High heat-resistant heat-conductive polyester composite material and preparation method thereof

A polyester composite material, high heat resistance technology, applied in the field of polyester resin, can solve the problems affecting material processing performance, mechanical properties and thermal conductivity, low thermal deformation temperature, etc., to improve processing performance, mechanical properties, comprehensive performance Excellent, the effect of increasing the heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

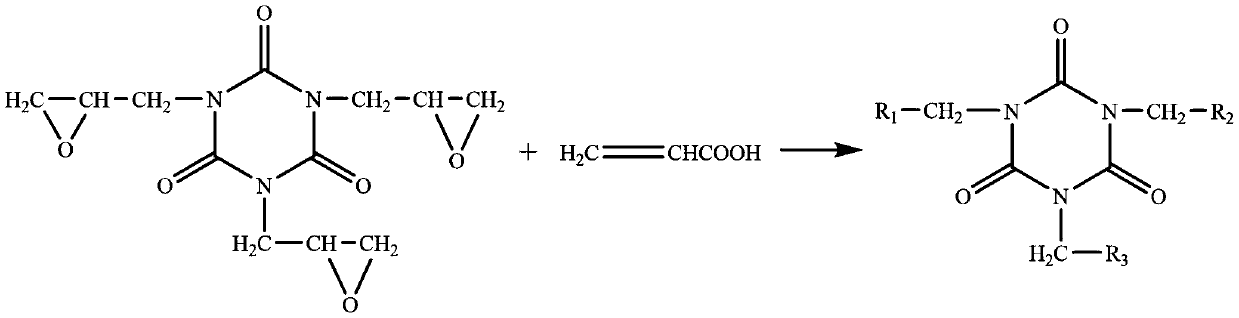

Method used

Image

Examples

Embodiment 1

[0029] Mix and stir 100 parts of deionized water, 100 parts of magnesium oxide powder with a particle size of 40 μm, 1 part of stearic acid, 10 parts of monomer I and 0.5 part of potassium persulfate in parts by mass, and heat to 70 ° C to make the The monomer is polymerized on the surface of magnesium oxide for 3-4 hours, filtered, heat-preserved and dried to obtain the heat-conducting powder; according to the following formula, each raw material is added to a high-speed mixer, and mixed at 60-80°C for 5-30 minutes; the above-mentioned materials It is fed into the twin-screw extruder from the hopper, melted and extruded, and granulated. The temperature of each zone of the extruder is set as follows: T1=190°C, T2=205°C, T3=210°C, T4=210°C, T5= 220 ° C, T6 = 225 ° C, T7 = 225 ° C, T8 = 235 ° C, T9 = 235 ° C, T mold = 220 ° C, the obtained pellets were placed in a blast dryer at 100 ° C for 4 hours, and passed through the injection molding mechanism The test samples were prepare...

Embodiment 2

[0032] By mass parts, the mixture of 200 parts of deionized water, 100 parts of magnesium oxide powder with a particle size of 1 μm, 3 parts of sodium stearate, 20 parts of monomer I and monomer II (the mass ratio of monomer I and monomer II is 6:4) and 0.8 parts of ammonium persulfate were mixed and stirred evenly, heated to 75° C., polymerized the monomer on the surface of magnesium oxide for 4 hours, filtered, heat-preserved and dried to obtain the heat-conducting powder.

[0033] The polyester composite material is prepared according to the following formula, and its process is the same as that of Example 1, and the test data are shown in Table 1.

[0034]

Embodiment 3

[0036]Mix 300 parts of deionized water, 100 parts of magnesium oxide powder with a particle size of 5 μm, 5 parts of sodium dodecylsulfonate, 30 parts of monomer I, monomer II, and monomer III in parts by mass (monomer I , monomer II, monomer III (mass ratio is 6:3:1) and 1 part of sodium persulfate are mixed and stirred evenly, heated to 80°C, polymerized on the surface of magnesium oxide for 4 hours, filtered, heat-preserved and dried to obtain The thermally conductive powder.

[0037] The polyester composite material is prepared according to the following formula, and its process is the same as that of Example 1, and the test data are shown in Table 1.

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com