High-barrier biaxially oriented polyamide color changing film and preparation method thereof

A technology of biaxial stretching and polyamide, applied in the field of high-barrier biaxial stretching polyamide color-changing film and its preparation, to achieve excellent mechanical properties and scratch resistance, solve uneven dispersion, and excellent hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

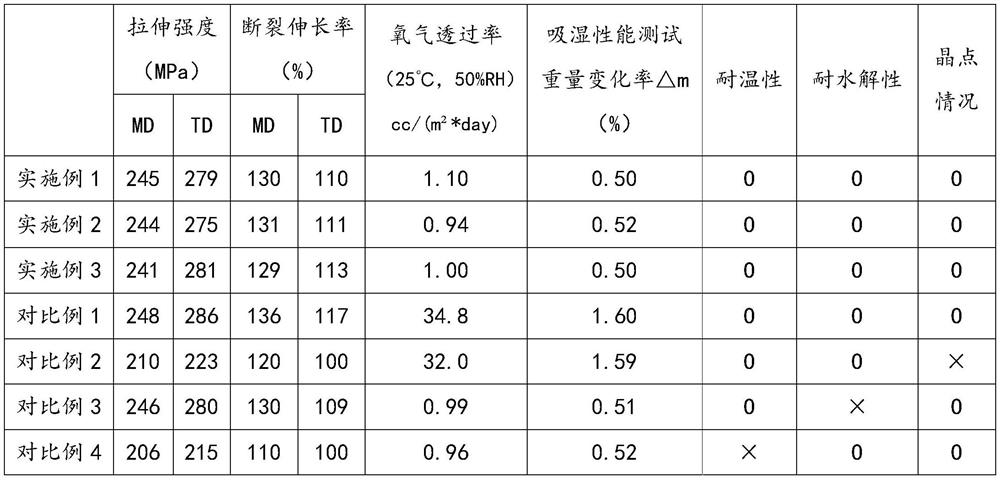

Embodiment 1

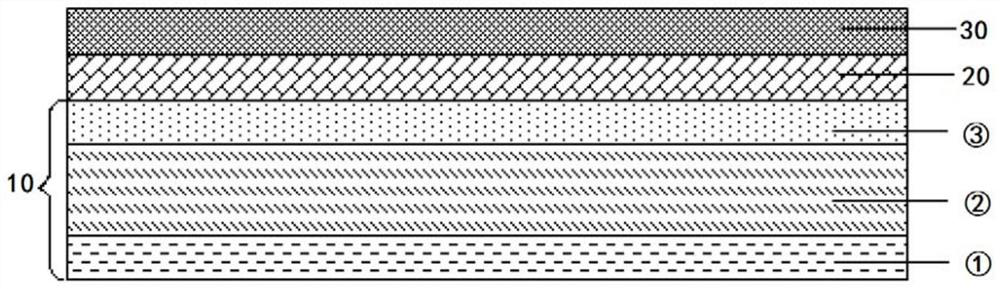

[0054] In this embodiment, a high-barrier biaxially stretched polyamide color-changing film is composed of a PU color film layer, an adhesive layer and a substrate layer; the thickness of the PU color film layer is 2.5 microns, and the thickness of the adhesive layer is 0.5 microns, and the thickness of the substrate layer is 15 microns.

[0055] The PU color film layer consists of 50% water-based polyurethane dispersion, 15% water, 5% alcohol, 2% film-forming aid, 1% leveling agent, 3% pH stabilizer, 20% pigment, 1% anti-scratch agent, 3% curing agent;

[0056] The bonding layer is composed of 50% water-based polyurethane dispersion, 40% water, 8% alcohol, and 2% curing agent;

[0057] The substrate layer is composed of an upper surface layer, a core layer and a lower surface layer, wherein the upper and lower surface layers are composed of 85% PA6, 13.5% PA12, 0.5% anti-blocking agent and 1.0% slip agent, and the core layer is composed of 100% The composition of EVOH.

[...

Embodiment 2

[0061] The difference between embodiment 2 and embodiment 1 is:

[0062] The PU color film layer consists of 30% aqueous polyurethane dispersion, 20% water, 8% alcohol, 3% film-forming aid, 2% leveling agent, 4.5% pH stabilizer, 25% Pigment, 2% anti-scratch agent, 5.5% curing agent;

[0063] The bonding layer is composed of 40% water-based polyurethane dispersion, 45% water, 12% alcohol, and 3% curing agent;

[0064] The substrate layer is composed of an upper surface layer, a core layer and a lower surface layer, wherein the upper and lower surface layers are composed of 70% PA6, 27% PA12, 1.0% anti-blocking agent and 2.0% slip agent, and the core layer is composed of 100% EVOH composition.

Embodiment 3

[0066] The difference between embodiment 3 and embodiment 1 is:

[0067] The PU color film layer consists of 40% aqueous polyurethane dispersion, 18% water, 6.5% alcohol, 2.5% film-forming aid, 1.5% leveling agent, 4.0% pH stabilizer, 22% Pigment, 1.5% anti-scratch agent, 4% curing agent;

[0068] The bonding layer is composed of 45% water-based polyurethane dispersion, 42.5% water, 10% alcohol, and 2.5% curing agent;

[0069] The substrate layer is composed of an upper surface layer, a core layer and a lower surface layer, wherein the upper and lower surface layers are composed of 80% PA6, 17% PA12, 1.0% anti-blocking agent and 2.0% slippery agent, and the core layer is composed of 100% EVOH composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com