High-infrared rapid-curing powder paint for coil steel and preparation method thereof

A fast-curing, powder coating technology, used in powder coatings, polyester coatings, coatings, etc., can solve the problems of poor compatibility between polyester resin and fluorocarbon polyester, and achieve poor compatibility and easy operation. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

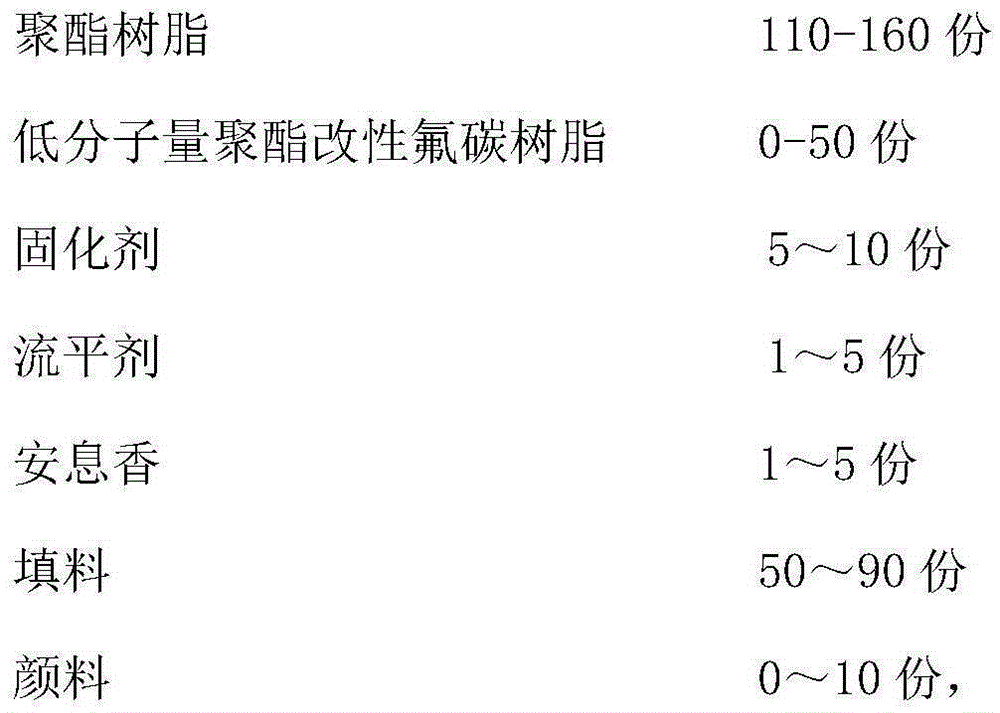

[0041] A high-infrared fast-curing powder coating for coil steel, its composition and weight ratio are:

[0042]

[0043]

[0044] Polyester polyester resin parameters (acid value 30-36mgKOH / g, viscosity 3500±500mPa·S)

[0045] Preparation:

[0046] (1) Take polyester resin curing agent, leveling agent, benzoin, filler, pigment by weight, place mixing tank, fully mix and crush, obtain mixed premixed material;

[0047](2) The mixed premixed material is sent to a twin-screw extruder for extrusion, and the extrusion temperature is controlled between 90-120°C;

[0048] (3) The extruded material is compressed by a tablet machine, cooled, crushed, and sieved to obtain a powder coating with a particle size of 30-40um.

[0049] Coating curing process:

[0050] (1) Use the above-mentioned powder coating as an electrostatic spraying model, and the coating thickness is 50mm±10mm.

[0051] (2) Adjust the heating gear of the high-infrared curing instrument to the highest gear, pr...

Embodiment 2

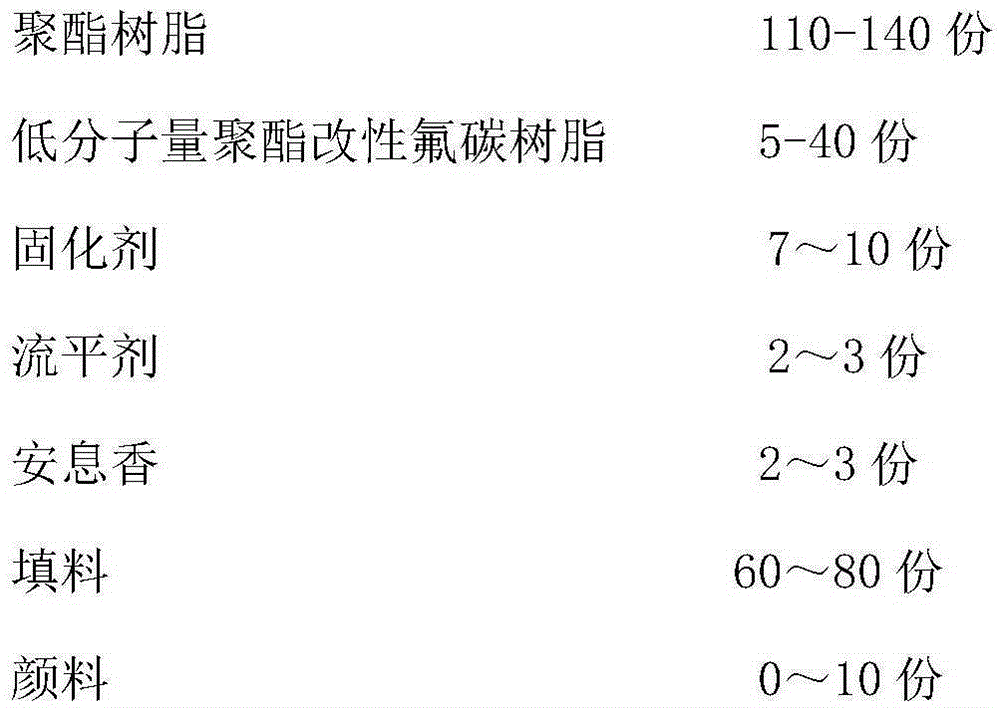

[0053] A high-infrared fast-curing powder coating for coil steel, its composition and weight ratio are:

[0054]

[0055]

[0056] Polyester polyester resin parameters (acid value 30-36mgKOH / g, viscosity 3500±500mPa·S)

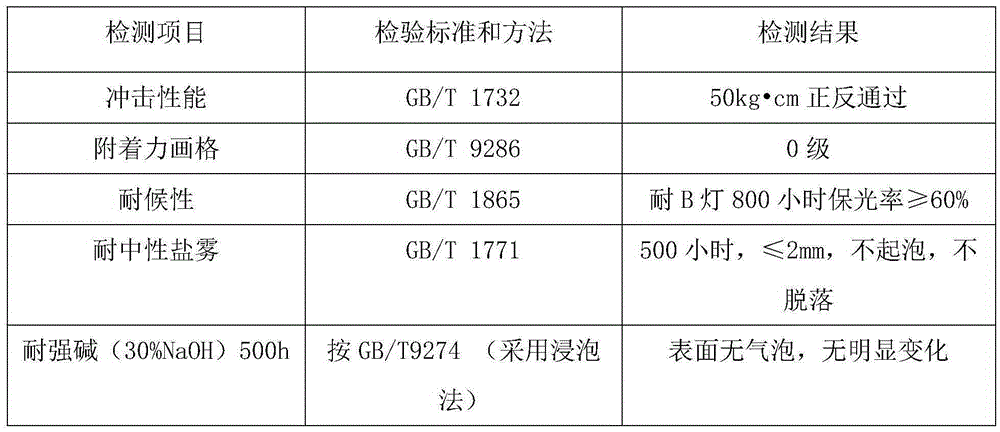

[0057] Get above-mentioned each component and make powder coating according to the preparation method of Example 1, then obtain the coating sample that is solidified and molded by this powder coating according to the coating process of Example 1, test the various properties of coating, the results are shown in Table 2 .

Embodiment 3

[0059] A high-infrared fast-curing powder coating for coil steel, its composition and weight ratio are:

[0060]

[0061] Polyester polyester resin parameters (acid value 30-36mgKOH / g, viscosity 3500±500mPa·S)

[0062] Get above-mentioned each component and make powder coating according to the preparation method of Example 1, then obtain the coating sample that is solidified and molded by this powder coating according to the coating process of Example 1, test the various properties of coating, the results are shown in Table 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com