Bi-component aqueous epoxy latex paint capable of substituting for ceramic tile

A water-based epoxy, two-component technology, used in latex paints, epoxy resin coatings, coatings, etc., can solve the problems that the use is not very easy, the environmental protection and odor of oil-based architectural coatings cannot be popularized and applied, and the use requirements are high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0121] A kind of preparation method of the two-component water-based epoxy latex paint component that can replace ceramic tile in the kitchen interior wall construction of the present invention comprises the steps:

[0122] The various components of the composition component A described in claim 1 are mixed to obtain the component A of the two-component water-based epoxy latex paint that can replace tiles in the kitchen interior wall construction.

[0123] Afterwards, component A and component B (100% water-based epoxy resin) are mixed in a certain proportion, and the preferred ratio of the two components is 100:8±1.0, so as to obtain the effect of the replaceable ceramic tile on the kitchen interior wall. Two-component waterborne epoxy latex paint composition.

[0124] In a specific embodiment, the component A of the two-component water-based epoxy latex paint that can replace ceramic tiles in kitchen interior wall construction is made by the method comprising the following ste...

specific Embodiment approach

[0145] The present invention is further illustrated below by examples and comparative examples.

[0146] In the following implementation and comparative examples, component A of the two-component water-based epoxy latex paint that can replace tiles in the kitchen interior wall construction is investigated for its freeze-thaw stability, film-forming property, mildew resistance, and scrub resistance; and After component B is mixed, test the hardness of the paint film, the bending resistance, abrasion resistance and stain resistance of the paint film, etc.

Embodiment 1~3

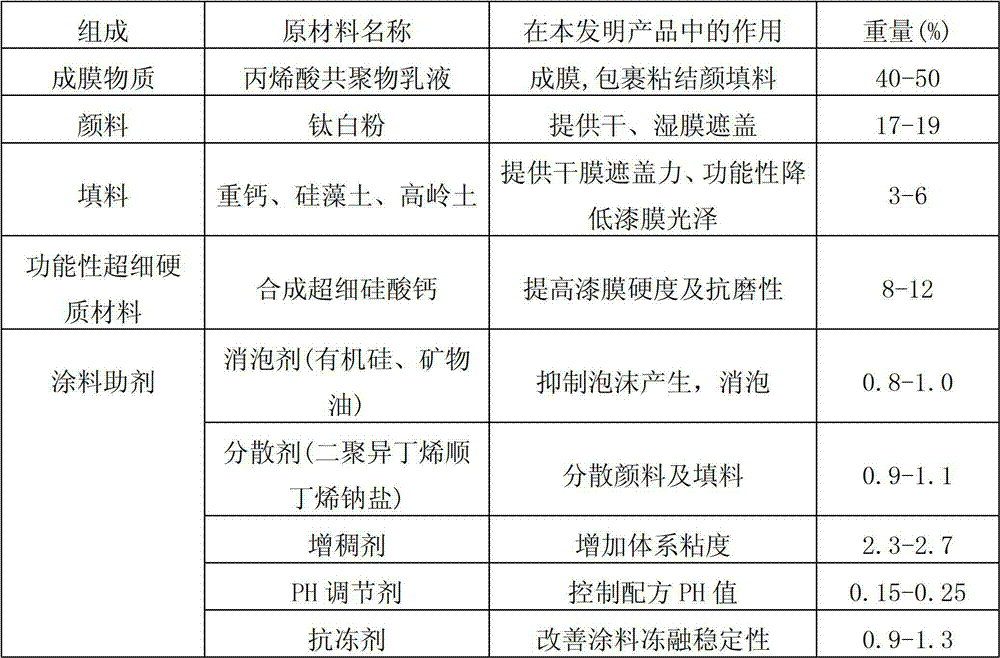

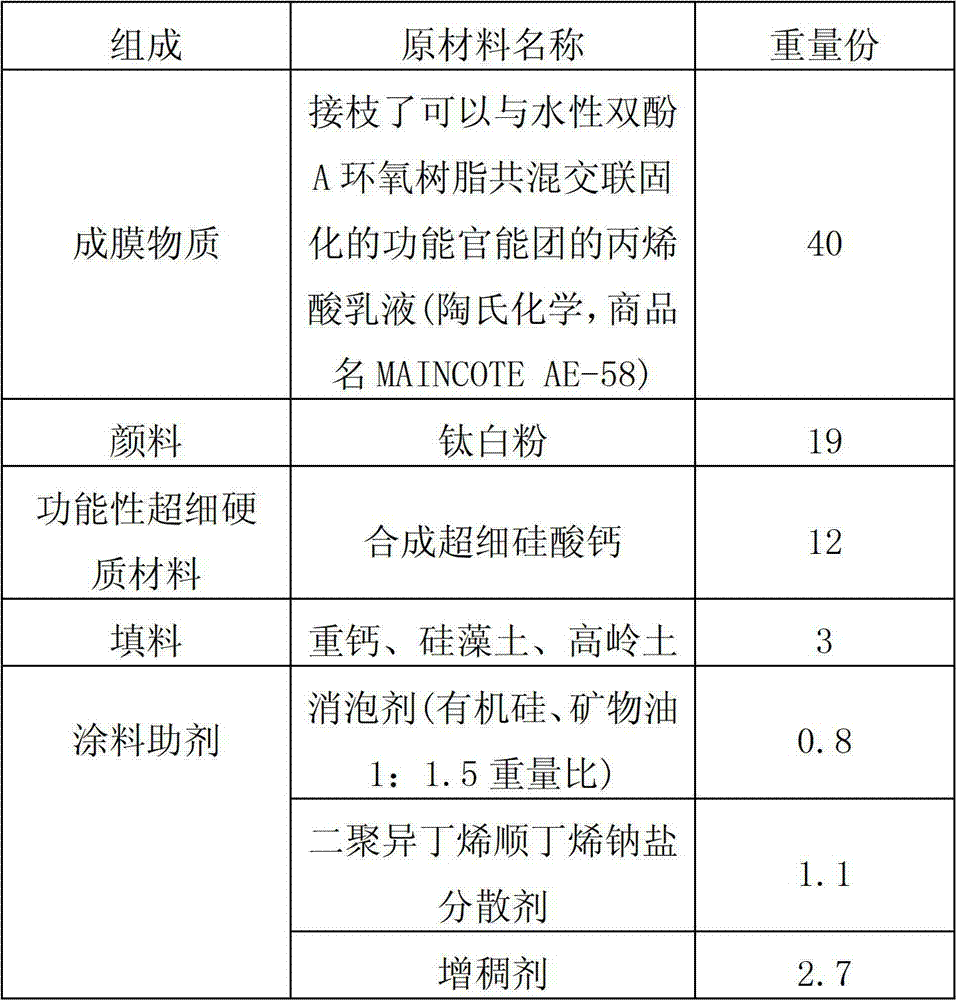

[0148] Prepare the raw materials for preparing the product of the present invention according to the weight percentages in Tables 1a-c.

[0149] Table 1a

[0150]

[0151]

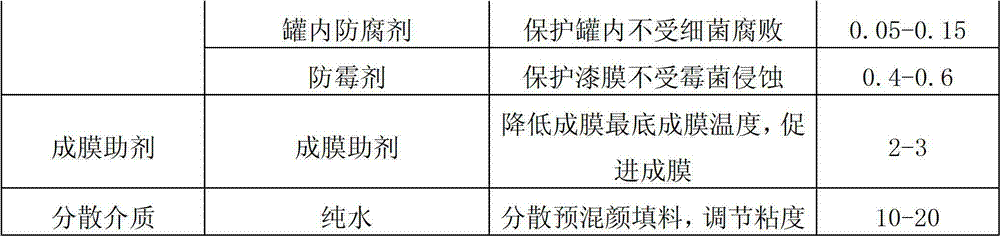

[0152] Table 1b

[0153]

[0154]

[0155] Table 1c

[0156]

[0157]

[0158] First pure water is put into the dispersing tank, and the rotating speed is controlled at 400-600 rpm; then add paint additives (2.5 ± 0.2 parts by weight of thickener; and 0.2 ± 0.05 parts by weight of pH regulator) and stir for 3 minutes; Slowly add coating additives (wetting and dispersing agent, partial defoamer) into the dispersion tank in turn in the dispersed state; add pigments and fillers and functional ultra-fine hard materials into the dispersion tank respectively, and gradually increase the speed to 1500 rpm , disperse for 15-20 minutes, during which the temperature of the slurry should not exceed 55°C; after the dispersion is completed, reduce the speed to 600-800 rpm, add the film-forming substa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com