A kind of high fluidity and low luster styrene-based thermoplastic elastomer material and preparation method thereof

A thermoplastic elastomer and styrene-based technology, which is applied in the field of high-fluidity and low-gloss styrene-based thermoplastic elastomer materials and their preparation, can solve problems such as high gloss and unbalanced gloss and fluidity of materials, and achieve Effects of low gloss, low compression set, and low environmental hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

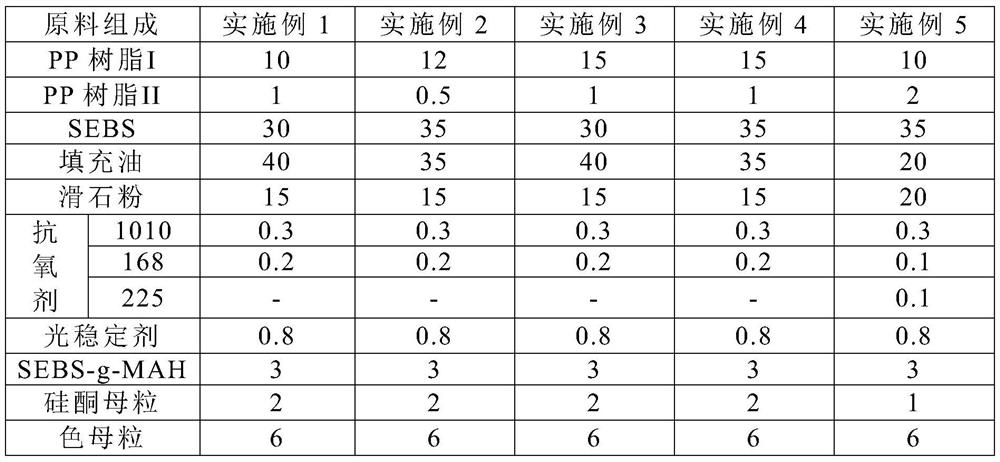

Embodiment 1-5

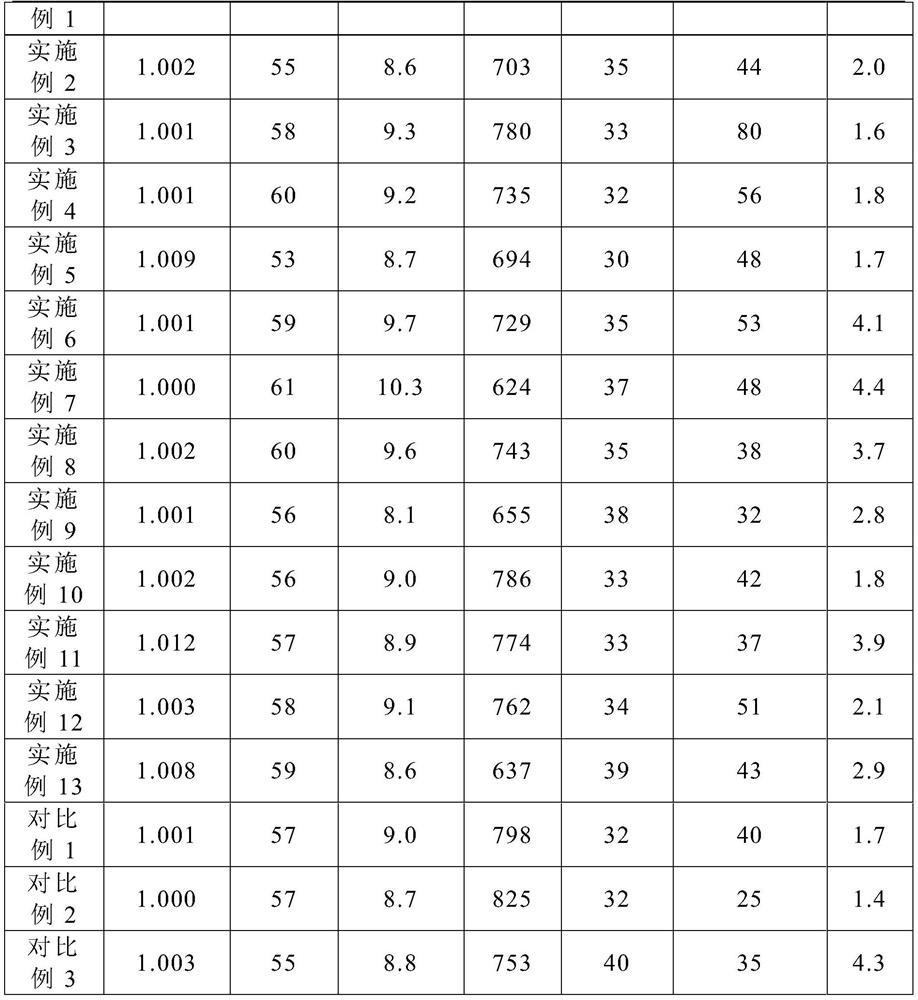

[0071] Examples 1-5 provide high-flow and low-gloss styrene-based thermoplastic elastomer materials, and the components and mass percentages of the raw materials are shown in Table 1. The PP resin I used in Examples 1-5 is block copolymerized PP resin 3500, and the melt mass flow rate is 50g / 10min under the test conditions of 230°C and 2.16KG, which can provide higher fluidity of the material; the SEBS used is TSRC's ultra-high molecular weight SEBS6159 has the characteristics of strong oil-locking ability, low gloss, and poor fluidity; the filler oil used is Hansheng Baiyou 1535, and its viscosity is 60mm 2 / s, the flash point is 240°C; the filler used is talcum powder 888 from Heshan Chemical Industry, with a particle size of 2500 mesh; the antioxidant is Beijing Jiyi Chemical’s antioxidant 1010 and antioxidant 168; the light stabilizer is Cytec Chemical 5411 and 770; the release agent is Dow Corning silicone masterbatch MB50-002; the melt mass flow rate of PP resin II in Ex...

Embodiment 6

[0075] The difference between the styrene-based thermoplastic elastomer material in Example 6 and Example 3 is that PP resin I is replaced by random copolymerized PP resin BX3920, and the melt mass flow rate is 100g / 10min, the types, contents and preparation methods of other raw materials were consistent with Example 3.

Embodiment 7

[0077] The difference between the styrene-based thermoplastic elastomer material in Example 7 and Example 4 is that PP resin I is replaced by random copolymerized PP resin BX3920, and the types, contents and preparation methods of other raw materials are consistent with Example 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com