Multi-carboxyl cage silsesquioxane modified epoxy resin and application thereof in coating

A technology of silsesquioxane and epoxy resin, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of blank, cage-type silsesquioxane difficult to disperse, and difficulty, and achieve fast reaction speed , good fullness and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

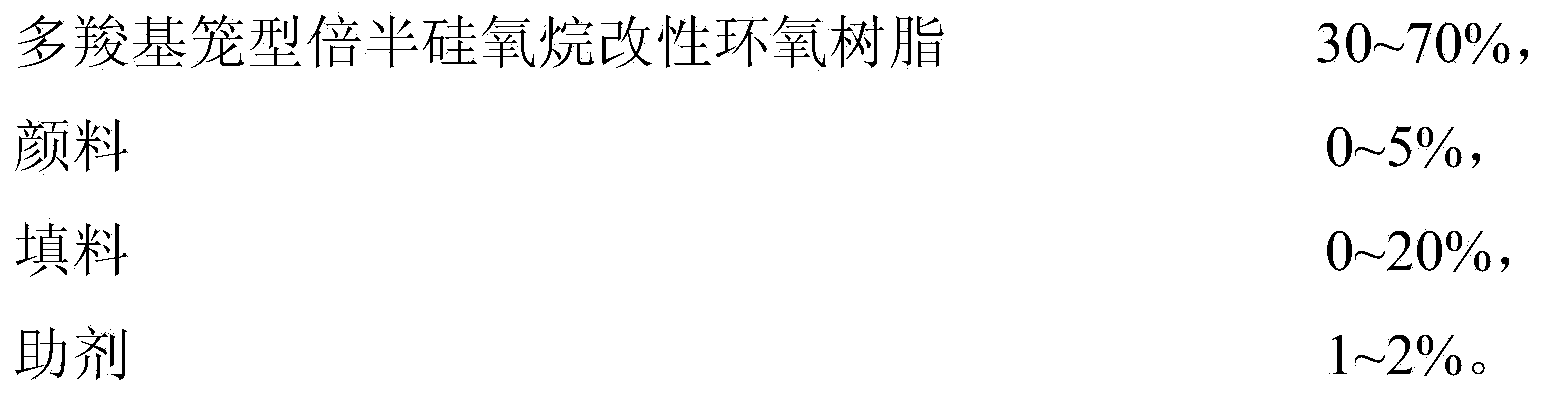

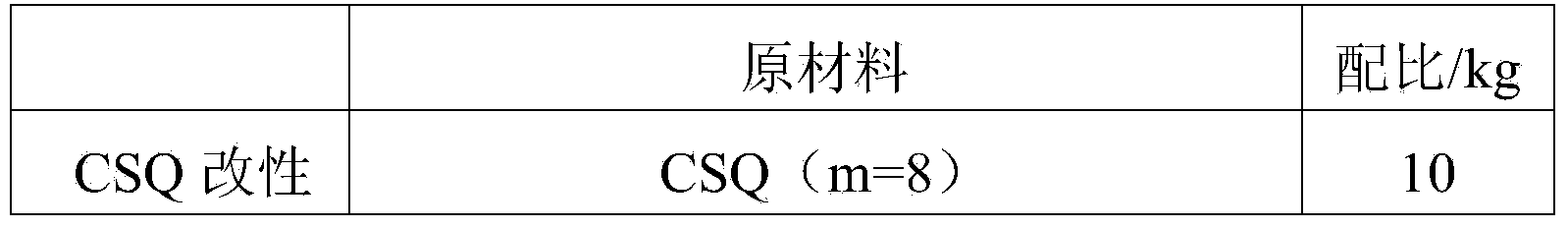

[0038] The polycarboxy cage type silsesquioxane modified epoxy resin of the present invention is prepared by the following method:

[0039]Polycarboxy cage silsesquioxane, epoxy resin, catalyst, and organic solvent are formulated according to the formula shown in Table 1. CSQ and epoxy resin are put into the reaction kettle, and then the catalyst triphenylphosphine and the organic solvent toluene are uniformly mixed. ; Heating to the range of 105-110° C., keeping the temperature for 3 hours, and stopping the reaction when the difference in acid value does not exceed 0.1 mgKOH / g. Dilute to a solid content of 75% with the amount of ethyl acetate and butyl acetate shown in Table 1, and filter the material to obtain a CSQ modified epoxy resin in the state of use containing highly active hydroxyl groups.

[0040] Table 1 The preparation formula table of CSQ modified epoxy resin

[0041]

[0042]

[0043] Adopt above-mentioned polycarboxyl cage silsesquioxane modified epoxy r...

Embodiment 2

[0045] The preparation method of polycarboxy cage type silsesquioxane modified epoxy resin is as follows:

[0046] Polycarboxy cage type silsesquioxane, epoxy resin and catalyst, organic solvent are pressed the formula shown in table 2, put CSQ and epoxy resin into reactor, then drop into catalyst tetrabutylphosphonium acetate and organic solvent respectively Mix xylene evenly; heat up to 110-115°C, keep warm for 2 hours, and terminate the reaction when the difference in acid value does not exceed 0.1mgKOH / g. Dilute to 75% solids with the amount of 200# solvent oil and butyl acetate shown in Table 2, and filter the material to obtain a CSQ modified epoxy resin containing a highly active hydroxyl group.

[0047] Using the above-mentioned polycarboxy cage silsesquioxane modified epoxy resin as a raw material, a high-hardness fast-curing coating is prepared. Before the curing agent is used, ethyl acetate is added to a solid content of 40%. The organic coating and the curing agent...

Embodiment 3

[0052] The preparation method of the polycarboxy cage silsesquioxane modified epoxy resin is the same as in Example 2, and the specific formula is shown in Table 3. Finally, it is diluted to 70% with the consumption of 200# solvent oil shown in table 3 to the solid content, and the material is filtered to obtain the CSQ modified epoxy resin containing highly reactive hydroxyl groups.

[0053] Using the above-mentioned polycarboxy cage silsesquioxane modified epoxy resin as raw material, prepare a high-hardness fast-curing coating, add ethyl acetate to the solid content of 35% before the curing agent is used, organic coating and curing agent The components and their content ratios are shown in Table 9; the drier in the auxiliary agent is naphthenic acid metal soap, the dispersant is polycarboxylate amine type and modified polysiloxane type, and the leveling agent is poly Acrylic ester and polyether modified silicone; Its method is with embodiment 1.

[0054] The preparation fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com