Low-viscosity epoxy potting material for packaging silicon carbide power module as well as preparation method and application of low-viscosity epoxy potting material

A power module and low-viscosity technology, applied in the field of materials, can solve problems such as high viscosity and complex operation process, and achieve the effects of low viscosity and CTE value, good manufacturability and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

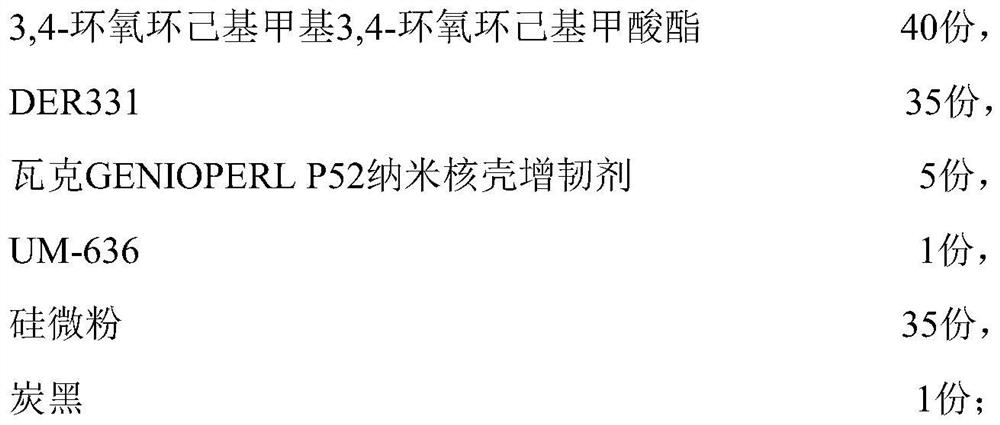

[0057] A low-viscosity epoxy potting compound for silicon carbide power module packaging, comprising A component and B component, the mass ratio of the two is 1:1; A component includes the following raw material components in parts by weight:

[0058]

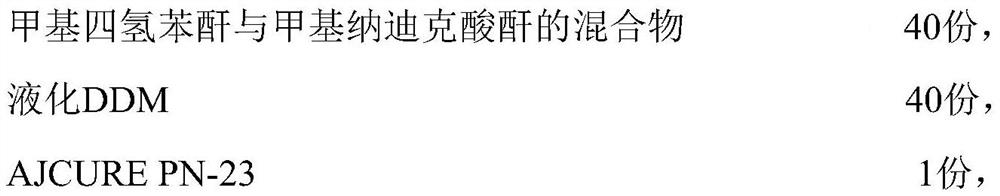

[0059] Component B is mainly composed of the following components by weight:

[0060]

[0061]

[0062] In this embodiment, the mass ratio of methyl tetrahydrophthalic anhydride to methyl nadic anhydride is 1:1.

[0063] A method for preparing the low-viscosity epoxy potting compound for encapsulating silicon carbide power modules in the present embodiment, comprising the following steps:

[0064] (1) The preparation process of component A is as follows: 40 parts of 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexyl carboxylate, 35 parts of high-purity epoxy DER331, 5 parts of WACKER GENIOPERL P52 nano Mix the core-shell toughener evenly at 40°C, add 1 part of UM-636, 35 parts of silicon micropowder and 1 part of carbon bl...

Embodiment 2

[0069] A low-viscosity epoxy potting compound for silicon carbide power module packaging, comprising A component and B component, the mass ratio of the two is 5:1; A component includes the following raw material components in parts by weight:

[0070]

[0071] Component B is mainly composed of the following components by weight:

[0072]

[0073] In this embodiment, the mass ratio of methyl tetrahydrophthalic anhydride to methyl nadic anhydride is 3:1.

[0074] A method for preparing the low-viscosity epoxy potting compound for encapsulating silicon carbide power modules in the present embodiment, comprising the following steps:

[0075] (1) The preparation process of component A is as follows: 65 parts of bis((3,4-epoxycyclohexyl)methyl)adipate, 60 parts of high-purity epoxy DER332, and 10 parts of WACKER GENIOPERL P52 nano core-shell toughening Mix the agent evenly at 60°C, add 5 parts of UM-996, 70 parts of silicon micropowder and 3 parts of carbon black, carry out h...

Embodiment 3

[0079] A low-viscosity epoxy potting compound for silicon carbide power module packaging, comprising A component and B component, the mass ratio of the two is 3:1; A component includes the following raw material components in parts by weight:

[0080]

[0081] Component B is mainly composed of the following components by weight:

[0082]

[0083] In this embodiment, the mass ratio of methyl tetrahydrophthalic anhydride to methyl nadic anhydride is 2:1.

[0084] A method for preparing the low-viscosity epoxy potting compound for encapsulating silicon carbide power modules in the present embodiment, comprising the following steps:

[0085] (1) The preparation process of component A is as follows: 50 parts of bis(7-oxabicyclo[4.1.0]3-heptylmethyl)adipate, 55 parts of high-purity epoxy DER332, and 8 parts of Wacker GENIOPERL P52 Mix the nano-core-shell toughener evenly at 50°C, add 1 part of UM-998, 60 parts of silicon micropowder and 2 parts of carbon black, perform high-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com