High-strength flexible polysiloxane aerogel and preparation method thereof

A technology of polysiloxane and airgel, which is applied in the field of preparation of high-strength flexible superhydrophobic polysiloxane airgel, and can solve problems such as low specific surface area, uneven airgel pore structure, and harsh control conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

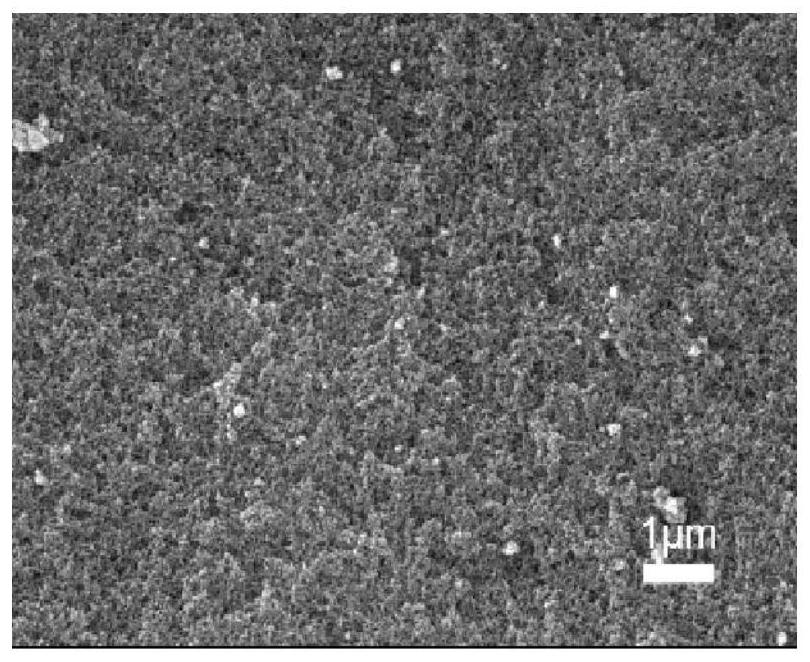

Embodiment 1

[0039] Weigh 1.2g of polysiloxane whose side group is ethoxy group and whose relative molecular mass is 1250 and 1.5g of octa(trimethoxysilyl-4-sulfidehexyl)cage silsesquioxane, add 4.6g of ethanol and 1.3g of water, stirred for 15 minutes to form a uniform solution, then added 0.03g of sodium hydroxide to adjust the pH to alkaline to promote the gelation process, stirred for 5 minutes, put the mixed solution into a mold, and aged in an oven at 50°C for two days , and then the aged gel was placed in ethanol and n-hexane for solvent replacement, respectively, for 2 times, each time for 8 hours, and then the gel was placed in a mixture of n-hexane and trimethylchlorosilane with a volume ratio of 100:7. Surface modification was carried out in the mixed solution for 2 days, and then the surface-modified gel was placed in n-hexane for solvent replacement twice, each time for 8 hours, and finally the gel was taken out of n-hexane and dried under normal pressure A polysiloxane airgel...

Embodiment 2

[0042] Weigh 1.2g of polysiloxane whose side groups are ethoxy and methyl (ethoxy:methyl = 1:3) and a relative molecular mass of 1250 and 0.9g of octa(trimethoxysilyl-4-sulfur Etherhexyl) cage silsesquioxane, add 4.6g ethanol and 1.3g water, stir for 15 minutes to form a uniform solution, then add 0.03g sodium hydroxide to adjust the pH to alkaline to promote the gel process, stir for 5 minutes The mixed solution was put into a mold and aged in an oven at 50°C for two days, then the aged gel was placed in ethanol and n-hexane successively for solvent replacement, 2 times for 8 hours each time, and then the gel was placed in Surface modification was carried out in a mixed solution of n-hexane and trimethylchlorosilane with a volume ratio of 100:7 for 2 days, and then the surface-modified gel was placed in n-hexane for solvent replacement twice, each time for 8 hours, Finally, the gel was taken out from n-hexane and dried under normal pressure to obtain polysiloxane airgel.

[...

Embodiment 3

[0045] Weigh 1.2g of polysiloxane whose side groups are ethoxy and methyl (ethoxy:methyl = 1:5) and a relative molecular mass of 1250 and 0.9g of octa(trimethoxysilyl-4-sulfur Etherhexyl) cage silsesquioxane, add 4.6g ethanol and 1.3g water, stir for 15 minutes to form a uniform solution, then add 0.03g sodium hydroxide to adjust the pH to alkaline to promote the gel process, stir for 5 minutes The mixed solution was put into a mold and aged in an oven at 50°C for two days, then the aged gel was placed in ethanol and n-hexane successively for solvent replacement, 2 times for 8 hours each time, and then the gel was placed in Surface modification was carried out in a mixed solution of n-hexane and trimethylchlorosilane with a volume ratio of 100:7 for 2 days, and then the surface-modified gel was placed in n-hexane for solvent replacement twice, each time for 8 hours, Finally, the gel was taken out from n-hexane and dried under normal pressure to obtain polysiloxane airgel.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compression modulus | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com