Local pressurization mechanism and method for producing automobile engine suspension shock insulators by same

An automobile engine, local pressurization technology, applied in the field of local pressurization mechanism and manufacturing engine suspension spacer, can solve the problems of low internal and surface hardness, poor internal quality of products, long production cycle, etc., and achieve small thermal shock , Simplify the production process, the effect of less heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

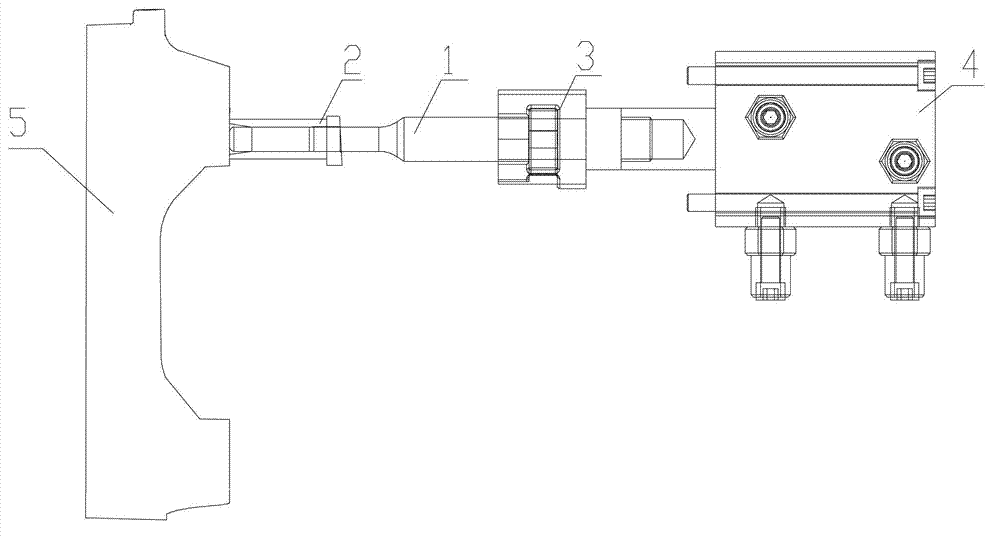

[0021] Specific implementation mode 1: Combination figure 1 To illustrate this embodiment, the mechanism of this embodiment includes a local pressurized insert 1, a cylinder 2, a connecting sleeve 3, and a cylinder 4. The transmission rod of the cylinder 4 is connected to one end of the local pressurized insert 1 through the connecting sleeve 3. The other end of the pressure insert 1 is installed in the cylinder 2 and contacts the pouring end of the part 5 to be processed, and the cylinder 2 is butted with the part 5 to be processed.

specific Embodiment approach 2

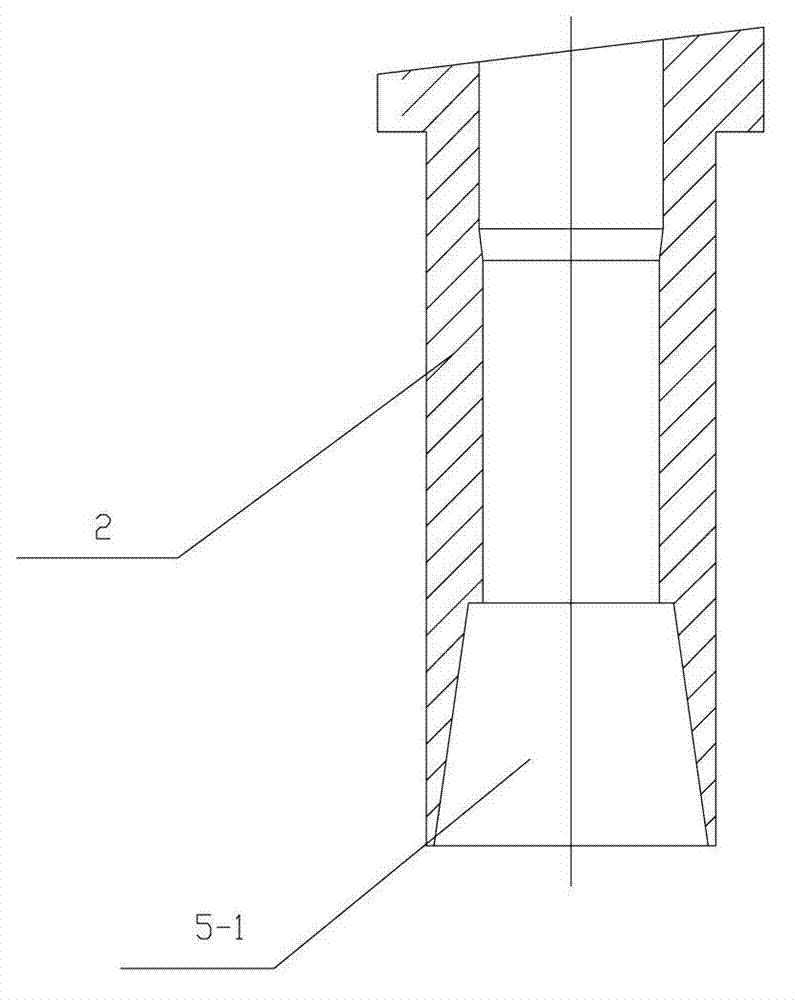

[0022] Specific implementation manner two: combination figure 2 To illustrate this embodiment, the end face of the cylinder 2 in this embodiment that is in contact with the part 5 to be processed is provided with a through hole 5-1 with a trapezoidal cross section, and the bottom angle of the trapezoid is 74°. The advantage of this structure is to avoid the cylinder wall The rapid solidification of the surrounding aluminum liquid hinders the operation of the local pressure mechanism. The other implementation steps are the same as the first embodiment.

specific Embodiment approach 3

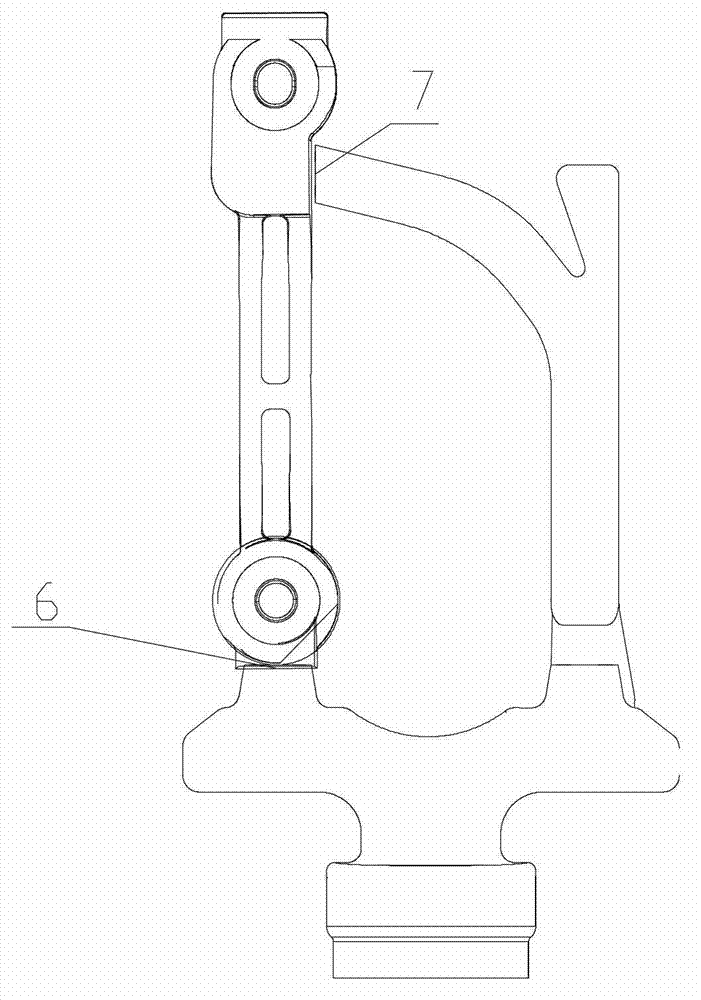

[0023] Specific implementation mode three: combination Figure 1-Figure 3 To illustrate this embodiment, the method of this embodiment includes the following steps:

[0024] Step 1. Design and molding of the mold: adopt double-runner pouring method, design the main runner gate size is 29×24mm, draft angle is 5°, and the auxiliary runner gate is opened at the top of the part 5 to be processed At the wall thickness, the size is 20×15mm, and the draft angle is 10°;

[0025] Step 2. Aluminum alloy smelting: Put the aluminum alloy in a crucible and heat it to melt; after the aluminum alloy is melted, the aluminum liquid is refined and slag removed, and the temperature is lowered to a near liquidus temperature of 600-640℃;

[0026] Step 3. Squeeze casting process: The mold temperature machine is connected to the extrusion die through the cylinder 4, and the extrusion die and the mold temperature machine are debugged respectively. The final mold temperature machine is adjusted to 220-270°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com