Method for extracting and separating tungsten molybdenum

A technology for separation and extraction of ammonium tungstate, applied in the field of tungsten products and separation of molybdenum in ammonium tungstate solution, can solve the problem of high cost and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

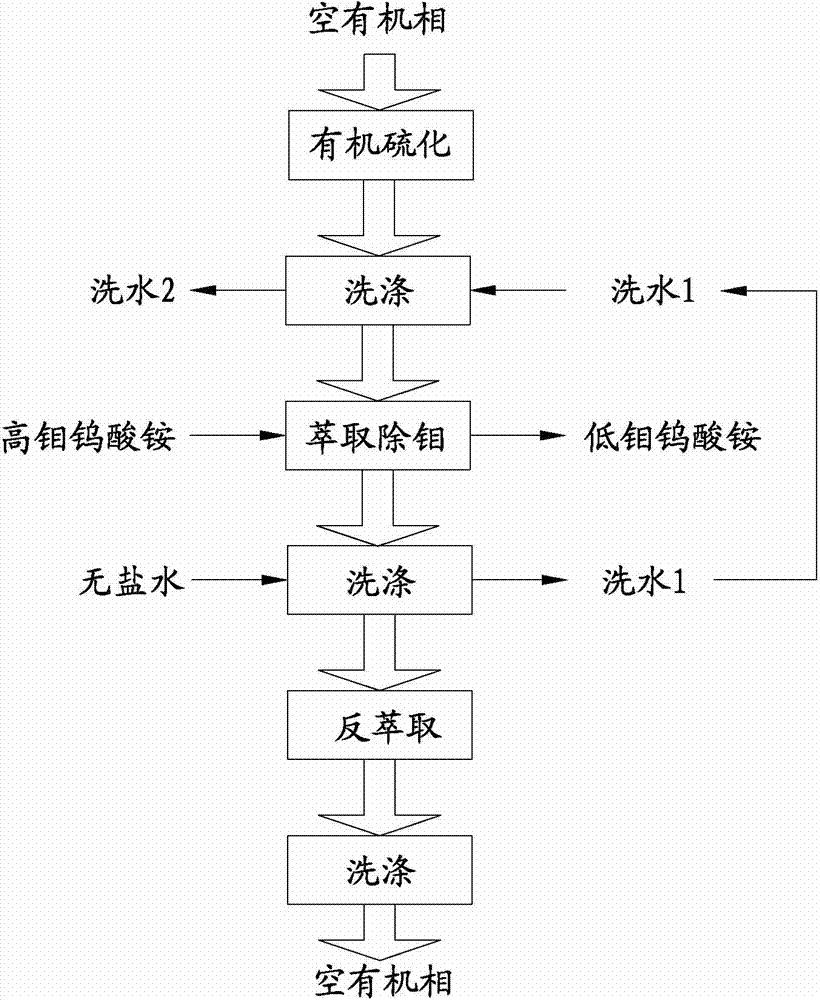

Image

Examples

Embodiment Construction

[0019] The component of the ammonium tungstate solution to be separated is WO 3 Mo: 235-285g / l, Mo: 20-30g / l.

[0020] The main instruments are separatory funnel and Kang's oscillator, and the extraction ratio is O / A=1:1.

[0021] The composition of the organic phase extracted and separated in the present invention is 20% N263, 20% isooctyl alcohol and 60% kerosene, O / A=1:1.

[0022] Vulcanization of the organic phase: the organic phase and the vulcanizing agent are mixed and fully contacted, and then the phases are separated to obtain a vulcanized organic phase.

[0023] Re-extraction to remove molybdenum: mix high-molybdenum ammonium tungstate into the sulfided organic phase for treatment, and only need to go through two or more extractions and separations to obtain a qualified low-molybdenum ammonium tungstate solution.

[0024] The negative molybdenum organic phase after extraction can be oxidized with sodium hypochlorite and back-extracted molybdenum to obtain sodium mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com