Refining process of Ganoderma lucidum polysaccharide

A technology of Ganoderma lucidum polysaccharide and process, applied in the field of refining process of Ganoderma lucidum polysaccharide, can solve the problems of high energy consumption in the extraction liquid concentration process, incomplete removal of protein impurities, large energy consumption in the separation and purification process, etc., and achieves low loss rate and mild conditions. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

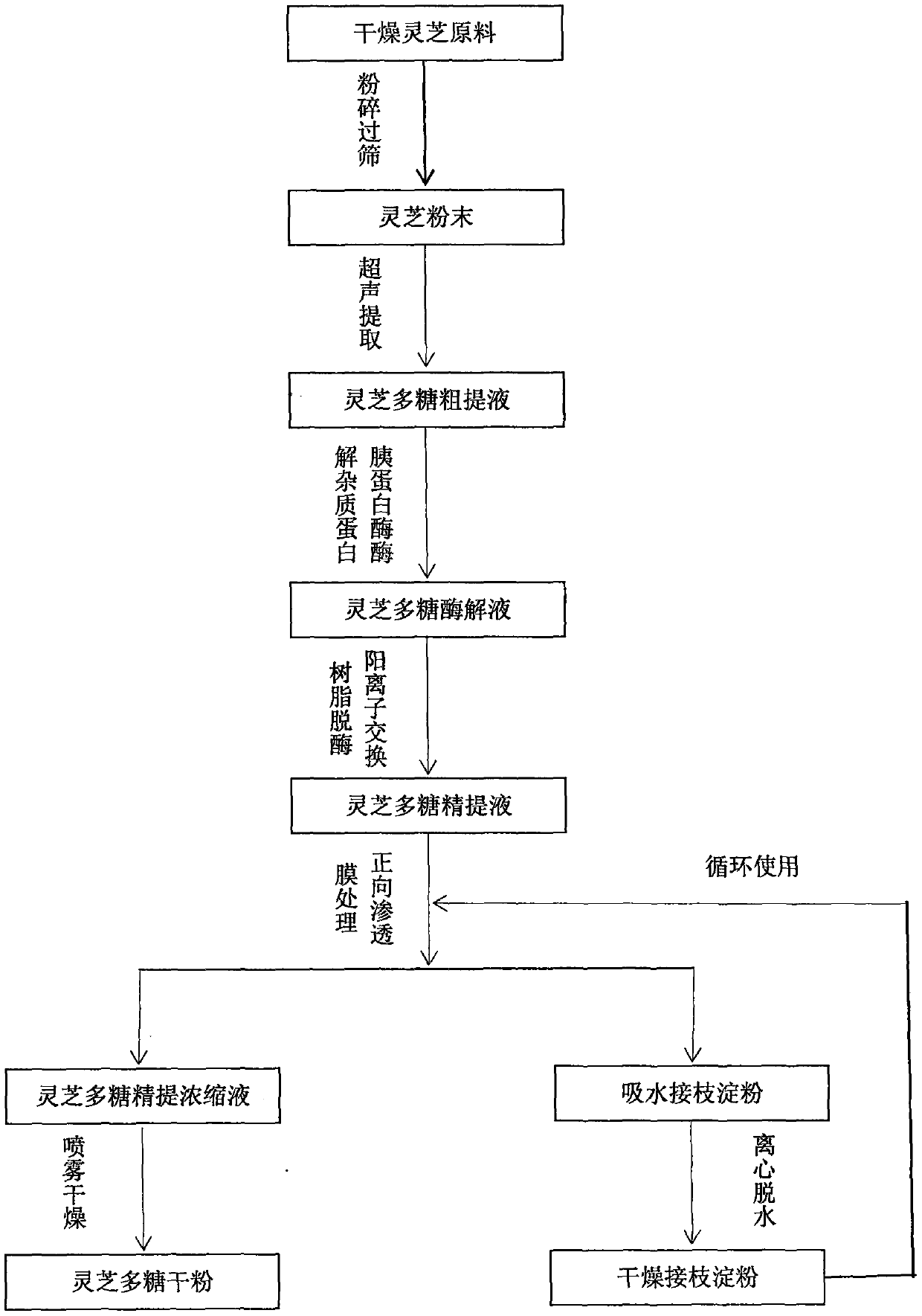

[0033] (1) Dried Ganoderma lucidum fruiting bodies are crushed and passed through a 100-mesh sieve to obtain Ganoderma lucidum fruiting body powder;

[0034] (2) Get 100g of Ganoderma lucidum fruiting body powder and add it to 50 times the quality of water, carry out ultrasonic extraction, centrifuge to get the supernatant, 4756g of polysaccharide crude extract;

[0035] (3) Adjust the pH of the crude polysaccharide extract to 7.8, add trypsin, enzymolyze the protein impurities in the extract at 38°C, centrifuge to get the supernatant, and obtain a polysaccharide enzymolysis solution of 4741g;

[0036] (4) Add cation exchange resin to the polysaccharide enzymolysis solution, stir, remove residual trypsin, filter and get the filtrate, polysaccharide essence extract 4690g;

[0037] (5) The polysaccharide essence extract is treated with a forward osmosis membrane, and the polysaccharide essence extract concentrate is 1000g;

[0038] (6) The concentrated solution of polysaccharid...

Embodiment 2

[0046] (1) Drying and crushing the spores of ganoderma lucidum through a 100-mesh sieve to obtain spore powder of ganoderma lucidum;

[0047] (2) Get 100g of Ganoderma lucidum spore powder and add it to 80 times the quality of water, carry out ultrasonic extraction, centrifuge to get the supernatant, polysaccharide crude extract 7732g;

[0048] (3) Adjust the pH of the crude polysaccharide extract to 7.8, add trypsin, enzymolyze the protein impurities in the extract at 38°C, centrifuge to get the supernatant, and obtain a polysaccharide enzymatic hydrolysis solution of 7713g;

[0049] (4) Add cation exchange resin to the polysaccharide enzymatic hydrolysis solution, stir, remove residual trypsin, filter and get the filtrate, polysaccharide fine extract 7656g;

[0050] (5) The polysaccharide essence extract is treated with a forward osmosis membrane, and the polysaccharide essence extract concentrate is 1000g;

[0051] (6) The concentrated polysaccharide extract was spray-drie...

Embodiment 3

[0059] (1) Dried Ganoderma lucidum fermented mycelia is passed through a 100-mesh sieve after being pulverized to obtain Ganoderma lucidum mycelium powder;

[0060] (2) Get 100g of Ganoderma lucidum mycelium powder and add it to 60 times the mass of water, carry out ultrasonic extraction, centrifuge to get the supernatant, 5741g of polysaccharide crude extract;

[0061] (3) Adjust the pH of the crude polysaccharide extract to 7.8, add trypsin, enzymolyze the protein impurities in the extract at 38°C, centrifuge to get the supernatant, and obtain 5726 g of polysaccharide enzymatic hydrolysis;

[0062] (4) Add cation exchange resin to the polysaccharide enzymolysis solution, stir, remove residual trypsin, filter and get the filtrate, polysaccharide essence extract 5669g;

[0063] (5) The polysaccharide essence extract is treated with a forward osmosis membrane, and the polysaccharide essence extract concentrate is 1000g;

[0064] (6) The concentrated polysaccharide extract was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com