Environment-friendly organosilicon ''three-prevention'' coating and preparation method thereof

A silicone and environment-friendly technology, applied in the coating and other directions, can solve the problems of slow curing speed, non-environmental protection and poor adhesion of silicone elastomer three-proof coatings, achieve small volume shrinkage, improve production efficiency, reduce The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

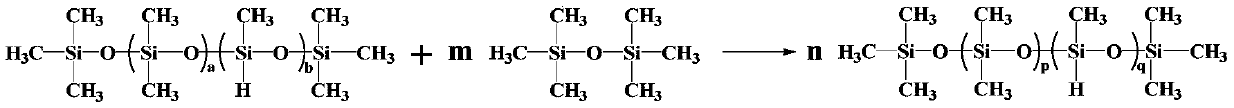

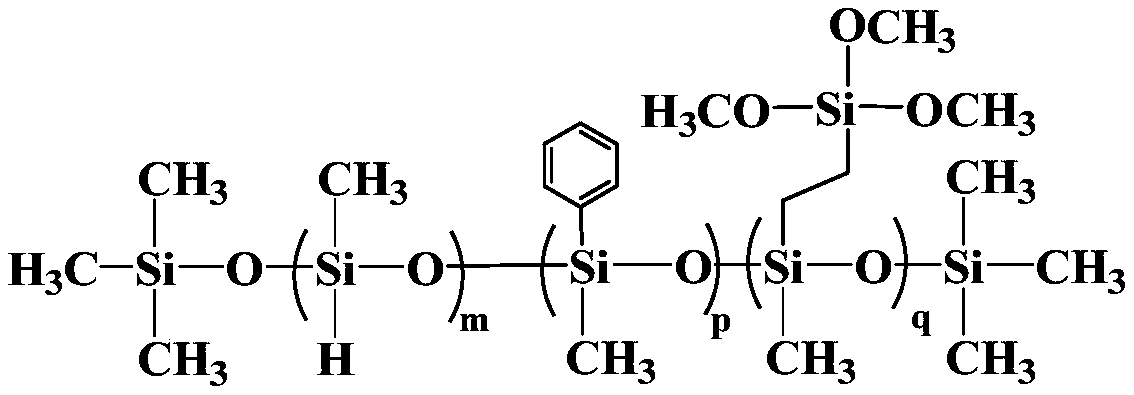

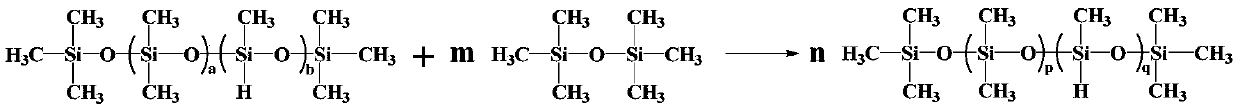

Method used

Image

Examples

Embodiment 1

[0069] 100 parts by weight of (A1), 3 parts by weight of (B1), 8.5 parts by weight of (C), 8 parts by weight of (D1), 2 parts by weight of (E1), 0.2 parts by weight of (F), 1 Parts by weight of (I1) were sequentially added to the power mixer according to the formula ratio, and the planetary dispersion speed was adjusted to 25Hz, the high-speed dispersion speed was 35Hz, stirred for 3 hours, and then 0.2 parts by weight of (G) and 0.2 parts by weight were added according to the formula ratio (H), continue stirring for 30 minutes, then vacuum defoaming for 15 minutes, filter and pack to obtain an environment-friendly silicone three-proof coating product.

Embodiment 2

[0071] 80 parts by weight of (A2), 4 parts by weight of (B2), 8 parts by weight of (C), 6 parts by weight of (D2), 4 parts by weight of (E1), 0.2 parts by weight of (F), 1.5 parts by weight Parts by weight of (I1) were sequentially added to the power mixer according to the formula ratio, and the planetary dispersion speed was adjusted to 25Hz, the high-speed dispersion speed was 35Hz, stirred for 3 hours, and then 0.2 parts by weight of (G) and 0.2 parts by weight were added according to the formula ratio (H), continue stirring for 30 minutes, then vacuum defoaming for 15 minutes, filter and pack to obtain an environment-friendly silicone three-proof coating product.

Embodiment 3

[0073] 90 parts by weight of (A1), 3.5 parts by weight of (B2), 9 parts by weight of (C), 10 parts by weight of (D2), 2 parts by weight of (E1), 0.2 parts by weight of (F), 1.5 parts by weight Parts by weight of (I2) were sequentially added to the power mixer according to the formula ratio, and the planetary dispersion speed was adjusted to 25Hz, the high-speed dispersion speed was 35Hz, stirred for 3 hours, and then 0.2 parts by weight of (G) and 0.2 parts by weight were added according to the formula ratio (H), continue stirring for 30 minutes, then vacuum defoaming for 15 minutes, filter and pack to obtain an environment-friendly silicone three-proof coating product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com