Transparent high-hardness yellowing-resistant epoxy stone face glue and preparation process thereof

A high-hardness, yellowing-resistant technology, used in epoxy resin adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of difficult procurement, insufficient supply of raw materials, high prices, etc., to reduce costs and resist yellowing. Excellent performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

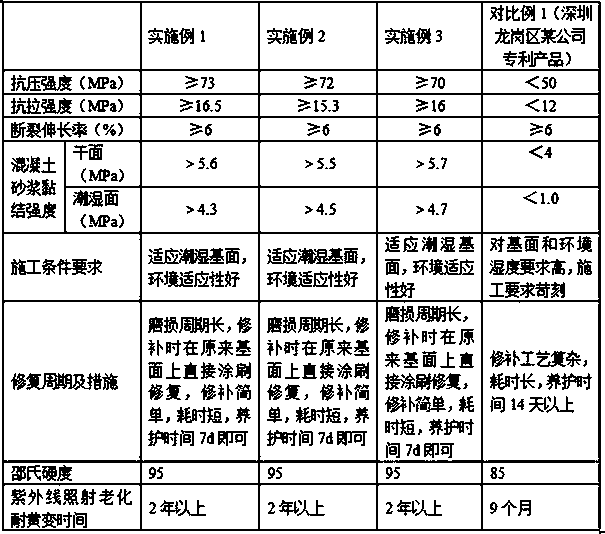

Examples

Embodiment 1

[0018] Preparation of glue A: 4 parts ("parts" means parts by mass)) benzyl alcohol, 0.3 parts of organosilane coupling agent 550, 0.3 parts of defoamer 6020, 0.2 parts of leveling agent BYK-306 and 0.2 parts of anti-ultraviolet Put agent L-9522 into the reaction kettle, stir at room temperature for 15 minutes, then add 5 parts of epoxy reactive diluent 622, 50 parts of epoxy resin 128, 25 parts of epoxy resin 127 and 15 parts of epoxy resin 170, heat up to 60 degrees and continue Stir for 30 min to obtain glue A.

[0019] Synthesis of B glue:

[0020] (1) Add 10 parts of 2-methylpentamethylenediamine and 20 parts of benzyl alcohol into the reaction kettle, and start stirring;

[0021] Raise the temperature to 40°C, add 10 parts of epichlorohydrin dropwise within 1 hour, control the reaction temperature at 50-70°C, and continue to keep warm for 1 hour after the dropwise addition is completed;

[0022] (2) Add 25 parts of isophorone diamine, 15 parts of 4,4-diaminodicyclohexy...

Embodiment 2

[0030] Preparation of glue A: 6 parts ("parts" means parts by mass)) of benzyl alcohol, 0.2 parts of organosilane coupling agent 550, 0.2 parts of defoamer 6020, 0.3 parts of leveling agent BYK-306 and 0.3 parts of anti-ultraviolet Put agent L-9522 into the reaction kettle, stir at room temperature for 12 minutes, then add 3 parts of epoxy reactive diluent 622, 60 parts of epoxy resin 128, 25 parts of epoxy resin 127 and 5 parts of epoxy resin 170, heat up to 60 degrees and continue Stir for 30 min to obtain glue A.

[0031] Synthesis of B glue:

[0032] (1) Add 20 parts of 2-methylpentamethylenediamine and 10 parts of benzyl alcohol into the reaction kettle, and start stirring;

[0033] Raise the temperature to 40°C, add 20 parts of epichlorohydrin dropwise within 1 hour, control the reaction temperature at 50-70°C, and continue to keep warm for 1 hour after the dropwise addition is completed;

[0034] (2) Add 10 parts of isophorone diamine, 10 parts of 4,4-diaminodicyclohe...

Embodiment 3

[0042] Preparation of glue A: 5 parts ("parts" means parts by mass)) benzyl alcohol, 0.3 parts of organosilane coupling agent 550, 0.3 parts of defoamer 6020, 0.2 parts of leveling agent BYK-306 and 0.2 parts of anti-ultraviolet Put agent L-9522 into the reaction kettle, stir at room temperature for 10 minutes, then add 4 parts of epoxy reactive diluent 622, 55 parts of epoxy resin 128, 20 parts of epoxy resin 127 and 15 parts of epoxy resin 170, and heat up to 60 degrees to continue Stir for 30 min to obtain glue A.

[0043] Synthesis of B glue:

[0044] (1) Add 15 parts of 2-methylpentamethylenediamine and 15 parts of benzyl alcohol into the reaction kettle, and start stirring;

[0045] Raise the temperature to 40°C, add 15 parts of epichlorohydrin dropwise within 1 hour, control the reaction temperature at 50-70°C, and continue to keep warm for 1 hour after the dropwise addition is completed;

[0046] (2) Add 15 parts of isophorone diamine, 13 parts of 4,4-diaminodicycloh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com