Method for improving metallurgical-method polycrystalline silicon growth interface

A technology of polysilicon growth and metallurgy, which is applied in the direction of polysilicon material growth, crystal growth, single crystal growth, etc., can solve the problems of polysilicon performance index instability, differences in propulsion methods, and many defects in the crystal, so as to improve the quality of silicon ingots , good compatibility, process and environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

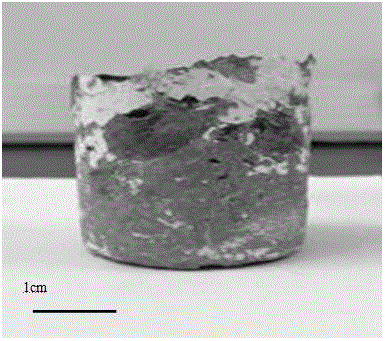

Embodiment 1

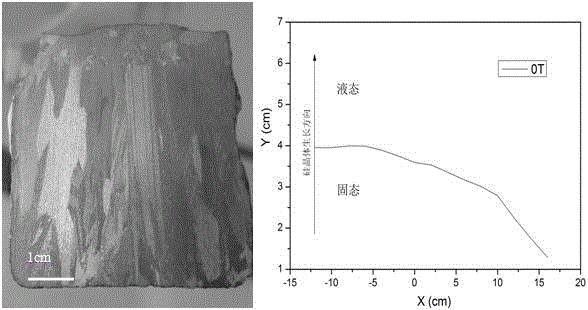

[0017] (1) Preparation stage: put 350g of metallurgical polysilicon material into a high-purity quartz crucible, then put it into a directional solidification furnace, and vacuumize at the same time until the vacuum degree in the furnace is less than 10Pa.

[0018] (2) Heating and melting stage: Start the heating device to raise the furnace temperature to 1450°C to melt the silicon material.

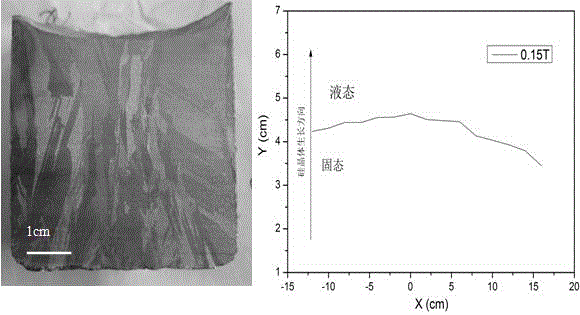

[0019] (3) External field control and crystal growth stage: turn on the static magnetic field generator to apply an axial magnetic field to the molten silicon material for external field control treatment, the magnetic field strength is 0.15T, and the processing time is 15 minutes. Then set the cooling rate of the furnace body to 5°C / min, and the moving part of the furnace body (crucible, graphite holder, graphite separator, base, etc.) to move down at a rate of 10 mm / h, so that the silicon melt slowly detaches from the heater and begins to grow. When the temperature drops to 1100°C, tur...

Embodiment 2

[0022] (1) Preparation stage: put 350g of metallurgical polysilicon material into a high-purity quartz crucible, then put it into a directional solidification furnace, and vacuumize at the same time until the vacuum degree in the furnace is less than 10Pa.

[0023] (2) Heating and melting stage: Start the heating device to raise the furnace temperature to 1450°C to melt the silicon material.

[0024] (3) External field control and crystal growth stage: Turn on the static magnetic field generator to apply an axial magnetic field to the molten silicon material for external field control treatment, the magnetic field strength is 0.2 T, and the processing time is 15 min. Then set the cooling rate of the furnace body to 5°C / min, and the moving part of the furnace body (crucible, graphite holder, graphite separator, base, etc.) to move down at a rate of 10 mm / h, so that the silicon melt slowly detaches from the heater and begins to grow. When the temperature drops to 1100°C, turn of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com