Pressurizing pipe with high-temperature resistance and preparation process thereof

A technology for preparation process and booster tube, which is applied in the field of booster tube with high temperature resistance and its preparation process, can solve problems affecting service life, etc., to improve tensile strength, maintain cross-linking density, and improve activity utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

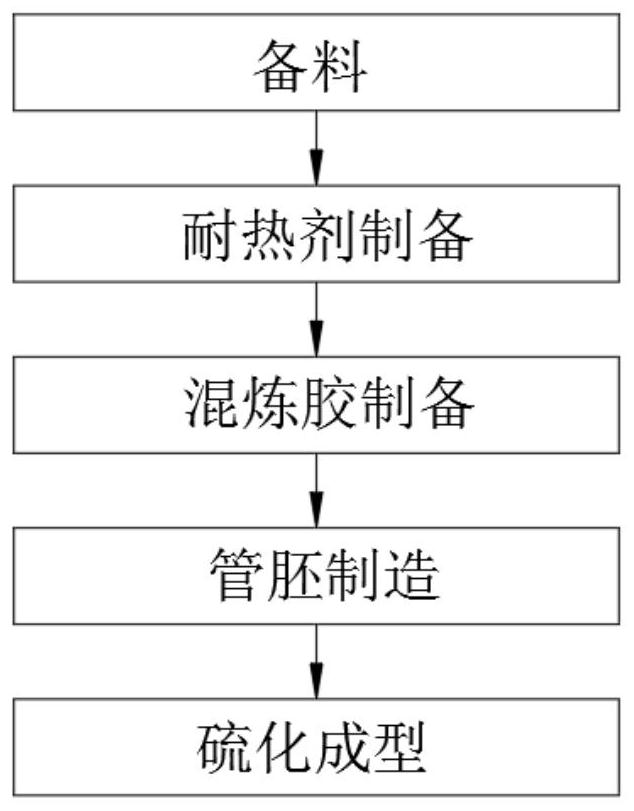

[0023] Embodiment 1: by figure 1 Given, the present invention provides the following technical solutions: a booster tube with high temperature resistance, made of the following raw materials in weight ratio: 50 parts of methyl vinyl silicone rubber, 30 parts of fluororubber premixed rubber, styrene-butadiene 30 parts of rubber, 15 parts of hydroxyl silicone oil, 2 parts of nano silicon powder, 4 parts of polymetallic organosiloxane, 6 parts of zinc oxide, 7 parts of fumed silica, 2 parts of tri-(trimethylsilyl) phosphate, 2 parts of zinc aromatic acid, 3 parts of mercaptobenzothiazole, 2 parts of flame retardant, 2 parts of vulcanizing agent, 2 parts of antiaging agent, 2 parts of crosslinking auxiliary agent and 2 parts of antioxidant.

[0024] Preferably, the preparation method of the fluororubber premixed rubber is to first melt the bisphenol AF and the vulcanization accelerator BPP in a stainless steel melting tank with stirring according to the ratio of 3:1, and discharge...

Embodiment 2

[0035] Embodiment 2: by figure 1 Given, the present invention provides the following technical solutions: a booster tube with high temperature resistance, made of the following raw materials by weight ratio: 40 parts of methyl vinyl silicone rubber, 20 parts of fluororubber premixed rubber, styrene-butadiene 20 parts of rubber, 10 parts of hydroxyl silicone oil, 1 part of nano silicon powder, 3 parts of polymetallic organosiloxane, 4 parts of zinc oxide, 3 parts of fumed silica, 1 part of tri-(trimethylsilyl) phosphate, 1 part of zinc aromatic acid, 2 parts of mercaptobenzothiazole, 1 part of flame retardant, 1 part of vulcanizing agent, 1 part of antiaging agent, 1 part of crosslinking auxiliary agent and 1 part of antioxidant.

[0036] Preferably, the preparation method of the fluororubber premixed rubber is to first melt the bisphenol AF and the vulcanization accelerator BPP in a stainless steel melting tank with stirring according to the ratio of 3:1, and discharge it to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com