Full solid waste dry-mixed mortar and preparation method thereof

A technology for dry-mixing mortar and ceramic waste, applied in the field of resource utilization of solid waste, can solve the problems of hollowing, easy cracking, large shrinkage, etc., and achieve the effect of expanding the application and increasing the addition ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

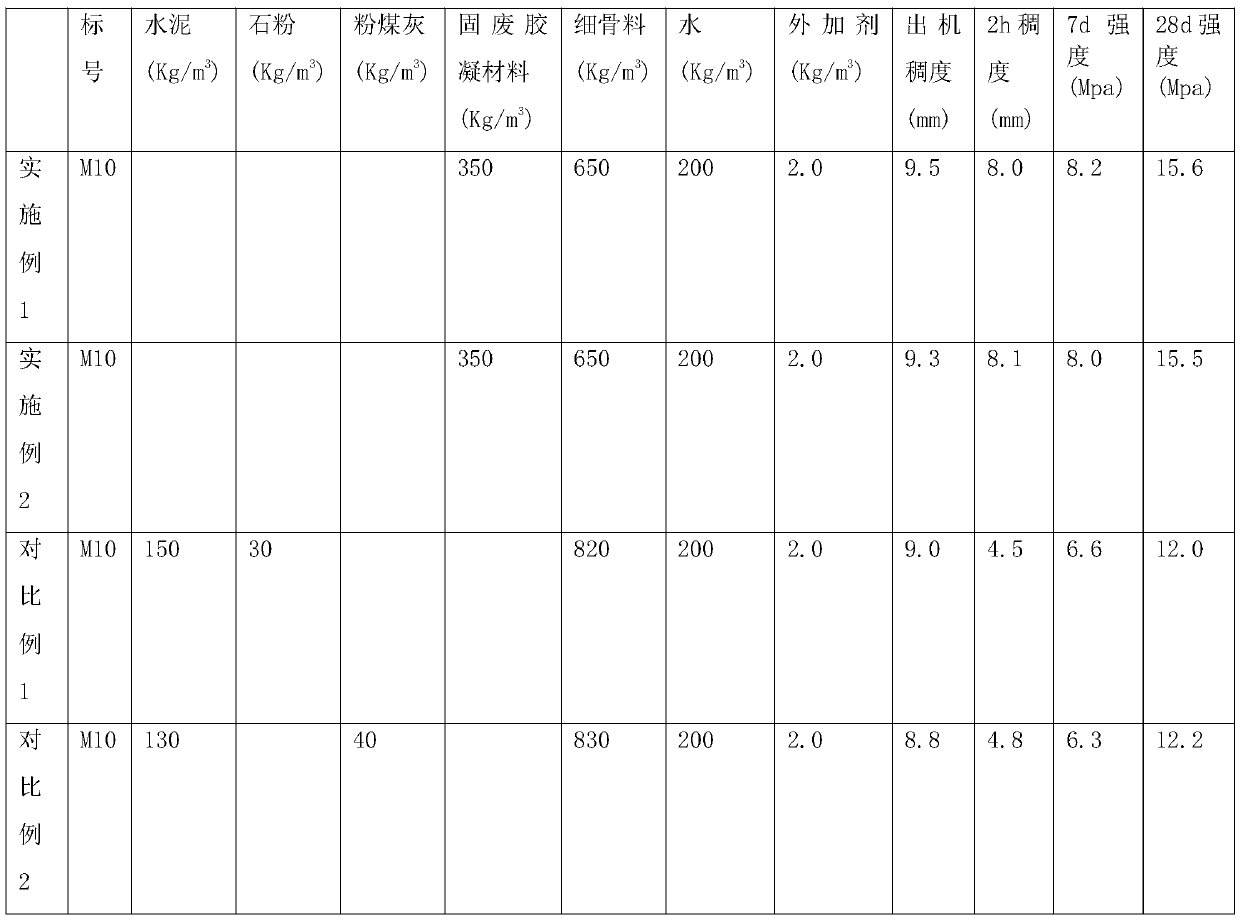

Examples

preparation example Construction

[0041] The present application also provides a method for preparing the above-mentioned all-solid waste dry-mixed mortar, comprising the following steps in sequence:

[0042] 1) Mix and grind the fly ash and steel slag, and obtain a powder material A after the mixing and grinding is completed, wherein the fineness of the powder material A is controlled to be 45 μm and the sieve residue is 4wt% to 6wt%;

[0043] The slag and gypsum are mixed and ground, and the powder material B is obtained after the mixing and grinding is completed, wherein the fineness of the powder material B is controlled so that the sieve residue of the 45 μm sieve is greater than zero and less than 1wt%;

[0044] The ceramic waste and slag are mixed and crushed, and the fine aggregate is obtained after the mixing and crushing is completed, wherein the maximum particle size of the fine aggregate is controlled to be less than 2.36mm;

[0045] 2) mixing the powder material A prepared in step 1) with the powd...

Embodiment 1

[0070] An all-solid waste dry-mixed mortar, which is formed by mixing various raw materials, including fly ash, steel slag produced by converter blowing, granulated blast furnace slag, gypsum, tile waste and coal-fired slag;

[0071] Wherein, the added mass of the fly ash accounts for 15% of the mass percentage of the finished all-solid waste dry-mixed mortar;

[0072] The added mass of the steel slag produced by the converter blowing accounted for 10% of the mass percentage of the finished all-solid waste dry-mixed mortar;

[0073] The added mass of the granulated blast furnace slag accounts for 5% of the mass percentage of the finished all-solid waste dry-mixed mortar;

[0074] The added mass of the gypsum accounts for 5% of the mass percent of the finished all-solid waste dry-mixed mortar;

[0075] The added mass of the tile waste accounts for 35% of the mass percentage of the finished all-solid waste dry-mixed mortar;

[0076] The added mass of the coal-fired slag accoun...

Embodiment 2

[0087] An all-solid waste dry-mixed mortar, which is formed by mixing various raw materials, including fly ash, steel slag produced by converter blowing, granulated blast furnace slag, gypsum, tile waste and coal-fired slag;

[0088] Wherein, the added mass of the fly ash accounts for 12% of the mass percentage of the finished all-solid waste dry-mixed mortar;

[0089] The added mass of the steel slag produced by the converter blowing accounted for 10% of the mass percentage of the finished all-solid waste dry-mixed mortar;

[0090] The added mass of the granulated blast furnace slag accounts for 8% of the mass percentage of the finished all-solid waste dry-mixed mortar;

[0091] The added mass of the gypsum accounts for 5% of the mass percent of the finished all-solid waste dry-mixed mortar;

[0092] The added mass of the tile waste accounts for 35% of the mass percentage of the finished all-solid waste dry-mixed mortar;

[0093] The added mass of the coal-fired slag accoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com