Polyaspartic acid ester-based polyurethane adhesive and preparation method thereof

An aspartic acid ester and polyurethane technology, which is applied in the field of polyurethane adhesive based on polyaspartic acid ester and its preparation, can solve the problems of poor environmental resistance, short construction time, high reactivity, etc. The effect of reaction speed, prolongation of operation time, and improvement of manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

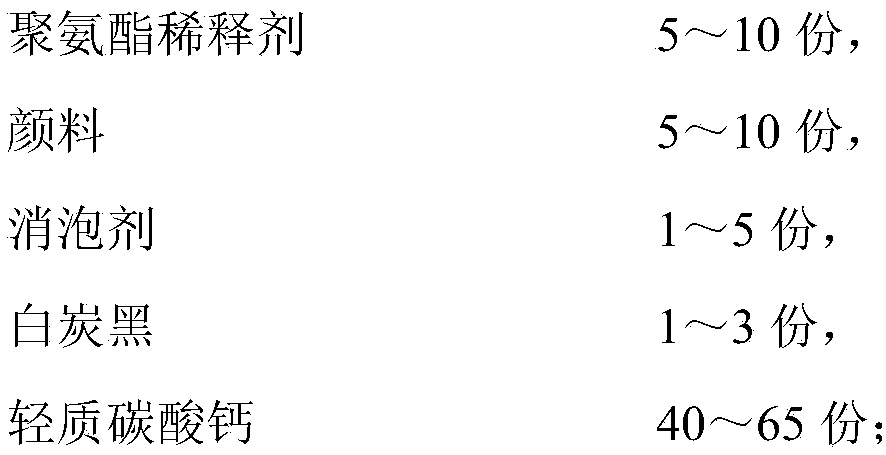

[0036] A polyurethane adhesive based on polyaspartic acid ester is a two-component, including A component and B component, and the A component is mainly prepared from the following raw materials in parts by mass:

[0037]

[0038]

[0039] Component B is a polyurethane adhesive curing agent system, which is mainly composed of the following components in parts by mass:

[0040] 50 parts of high-functionality isocyanate (isocyanate > 4),

[0041] 10 parts of diphenylmethane diisocyanate,

[0042] 10 parts of polyurethane thinner (hexanedione).

[0043] The preparation method of the polyurethane adhesive glue of the present embodiment may further comprise the steps:

[0044] (1) Preparation of resin component A: Add 10 parts of polyurethane diluent, 5 parts of pigment, 1 part of defoamer, 1 part of white to 20 parts of polyaspartic acid ester resin and 5 parts of polyether polyol resin Carbon black and 40 parts of light calcium carbonate were dispersed at a high speed fo...

Embodiment 2

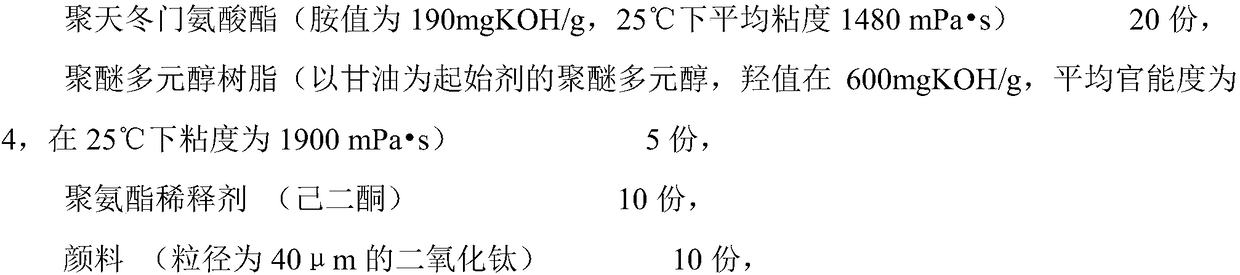

[0049] A polyurethane adhesive based on polyaspartic acid ester is a two-component, including A component and B component, and the A component is mainly prepared from the following raw materials in parts by mass:

[0050]

[0051] Component B is a polyurethane adhesive curing agent system, which is mainly composed of the following components in parts by mass:

[0052] 70 parts of high-functionality isocyanate (isocyanate > 4),

[0053] 20 parts of diphenylmethane diisocyanate,

[0054] Polyurethane diluent (diacetyl) 25 parts.

[0055] The preparation method of the polyurethane adhesive glue of the present embodiment may further comprise the steps:

[0056](1) Preparation of resin component A system: Add 10 parts of polyurethane diluent, 10 parts of pigment, 5 parts of defoamer, 3 parts of White carbon black and 65 parts of light calcium carbonate were dispersed at high speed for 30 minutes under the protection of nitrogen, and the rotation speed was 3500 rpm to prepare ...

Embodiment 3

[0061] A polyurethane adhesive based on polyaspartic acid ester is a two-component, including A component and B component, and the A component is mainly prepared from the following raw materials in parts by mass:

[0062]

[0063] Component B is a polyurethane adhesive curing agent system, which is mainly composed of the following components in parts by mass:

[0064] 60 parts of high-functionality isocyanate (isocyanate > 4),

[0065] 15 parts of diphenylmethane diisocyanate,

[0066] 20 parts of polyurethane thinner (cyclohexanedione).

[0067] The preparation method of the polyurethane adhesive glue of the present embodiment may further comprise the steps:

[0068] (1) Preparation of resin component A system: Add 13 parts of polyurethane diluent, 8 parts of pigment, 3 parts of defoamer, 2 parts of White carbon black and 55 parts of light calcium carbonate were dispersed at high speed for 30 minutes under the protection of nitrogen, and the rotation speed was 3500 rpm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com