Methyl organic silicon adhesive with excellent flexibility and strong adhesion for LED

An adhesive and flexible technology, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of large contact area between large-sized chips and substrates, chip and substrate peeling, Colloid cracking and other problems, to achieve long-term stable storage, increase flexibility, and promote the effect of complete addition reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

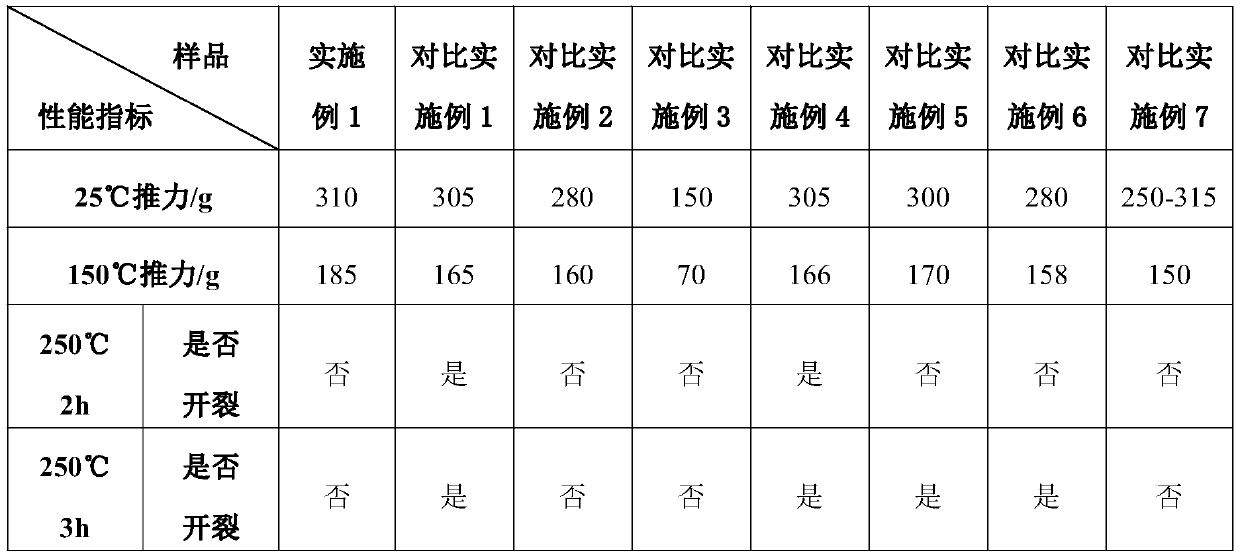

Embodiment 1

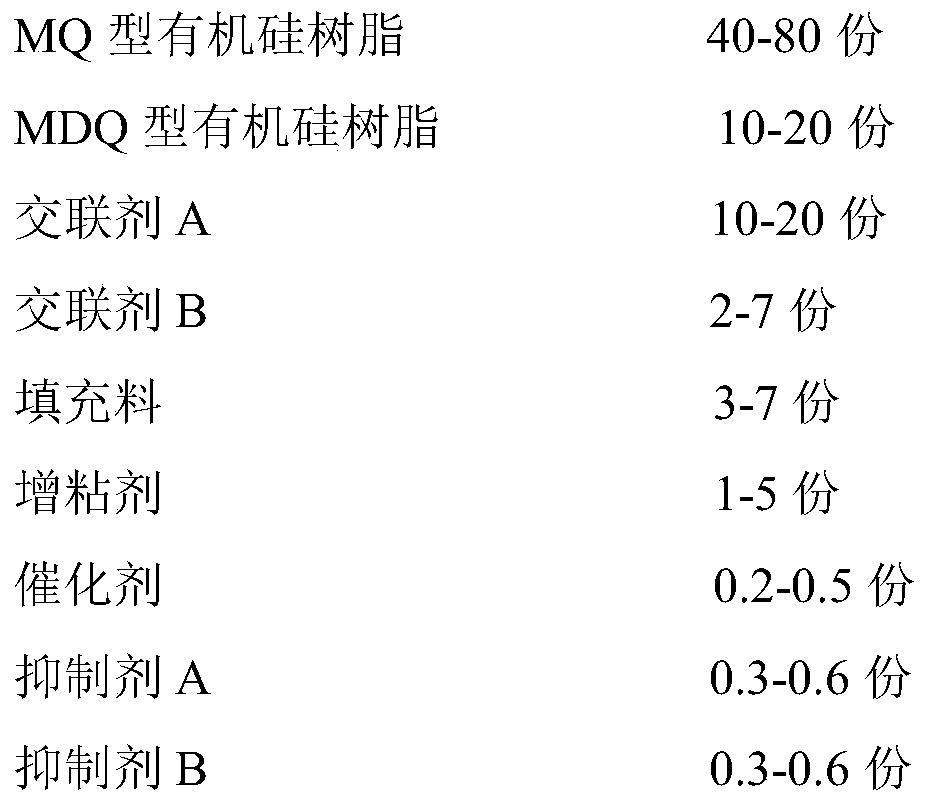

[0037] This implementation proposes a method for preparing a methyl silicone adhesive for LEDs with excellent flexibility and strong adhesion, including the following steps:

[0038] Weigh 60 parts of raw material MQ type silicone resin (molecular weight is about 11000, viscosity is about 25000mPa.s, vinyl weight fraction 4.0%) and MDQ type silicone resin 15 parts (molecular weight is about 3000, viscosity is about 7000mPa.s, vinyl weight fraction 4.0%), mix uniformly; Weigh 16 parts of crosslinking agent A (viscosity is 30mPa.s, molecular weight is 500, hydrogen mass fraction is 0.4%), crosslinking agent B 4 parts (viscosity is 60mPa.s, molecular weight 2500, hydrogen mass fraction 1.4%), mix uniformly; mix the mixture of main resin and crosslinking agent at 60°C, cool to room temperature; then add 3 parts of tackifier, inhibitor 0.4 parts of A, 0.4 parts of inhibitor B, and mix evenly again; then add 0.3 parts of catalyst and 5 parts of fillers and mix evenly; finally, after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com