Patents

Literature

41results about How to "Play the role of chain extension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil-displacing agent composition used for improving recovery ratio of high-temperature reservoir and preparation method of composition

ActiveCN103666433AHigh molecular weightIncrease the relative molecular massDrilling compositionActive agentCarboxylic acid

The invention relates to an oil-displacing agent composition for improving a recovery ratio of a high-temperature reservoir and a preparation method of the composition, mainly solving the problems that a polymer-containing oil-displacing agent in the prior art is poor in temperature resistance, salt resistance and thermal stability resistance, and low in displacement efficiency. In order to solve the problems better, a following technical scheme is adopted as follows: the oil-displacing agent composition comprises the following components in percentage by weight: 0.005%-8.0% of high-temperature-resistant and oil-displacing acrylamide polymers, 0.005%-5.0% of a fatty alcohol polyoxyethylene ether carboxylate surfactant and 87.0%-99.99% of injected water. The preparation method of the oil-displacing agent composition comprises the following steps: regulating a pH value; ventilating a nitrogen gas and removing an oxygen gas; carrying out hydrolysis reaction; drying, crushing and sieving to obtain acrylamide polymers; stirring the acrylamide polymers, the fatty alcohol polyoxyethylene ether carboxylate and the injected water for 0.5 hour-5 hours at 5 DEG C-45 DEG C, and uniformly mixing to obtain the oil-displacing agent composition. And therefore, the oil-displacing agent composition can be used for tertiary oil recovery production of the high-temperature reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

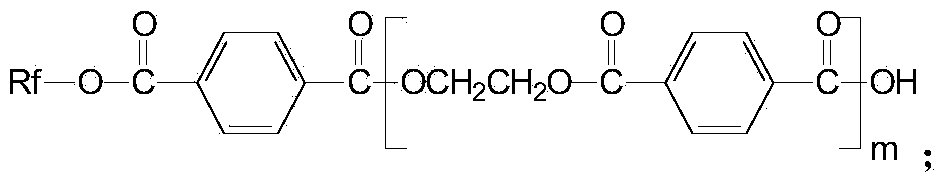

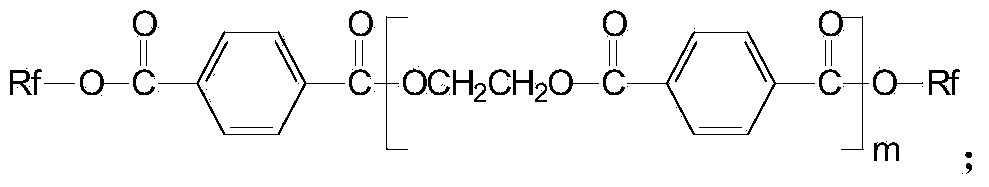

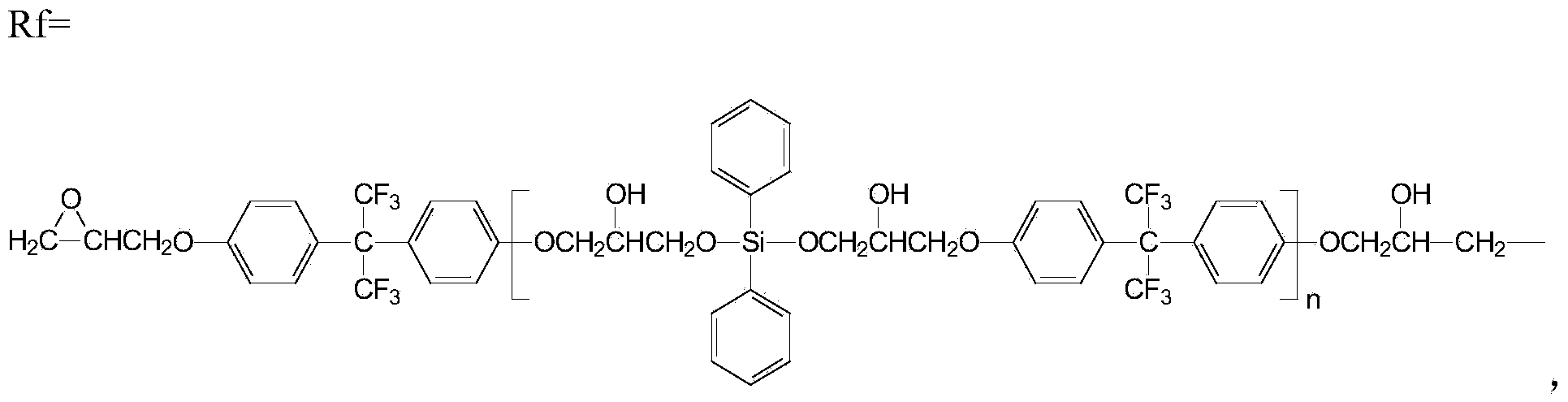

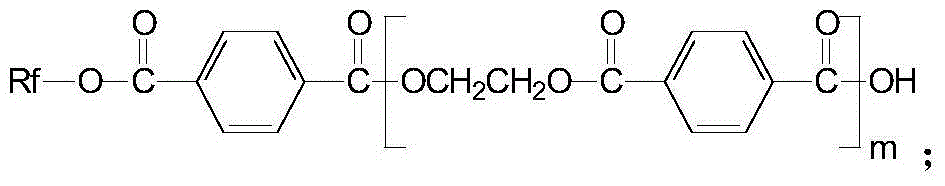

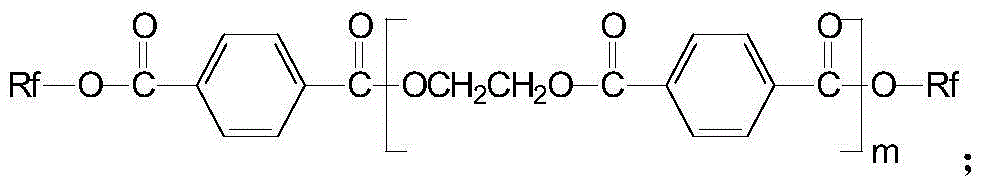

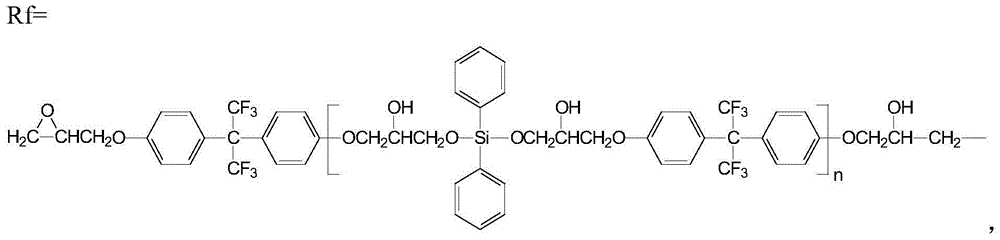

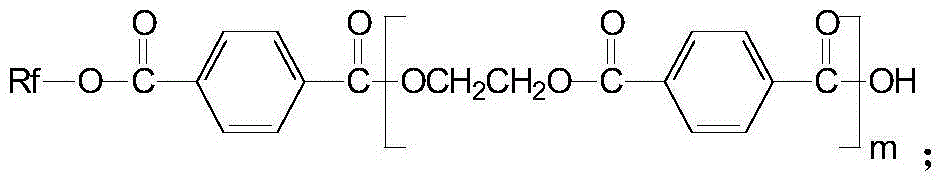

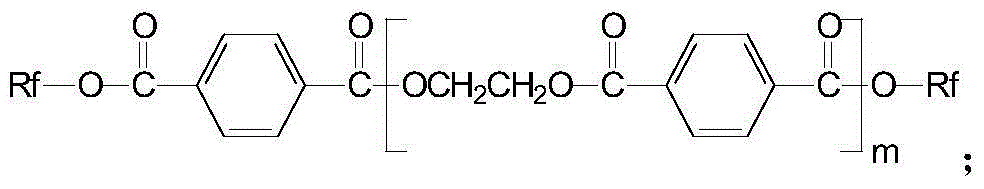

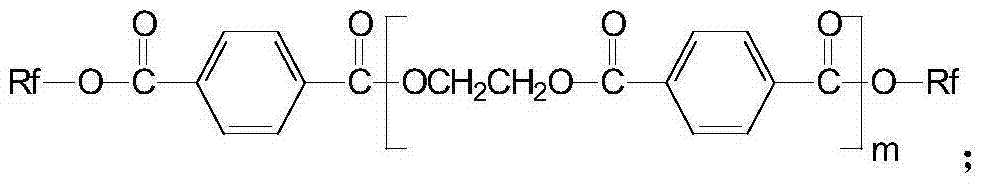

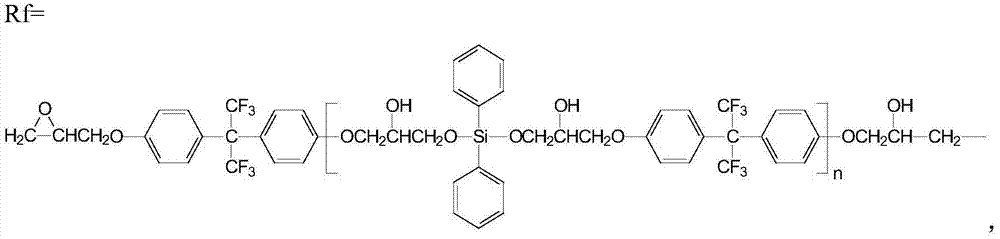

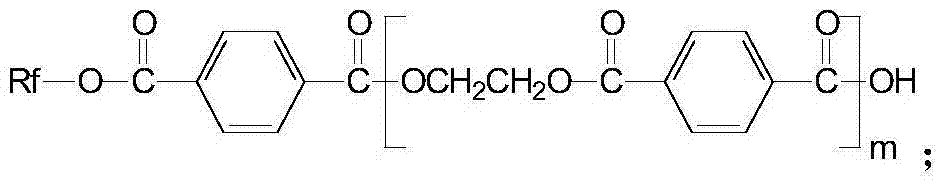

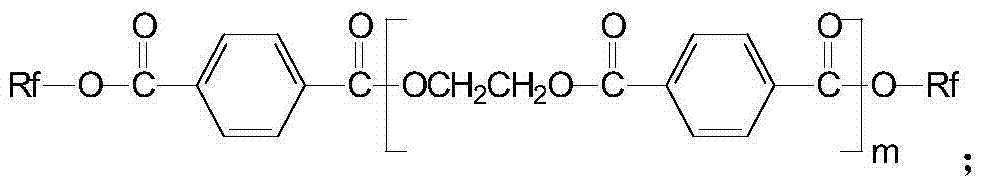

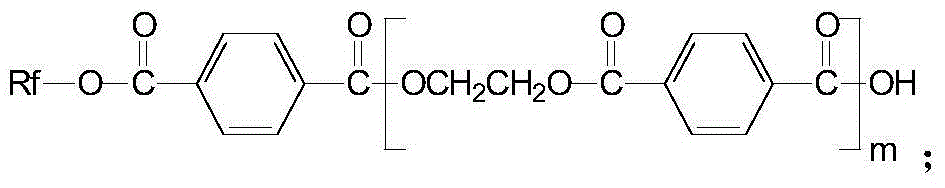

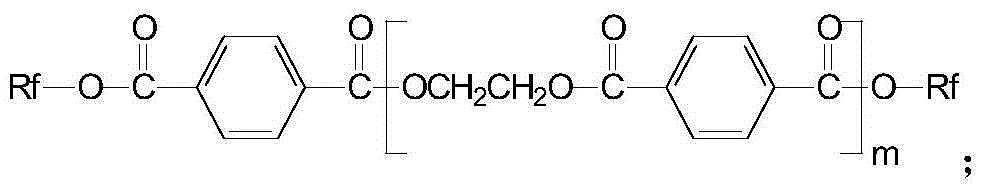

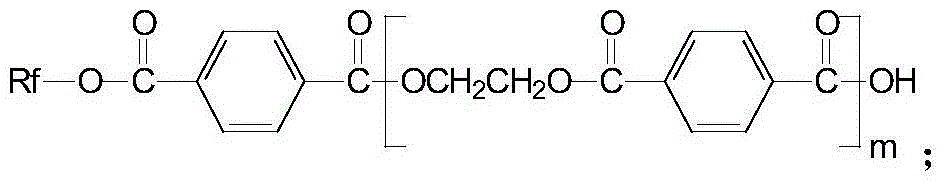

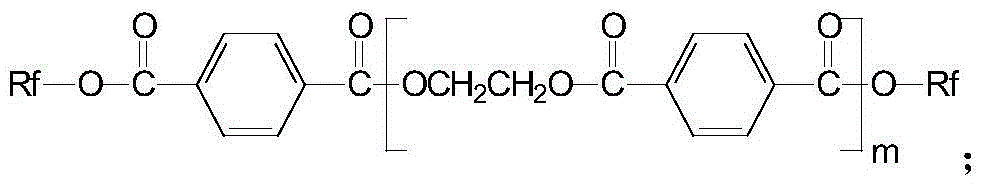

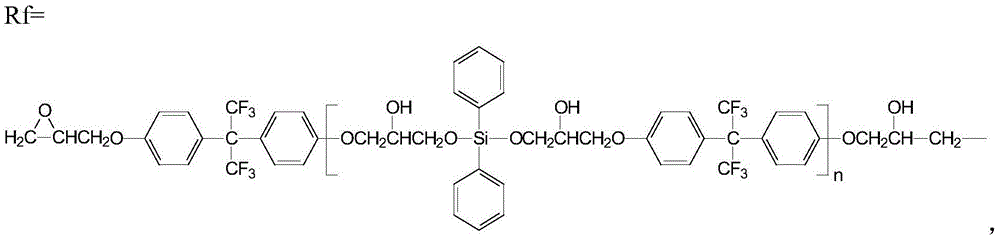

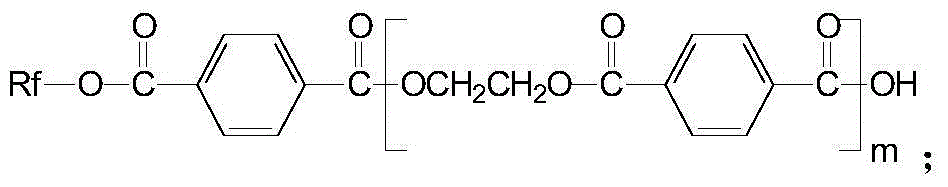

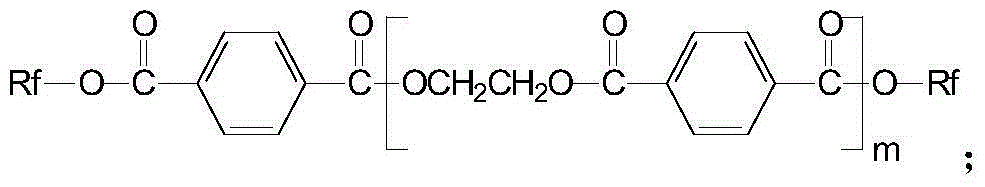

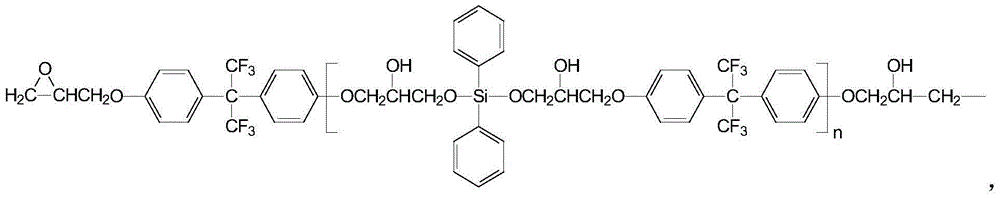

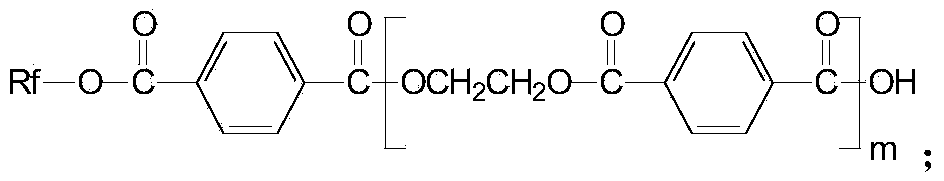

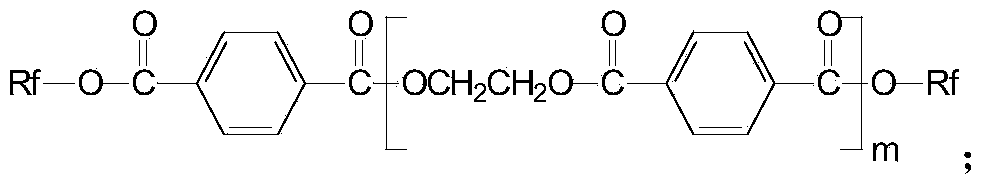

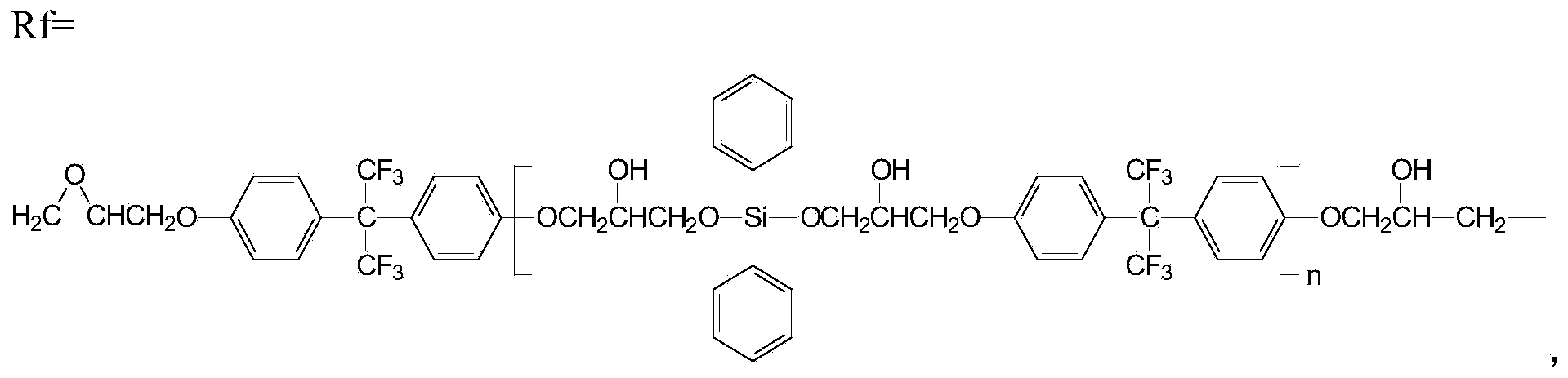

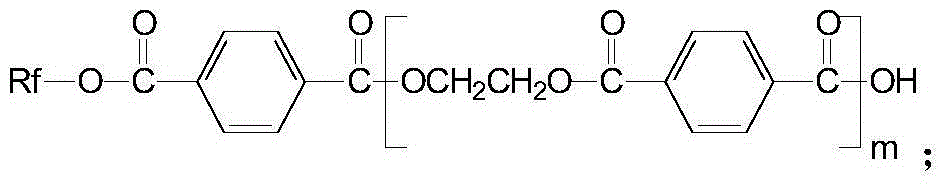

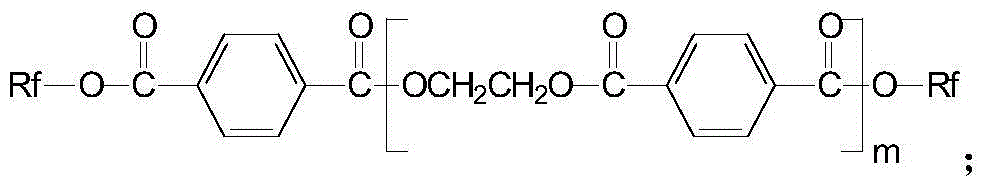

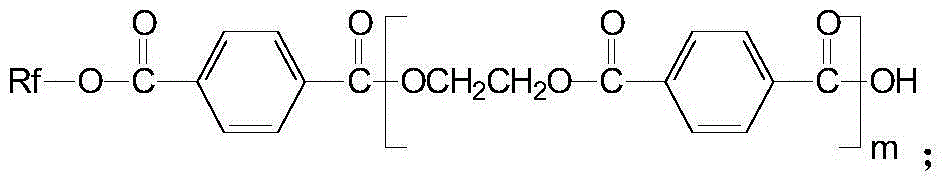

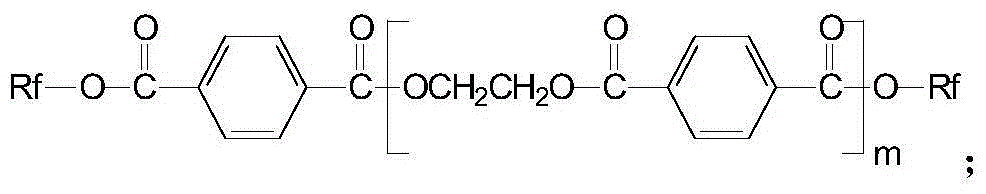

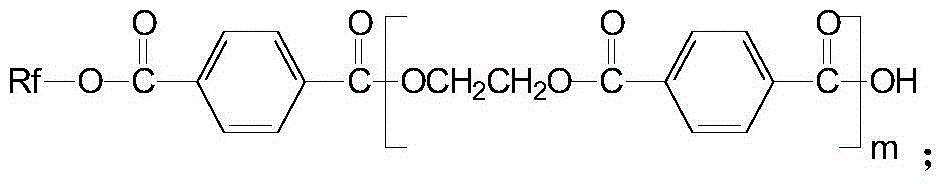

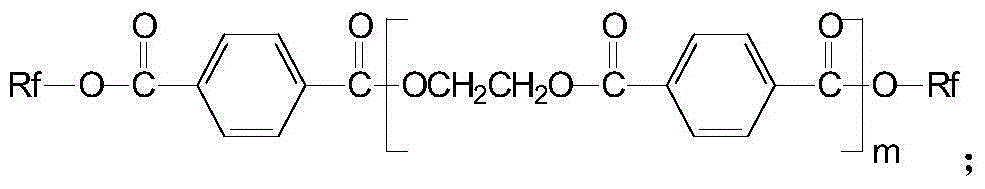

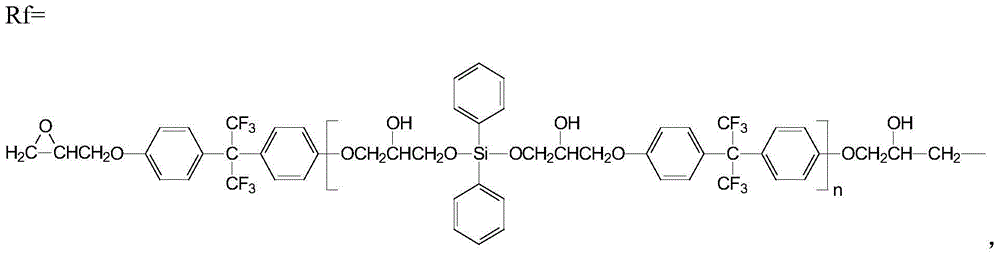

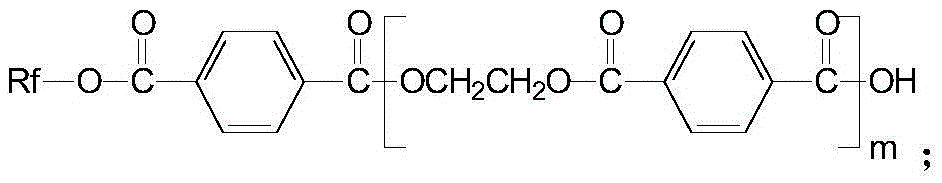

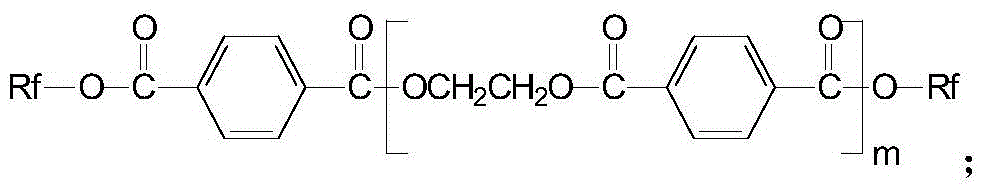

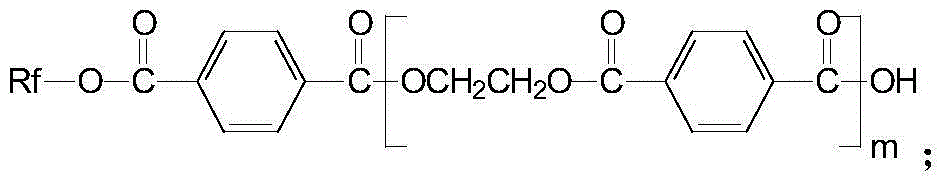

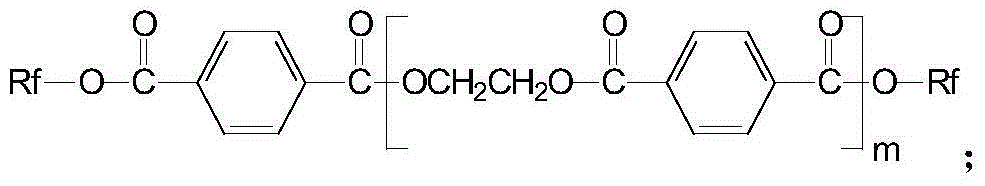

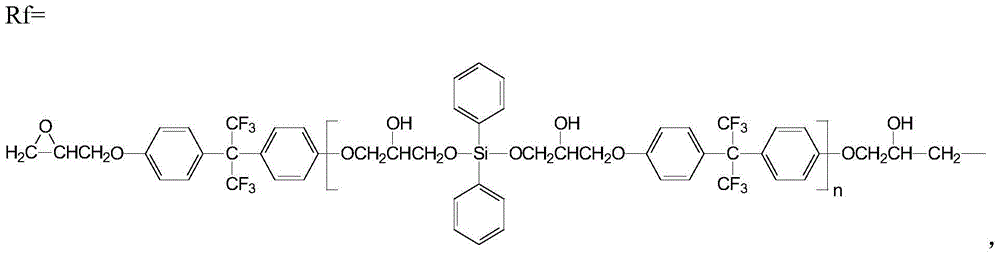

Water-repellent creep-resistant polyester fully drawn yarn (FDY) fiber and preparation method thereof

ActiveCN103526325AIncrease forcePlay the role of creep resistanceFibre typesMonocomponent copolyesters artificial filamentPolyesterYarn

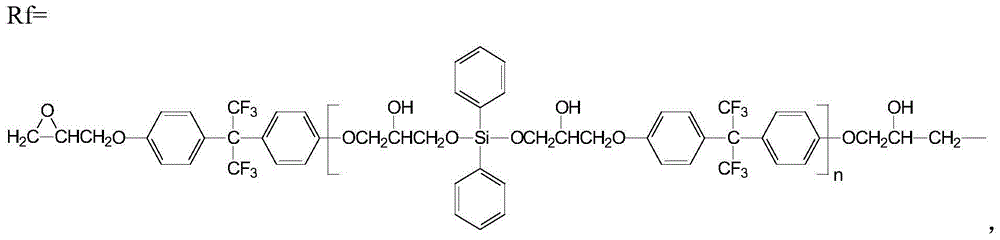

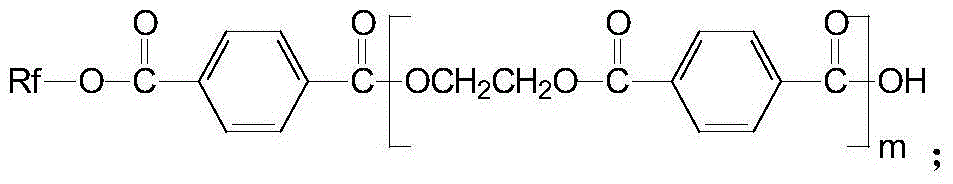

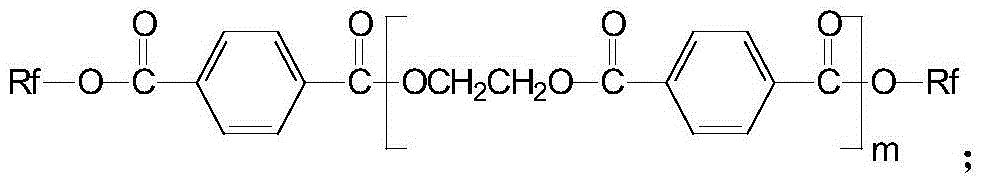

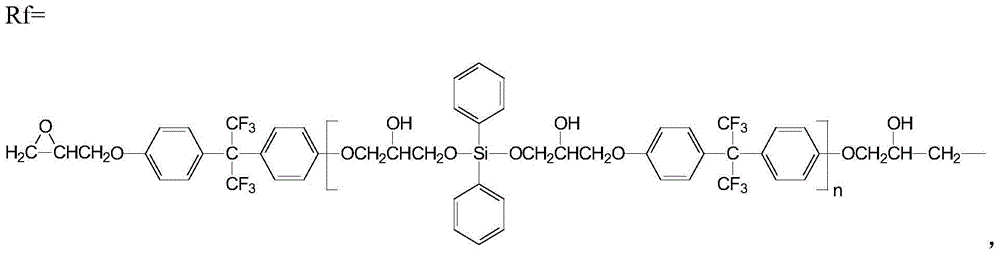

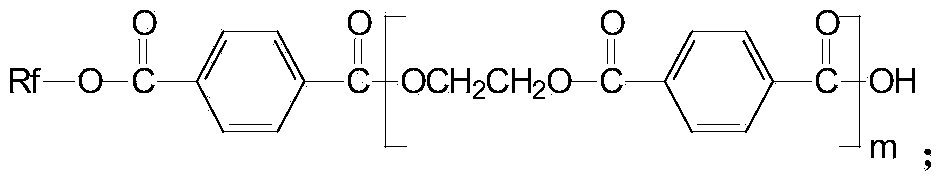

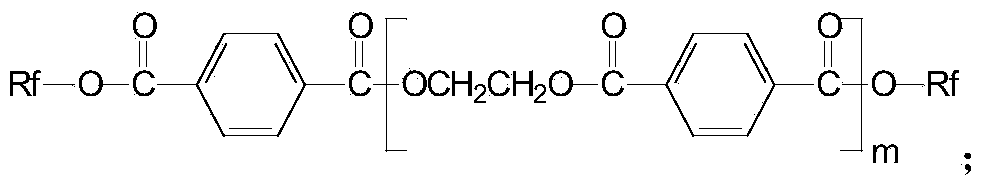

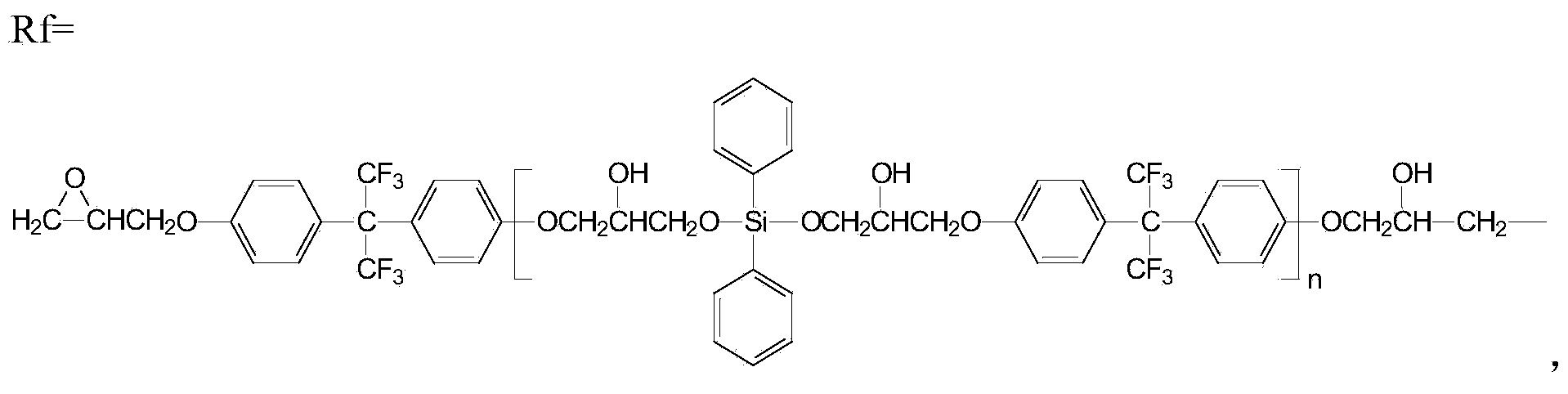

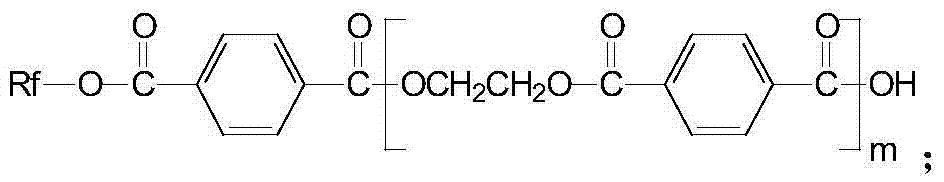

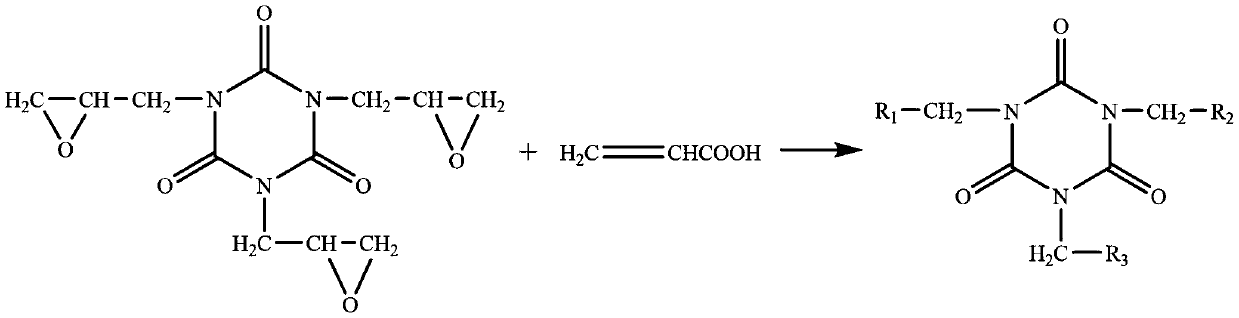

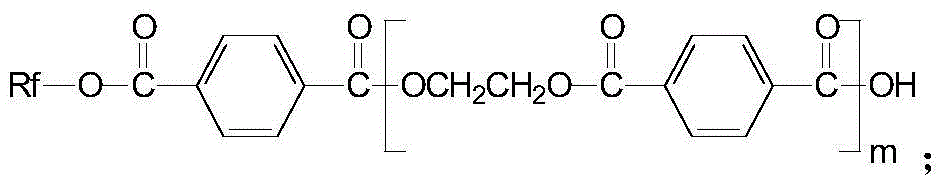

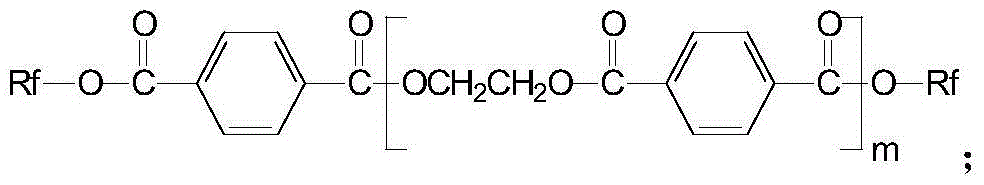

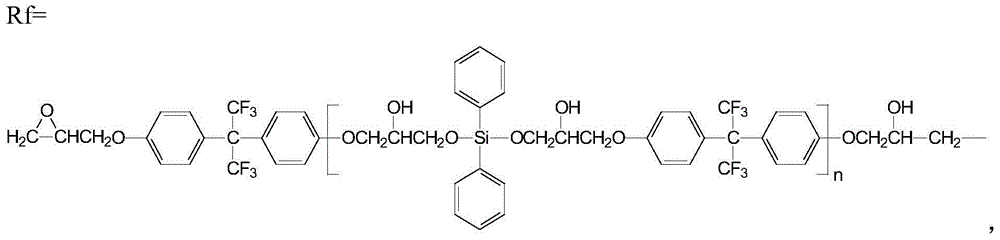

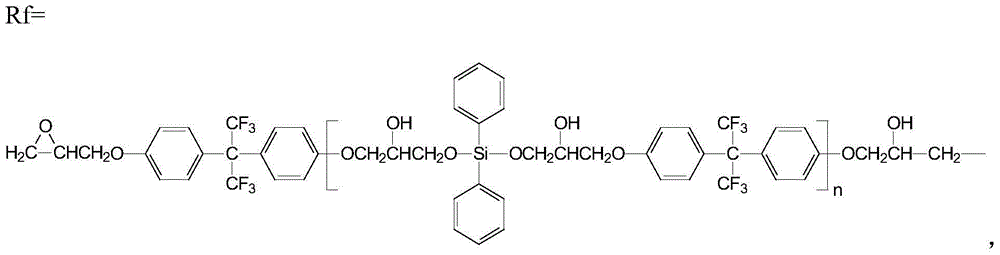

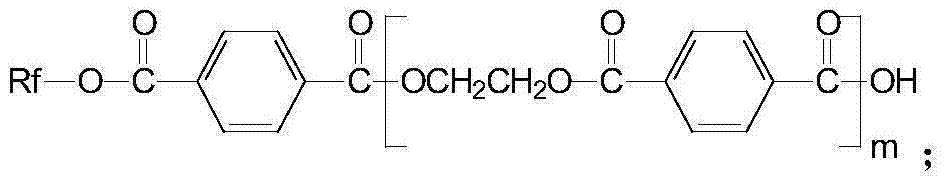

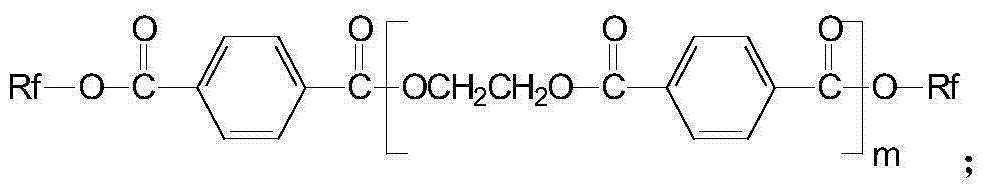

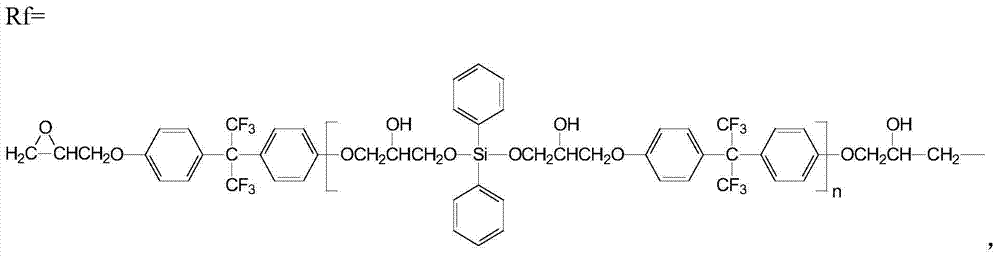

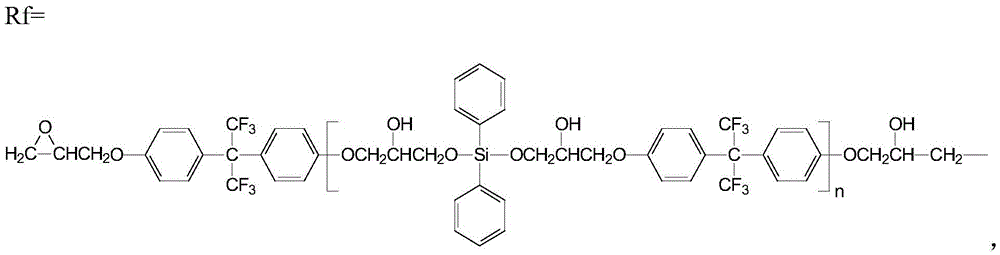

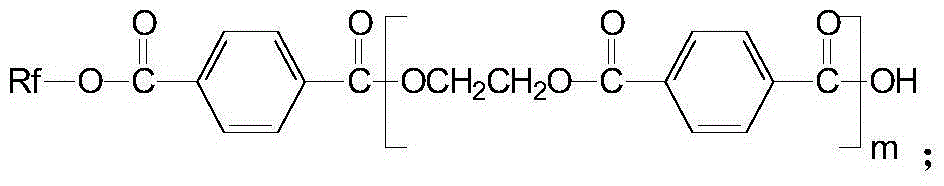

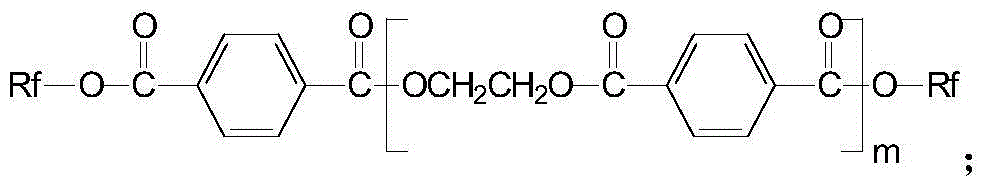

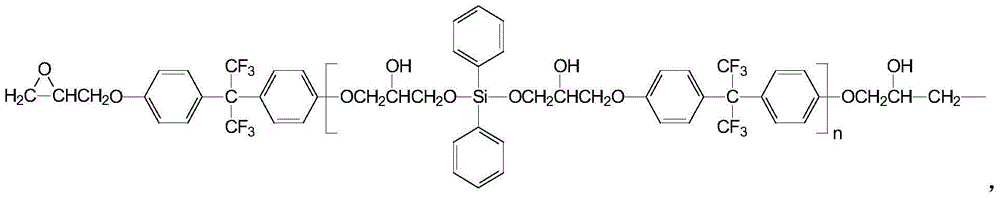

The invention relates to a water-repellent creep-resistant polyester fully drawn yarn (FDY) fiber and a preparation method thereof. The preparation method comprises the preparation of a creep-resistant polyester melt and the preparation of the water-repellent creep-resistant polyester FDY fiber; polyester is blended or added with a fluorine-containing epoxy compound during polyester synthesizing to obtain the creep-resistant polyester melt; then the creep-resistant polyester melt is subjected to metering, extruding, cooling, oiling, stretching and winding to obtain the water-repellent creep-resistant polyester FDY fiber, wherein the oiling operation refers to the operation of coating the surface of the water-repellent creep-resistant polyester FDY fiber with water repellents. The water-repellent creep-resistant polyester FDY fiber has certain creep resistance, hydrolysis resistance and performance stability, can be used in a humid field environment or a high-temperature high-humidity environment for a long time, and has great prospect in the fields of plastic packaging, waterproof fabrics, ropes, mooring ropes, marine fibers and the like.

Owner:JIANGSU HENGLI CHEM FIBER

High-temperature-resistant light emitting diode (LED) lamp filament encapsulation adhesive

InactiveCN105950104AReduce silanol contentAlleviate the oily situationNon-macromolecular adhesive additivesSemiconductor devicesScavengerHydrogen

The invention relates to high-temperature-resistant light emitting diode (LED) lamp filament encapsulation adhesive, prepared from a component A and a component B, wherein the component A is prepared from 97.5-99% parts by weight of vinyl silicone oil and 1-2.5 parts by weight of a catalyst; the component B is prepared from 50-88.2 parts by weight of the vinyl silicone oil, 5-40 parts by weight of vinyl silicone resin, 2-5.5 parts by weight of hydrogen-containing silicone oil, 3.5-7 parts by weight of a thixotropic agent, 0.5-1.5 parts by weight of a hydroxyl scavenger, 0.01-0.02 part by weight of an inhibitor and 0.8-1.5 parts by weight of a tackifier; when in use, the component A is mixed with the component A according to the mass ratio of 1: 10. The LED encapsulation adhesive has excellent heat resistance stability, is applicable to LED lamp filament encapsulation, can resist high temperature cracking, and produces less oil after a lamp is lightened for a long time.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

Creep-resistant polyester ultralow-shrinkage industrial yarn and its preparation method

ActiveCN103556285AIncrease forcePlay the role of creep resistanceNew-spun product collectionMonocomponent copolyesters artificial filamentPolyesterEpoxy

The invention relates to a creep-resistant polyester ultralow-shrinkage industrial yarn and its preparation method. The preparation method includes preparation of a creep-resistant polyester hyperviscous slice and preparation of a creep-resistant polyester ultralow-shrinkage industrial yarn. According to the preparation method, polyester is tackified through solid phase polycondensation and then the tackified polyester is mixed with a fluorine-containing epoxy compound to react so as to obtain the creep-resistant polyester hyperviscous slice; and the creep-resistant polyester ultralow-shrinkage industrial yarn is prepared from the obtained creep-resistant polyester hyperviscous slice by metering, extrusion, cooling, oiling, stretching, thermoforming and coiling. The obtained creep-resistant polyester ultralow-shrinkage industrial yarn has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a hot and humid environment for a long time, and has a huge prospect in the fields of plastic packing, waterproof fabric, ropes, cables, marine fiber and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Creep-resistant polyester color yarn and its preparation method

ActiveCN103556287AIncrease forcePlay the role of creep resistanceNew-spun product collectionMonocomponent copolyesters artificial filamentYarnEpoxy

The invention relates to a creep-resistant polyester color yarn and its preparation method. The preparation method includes preparation of a creep-resistant polyester hyperviscous slice and preparation of a creep-resistant polyester color yarn. According to the preparation method, polyester is tackified through solid phase polycondensation and then the tackified polyester is mixed with a fluorine-containing epoxy compound to react so as to obtain the creep-resistant polyester hyperviscous slice; and the creep-resistant polyester color yarn is prepared from the obtained creep-resistant polyester hyperviscous slice by metering, mixing with a black masterbatch, extrusion, cooling, oiling, stretching and coiling. The creep-resistant polyester color yarn has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a hot and humid environment for a long time, and has a huge prospect in the fields of automobile safety belts, bags fabric for military use, lifting belts and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Creep-resistant polyester and its preparation method

ActiveCN103556289AIncrease forcePlay the role of creep resistanceMonocomponent copolyesters artificial filamentConjugated synthetic polymer artificial filamentsFiberEpoxy

The invention relates to creep-resistant polyester and its preparation method. According to the preparation method, polyester is mixed with a fluorine-containing epoxy compound or a fluorine-containing epoxy compound is added during the synthesis process of polyester. Then, the creep-resistant polyester can be obtained. By the use of the fluorine-containing epoxy compound for blocking modification of the polyester, creep-resistant performance of the polyester can be improved to some extent, and hydrolysis resistance and performance stability of the polyester can be raised. Fiber prepared from the creep-resistant polyester can be used in a hot and humid environment for a long time, and has a huge prospect in the fields of plastic packing, waterproof fabric, ropes, cables, marine fiber and the like.

Owner:JIANGSU HENGLI CHEM FIBER

High-modulus low-shrinkage creep-resistant polyester industrial yarn and preparation method thereof

ActiveCN103526327AIncrease the relative molecular massImproved creep resistanceMonocomponent copolyesters artificial filamentMelt spinning methodsSolid phasesChemistry

The invention relates to a high-modulus low-shrinkage creep-resistant polyester industrial yarn and a preparation method thereof. The preparation method comprises the preparation of a high-viscosity creep-resistant polyester chip and the preparation of the high-modulus low-shrinkage creep-resistant polyester industrial yarn; polyester is subjected to solid phase polycondensation for viscosifying and then is blended and reacted with a fluorine-containing epoxy compound to obtain the high-viscosity creep-resistant polyester chip; then the high-viscosity creep-resistant polyester chip is subjected to metering, extruding, cooling, oiling, stretching, heat setting and winding to obtain the high-modulus low-shrinkage creep-resistant polyester industrial yarn. The high-modulus low-shrinkage creep-resistant polyester industrial yarn has certain creep resistance, hydrolysis resistance and performance stability, can be used in a high-temperature high-humidity environment for a long time, and has great prospect in the fields of plastic packaging, waterproof fabrics, ropes, mooring ropes, marine fibers and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Creep-resistant polyester high-strength low-shrinkage industrial yarn and preparation method thereof

ActiveCN103541038AIncrease forcePlay the role of creep resistanceMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterYarn

The invention relates to creep-resistant polyester high-strength low-shrinkage industrial yarn and preparation method thereof. The method comprises the preparation of creep-resistant polyester high-viscosity slice and the preparation of the creep-resistant polyester high-strength low-shrinkage industrial yarn. According to the invention, polyester is subjected to tackifying through solid-phase polycondensation; the polyester is subjected to a blending reaction with a fluorine-containing epoxy compound, such that the creep-resistant polyester high-viscosity slice is obtained; the creep-resistant polyester high-viscosity slice is subjected to measuring, extruding, cooling, oiling, stretching, heat setting, and winding, such that the creep-resistant polyester high-strength low-shrinkage industrial yarn is prepared. The creep-resistant polyester high-strength low-shrinkage industrial yarn has certain creep resistance, hydrolysis resistance, and performance stability. The yarn can be applied in high-temperature high-humidity environments for a long time. The yarn has great application prospect in the fields such as plastic packaging, waterproof fabrics, ropes, cables, marine fiber, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Creep-resistant polyester high-strength safety belt industrial yarn and preparation method thereof

ActiveCN103541037AIncrease forcePlay the role of creep resistanceMonocomponent copolyesters artificial filamentMelt spinning methodsEpoxyPolyester

The invention relates to a creep-resistant polyester high-strength safety belt industrial yarn and a preparation method thereof. The method comprises the preparation of creep-resistant polyester high-viscosity slice and the preparation of the creep-resistant polyester high-strength safety belt industrial yarn. According to the invention, polyester is subjected to tackifying through solid-phase polycondensation; the polyester is subjected to a blending reaction with a fluorine-containing epoxy compound, such that the creep-resistant polyester high-viscosity slice is obtained; the creep-resistant polyester high-viscosity slice is subjected to measuring, extruding, cooling, oiling, stretching, heat setting, and winding, such that the creep-resistant polyester high-strength safety belt industrial yarn is prepared. The creep-resistant polyester high-strength safety belt industrial yarn has certain creep resistance, hydrolysis resistance, and performance stability. The yarn can be applied in high-temperature high-humidity environments for a long time. The yarn can be applied in high-strength safety belts.

Owner:JIANGSU HENGLI CHEM FIBER

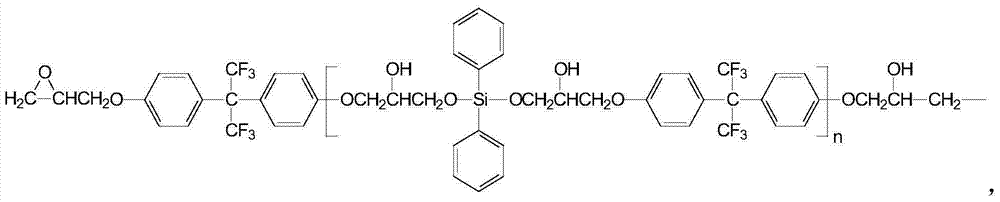

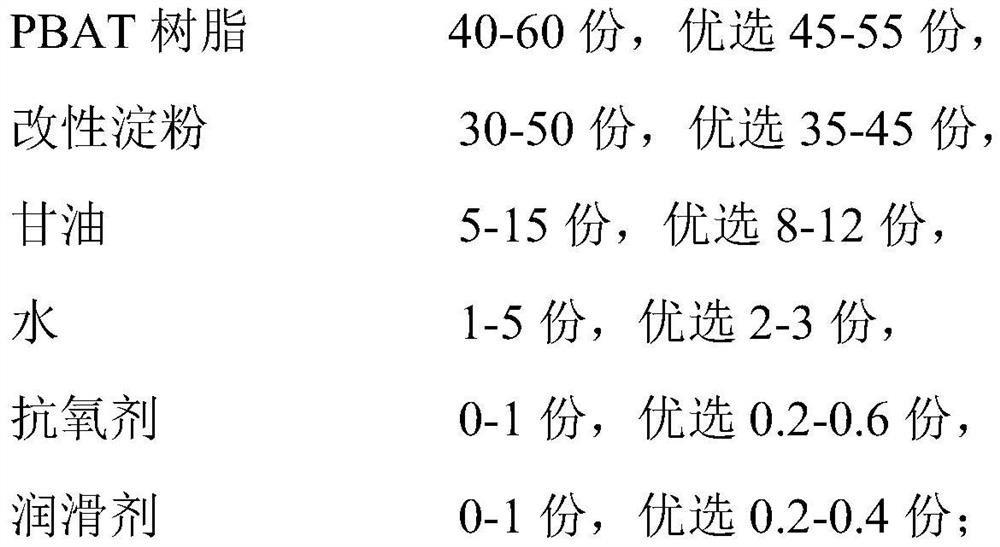

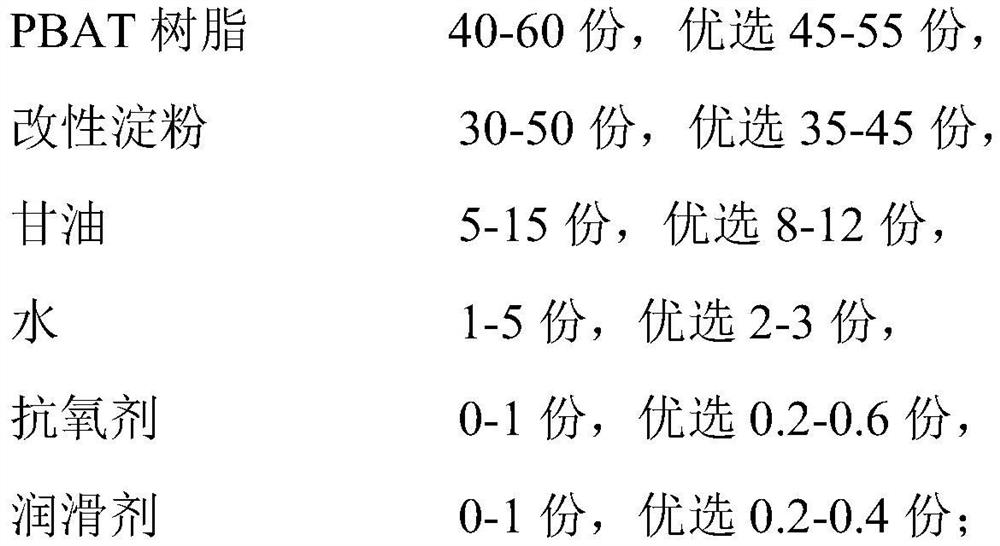

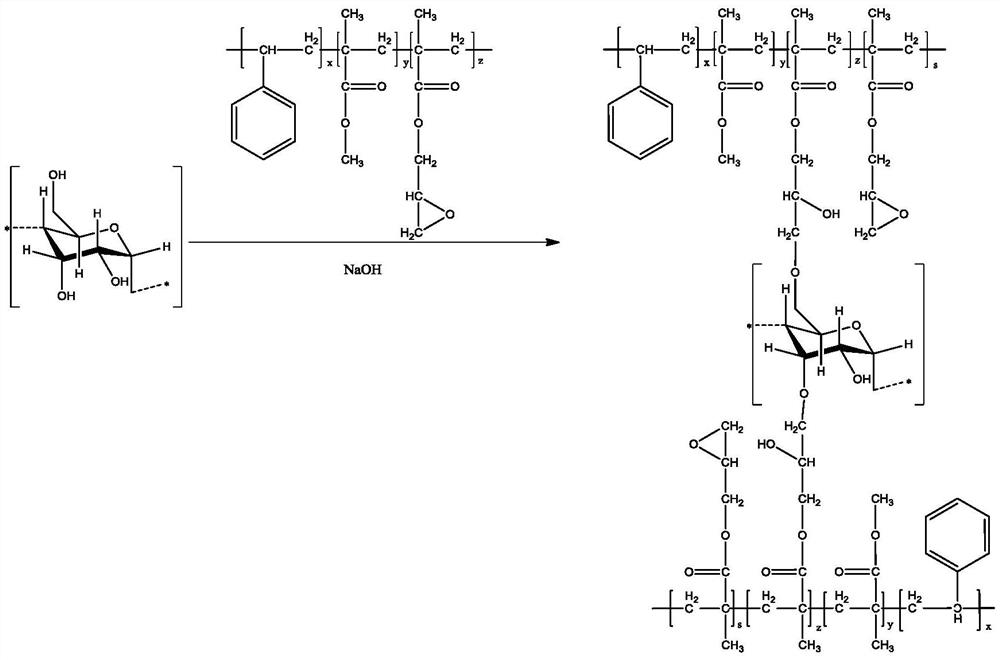

Biodegradable PBAT alloy with high starch content and preparation method of biodegradable PBAT alloy

The invention provides a biodegradable PBAT alloy with high starch content and a preparation method of the biodegradable PBAT alloy. The PBAT alloy is prepared from the following components: PBAT resin, modified starch, glycerol, water, an antioxidant and a lubricant, wherein the modified starch is multi-epoxy-group modified starch containing epoxy groups. Epoxy groups in the modified starch can react with PBAT, so that the interfacial compatibility of the starch and the PBAT is improved, the proportion of the starch is increased, a chain extension effect can be achieved, and the problem thatthe mechanical property of the PBAT is reduced due to degradation in the processing process is solved.

Owner:WANHUA CHEM (SICHUAN) CO LTD +2

Creep-resistant polyester high-grade highway protective fence framework material industrial yarn and its preparation method

ActiveCN103556290AIncrease forcePlay the role of creep resistanceNew-spun product collectionMonocomponent copolyesters artificial filamentEpoxyPolyester

The invention relates to a creep-resistant polyester high-grade highway protective fence framework material industrial yarn and its preparation method. The preparation method includes preparation of a creep-resistant polyester hyperviscous slice and preparation of a creep-resistant polyester high-grade highway protective fence framework material industrial yarn. According to the preparation method, polyester is tackified through solid phase polycondensation and then the tackified polyester is mixed with a fluorine-containing epoxy compound to react so as to obtain the creep-resistant polyester hyperviscous slice; and the creep-resistant polyester high-grade highway protective fence framework material industrial yarn is prepared from the obtained creep-resistant polyester hyperviscous slice by metering, extrusion, cooling, oiling, stretching, thermoforming and coiling. The creep-resistant polyester high-grade highway protective fence framework material industrial yarn has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a hot and humid environment for a long time, and is applied to a polyester industrial-yarn reinforced plastic protective fence.

Owner:JIANGSU HENGLI CHEM FIBER

Extrusion impurity-removal method for modified reworked plastic

InactiveCN105946138AHigh molecular weightImprove physical and chemical propertiesPlastic recyclingOrganic non-surface-active detergent compositionsPulverizerDouble stage

An extrusion impurity-removal method for modified reworked plastic includes the following steps that (1) waste plastic is collected and selected, large impurities are selected and removed, the plastic is classified according to colors, and the waste plastic of the same type is crushed into 3-5 cm particles; (2) the crushed waste plastic particles are delivered into a cleaning tank, clear water is added into the cleaning tank, the waste plastic particles are cleaned and then fished out, and water in the waste plastic particles is drained; (3) the plastic particles with water drained are delivered into drying equipment to be dried with dehumidified dry air, and the drying effect is improved; (4) the dried plastic particles are delivered into a pulverizer to be processed, pulverized materials are delivered into a powder mixing machine, an assistant is added, and even mixing is conducted; (5) the plastic particles mixed with the assistant are delivered into an extruder and filtered through a double-stage filtering die head, high-quality melt is obtained, and the filtered melt is further evenly mixed so as to be consistent in viscosity; and (6) the melt which is further evenly mixed is subjected to pelleting through an extrusion pelletizer, and the high-purity reworked plastic is obtained.

Owner:安徽省华晨塑业科技有限公司

Creep-resistant polyester ultrahigh-strength industrial yarn and its preparation method

ActiveCN103556292AIncrease the relative molecular massImproved creep resistanceNew-spun product collectionMonocomponent copolyesters artificial filamentSolid phasesChemistry

The invention relates to a creep-resistant polyester ultrahigh-strength industrial yarn and its preparation method. The preparation method includes preparation of a creep-resistant polyester hyperviscous slice and preparation of a creep-resistant polyester ultrahigh-strength industrial yarn. According to the preparation method, polyester is tackified through solid phase polycondensation and then the tackified polyester is mixed with a fluorine-containing epoxy compound to react so as to obtain the creep-resistant polyester hyperviscous slice; and the creep-resistant polyester ultrahigh-strength industrial yarn is prepared from the obtained creep-resistant polyester hyperviscous slice by metering, extrusion, cooling, oiling, stretching, thermoforming and coiling. The creep-resistant polyester ultrahigh-strength industrial yarn has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a hot and humid environment for a long time, and has a huge prospect in the fields of plastic packing, waterproof fabric, ropes, cables, marine fiber and the like.

Owner:JIANGSU HENGLI CHEM FIBER

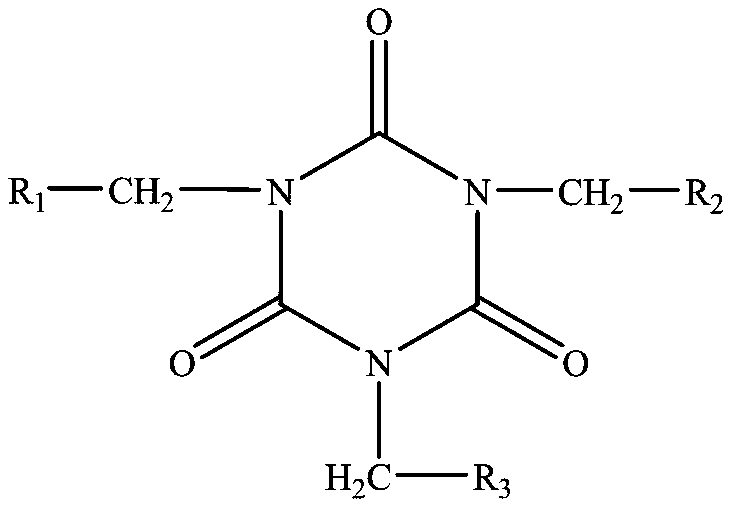

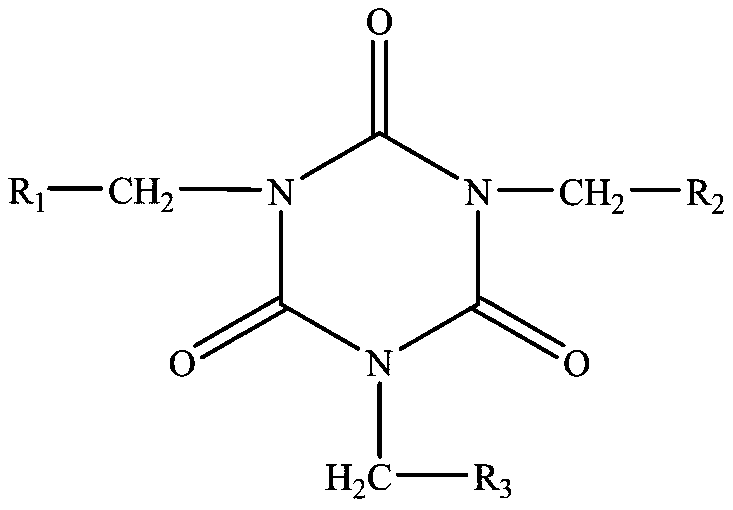

High heat-resistant heat-conductive polyester composite material and preparation method thereof

The invention discloses a high heat-resistant heat-conductive polyester composite material and a preparation method thereof. The material is composed of the following components, in parts by mass: 49.6-89.6 parts of polyester, 10-50 parts of a heat-conductive filler, 0.2-0.5 part of an antioxidant, and 0.2-0.5 part of an anti-hydrolysis agent. According to the composite material provided by the invention, the heat-conductive filler in the composite material is obtained by initiating in-situ polymerization of a triazine acrylate monomer at the surface of magnesium oxide by a radical initiator,and the filler can give thermal conductivity to the polyester composite material and improve the heat resistance and processing stability of the composite material; and the composite material can broaden an application field of polyester materials.

Owner:FOSHAN SANSHUI JINGE NEW MATERIALS CO LTD

Creep-resistant polyester high-strength car-model industrial yarn and its preparation method

ActiveCN103556288AIncrease forcePlay the role of creep resistanceNew-spun product collectionMonocomponent copolyesters artificial filamentPolyesterYarn

The invention relates to a creep-resistant polyester high-strength car-model industrial yarn and its preparation method. The preparation method includes preparation of a creep-resistant polyester hyperviscous slice and preparation of a creep-resistant polyester high-strength car-model industrial yarn. According to the preparation method, polyester is tackified through solid phase polycondensation and then the tackified polyester is mixed with a fluorine-containing epoxy compound to react so as to obtain the creep-resistant polyester hyperviscous slice; and the creep-resistant polyester high-strength car-model industrial yarn is prepared from the obtained creep-resistant polyester hyperviscous slice by metering, extrusion, cooling, oiling, stretching, thermoforming and coiling. The creep-resistant polyester high-strength car-model industrial yarn has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a hot and humid environment for a long time, and is applied to tyre cord fabrics.

Owner:JIANGSU HENGLI CHEM FIBER

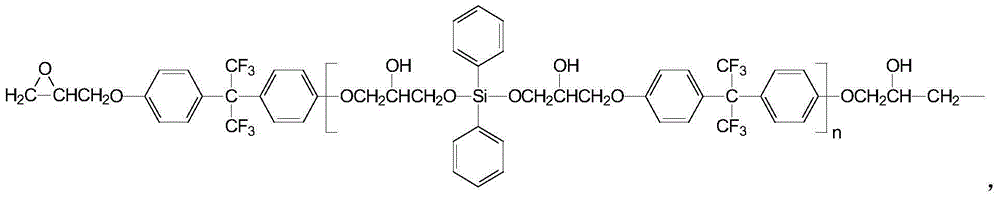

Creep-resistant hydrolysis-resistance polyester FDY fiber and its preparation method

ActiveCN103556291AIncrease forcePlay the role of creep resistanceNew-spun product collectionArtificial filament heat treatmentFiberPolyester

The invention relates to a creep-resistant hydrolysis-resistance polyester FDY fiber and its preparation method. The preparation method includes preparation of a creep-resistant hydrolysis-resistance polyester melt and preparation of the creep-resistant hydrolysis-resistance polyester FDY fiber. According to the preparation method, polyester is mixed with a fluorine-containing epoxy compound and a carbodiimide stabilizer or a fluorine-containing epoxy compound and a carbodiimide stabilizer are added during the synthesis process of polyester so as to obtain the creep-resistant hydrolysis-resistance polyester melt; and the creep-resistant hydrolysis-resistance polyester FDY fiber is prepared from the creep-resistant hydrolysis-resistance polyester melt by metering, extrusion, cooling, oiling, stretching and coiling. The obtained creep-resistant hydrolysis-resistance polyester FDY fiber has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a wild humid environment or a hot and humid environment for a long time, and has a huge prospect in the fields of plastic packing, waterproof fabric, ropes, cables, marine fiber and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Creep resistant polyester supplementary restraint system industrial yarn and preparation method thereof

ActiveCN103526328AIncrease forcePlay the role of creep resistanceMonocomponent copolyesters artificial filamentMelt spinning methodsEpoxyPolyester

The invention relates to a creep resistant polyester supplementary restraint system industrial yarn and a preparation method of the creep resistant polyester supplementary restraint system industrial yarn. The method comprises steps of preparation of creep resistant polyester high-viscosity slices and preparation of the creep resistant polyester supplementary restraint system industrial yarns, wherein the viscosity of the polyester is increased through solid phase polycondensation, then blending reaction is carried out on the polyester and fluorine-containing epoxy compound so as to obtain the creep resistant polyester high-viscosity slices; and the creep resistant polyester high-viscosity slices are prepared into the creep resistant polyester supplementary restraint system industrial yarns through metering, extruding, cooling, applying oil, stretching, thermoforming and winding. The creep resistant polyester supplementary restraint system industrial yarn has certain creep resistance, hydrolytic resistance and performance stability, can be used in high temperature and humidity environment for long time, and is applicable to airbag fabric.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of colored yarn of creep-resistant polyester and its preparation method

ActiveCN103556287BIncrease forcePlay the role of creep resistanceNew-spun product collectionMonocomponent copolyesters artificial filamentFiberMasterbatch

The invention relates to a creep-resistant polyester color yarn and its preparation method. The preparation method includes preparation of a creep-resistant polyester hyperviscous slice and preparation of a creep-resistant polyester color yarn. According to the preparation method, polyester is tackified through solid phase polycondensation and then the tackified polyester is mixed with a fluorine-containing epoxy compound to react so as to obtain the creep-resistant polyester hyperviscous slice; and the creep-resistant polyester color yarn is prepared from the obtained creep-resistant polyester hyperviscous slice by metering, mixing with a black masterbatch, extrusion, cooling, oiling, stretching and coiling. The creep-resistant polyester color yarn has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a hot and humid environment for a long time, and has a huge prospect in the fields of automobile safety belts, bags fabric for military use, lifting belts and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Water-repellent creep-resistant polyester fully drawn yarn (FDY) fiber and preparation method thereof

ActiveCN103526325BIncrease forcePlay the role of creep resistanceFibre typesMonocomponent copolyesters artificial filamentPolyesterEpoxy

Owner:JIANGSU HENGLI CHEM FIBER

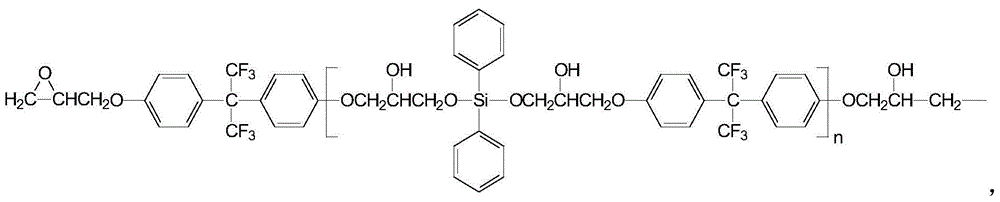

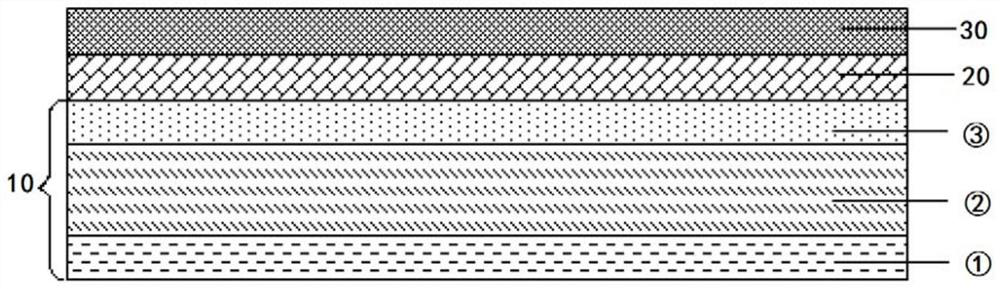

High-barrier biaxially oriented polyamide color changing film and preparation method thereof

ActiveCN112549719AWide choice of colorsSolve single colorPolyureas/polyurethane adhesivesSynthetic resin layered productsPolyurethane dispersionColor film

The invention discloses a high-barrier biaxially oriented polyamide color changing film and a preparation method thereof. The color changing film is composed of a PU color film layer, a bonding layerand a base material layer. Slurry of the PU color film layer and slurry of the bonding layer both adopt waterborne polyurethane dispersion liquid, and the base material layer is sequentially composedof an upper surface layer, a core layer and a lower surface layer; the upper surface layer and the lower surface layer are made of a mixture of PA6 and PA12, and the core layer is made of EVOH. According to the invention, the PU color film layer coated on a release film is transferred to the surface of the biaxially oriented polyamide film obtained by three-layer co-extrusion casting stretching toobtain the biaxially oriented polyamide color changing film, and the film has the advantages of uniform color, good color coverage rate, high barrier property, scratch resistance, low moisture absorption and the like; and the PU color film layer is widely applied to packaging and decoration.

Owner:厦门长塑实业有限公司

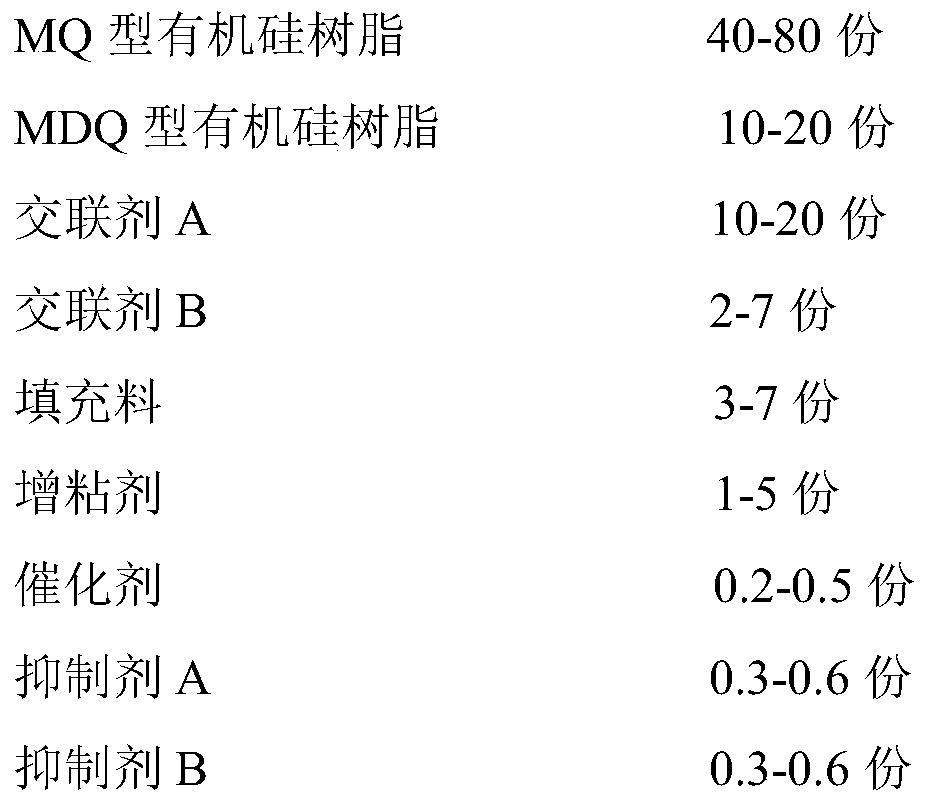

Methyl organic silicon adhesive with excellent flexibility and strong adhesion for LED

ActiveCN111410932AGuaranteed Vinyl ContentGood flexibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a methyl organic silicon adhesive with excellent flexibility and strong adhesion for an LED. The formula comprises the following raw materials in parts by weight; 40-80 parts of MQ type methyl vinyl silicone resin, 10-20 parts of MDQ type methyl vinyl silicone resin, 10-20 parts of a cross-linking agent A, 2-7 parts of a cross-linking agent B, 3-7 parts of a specially-madefiller, 1-5 parts of a tackifier, 0.2-0.5 part of a catalyst, 0.3-0.6 part of an inhibitor A and 0.3-0.6 part of an inhibitor B. According to the organic silicon adhesive prepared by the invention, acured main body structure does not contain phenyl and has relatively high flexibility, and meanwhile, through optimal design of molecular structures of the main body resin and the cross-linking agent,the high-temperature stability and the adhesive property of the organic silicon adhesive are effectively improved, and the organic silicon adhesive is particularly suitable for die bonding of large-size chips.

Owner:南京科矽新材料科技有限公司

Polyurethane pouring sealant as well as preparation method and application thereof

ActiveCN114316878AEasy to synthesizeHigh elongationNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to a polyurethane pouring sealant and a preparation method and application thereof.The polyurethane pouring sealant is composed of a component A and a component B. The mass ratio of the component A to the component B is 40-60: 100, and the component A is prepared from, by weight, 10-40 parts of hydroxyl-terminated polybutadiene A, 5-20 parts of polymer polyol, 5-30 parts of plasticizer and 35-75 parts of isocyanate; the component B comprises the following raw materials in parts by weight: 20-60 parts of hydroxyl-terminated polybutadiene B, 5-30 parts of polymer polyol, 5-30 parts of a plasticizer, 5-25 parts of a chain extender, 5-40 parts of a flame retardant, 0.5-5 parts of carbon black, 0.01-1 part of a catalyst and 0.1-1 part of a defoaming agent; the hydroxyl-terminated polybutadiene A is a special hydroxyl-terminated polybutadiene with low functionality; the hydroxyl-terminated polybutadiene B is polyfunctional special hydroxyl-terminated polybutadiene and / or epoxidized special hydroxyl-terminated polybutadiene. The pouring sealant disclosed by the invention has the characteristics of high mechanical property, good adhesive property, excellent insulation and flame retardance and low-temperature resistance, and can be used for pouring and sealing electronic components such as cables.

Owner:LIMING RES INST OF CHEM IND

A kind of anti-creep anti-hydrolysis polyester FDY fiber and preparation method thereof

ActiveCN103556291BIncrease forcePlay the role of creep resistanceNew-spun product collectionArtificial filament heat treatmentFiberPolyester

The invention relates to a creep-resistant hydrolysis-resistance polyester FDY fiber and its preparation method. The preparation method includes preparation of a creep-resistant hydrolysis-resistance polyester melt and preparation of the creep-resistant hydrolysis-resistance polyester FDY fiber. According to the preparation method, polyester is mixed with a fluorine-containing epoxy compound and a carbodiimide stabilizer or a fluorine-containing epoxy compound and a carbodiimide stabilizer are added during the synthesis process of polyester so as to obtain the creep-resistant hydrolysis-resistance polyester melt; and the creep-resistant hydrolysis-resistance polyester FDY fiber is prepared from the creep-resistant hydrolysis-resistance polyester melt by metering, extrusion, cooling, oiling, stretching and coiling. The obtained creep-resistant hydrolysis-resistance polyester FDY fiber has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a wild humid environment or a hot and humid environment for a long time, and has a huge prospect in the fields of plastic packing, waterproof fabric, ropes, cables, marine fiber and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Resin recycling modified technique

A resin recycling modified technique includes the steps: (1) collecting waste resin, placing the collected waste resin on a vibrating screen to separate large impurities, crushing waste plastics intoplastic granules, feeding the plastic granules into a cold air drying device, and performing cold air drying for 30-35 minutes at the temperature of 50-55 DEG C; feeding the resin granules after coldair drying into a vacuum tumbler to tumble the resin granules, vacuumizing once every 5-8 minutes in tumbling, tumble the resin granules for 5-10 minutes after vacuumizing is completed once, discharging vacuum, and cycling the steps for 2-4 times; (3) draining moisture of sprayed resin granules, and feeding the resin granules into a drying device to dry the resin granules at the temperature of 55-60 DEG C until the surfaces of the resin granules do not have moisture; (4) feeding the dried resin granules into a low-temperature device to perform low-temperature treatment for 20 minutes at the temperature of 15 DEG C below zero; (5) mixing the resin granules after cold-resistant treatment and activating agents according to the weight ratio of 1:(0.05-0.1), feeding mixture into an extruding machine for granulation to modify resin.

Owner:袁园

A kind of anti-wicking industrial yarn of anti-creep polyester and its preparation method

ActiveCN103774273BIncrease forcePlay the role of creep resistanceMonocomponent polyesters artificial filamentYarnEpoxy

The invention relates to a creep resistant polyester anti-wicking industrial yarn and a preparation method thereof. The preparation method comprises preparation of a creep resistant polyester hyperviscous slice and preparation of a creep resistant polyester anti-wicking industrial yarn. The preparation method specifically comprises the following steps: tackifying the polyester through solid phase polycondensation, and then alloying with a fluorine-containing epoxy compound to obtain the creep resistant polyester hyperviscous slice; preparing the creep resistant polyester anti-wicking industrial yarn through the obtained creep resistant polyester hyperviscous slice by the following steps: metering; extruding; cooling; oiling; stretching; thermally setting; oiling an anti-wicking oil absorber; coiling; plastifying; carrying out heat balance treatment. The obtained creep resistant polyester anti-wicking industrial yarn has certain creep resistance, hydrolysis resistance and performance stability, can be used in high temperature and high humidity environments for a long time, and has huge prospect in the fields such as advertising lamp boxes, sun cloth and water storage containers.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of ultra-high-strength industrial yarn of creep-resistant polyester and its preparation method

ActiveCN103556292BIncrease forcePlay the role of creep resistanceNew-spun product collectionMonocomponent copolyesters artificial filamentPolyesterEpoxy

The invention relates to a creep-resistant polyester ultrahigh-strength industrial yarn and its preparation method. The preparation method includes preparation of a creep-resistant polyester hyperviscous slice and preparation of a creep-resistant polyester ultrahigh-strength industrial yarn. According to the preparation method, polyester is tackified through solid phase polycondensation and then the tackified polyester is mixed with a fluorine-containing epoxy compound to react so as to obtain the creep-resistant polyester hyperviscous slice; and the creep-resistant polyester ultrahigh-strength industrial yarn is prepared from the obtained creep-resistant polyester hyperviscous slice by metering, extrusion, cooling, oiling, stretching, thermoforming and coiling. The creep-resistant polyester ultrahigh-strength industrial yarn has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a hot and humid environment for a long time, and has a huge prospect in the fields of plastic packing, waterproof fabric, ropes, cables, marine fiber and the like.

Owner:JIANGSU HENGLI CHEM FIBER

A kind of anti-creep anti-hydrolysis polyester poy fiber and preparation method thereof

ActiveCN103556286BIncrease forcePlay the role of creep resistanceMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterFiber

The invention relates to a creep-resistant hydrolysis-resistance polyester POY fiber and its preparation method. The preparation method includes preparation of a creep-resistant hydrolysis-resistance polyester melt and preparation of the creep-resistant hydrolysis-resistance polyester POY fiber. According to the preparation method, polyester is mixed with a fluorine-containing epoxy compound and a carbodiimide stabilizer or a fluorine-containing epoxy compound and a carbodiimide stabilizer are added during the synthesis process of polyester so as to obtain the creep-resistant hydrolysis-resistance polyester melt; and the creep-resistant hydrolysis-resistance polyester POY fiber is prepared from the creep-resistant hydrolysis-resistance polyester melt by metering, extrusion, cooling, oiling and coiling. The obtained creep-resistant hydrolysis-resistance polyester POY fiber has a certain creep resistance, hydrolysis resistance and performance stability, can be used in a wild humid environment or a hot and humid environment for a long time, and has a huge prospect in the fields of plastic packing, waterproof fabric, ropes, cables, marine fiber and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Oil-displacing agent composition for high-temperature reservoir enhanced recovery and preparation method thereof

ActiveCN103666433BHigh molecular weightIncrease the relative molecular massDrilling compositionNitrogen gasFatty alcohol

The invention relates to an oil-displacing agent composition for improving a recovery ratio of a high-temperature reservoir and a preparation method of the composition, mainly solving the problems that a polymer-containing oil-displacing agent in the prior art is poor in temperature resistance, salt resistance and thermal stability resistance, and low in displacement efficiency. In order to solve the problems better, a following technical scheme is adopted as follows: the oil-displacing agent composition comprises the following components in percentage by weight: 0.005%-8.0% of high-temperature-resistant and oil-displacing acrylamide polymers, 0.005%-5.0% of a fatty alcohol polyoxyethylene ether carboxylate surfactant and 87.0%-99.99% of injected water. The preparation method of the oil-displacing agent composition comprises the following steps: regulating a pH value; ventilating a nitrogen gas and removing an oxygen gas; carrying out hydrolysis reaction; drying, crushing and sieving to obtain acrylamide polymers; stirring the acrylamide polymers, the fatty alcohol polyoxyethylene ether carboxylate and the injected water for 0.5 hour-5 hours at 5 DEG C-45 DEG C, and uniformly mixing to obtain the oil-displacing agent composition. And therefore, the oil-displacing agent composition can be used for tertiary oil recovery production of the high-temperature reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of high-strength and low-shrinkage industrial yarn of creep-resistant polyester and its preparation method

ActiveCN103541038BIncrease forcePlay the role of creep resistanceMonocomponent copolyesters artificial filamentMelt spinning methodsPolyesterYarn

The invention relates to creep-resistant polyester high-strength low-shrinkage industrial yarn and preparation method thereof. The method comprises the preparation of creep-resistant polyester high-viscosity slice and the preparation of the creep-resistant polyester high-strength low-shrinkage industrial yarn. According to the invention, polyester is subjected to tackifying through solid-phase polycondensation; the polyester is subjected to a blending reaction with a fluorine-containing epoxy compound, such that the creep-resistant polyester high-viscosity slice is obtained; the creep-resistant polyester high-viscosity slice is subjected to measuring, extruding, cooling, oiling, stretching, heat setting, and winding, such that the creep-resistant polyester high-strength low-shrinkage industrial yarn is prepared. The creep-resistant polyester high-strength low-shrinkage industrial yarn has certain creep resistance, hydrolysis resistance, and performance stability. The yarn can be applied in high-temperature high-humidity environments for a long time. The yarn has great application prospect in the fields such as plastic packaging, waterproof fabrics, ropes, cables, marine fiber, and the like.

Owner:JIANGSU HENGLI CHEM FIBER

High-modulus low-shrinkage creep-resistant polyester industrial yarn and preparation method thereof

ActiveCN103526327BIncrease forcePlay the role of creep resistanceMonocomponent copolyesters artificial filamentMelt spinning methodsYarnEpoxy

The invention relates to a high-modulus low-shrinkage creep-resistant polyester industrial yarn and a preparation method thereof. The preparation method comprises the preparation of a high-viscosity creep-resistant polyester chip and the preparation of the high-modulus low-shrinkage creep-resistant polyester industrial yarn; polyester is subjected to solid phase polycondensation for viscosifying and then is blended and reacted with a fluorine-containing epoxy compound to obtain the high-viscosity creep-resistant polyester chip; then the high-viscosity creep-resistant polyester chip is subjected to metering, extruding, cooling, oiling, stretching, heat setting and winding to obtain the high-modulus low-shrinkage creep-resistant polyester industrial yarn. The high-modulus low-shrinkage creep-resistant polyester industrial yarn has certain creep resistance, hydrolysis resistance and performance stability, can be used in a high-temperature high-humidity environment for a long time, and has great prospect in the fields of plastic packaging, waterproof fabrics, ropes, mooring ropes, marine fibers and the like.

Owner:JIANGSU HENGLI CHEM FIBER

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com