Water-repellent creep-resistant polyester fully drawn yarn (FDY) fiber and preparation method thereof

A polyester fiber and creep-resistant technology, which is applied in the field of creep-resistant polyester water-repellent FDY fiber and its preparation, to achieve the effects of expanding the application range, improving hydrolysis resistance, and improving creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

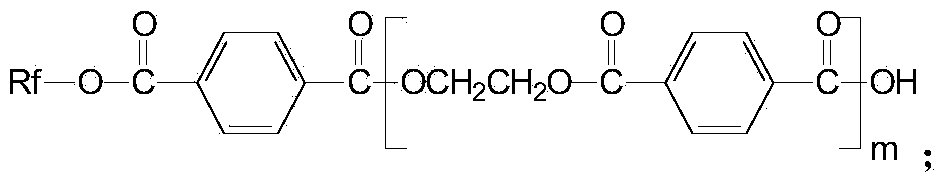

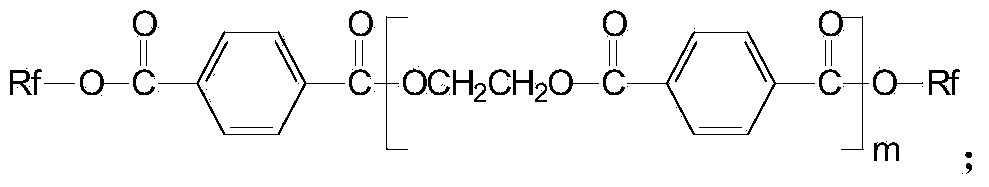

Method used

Image

Examples

Embodiment 1

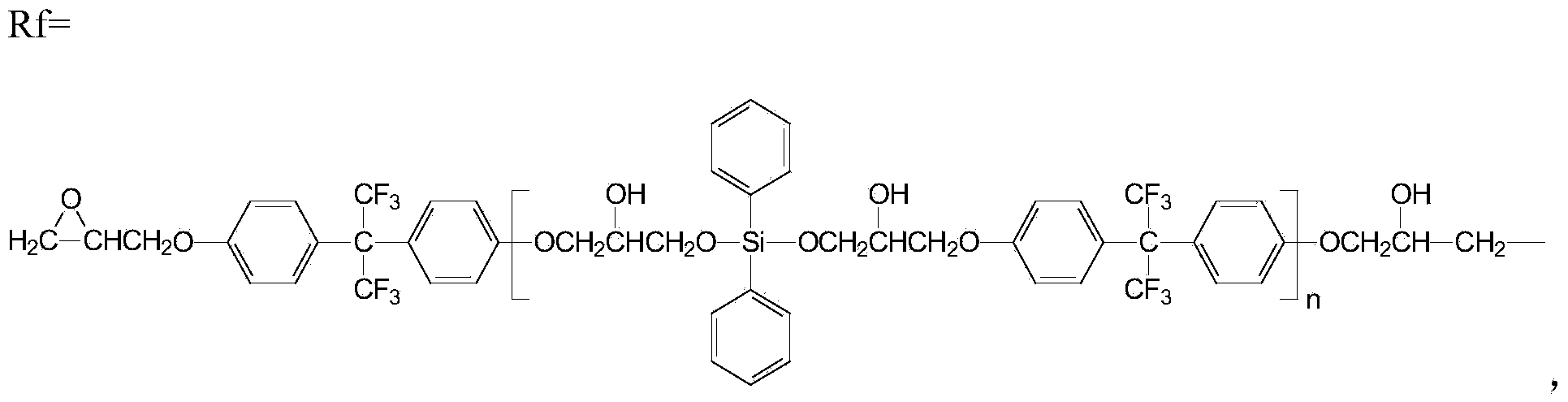

[0076] Preparation of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether:

[0077] In a nitrogen atmosphere, mix epichlorohydrin and 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylidene]diphenol at a molar ratio of 4:1 , add 1.5% 15mol / L sodium hydroxide solution of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol mass, at room temperature Stir the reaction for 16h; then cool to room temperature, then add 30% of the mass of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol with anhydrous carbonic acid Sodium-saturated 5mol / L sodium hydroxide solution, stirred and reacted at room temperature for 10h; then extracted with chloroform, and the resulting organic phase was evaporated to remove chloroform and excess epichlorohydrin to obtain a thick liquid, which was added to anhydrous Recrystallization in ethanol to obtain crystals of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether;

[0078] Preparation of fluor...

Embodiment 2

[0084] Preparation of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether:

[0085] In a nitrogen atmosphere, mix epichlorohydrin and 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylidene]diphenol at a molar ratio of 4:1 , add 2.0% 10mol / L sodium hydroxide solution of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol mass, at room temperature Stir the reaction for 18 hours; cool to room temperature, then add 40% of the mass of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol with anhydrous sodium carbonate Saturated 3mol / L sodium hydroxide solution, stirred and reacted at room temperature for 15h; then extracted with chloroform, the resulting organic phase was evaporated to remove chloroform and excess epichlorohydrin to obtain a thick liquid, which was added to absolute ethanol Medium recrystallization, namely obtain the crystal of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether;

[0086] Preparation of fl...

Embodiment 3

[0092] Preparation of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether:

[0093] In a nitrogen atmosphere, mix epichlorohydrin and 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylidene]diphenol at a molar ratio of 4:1 , add 1.8% 12mol / L sodium hydroxide solution of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol mass, at room temperature Stir the reaction for 17 hours; cool to room temperature, then add 35% of the mass of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol with anhydrous sodium carbonate Saturated 4mol / L sodium hydroxide solution, stirred and reacted at room temperature for 13h; then extracted with chloroform, the resulting organic phase was evaporated to remove chloroform and excess epichlorohydrin to obtain a thick liquid, which was added to absolute ethanol Medium recrystallization, namely obtain the crystal of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether;

[0094] Preparation of fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com