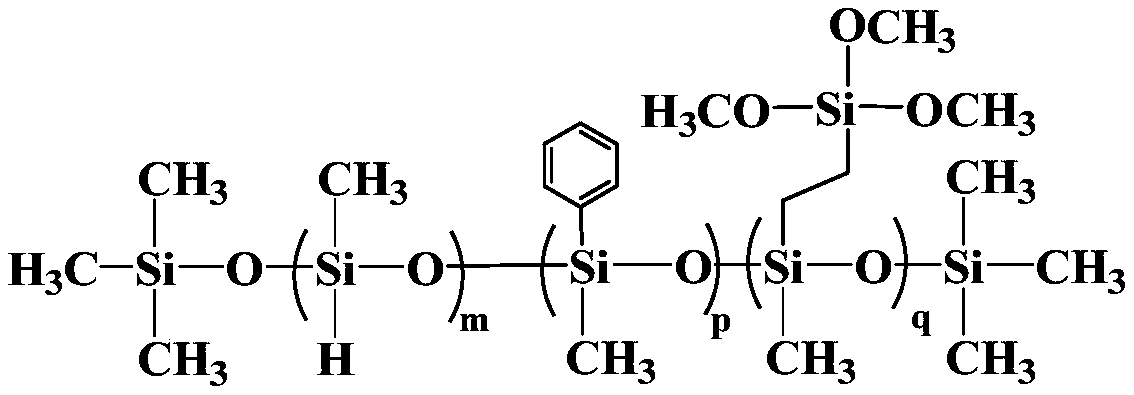

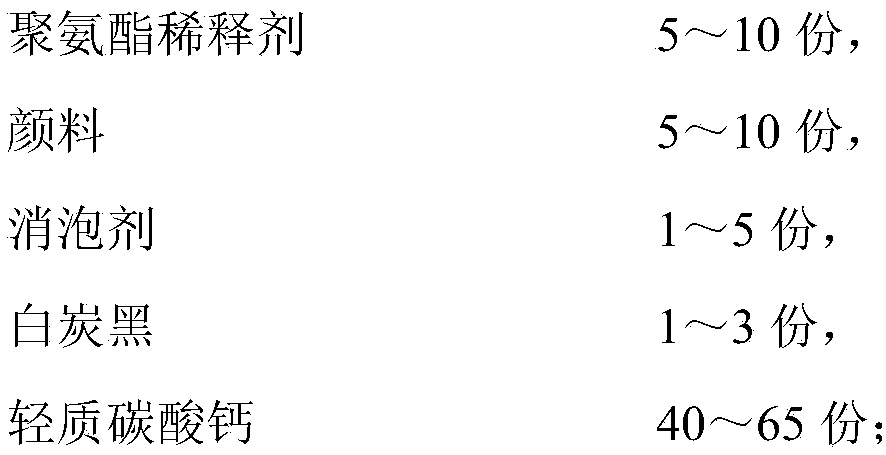

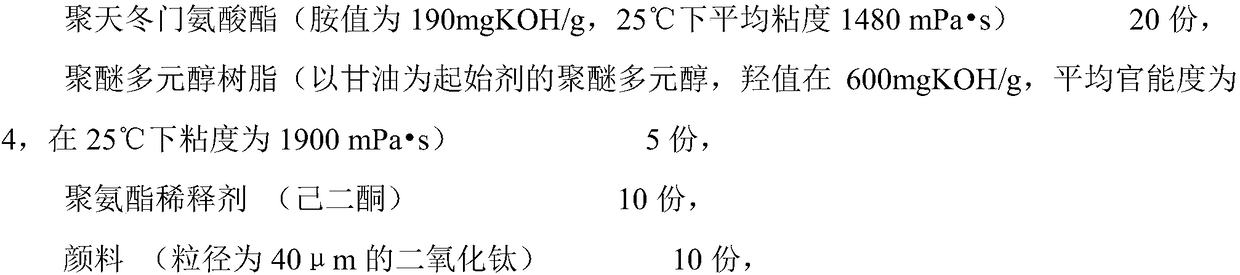

Polyaspartic acid ester-based polyurethane adhesive and preparation method thereof

ActiveCN109468111AGuaranteed crosslink densityGuaranteed hardnessNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesiveChemistry

The invention discloses a polyaspartic acid ester-based polyurethane adhesive which comprises a component A and a component B, wherein the component A is prepared from the following main raw materialsin parts by mass: polyaspartic acid ester, polyether polyol resin, a polyurethane diluent, pigment, a defoaming agent, white carbon black and light calcium carbonate; and component B is prepared fromthe following main raw materials in parts by mass: high-functionality isocyanate, diphenylmethane diisocyanate and a polyurethane diluent. The invention also discloses a preparation method of the polyurethane adhesive. According to the invention, the polyaspartic acid ester is applied in the polyurethane adhesive for the first time, so that the density of hydroxyl groups of a product can be limitedly controlled, the operation time of the polyurethane adhesive is obviously prolonged, and the polyaspartic acid ester is ensured to have relatively good toughness after curing; and at the same time, the polyaspartic acid ester has excellent weatherability, therefore, the polyurethane adhesive is also endowed with excellent weatherability and mechanical strength.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

Transparent high-hardness yellowing-resistant epoxy stone face glue and preparation process thereof

InactiveCN109266277AOptimize operating timeAppearance colorless and transparentNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyAdhesion force

The invention relates to transparent high-hardness yellowing-resistant epoxy stone face glue and a preparation process thereof. The transparent high-hardness yellowing-resistant epoxy stone face glueis characterized by being prepared from glue A and glue B, wherein the glue A is prepared from epoxy resin 128, epoxy resin 127, epoxy resin 170, phenylcarbinol, an epoxy active diluent 622, an organic silane coupling agent 550, an anti-foaming agent 6020, a leveling agent BYK-306 and an anti-ultraviolet agent L-9522; the glue B is a modified amine curing agent; the glue A and the glue B are uniformly mixed according to the mass ratio of (2 to 4):1; de-foaming is performed in vacuum; then, the glue is scraped onto a stone panel; curing is firstly performed for 30min at the room temperature; then, curing is continuously performed at 60 DEG C for 1h; next, the material is taken out; after the cooling, the shore hardness of an obtained cured object is 88 or higher; the grinding performance isgood; the adhesion force reaches grade 1; the yellowing resistant performance is good; no obvious yellowing occurs after the sunlight irradiation for 1 year; the glue A does not crystallize. The rawmaterials in a formula can be easily obtained; the cost is low; the performance is excellent; the face glue is suitable for large-scale popularized use.

Owner:HUBEI GREENHOME MATERIALS TECH INC

Organosilicon sealing glue with moderate toughness, and preparation method thereof

InactiveCN109694688ALow modulusHigh elongationNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceSilanes

The invention relates to an organosilicon sealing glue with moderate toughness, and a preparation method thereof, and belongs to the technical field of organosilicon sealing glues, wherein the organosilicon sealing glue comprises medium-viscosity [alpha],[omega]-dihydroxy polydimethylsiloxane, low-viscosity [alpha],[omega]-dihydroxy polydimethylsiloxane, dimethyl silicone oil, dimethyl dibutanoneoximido silane, polyethylene glycol, fumed titanium dioxide, nano-scale calcium carbonate, methyltriacetoxysilane, di-tert-butoxydiacetoxysilane, dioctyltin dilaurate, stannous octoate, and methylphenyl bis(N-methylacetamido)silane. The organosilicon sealing glue of the present has moderate toughness within a controlled range.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

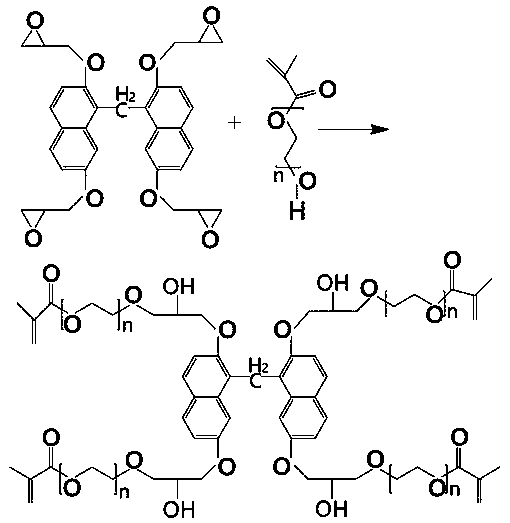

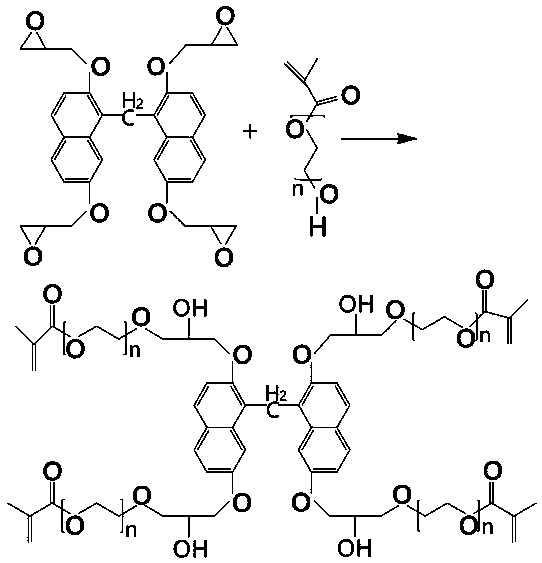

Epoxy resin for crazing-resistant photocuring solder resist coating material and preparation method of epoxy resin

PendingCN112812274AGood weather resistanceImprove low temperature resistancePhotosensitive materials for photomechanical apparatusEpoxy resin coatingsCrazingWeather resistance

The invention provides an epoxy resin for a crazing-resistant photocuring solder resist coating material and a preparation method of the epoxy resin, and provides the crazing-resistant photocuring solder resist coating material prepared from the epoxy resin, and a preparation method of the crazing-resistant photocuring solder resist coating material. According to the invention, acrylic acid is introduced through a ring-opening reaction, and then the hydroxyl group and long aliphatic chain anhydride are subjected to an esterification reaction to obtain the epoxy resin, wherein the long chain anhydride is introduced into the reaction of hydroxyl and anhydride in the second step, so that flexibility is provided for the system, chain segment movement is enhanced, the glass transition temperature of the polymer is reduced, and the purposes of reducing the development of the crazing or easily treating the crazing to retract and disappear can be achieved; and the weather resistance, low temperature resistance, impact strength, fatigue resistance and other properties of a cured product of the coating material are enhanced, the application field of the solder resist photocureable coating material is widened, and the requirements of the current photocureable industry on the solder resist coating material are met.

Owner:鹤山市炎墨科技有限公司

Bifunctional organic thiosulfate and preparation method thereof

ActiveCN103626685AImprove thermal stabilityIncrease crosslink densityOrganic chemistryCross-linkPolymer science

The invention relates to a bifunctional organic thiosulfate of an anti-reversion agent for rubber industry and a preparation method thereof. The bifunctional organic thiosulfate provided by the invention has two active groups, a sulfur-containing active group generates a cross-linking reaction with rubber macromolecules in a rubber vulcanization process to insert a thermostable alkyl into a sulfur crosslinking bond; in addition, when reversion occurs in an over-vulcanization or application process of vulcanized rubber, the unsaturated double bond groups of the bifunctional organic thiosulfate would generate a Diels-Adel reaction with the C=C bond in the rubber so as to generate a thermostable C-C crosslinking bond to maintain the crosslinking density of the vulcanized rubber, improve the vulcanized reversion of the vulcanized rubber and enhance the service performance and service life of the products.

Owner:BEIJING RED AVENUE INNOVA

Method for improving zinc oxide sulfuration activity

The invention relates to a method for improving zinc oxide sulfuration activity and belongs to the technical field of natural rubber processing. The method comprises adding 0.5-10 parts of rare earth oxide into 100 parts of common zinc oxide and carrying out ball milling and high temperature sintering rare earth doping. According to inherent characteristics of rare earth, zinc oxide particle conformation structure and ion surface chemical properties are changed, sulfuration activity is improved, a use ratio of zinc oxide in the rubber formula is reduced from 5: 100 to 2: 100, sulfuration time is shortened, natural vulcanized rubber crosslinking density and mechanical properties are improved and reasonable utilization and saving of a zinc ore resource are realized.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

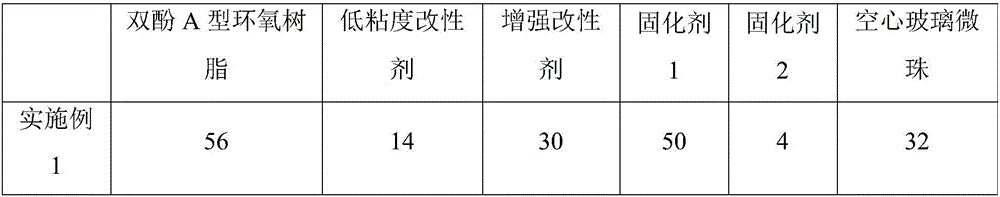

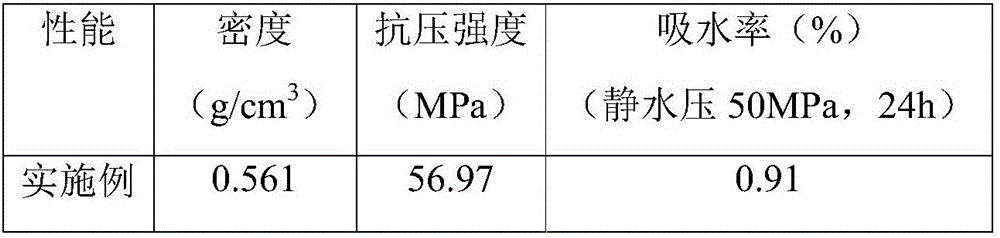

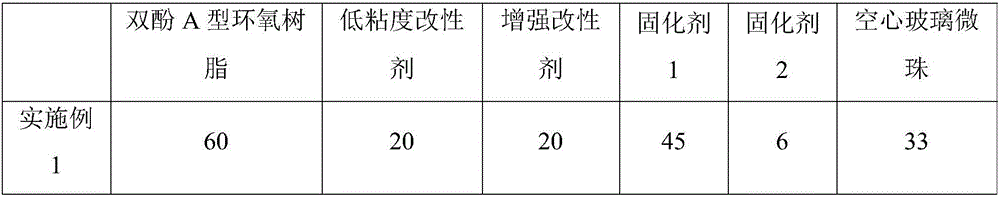

Light pressure-resistant buoyancy material for deep submergence vehicle and preparation method of buoyancy material

The invention provides a light pressure-resistant buoyancy material for a deep submergence vehicle and a preparation method of the buoyancy material. The buoyancy material is prepared from, in parts by mass, 50-60 parts of bisphenol-A epoxy resin, 20-40 parts of a reinforced modifier, 10-20 parts of a low-viscosity modifier, 40-60 parts of a first curing agent, 2-8 parts of a second curing agent and 30-40 parts of hollow glass beads, wherein the reinforced modifier is hexahydrophthalic diglycidyl ester, the low-viscosity modifier is neopentyl glycol diglycidyl ether, the first curing agent is a liquid-state organic acid anhydride curing agent, and the second curing agent is a liquid-state imidazole curing agent. The prepared light pressure-resistant buoyancy material for the deep submergence vehicle has the density of 0.50-0.57 g / cm<3>, the compression strength reaching 40-60 MPa and the isostatic hydrostatic pressure water absorption rate smaller than 1% and can meet requirements of the deep sea submergence vehicle at 3,000-5,000 m underwater.

Owner:HARBIN ENG UNIV

High-strength flexible transparent wear-resistant hardened coating on surface of folding screen and preparation method thereof

ActiveCN111454648AGuaranteed crosslink densityHigh hardnessOrganic compound preparationCarboxylic acid esters preparationPolyethylene glycolAcrylate ester

The invention relates to a high-strength flexible transparent wear-resistant hardened coating on the surface of a folding screen mobile phone and a preparation method thereof, and is characterized inthat the high-strength flexible transparent wear-resistant hardened coating comprises a UV-curable hardening liquid, which is prepared by uniformly mixing naphthalene ring type polyethylene glycol acrylate, a diluent, a photoinitiator and octavinyl-POSS. The hardness and wear resistance of the flexible transparent polymer film material can be improved, the rigid-flexible joint characteristic is good, the hardness and flexibility can be well combined, the wear resistance and hardness can be well combined, bending frequency of the coating is not limited, the bending resistance is good, and the wear resistance is good.

Owner:SHUNDE POLYTECHNIC

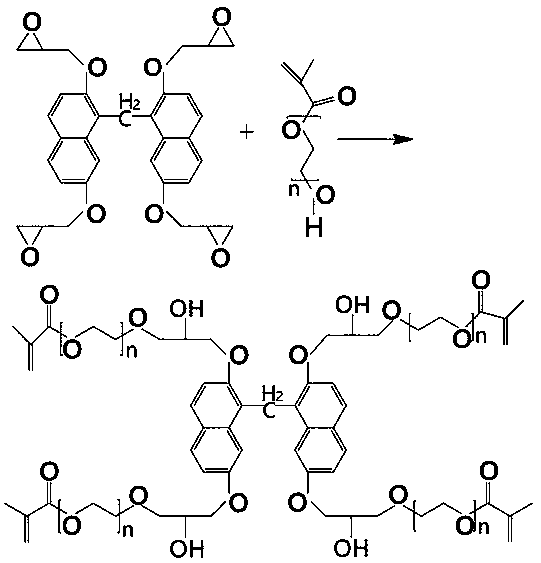

Pressurizing pipe with high-temperature resistance and preparation process thereof

The invention discloses a pressurizing pipe with high-temperature resistance and a preparation process thereof. The pressurizing pipe is prepared from the following raw materials in parts by weight: methyl vinyl silicone rubber, fluororubber premixed rubber, butadiene styrene rubber, hydroxyl silicone oil, nano silicon powder, polymetallic organosiloxane, zinc oxide, vapor white carbon black and the like. The heat-resistant agent is prepared from the polyorganometallic siloxane, the zinc oxide, the vapor white carbon black, the tris(trimethylsilyl)phosphate, an aromatic acid zine salt and mercaptobenzothiazole, and by reasonable combination of the polyorganometallic siloxane and the tris(trimethylsilyl)phosphate, good dispersity of the components and compatibility of the rubber are utilized to improve the activity utilization rate of zine oxide and vapor white carbon black; and mercaptobenzothiazole is used for promoting more polysulfide cross-linking bonds of the rubber, so that the endogenous heat in the processing process of the rubber material can be effectively reduced, the stability of the polysulfide cross-linking bonds is improved, the cross-linking density of vulcanized rubber is kept, and the heat resistance of the rubber is greatly improved.

Owner:宁波星箭航空机械制造有限公司

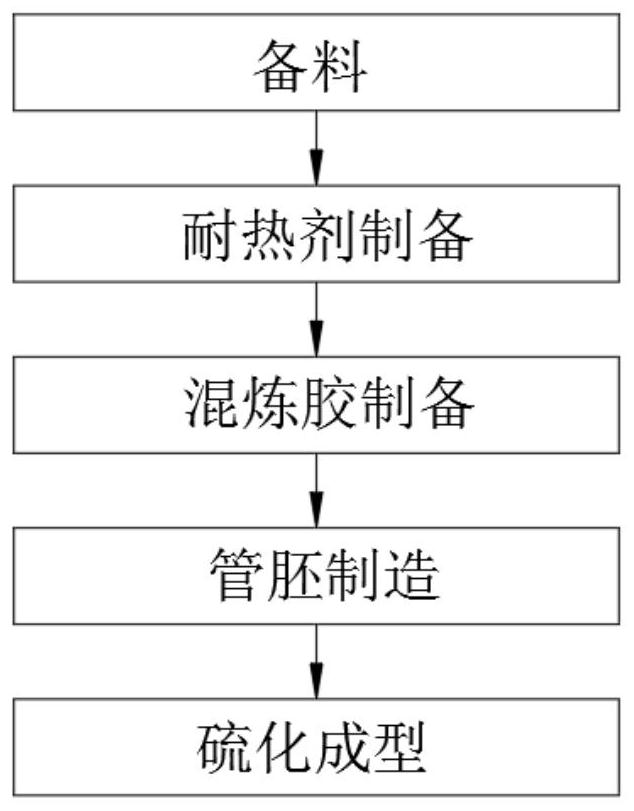

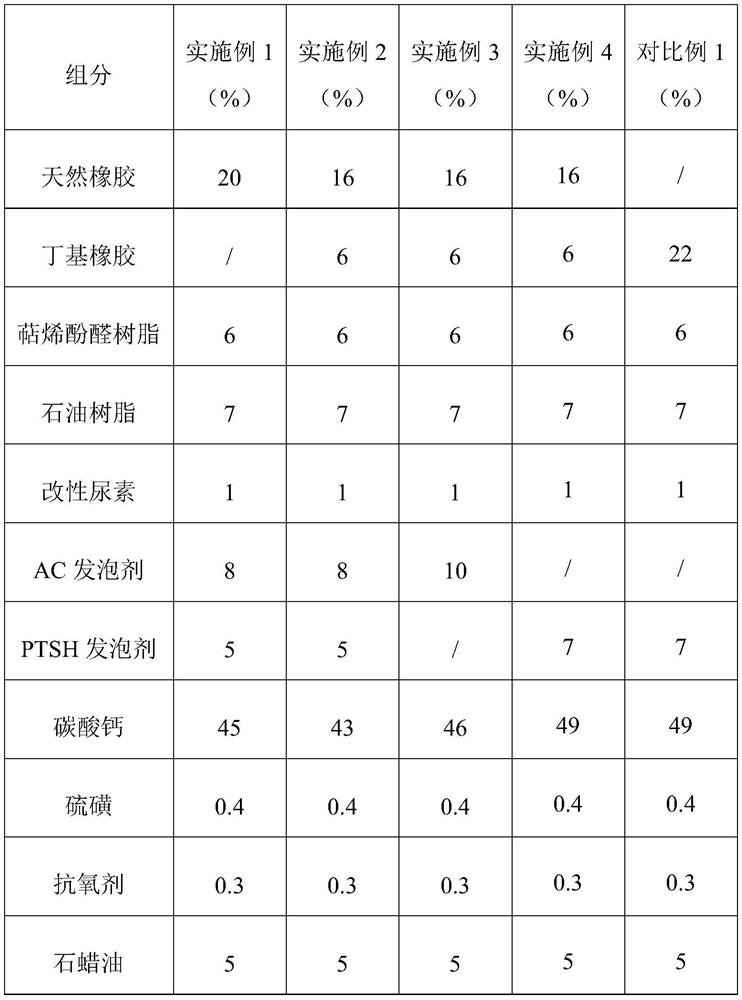

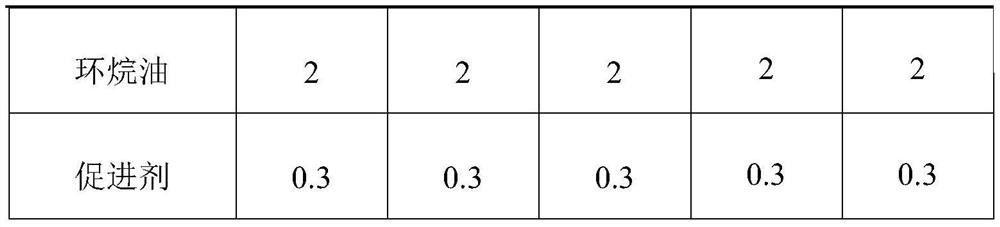

A self-adhesive single-layer high-magnification expansion rubber strip and its preparation method

ActiveCN111286287BImprove sound insulation and noise reductionGuaranteed crosslink densityNatural rubber adhesivesPolymer scienceFoaming agent

The invention discloses a self-adhesive single-layer high-magnification expansion rubber strip, which comprises the following components in parts by weight: 14-20 parts by weight of natural rubber; 4-9 parts by weight of butyl rubber; 0-4 parts by weight of modified urea Parts by weight; 40-50 parts by weight of filler; 9-20 parts by weight of tackifying resin; 9-17 parts by weight of blowing agent; 0.2-0.6 parts by weight of sulfur; 0.1-0.5 parts by weight of antioxidant; 0.2-0.6 parts by weight of accelerator Part; Solvent 4-14 parts by weight. The self-adhesive single-layer high-magnification expansion rubber strip of the present invention uses natural rubber and butyl rubber in combination as raw materials, so that the expansion rubber strip can not only ensure a certain crosslinking density, but also ensure a certain airtightness. AC foaming agent and PTSH foaming agent are used together to better improve and ensure the foaming ratio. The foaming ratio is increased to 500%-600%, and it is a single-layer structure, which improves the sound insulation and noise reduction effect of the product on the car.

Owner:科建高分子材料(上海)股份有限公司

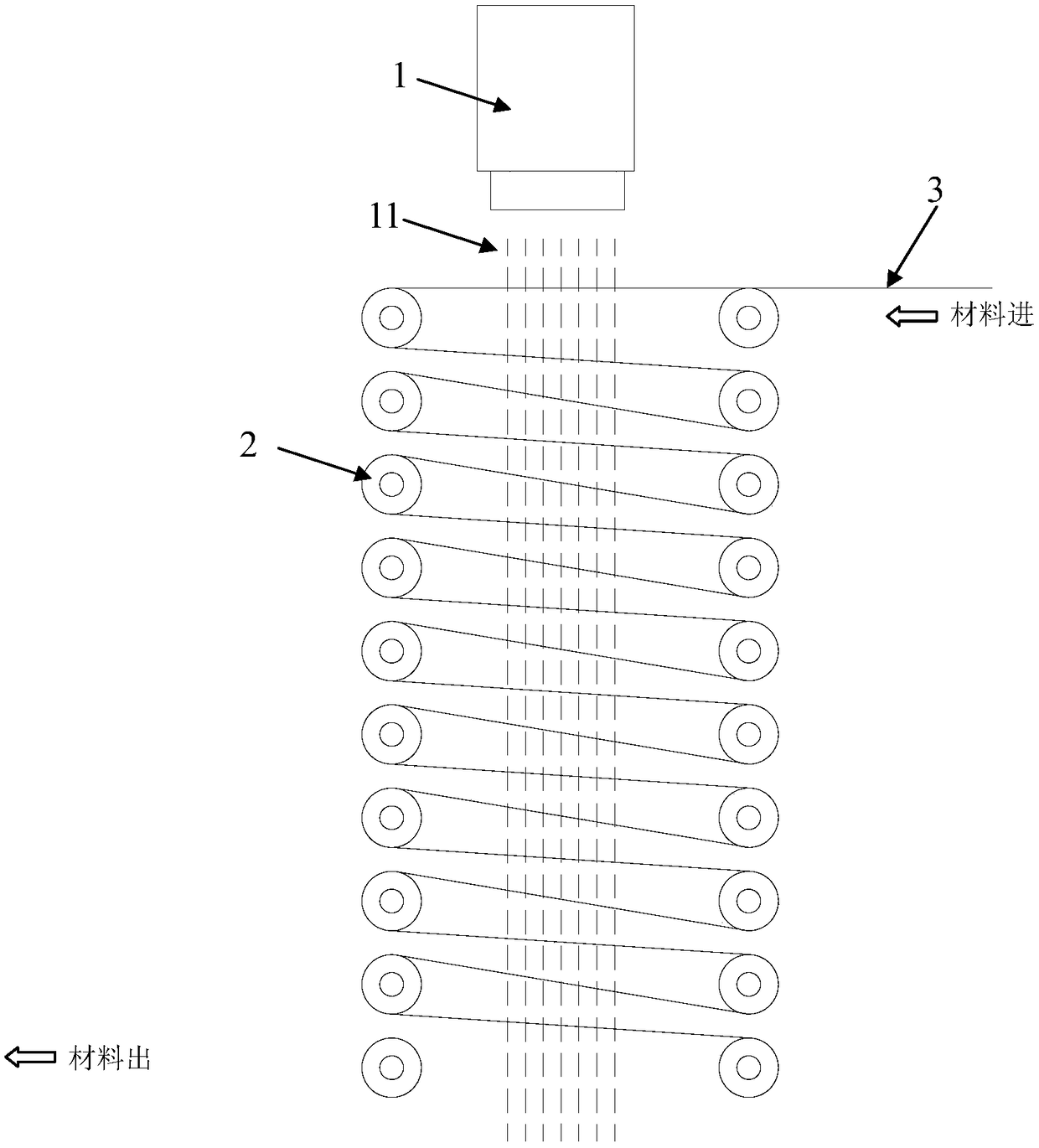

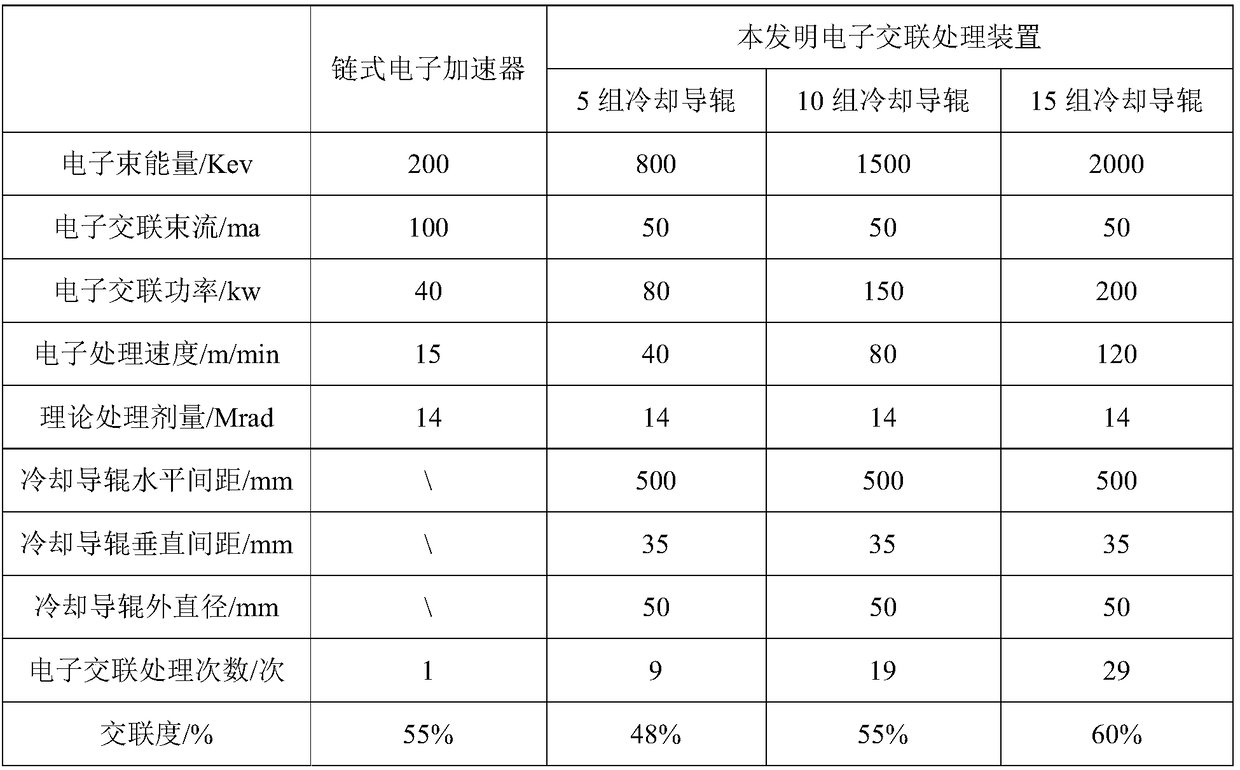

Electronic crosslinking treatment device and film material electronic crosslinking treatment method

The invention discloses an electronic crosslinking treatment device and method. The device comprises a scanning type electronic accelerator and a transmission device. The transmission device is composed of multiple cooling guide rollers, wherein the multiple cooling guide rollers are distributed into two columns to be located on the two sides of an electronic beam transmitting route of the scanning type electronic accelerator correspondingly. The multiple cooling guide rollers are of hollow structures, and cooling media are led in cavities. The electronic crosslinking treatment device is simple in structure and low in cost, due to the fact that the two columns of cooling guide rollers are arranged on the two sides of the electronic beam transmitting route of the scanning type electronic accelerator, a to-be-treated film material can bypass the two columns of the cooling guide rollers one by one in a left-right manner and stretches across the electronic beam transmitting route back andforth, an electronic beam is used for conducting multiples times of electronic crosslinking treatment on a film material, and therefore energy efficiency and crosslinking density of the scanning typeelectronic accelerator treating film type materials are improved; and in addition, due to a method that the cooling guide rollers communicate with cooling water, the heating and sticking problems caused after electronic crosslinking treatment of the film material are solved, and the production efficiency is further improved.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

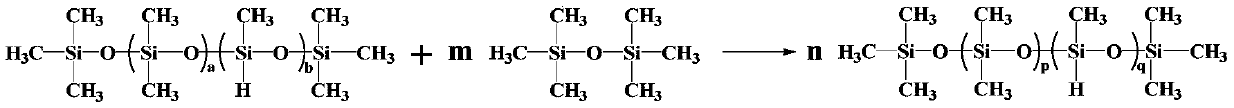

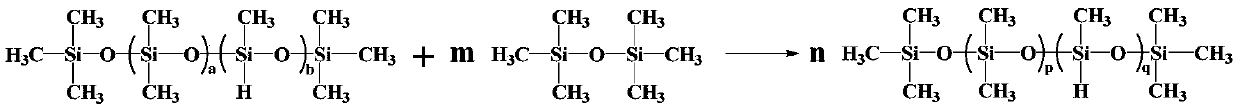

Methyl organic silicon adhesive with excellent flexibility and strong adhesion for LED

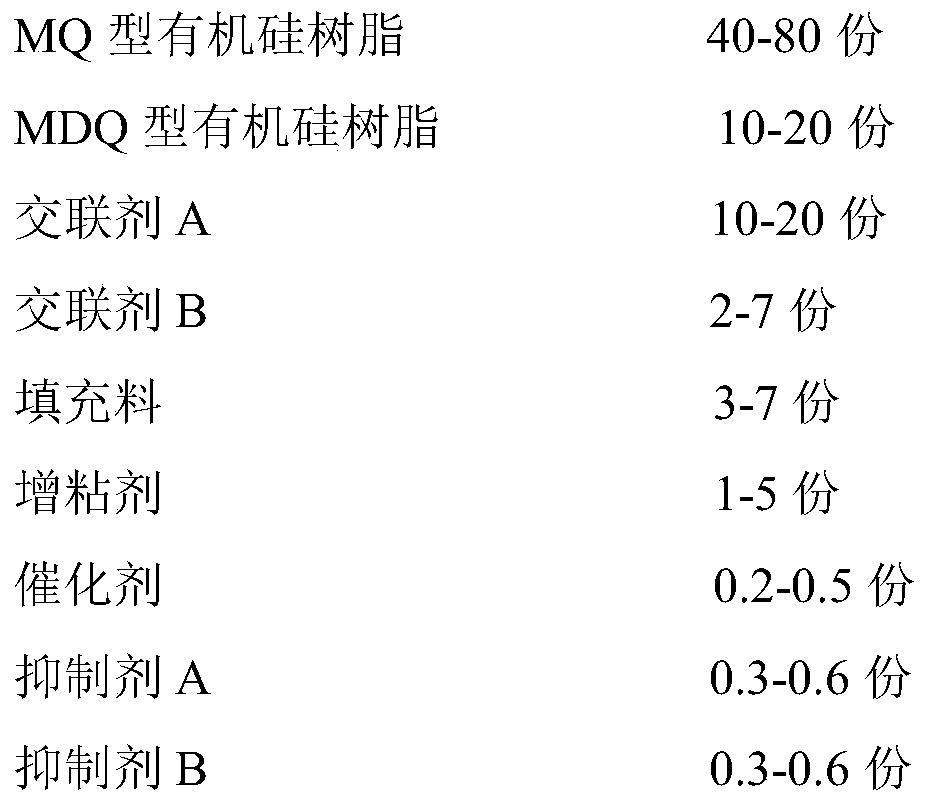

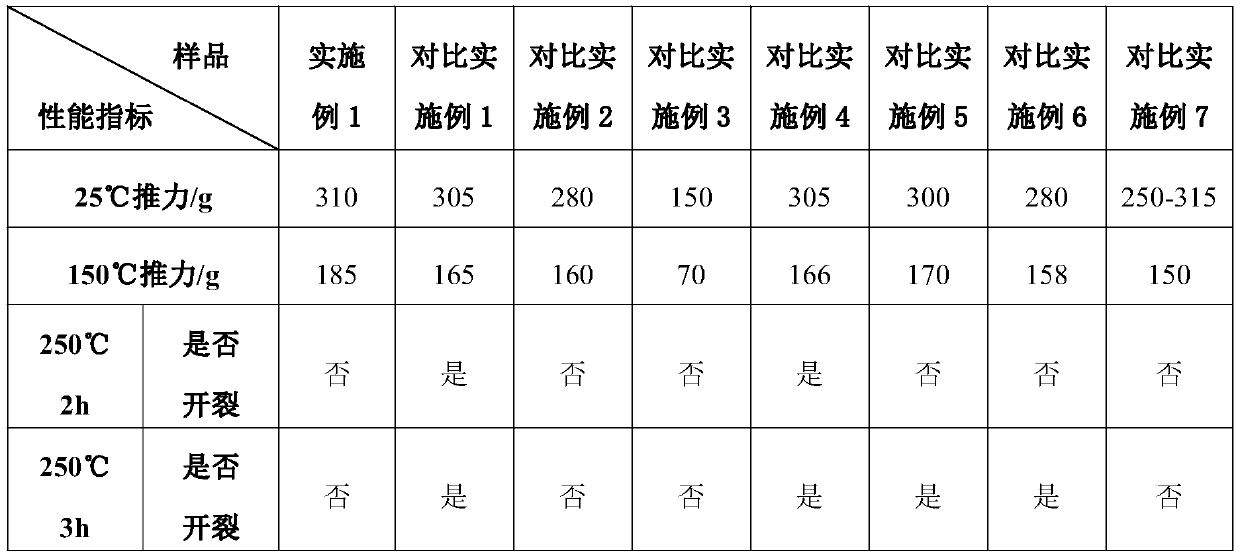

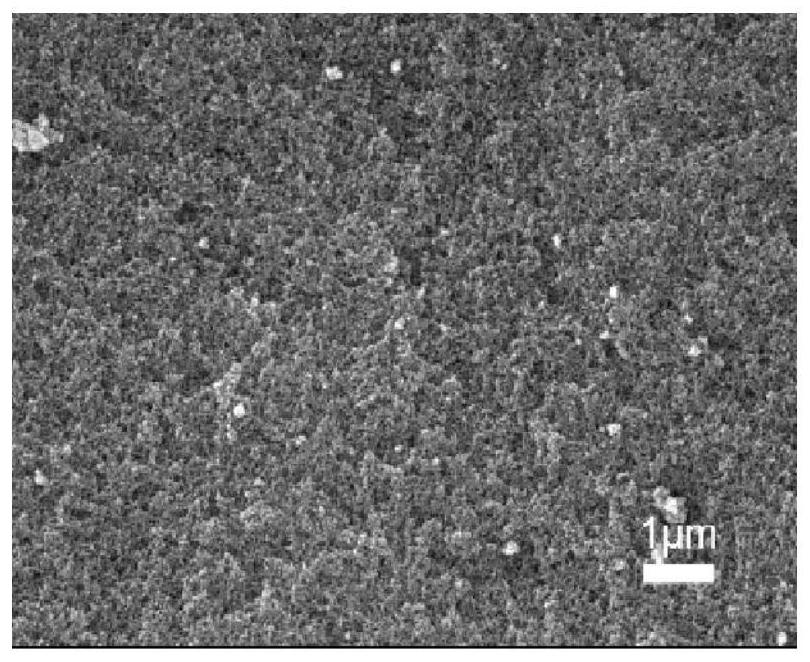

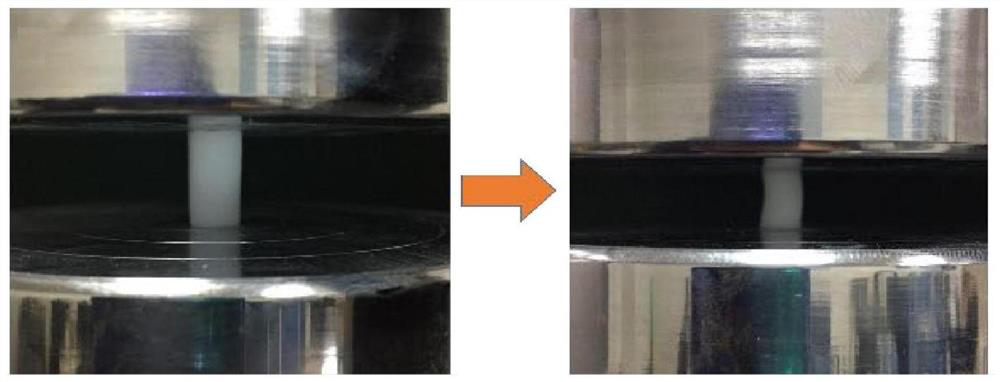

ActiveCN111410932AGuaranteed Vinyl ContentGood flexibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a methyl organic silicon adhesive with excellent flexibility and strong adhesion for an LED. The formula comprises the following raw materials in parts by weight; 40-80 parts of MQ type methyl vinyl silicone resin, 10-20 parts of MDQ type methyl vinyl silicone resin, 10-20 parts of a cross-linking agent A, 2-7 parts of a cross-linking agent B, 3-7 parts of a specially-madefiller, 1-5 parts of a tackifier, 0.2-0.5 part of a catalyst, 0.3-0.6 part of an inhibitor A and 0.3-0.6 part of an inhibitor B. According to the organic silicon adhesive prepared by the invention, acured main body structure does not contain phenyl and has relatively high flexibility, and meanwhile, through optimal design of molecular structures of the main body resin and the cross-linking agent,the high-temperature stability and the adhesive property of the organic silicon adhesive are effectively improved, and the organic silicon adhesive is particularly suitable for die bonding of large-size chips.

Owner:南京科矽新材料科技有限公司

Oil-resistant acrylic adhesive and preparation method thereof

ActiveCN114671984AGood oil resistanceImprove water resistanceGraft polymer adhesivesAdhesive cementPolymer science

According to the scheme, monomers such as acrylate monomers, dibutyl itaconate copolymers and fluorine-containing vinyl silane are used as main raw materials, and the adhesive with a three-layer core-shell structure is synthesized through emulsion polymerization; according to the scheme, during preparation, firstly, the core layer monomer, the middle layer monomer and the shell layer monomer are pre-emulsified, and in the step, component selection and content of the core layer monomer, the middle layer monomer and the shell layer monomer are limited, so that the oil resistance and the water resistance of the adhesive are improved, and the high-temperature resistance of the adhesive is improved. The invention discloses an oil-resistant acrylic adhesive and a preparation method thereof, the acrylic adhesive with a core layer-middle layer-shell layer composite structure is prepared, and the adhesive has excellent high temperature resistance, excellent water resistance, excellent oil resistance, good chemical corrosion resistance and high practicability.

Owner:CHANGZHOU BAOLI ADHESIVE

High-strength flexible polysiloxane aerogel and preparation method thereof

The invention provides a high-strength flexible polysiloxane aerogel material and a preparation method thereof. The method comprises the following steps of: firstly, synthesizing a linear flexible polysiloxane monomer, then taking polyalkoxy polyhedral oligomeric silsesquioxane as a cross-linking agent, changing the proportion of side groups in the polysiloxane monomer and the ratio of the polysiloxane monomer to the polyhedral oligomeric silsesquioxane cross-linking agent, and preparing a series of high-strength flexible super-hydrophobic polysiloxane aerogel materials by adopting a sol-gel method and normal-pressure drying. The preparation process is simple, the mechanical property is excellent, normal-pressure drying is adopted, the material is suitable for industrial large-scale production and can be applied to the fields of adsorbents, thermal insulation materials, thermal insulation materials and the like, and the preparation method and variety of the aerogel material are expanded.

Owner:BEIJING UNIV OF CHEM TECH

A method for improving zinc oxide vulcanization activity

The invention relates to a method for improving zinc oxide sulfuration activity and belongs to the technical field of natural rubber processing. The method comprises adding 0.5-10 parts of rare earth oxide into 100 parts of common zinc oxide and carrying out ball milling and high temperature sintering rare earth doping. According to inherent characteristics of rare earth, zinc oxide particle conformation structure and ion surface chemical properties are changed, sulfuration activity is improved, a use ratio of zinc oxide in the rubber formula is reduced from 5: 100 to 2: 100, sulfuration time is shortened, natural vulcanized rubber crosslinking density and mechanical properties are improved and reasonable utilization and saving of a zinc ore resource are realized.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

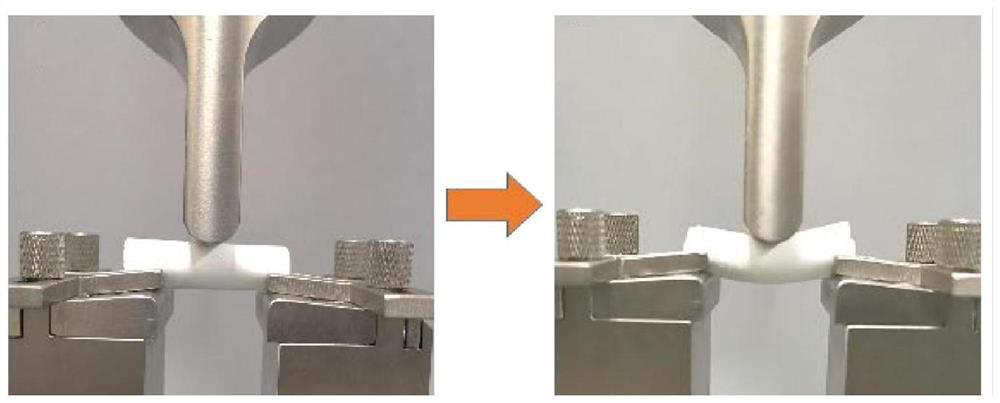

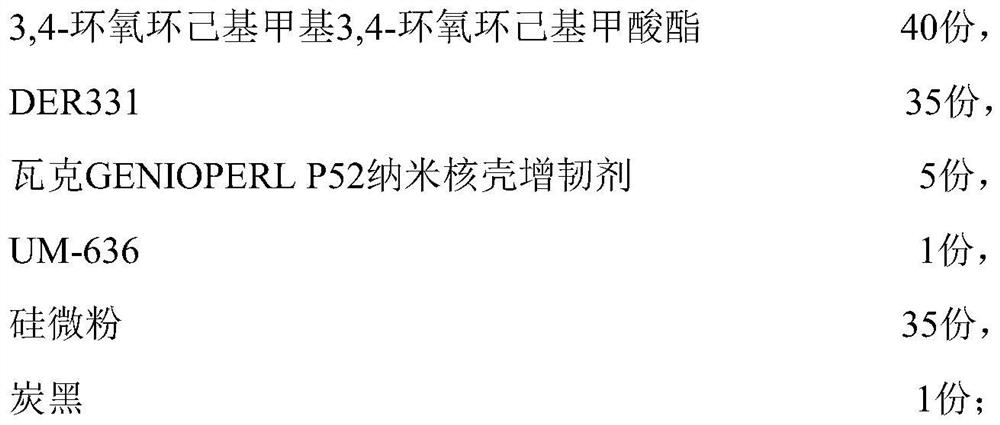

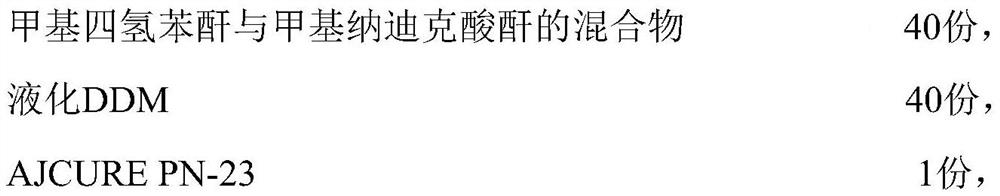

Low-viscosity epoxy potting material for packaging silicon carbide power module as well as preparation method and application of low-viscosity epoxy potting material

ActiveCN113980624ALow viscosityImprove thermal stabilitySemiconductor/solid-state device detailsSolid-state devicesCarbide siliconFirming agent

The invention discloses a low-viscosity epoxy potting material for packaging a silicon carbide power module and a preparation method and application of the material. The epoxy potting material is obtained by mixing a component A and a component B. The component A is prepared from low-viscosity alicyclic epoxy resin, high-purity bisphenol A epoxy resin, a nanometer core-shell toughening agent, a coupling agent, silica powder and carbon black; and the component B comprises a curing agent A, a curing agent B, a latent accelerator and silica powder. The epoxy potting material disclosed by the invention has the advantages of very low viscosity and CTE value, long operation time and high manufacturability, can be used for directly potting a silicon carbide power module, and can be used for well improving the integrity and impact resistance of the module; the epoxy potting material has very great significance in better meeting the packaging process requirements of the silicon carbide power module and expanding the popularization and application of the epoxy potting material in the packaging of the silicon carbide power module, and also has the advantages of high use value, good application prospect, simple preparation method process, convenience in operation and the like, can realize large-scale preparation, and is suitable for industrial production.

Owner:湖南国芯半导体科技有限公司

A kind of high toughness, impact resistance, high flexibility epoxy potting glue and preparation method thereof

ActiveCN106281174BGuaranteed heat resistanceGuaranteed stiffnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesTO-18Diluent

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

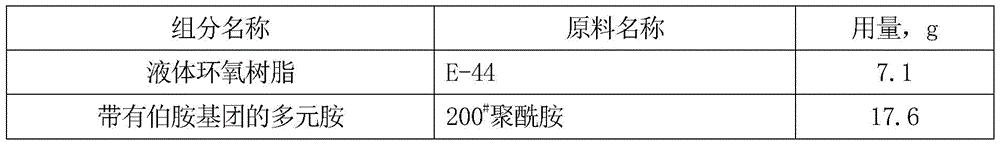

A kind of coating system for aircraft

ActiveCN104449241BReduce weightGuaranteed crosslink densityAnti-corrosive paintsEpoxy resin coatingsAviationEpoxy

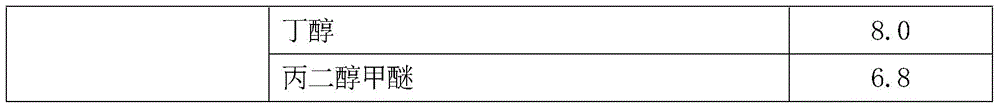

The invention relates to a coating system for an aerial aircraft. The coating system consists of an anti-corrosion coloring bottom coating and a weather-resistant transparent surface course coating matched in use, wherein the bottom coating consists of a component A1 and a component B1 in a mass ratio of (4-6): 1 and the surface course coating consists of a component A2 and a component B2 in a mass ratio of (1-4): 1; the component A1 comprises 15-30% of hydrogenated terpinene-maleic ester type epoxy resin, 2-10% of modified resin, 10-20% of coloring pigments, 10-20% of an environment-friendly anti-corrosion pigment, 5-15% of filler, 0.5-1% of auxiliaries and the balance of a solvent; the component B1 comprises 3-15% of liquid epoxy resin, 5-25% of polyamine with a primary amine and the balance of a solvent; the component A2 comprises 50-80% of polyhydric alcohol resin, 1-4% of auxiliaries and the balance of a solvent; and the component B2 comprises 60-90% of aliphatic polyisocyanate and the balance of a solvent. The coating system is light, good in comprehensive performance and time-saving in construction.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Low temperature resin composition and preparation method thereof

The invention discloses a low-temperature resin composition and a preparation method thereof. The preparation method of the low-temperature resin composition comprises the steps of adding 15 parts by weight of low-molecular weight polyester resin, 30-50 parts by weight of phenolic novolac resin, 0-15 parts by weight of polyvinyl butyral resin and 100-240 parts by weight of solvent to a reactor, stirring for 1-2 hours at 40-60 DEG C, cooling to a room temperature, next, adding 40-60 parts by weight of epoxy resin and 1-5 parts by weight of hexamethylenetetramine, stirring thoroughly for dissolving, and finally, adding 0.5-5 parts by weight of nano silicon dioxide, and thoroughly dispersing and evenly stirring to obtain the low-temperature resin composition. The invention provides a low-temperature resin mixture which can be used as a support structure at minus 196 to 130 DEG C for a glass fiber cloth reinforcing material; the low-temperature resin mixture is especially applicable to low temperatures, has the characteristics of high strength, good toughness, not easy cracking and the like at low temperatures, and is excellent in product properties and high in practicability.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

A kind of high-infrared fast-curing powder coating for coil steel and preparation method thereof

ActiveCN105273581BGood compatibilityImprove the disadvantage of poor compatibilityPowdery paintsPolyester coatingsCoated surfaceWeather resistance

The invention discloses a high-infrared fast-curing powder coating for coil steel, which is prepared from polyester resin, low molecular weight polyester modified fluorocarbon resin, curing agent, leveling agent, benzoin, filler and pigment in parts by weight , the powder coating of the present invention improves the surface condition and performance requirements of the coating by using polyester resin with moderate viscosity and acid value to compound low molecular weight polyester modified fluorocarbon resin, and can be cured by high infrared heating for 15-30s. After curing The powder coating of the invention has good adhesion, and has excellent weather resistance and alkali resistance; the powder coating of the present invention has the characteristics of short curing time, excellent comprehensive performance, etc., and can realize energy saving and environmental protection.

Owner:GUANGZHOU KINTE IND

A coating composition for quickly repairing damaged skin coatings of aircraft

ActiveCN104387916BGuaranteed crosslink densityGood flexibilityAnti-corrosive paintsEpoxy resin coatingsAviationCoating system

The invention relates to a coating composition for rapidly repairing a damaged skin coat of a spacecraft. The coating composition comprises a component A and a component B, wherein the component A comprises the following components in percentages by mass: 15%-25% of medium-high molecular weight epoxy resin, 2%-12% of modified resin, 15%-30% of conventional-type pigment and filler, 15%-30% of environment-friendly anti-corrosion paint, 0.5%-1% of additive and the balance of the solvent; the component B comprises the following components in percentages by mass: 60%-90% of epoxy-amine adduct, 10%-40% of epoxy-polyaminoalkoxysilane adduct, and the sum of epoxy-amine adduct and epoxy-polyaminoalkoxysilane adduct is 100%; before construction, the component A and the component B are evenly mixed at a mass ratio of (4 to 6): 1. The coating composition has excellent comprehensive performance which is comparable to that of the novel coating system, the repair time is shortened, the repair efficiency is increased, the wastes of energy and resources are decreased and the labor intensity of workers is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com