Anti-PID ethylene vinyl acetate film, package assembly and packaging method

A technology of ethylene vinyl acetate film and vinyl acetate, applied in adhesives, electrical components, semiconductor devices, etc., can solve the problems of high technical requirements and component reliability, etc., to ensure cross-linking density, reduce hydrolysis, inhibit The effect of PID

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

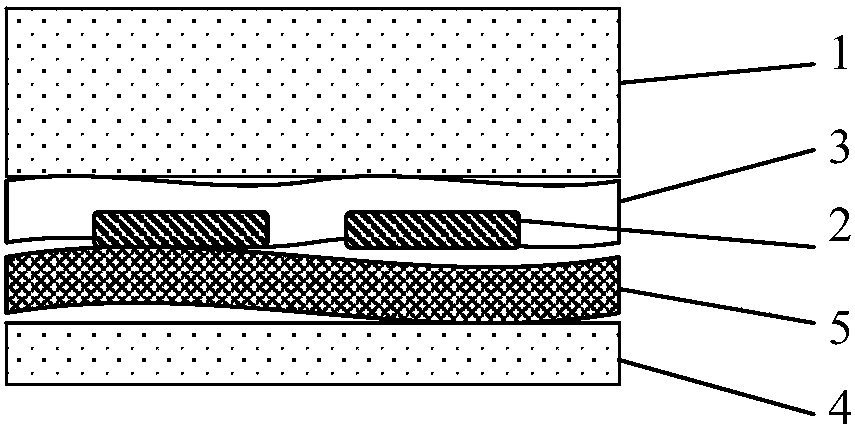

Image

Examples

preparation example Construction

[0035] In the anti-PID ethylene vinyl acetate film prepared by the present invention, the crosslinking accelerator includes but not limited to acrylic acid, methacrylic acid, acrylamide, allyl, epoxy compound one or more.

[0036] Specific examples of (meth)acrylic co-crosslinking agents include trimethylolpropane trimethacrylate, ethoxylated trimethylolpropane trimethacrylate, trimethylolpropane trimethacrylate, Acrylates, Ethoxylated Trimethylolpropane Triacrylate, Ethylene Glycol Dimethacrylate, Polybutadiene Dimethacrylate, Magnesium Methacrylate, Zinc Methacrylate, etc.

[0037] Specific examples of acrylamide-based co-crosslinking agents include N,N'-m-phenylene bismaleimide, 4,4'-dithiobisphenylmaleimide, 4,4 - Methylene diphenyl bismaleimide and the like.

[0038] Specific examples of the allyl-based crosslinking assistant include triallyl isocyanurate, triallyl cyanurate, diallyl phthalate, and the like.

[0039] Specific examples of the epoxy compound-based crossl...

Embodiment 1

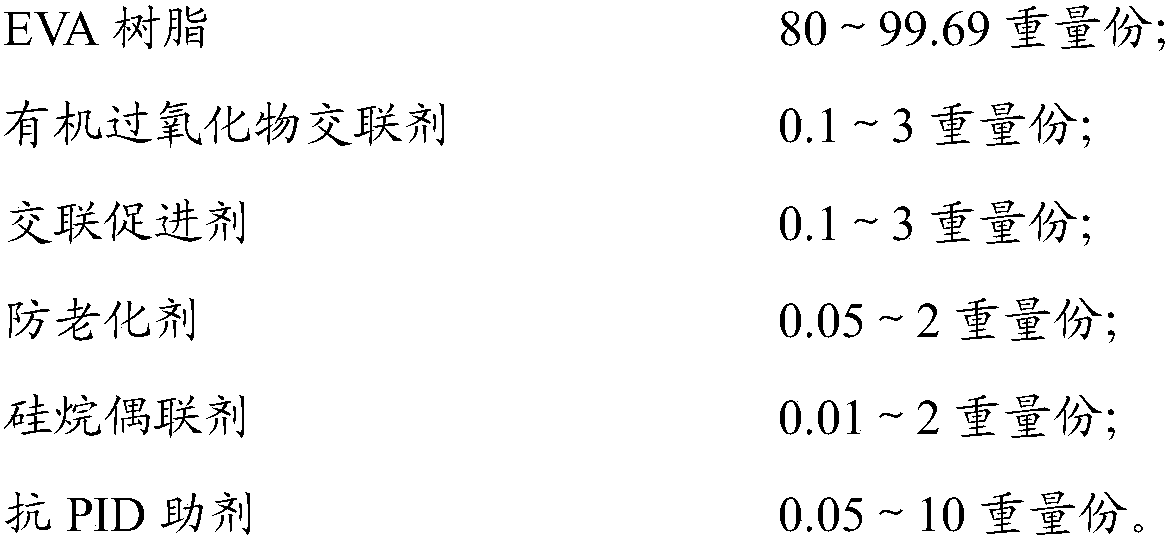

[0053] The formula component of a kind of embodiment of the anti-PID ethylene vinyl acetate adhesive film among the present invention is as follows:

[0054] Element

[0055] Mix the above components thoroughly and add them to the extruder. The temperature of the extruder is 90°C, and the temperature of the mold is 90°C; extrude through a T-shaped flat die to form a film, or directly pass through two calender rolls to form a film and wind it up. . Cut the rolled anti-PID ethylene vinyl acetate film to the size of the solar photovoltaic module, and stack them in the order of glass / anti-PID ethylene vinyl acetate film / cell sheet / common EVA film / back sheet at 145 Vacuuming and lamination under ℃, the vacuuming time is 5 minutes, and the lamination time is 12 minutes. In the PID experiment (85% humidity and 85 ℃, -1000V, 500hr), the obtained laminate has a power decay of 3%. Under the same conditions, the power of the module with ordinary EVA film on the upper and lower...

Embodiment 2

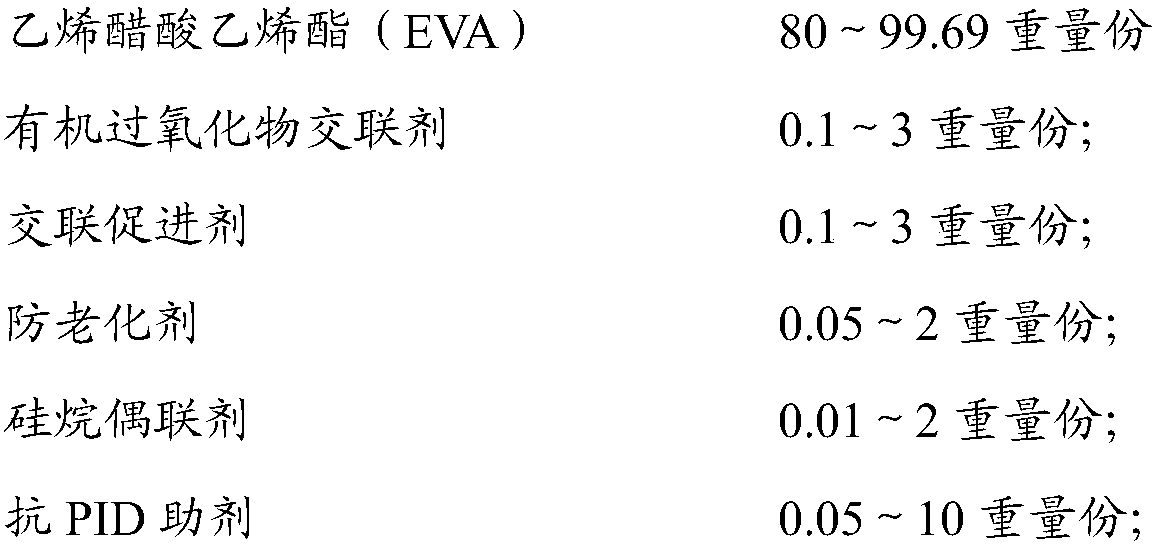

[0057] The formula component of a kind of embodiment of the anti-PID ethylene vinyl acetate adhesive film among the present invention is as follows:

[0058] Element

[0059] Mix the above components thoroughly and add them to the extruder. The temperature of the extruder is 160°C, and the temperature of the mold is 160°C; extrude through a T-shaped flat die to form a film, or directly pass through two calender rolls to form a film and wind it up. . Cut the rolled anti-PID ethylene vinyl acetate film to the size of the solar photovoltaic module, and stack them in the order of glass / anti-PID ethylene vinyl acetate film / cell sheet / common EVA film / back sheet at 145 Vacuuming and lamination under ℃, the vacuuming time is 5 minutes, and the lamination time is 12 minutes. In the PID experiment (85% humidity and 85 ℃, -1000V, 500hr), the obtained laminate has a power decay of 5%. Under the same conditions, the power of the module with ordinary EVA film on the upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com