High-toughness, anti-impact and high-flexibility epoxy pouring sealant and preparation method thereof

A potting glue and impact-resistant technology, applied in the field of potting glue, can solve the problems of insufficient crosslinking density, insufficient rigidity of cured products, reduced heat resistance, etc., and achieve stable curing rate, good flexibility, and small heat release Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

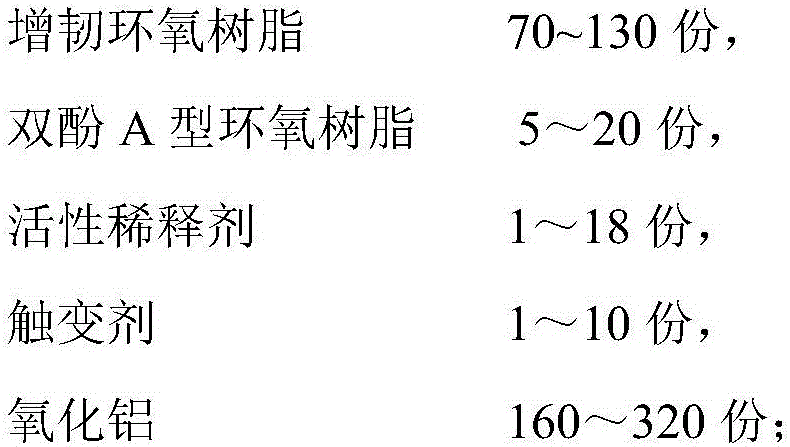

[0039] A high toughness, impact resistance and high flexibility epoxy potting compound of the present invention, comprising A component and B component with a mass ratio of 10:1, wherein A component is composed of the following raw materials:

[0040]

[0041] Component B consists of the following raw materials:

[0042] Mixture of Huntsman D230 and T403 35g;

[0043] Hyperbranched curing agent (complex of hyperbranched polyethyleneimine and isophorone diamine) 25g and DMP-302g.

[0044] The preparation method of the high toughness, impact resistance and high flexibility epoxy potting glue of the present embodiment comprises the following steps:

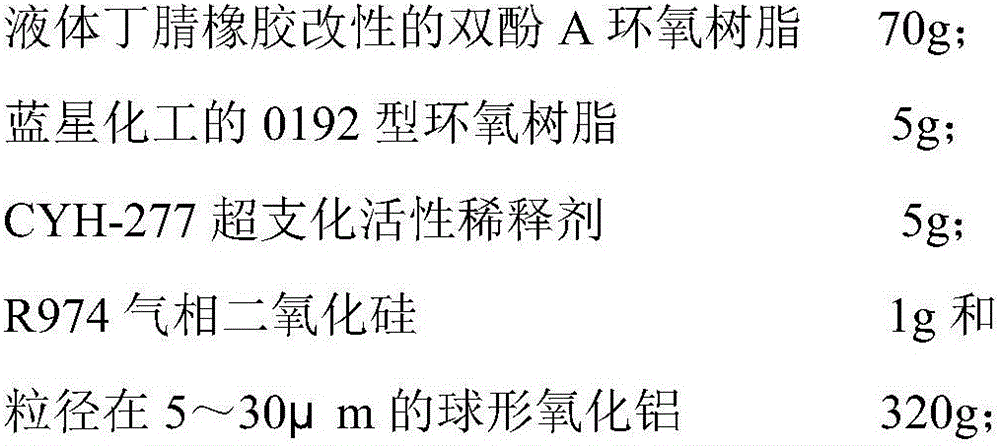

[0045] (1) Preparation of matrix resin component system (component A): add 70g of liquid nitrile rubber-modified bisphenol A epoxy resin to the high-speed disperser kettle, and then add 5g of Bluestar Chemical’s 0192 type After the CYH-277 hyperbranched reactive diluent of epoxy resin, 5g is mixed homogeneously, then add the R974 ...

Embodiment 2

[0049] A high toughness, impact resistance and high flexibility epoxy potting compound of the present invention, comprising A component and B component with a mass ratio of 15:1, wherein A component is composed of the following raw materials:

[0050]

[0051] Component B consists of the following raw materials:

[0052] Mixture of Huntsman D2000 and T403 20g;

[0053] Hyperbranched curing agent (complex of hyperbranched polyethyleneimine and isophorone diamine) 40g and triethanolamine 3g.

[0054] The preparation method of the high toughness, impact resistance and high flexibility epoxy potting glue of the present embodiment comprises the following steps:

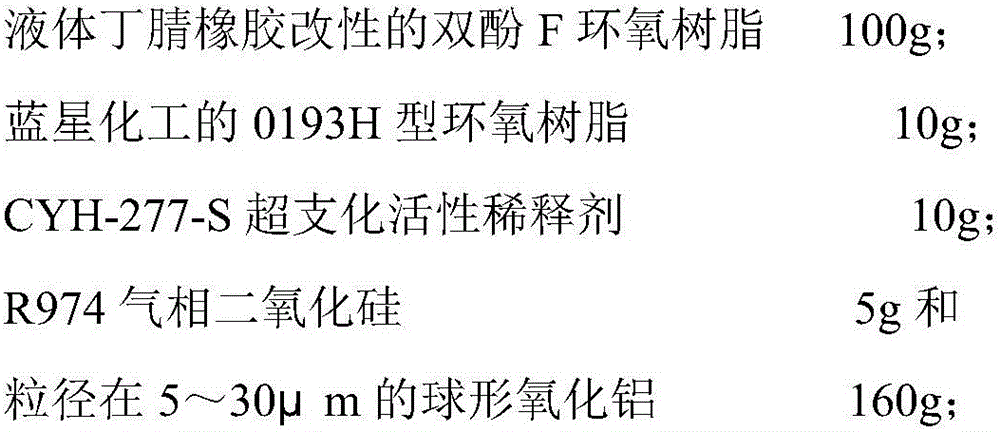

[0055] (1) Preparation of the matrix resin component system (component A): add 100g of liquid nitrile rubber-modified bisphenol F epoxy resin to the high-speed disperser kettle, and then add 10g of Bluestar Chemical’s 0193H type Epoxy resin, 10g of CYH-277-S hyperbranched reactive diluent are mixed evenly, then add 5g...

Embodiment 3

[0059] A high-toughness, impact-resistant, high-flexibility epoxy potting adhesive of the present invention, comprising A component and B component with a mass ratio of 20:1, wherein A component is composed of the following raw materials:

[0060]

[0061] Component B consists of the following raw materials:

[0062] Huntsman ED-600 and EDR-176 mixture 50g;

[0063] Hyperbranched curing agent (complex of hyperbranched polyethyleneimine and isophorone diamine) 50g and resorcinol 5g.

[0064] The preparation method of the high toughness, impact resistance and high flexibility epoxy potting glue of the present embodiment comprises the following steps:

[0065] (1) Preparation of matrix resin component system (component A): add 130g of liquid nitrile rubber-modified bisphenol A epoxy resin to the high-speed disperser kettle, and then add 20g of Bluestar Chemical’s 0191H type Epoxy resin, 18 parts of CYH-277-S hyperbranched reactive diluent are mixed evenly, then add 10 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com