Novel wear-proof and twist-resistant reflecting material and preparation method thereof

A reflective material, resistant to bending technology, used in optics, optical components, instruments, etc., to achieve the effect of strong integration, tight integration, and no processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

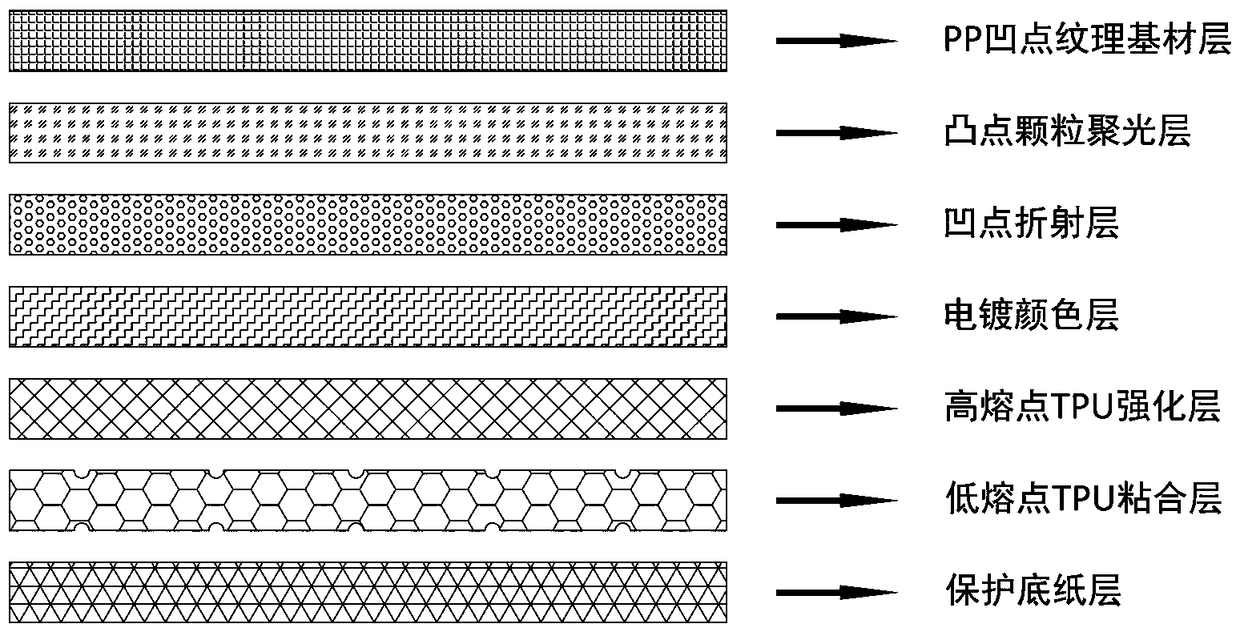

[0023] In order to enable the examiners to further understand the purpose, features and functions of the present invention, the present invention will be further described below in conjunction with the accompanying drawings:

[0024] see figure 1 As shown, it is a schematic diagram of the structure of the present invention. The present invention is a new wear-resistant and twist-resistant reflective material, which is characterized in that:

[0025] The reflective material consists of 7 layers, one layer is a PP concave point texture substrate layer, the second layer is a bump particle light-gathering layer, the third layer is a concave point refraction layer, the fourth layer is an electroplating color layer, and the fifth layer is a high melting point layer. TPU reinforcement layer, six layers are low melting point TPU adhesive layer, seven layers are protective backing paper layer.

[0026] Further, the layer of PP pit texture substrate layer is made of polypropylene mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com