A kind of anti-creep anti-hydrolysis polyester FDY fiber and preparation method thereof

A technology of anti-hydrolysis and anti-creep, which is applied in the direction of fiber treatment, single-component copolyester rayon, melt spinning, etc., to achieve the effect of improving hydrolysis resistance, improving creep resistance and expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

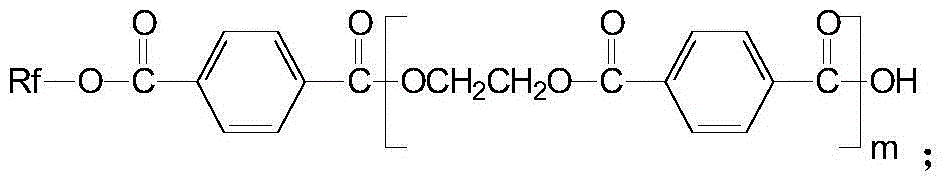

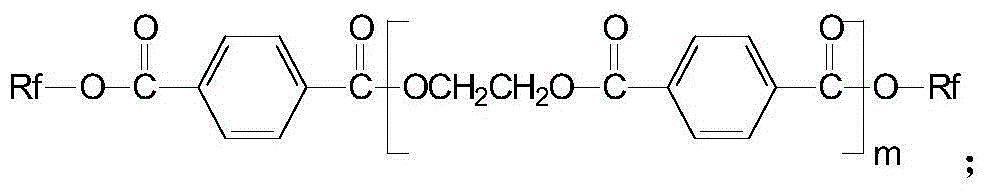

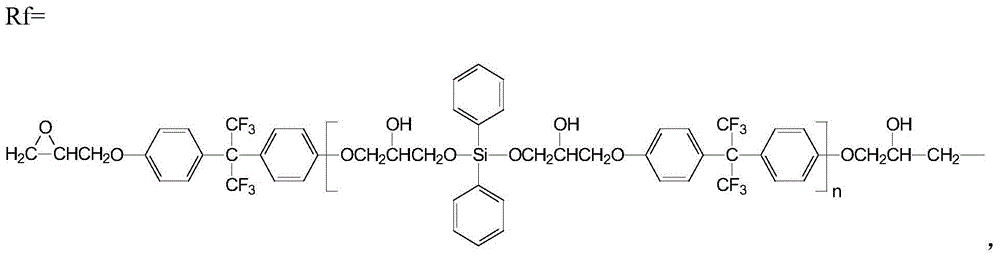

Method used

Image

Examples

Embodiment 1

[0063] Preparation of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether:

[0064] In a nitrogen atmosphere, mix epichlorohydrin and 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylidene]diphenol at a molar ratio of 4:1 , add 1.5% of 15mol / L sodium hydroxide solution of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl) ethylene] diphenol mass, at room temperature Stir the reaction for 16 hours; then cool to room temperature, then add 5mol / L of 30% of the mass of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol Sodium hydroxide solution, the sodium hydroxide solution is a solution saturated with anhydrous sodium carbonate, stirred and reacted at room temperature for 10 h; then extracted with chloroform, and the resulting organic phase was obtained by distilling off chloroform and excess epichlorohydrin to obtain a thick like liquid, which was added to absolute ethanol for recrystallization to obtain 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]dip...

Embodiment 2

[0071] Preparation of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether:

[0072] In a nitrogen atmosphere, mix epichlorohydrin and 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylidene]diphenol at a molar ratio of 4:1 , add 2.0% 10mol / L sodium hydroxide solution of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol mass, at room temperature Stir the reaction for 18 hours; cool to room temperature, then add 40% of the mass of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol of 3mol / L Sodium hydroxide solution, sodium hydroxide solution is a solution saturated with anhydrous sodium carbonate, stirred and reacted at room temperature for 15 hours; then extracted with chloroform, and the resulting organic phase was obtained by distilling off chloroform and excess epichlorohydrin to obtain a thick liquid, add it to absolute ethanol for recrystallization, and obtain 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl Crys...

Embodiment 3

[0079]Preparation of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl ether:

[0080] In a nitrogen atmosphere, mix epichlorohydrin and 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylidene]diphenol at a molar ratio of 4:1 , add 1.8% of 12mol / L sodium hydroxide solution of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol mass, at room temperature Stir the reaction for 17h; cool to room temperature, then add 35% of the mass of 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol of 4mol / L Sodium hydroxide solution, sodium hydroxide solution is a solution saturated with anhydrous sodium carbonate, stirred and reacted at room temperature for 13h; then extracted with chloroform, and the resulting organic phase was obtained by distilling off chloroform and excess epichlorohydrin to obtain a thick liquid, add it to absolute ethanol for recrystallization, and obtain 4,4'-[2,2,2-trifluoro-1-(trifluoromethyl)ethylene]diphenol diglycidyl Crystals of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com