Biodegradable PBAT alloy with high starch content and preparation method of biodegradable PBAT alloy

A high-starch, alloy technology, applied in biological packaging, sustainable manufacturing/processing, sustainable packaging industry and other directions, can solve the problems of hindered promotion, poor compatibility between starch and PBAT matrix, high requirements for raw material types and processing methods, etc. To achieve the effect of improving the compatibility of the two phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

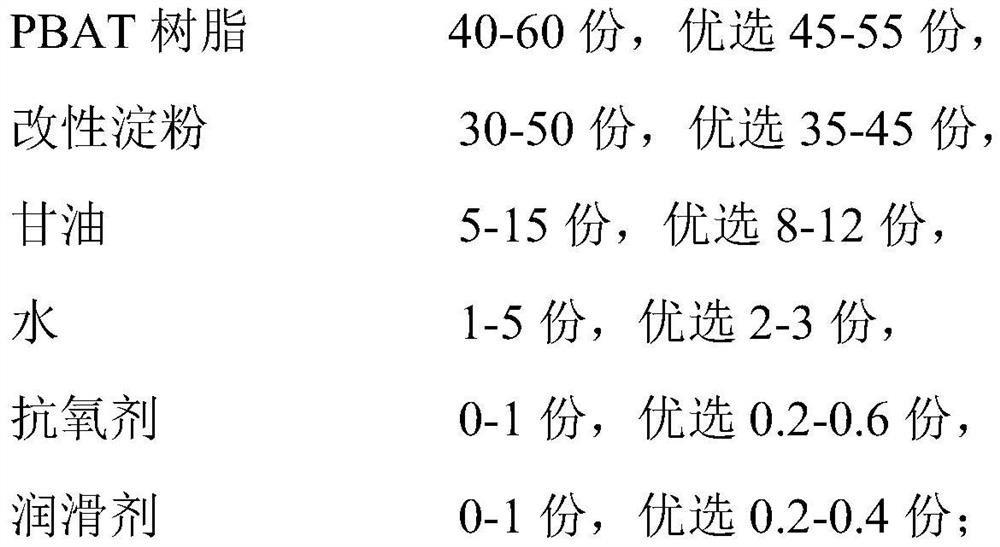

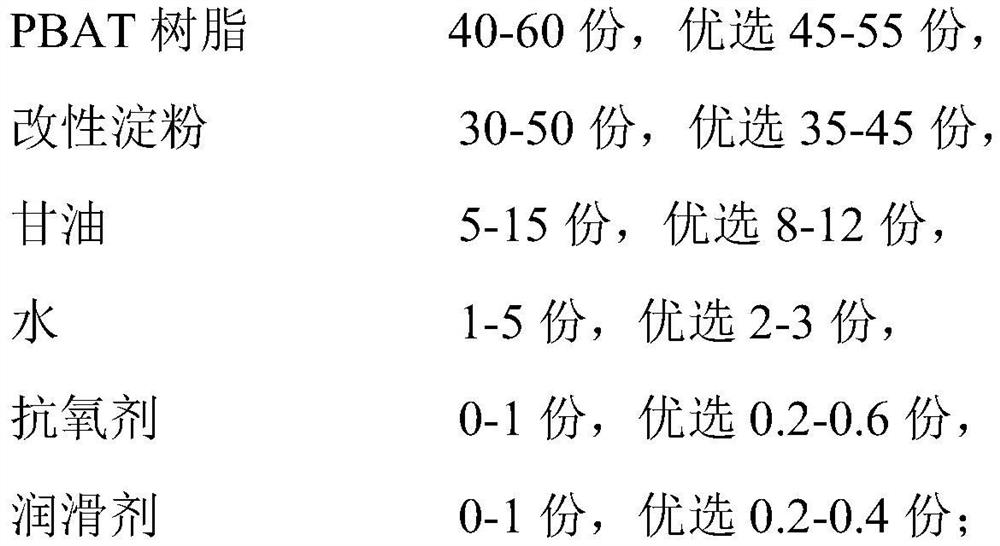

Method used

Image

Examples

Embodiment 1

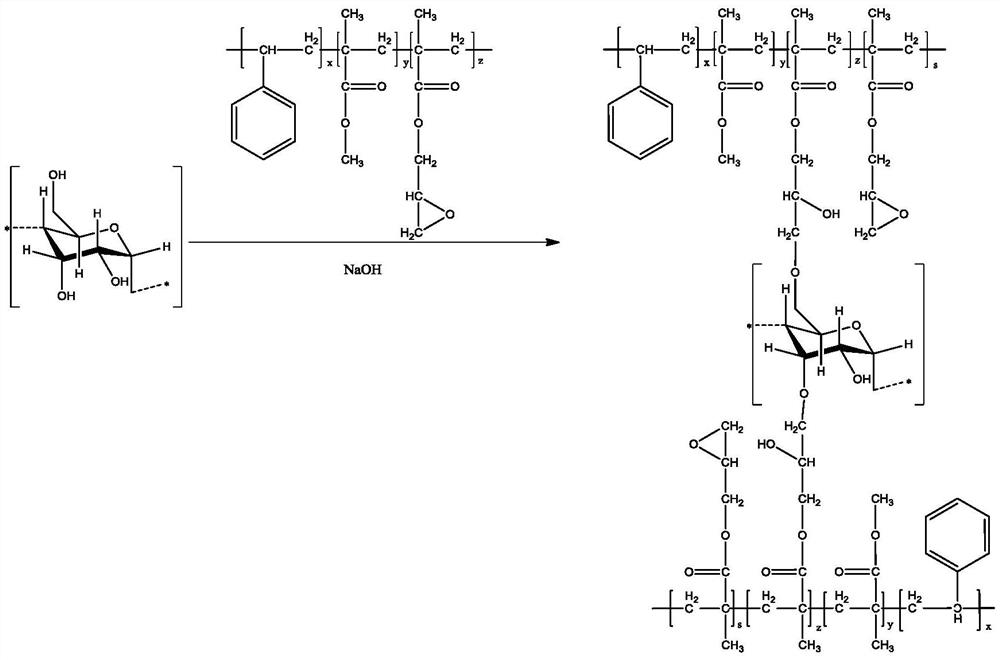

[0049] (1) Preparation of modified starch (M-starch A):

[0050] Weigh 50g of cornstarch into a three-necked flask, add 800mL of distilled water, put the three-necked flask into a constant temperature water bath, heat and stir, and make it gelatinize at 90°C for 1h. Then add 5g of NaOH and stir evenly, quickly add 25g of ADR4370, react in a closed container at 90°C for 10h, cool to 25°C for 5min, then adjust the pH to neutral with 10% dilute hydrochloric acid, take part of the adjusted pH value of the emulsion and freeze Dry, put the obtained powder into a Soxhlet extractor, wash it with absolute ethanol for 5 hours under reflux, remove unreacted NaOH and other impurities, then dry it in a vacuum oven for 4 hours, and grind it in a crucible to obtain a powdered epoxy-modified starch product , its epoxy value is 0.08.

[0051](2) With modified starch and formula component in table 1 as raw material, and with reference to the raw material consumption in table 1, prepare PBAT al...

Embodiment 2

[0057] (1) Preparation of modified starch (M-starch B):

[0058] Weigh 50g of tapioca starch into a three-necked flask, add 800m L of distilled water, put the three-necked flask into a constant temperature water bath, heat and stir, and make it gelatinize at 95°C for 1h. Then add 5g Na 2 CO 3 And stir evenly, quickly add 10g of epoxy resin E51, react in a closed container at 90°C for 8h, cool to 25°C and keep for 5min, then adjust the pH to neutral with 10% dilute hydrochloric acid, take part of the adjusted pH value of the emulsion and freeze After drying, the obtained powder was put into a Soxhlet extractor and washed with absolute ethanol for 5 h under reflux to remove unreacted Na 2 CO 3 and other impurities, dried in a vacuum oven for 4 hours, and ground in a crucible to obtain a powdery epoxy-modified starch product with an epoxy value of 0.01.

[0059] Using the modified starch (M-starch B) prepared in Example 2 as raw material, and prepare the PBAT alloy according ...

Embodiment 3

[0061] Using the modified starch (M-starch A) prepared in Example 1 as raw material, and prepare the PBAT alloy according to the method in Example 1, the difference is only in the difference in formula and raw material consumption in Table 1, the extrusion of twin-screw extruder The conditions are: the screw speed is 600rpm, and the screw temperature is set in sections from the feeding port to the head: 100°C, 105°C, 110°C, 120°C, 130°C, 135°C, 135°C, 135°C, 145°C, 145°C , 135°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com