Comprehensive utilization method for iron and steel smelting dust washing wastewater

A technology for iron and steel smelting and waste water, applied in the field of comprehensive utilization of resources, can solve the problems of large equipment and building damage, crevice corrosion and pitting corrosion, serious environmental pollution, etc., and achieve the effects of reduced energy consumption, economical efficiency, and friendly process environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

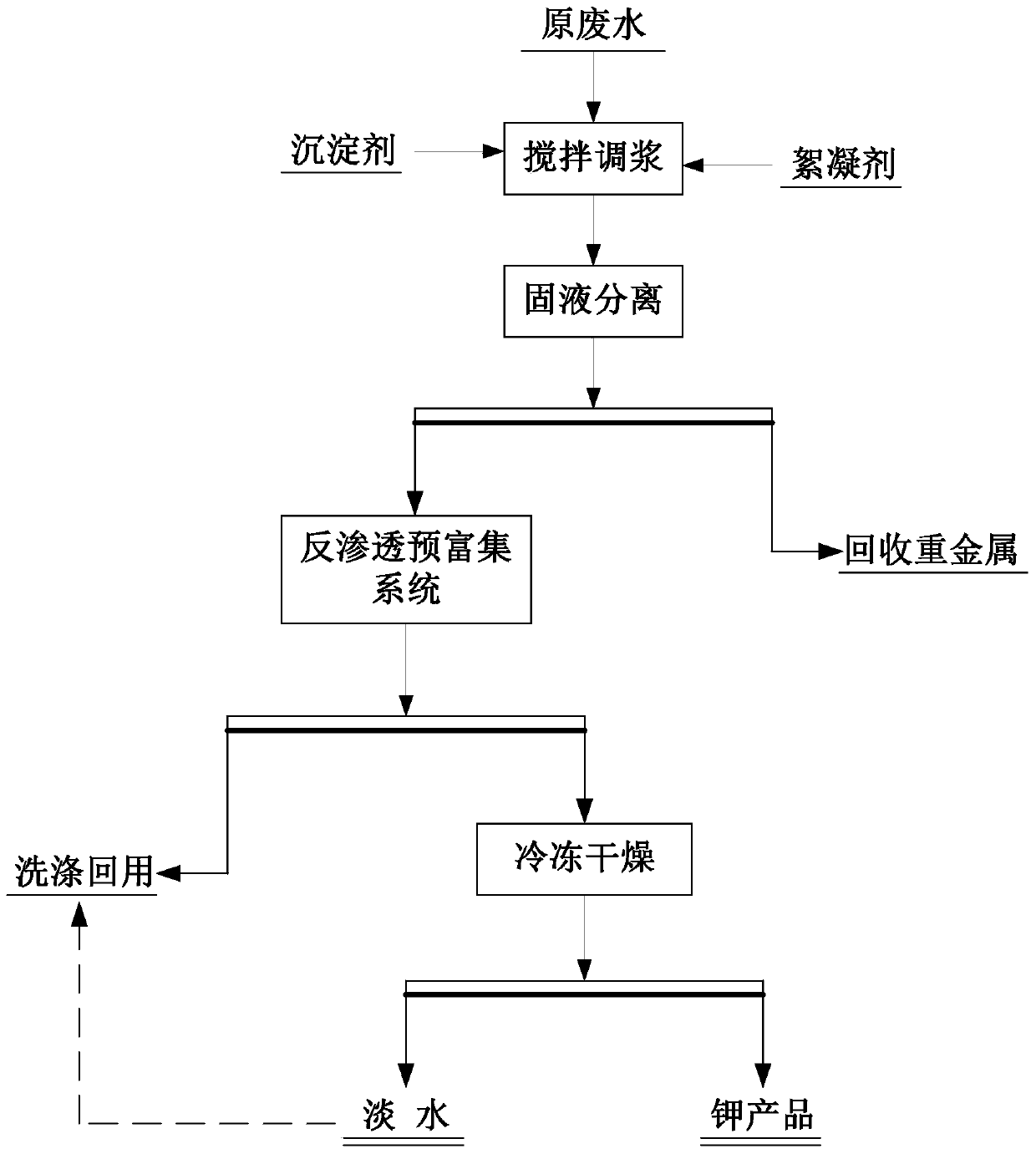

[0025] Aiming at the comprehensive utilization of the machine head ash washing wastewater in a steel plant, firstly, 0.5% of the mass of the washing wastewater was added to the potassium hydroxide as a precipitant, and 0.1% of the mass of the washing wastewater was used as a flocculant, and then The wastewater after flocculation and sedimentation treatment is separated from solid and liquid by plate and frame filter press, and the solid phase is used for comprehensive recovery of heavy metals (by one or more comprehensive recovery of heavy metals in flotation, gravity separation, magnetic separation and other beneficiation methods), The method for comprehensively recovering heavy metals is a conventional method in the art and will not be repeated here. The liquid phase is adjusted to a pH between 7.5 and 8.5 with hydrochloric acid, and sent to the reverse osmosis pre-enrichment system for pre-enrichment of alkali metals and chloride ions at a temperature of 15°C to maintain the...

Embodiment 2

[0029] To comprehensively utilize the gas ash washing wastewater from a steel plant, first add 0.7% potassium hydroxide as a precipitant and 0.1% polyacrylamide to it, and then flocculate and settle The final waste water is separated from solid and liquid using a plate and frame filter press, and the solid phase is used for comprehensive recovery of heavy metals (by one or more comprehensive recovery of heavy metals in mineral processing methods such as flotation, gravity separation, and magnetic separation), and the comprehensive recovery The heavy metal method is a conventional method in the art and will not be repeated here. The liquid phase is adjusted to a pH between 7.5 and 8.0 with hydrochloric acid, and sent to the reverse osmosis pre-enrichment system for pre-enrichment of alkali metals and chloride ions at a temperature of 25°C, maintaining a recovery desalination rate of about 95%, and completing pre-enrichment After collection, the low brine (potassium chloride con...

Embodiment 3

[0033] Aiming at the comprehensive utilization of the machine head ash washing wastewater in a steel plant, firstly, 0.4% potassium oxide was added as a precipitant, and 0.1% polyacrylamide was used as a flocculant, and then the The wastewater after flocculation and sedimentation treatment is separated from solid and liquid by plate and frame agent filter press, and the solid phase is used for comprehensive recovery of heavy metals (by one or more comprehensive recovery of heavy metals in flotation, gravity separation, magnetic separation and other beneficiation methods), The method for comprehensively recovering heavy metals is a conventional method in the art and will not be repeated here. The liquid phase is adjusted to a pH between 7.5 and 8.5 with hydrochloric acid, and transported to the reverse osmosis pre-enrichment system for pre-enrichment of alkali metals and chloride ions at a temperature of 35°C, maintaining a recovery desalination rate of about 90%, and completing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com