Fluorescent powder thin film for light emitting diode

A technology of light-emitting diodes and phosphors, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as difficulty in controlling the consistency of quality, uneven thickness of phosphors, and inability to produce excellent light, saving time and money , a wide range of applications, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

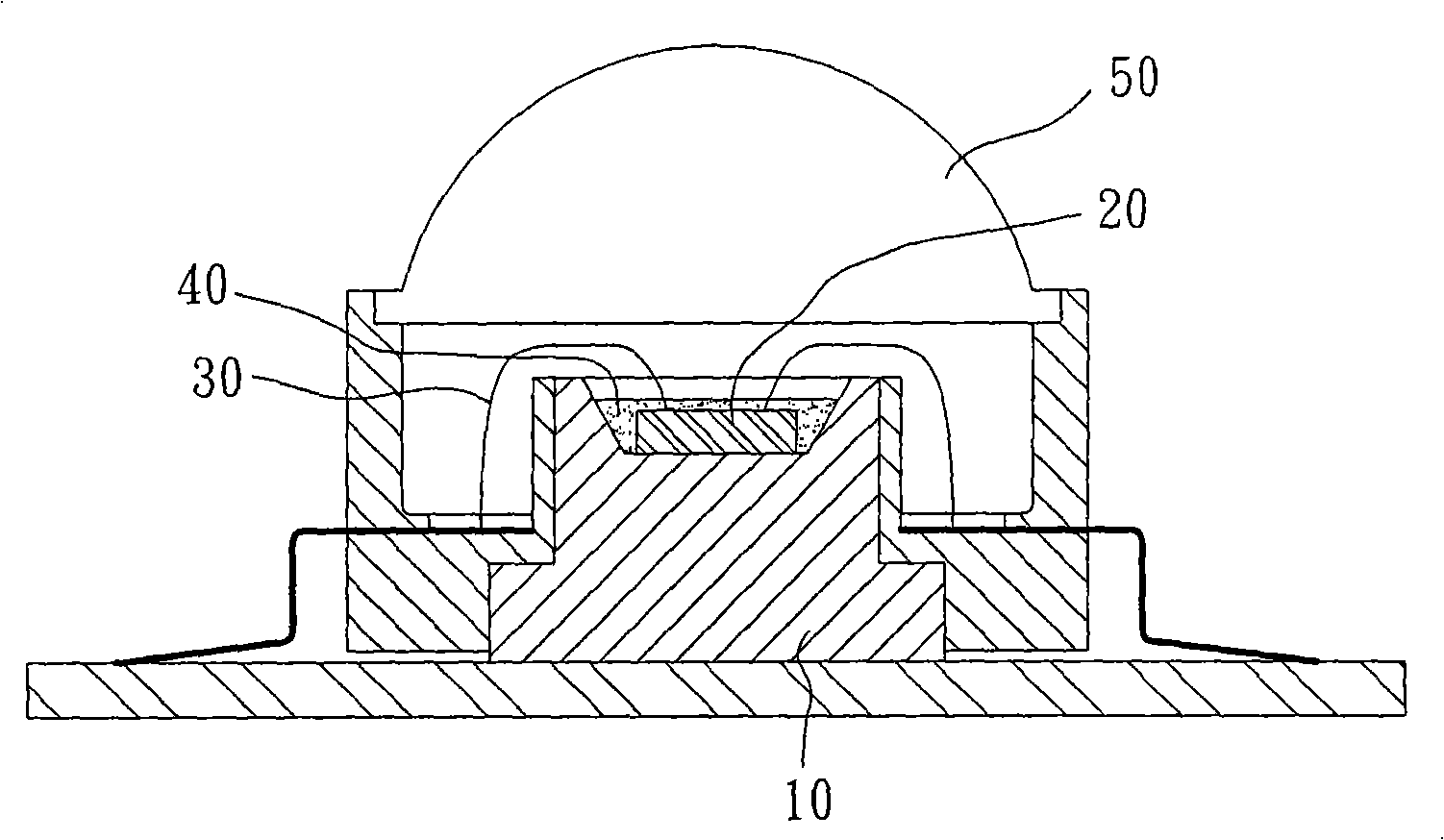

[0025] In order to further reveal the specific technical content of the present invention, please refer to the accompanying drawings.

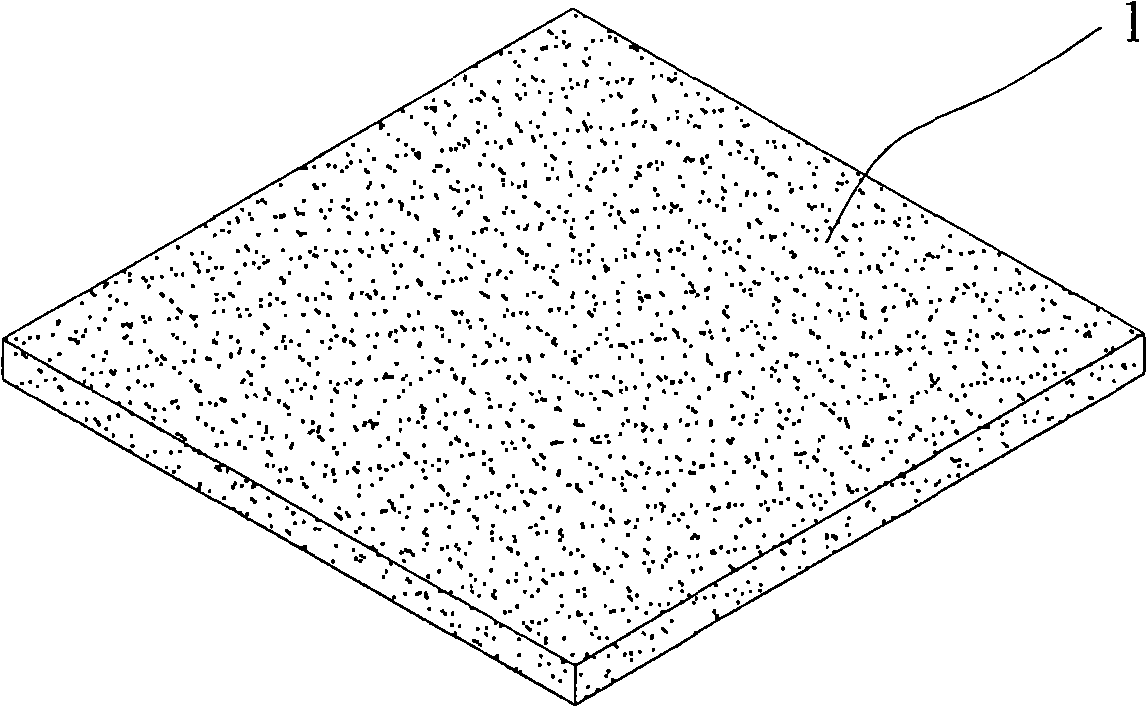

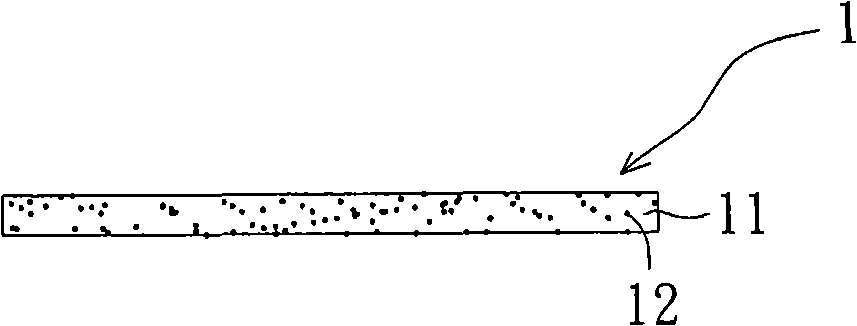

[0026] like Figure 2 to Figure 3 As shown, basically, the present invention is used for the phosphor powder film 1 of light-emitting diodes, which utilizes an appropriate amount of any transparent glue or transparent plastic material 11 and phosphor powder 12 to mix and stir evenly according to an appropriate ratio, and then coat it on a flat surface. on the fixture, and put it into the ultrasonic vibration arrangement mechanism and let it stand for a period of time, so that the fluorescent powder 12 can be fully and uniformly deposited on the surface of the plane fixture, and then the required phosphor film 1 is made, and finally the phosphor The powder film 1 is sent into a baking oven for baking, and becomes the finished phosphor film 1 after curing. However, the above-mentioned film-forming method is only one of the embodiments, and it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com