Casting mold for high-temperature alloy cast ingot with large height-diameter ratio and application

A high-temperature alloy and high-diameter ratio technology, which is applied in the field of high-temperature alloy material preparation, can solve the problems of discontinuous distribution, poor feasibility, and high melt viscosity of nickel-based superalloys, so as to improve product yield, facilitate large-scale production, The effect of improving the quality of ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

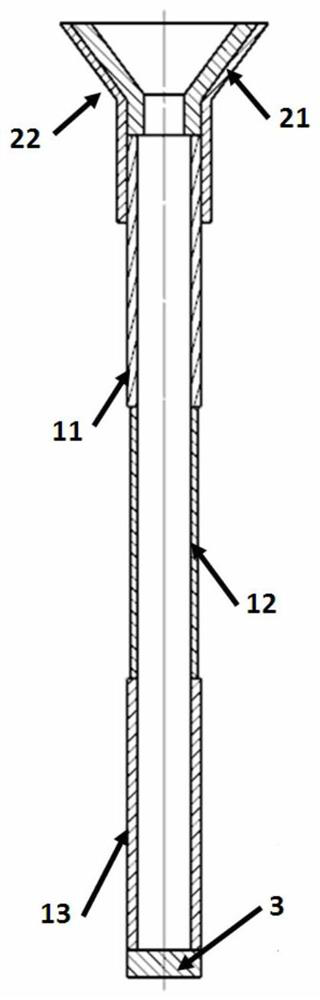

[0070] Provide a casting mold 1# for high-temperature alloy ingot with large aspect ratio, such as figure 1 As shown, the material of the mold unit is No. 45 carbon structural cast steel. The mold unit is tubular, the height-to-diameter ratio of the mold unit is 6.4, the inner diameter of the mold unit is 125mm, and the height is 800mm. The height of the first section is 160mm, accounting for 20% of the height of the mold unit; the height of the second section is 320mm, accounting for 40% of the height of the mold unit; the height of the third section is 320mm, accounting for 40% of the height of the mold unit . The wall thickness of the first section is 20mm; the wall thickness of the second section is 10mm; the thickness of the third section is 35mm; so that the wall thickness difference between the first section and the second section is 10mm, the first section The difference in wall thickness from the third section is 15mm.

[0071] The height-to-diameter ratio of the r...

Embodiment 2

[0075] Provide a casting mold 2# for high-temperature alloy ingot with large aspect ratio, such as figure 1 As shown, the material of the mold unit is stainless steel. The mold unit is tubular, the aspect ratio of the mold unit is 16, the inner diameter of the mold unit is 50mm, and the height is 800mm. The height of the first section is 320mm, accounting for 40% of the height of the mold unit; the height of the second section is 240mm, accounting for 30% of the height of the mold unit; the height of the third section is 240mm, accounting for 30% of the height of the mold unit . The wall thickness of the first section is 30mm; the wall thickness of the second section is 20mm; the thickness of the third section is 40mm; so that the wall thickness difference between the first section and the second section is 10mm, the first section The difference in wall thickness from the third section is 10mm.

[0076] The height-to-diameter ratio of the riser unit is 0.6. The material in...

Embodiment 3

[0080] Provide a casting mold 3# for high-temperature alloy ingots with a large aspect ratio, such as figure 1 As shown, the material of the mold unit is No. 45 carbon structural cast steel. The casting mold unit is tubular, the aspect ratio of the casting mold unit is 24, the inner diameter of the casting mold unit is 50mm, and the height is 1200mm. The height of the first section is 360mm, accounting for 30% of the height of the mold unit; the height of the second section is 600mm, accounting for 50% of the height of the mold unit; the height of the third section is 240mm, accounting for 20% of the height of the mold unit . The wall thickness of the first section is 25mm; the wall thickness of the second section is 20mm; the thickness of the third section is 40mm; so that the wall thickness difference between the first section and the second section is 5mm, the first section The difference in wall thickness from the third section is 15mm.

[0081] The height-to-diameter r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com