Patents

Literature

42results about How to "Productivity impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resistant full-biodegradable straw and preparation method thereof

The invention belongs to the technical field of high polymer material processing, and particularly relates to a heat-resistant full-biodegradable straw which comprises the following components in parts by mass: 100 parts of full-biodegradable resin, 3-5 parts of a nucleating agent, 2-4 parts of a chain extender, 20-35 parts of an inorganic filler, 1-2 parts of a lubricant, 1-2 parts of a compatibilizer and 20-30 parts of a biomass filler. The preparation method comprises the following steps of: firstly, putting the inorganic filler, the biomass filler, the lubricant and the compatibilizer into high-temperature mixing equipment, stirring at a high speed for modification, then adding the full-biodegradable resin, the chain extender and the nucleating agent, uniformly mixing, then putting the raw materials into an internal mixer for internal mixing, putting the internally mixed blend into a double-screw extruder, extruding and granulating, then adding the obtained material into a suction tube extruder, extruding the material into a tube shape, then stretching the tube into post-processing equipment, enabling the tube to quickly pass through the equipment for secondary crystallization, and finally cutting the tube into a preset length. The heat resistance of the full-biodegradable straw can be remarkably improved, so that the full-biodegradable straw can be applied to more use scenes, the product value is improved, the processing efficiency is high, and better economic benefits are obtained.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

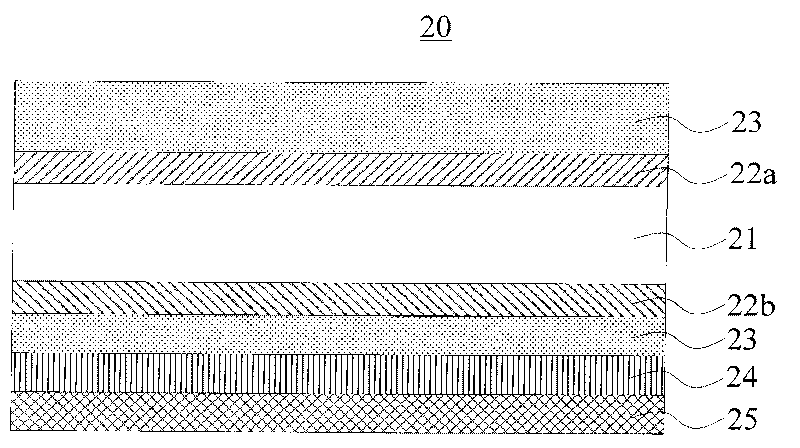

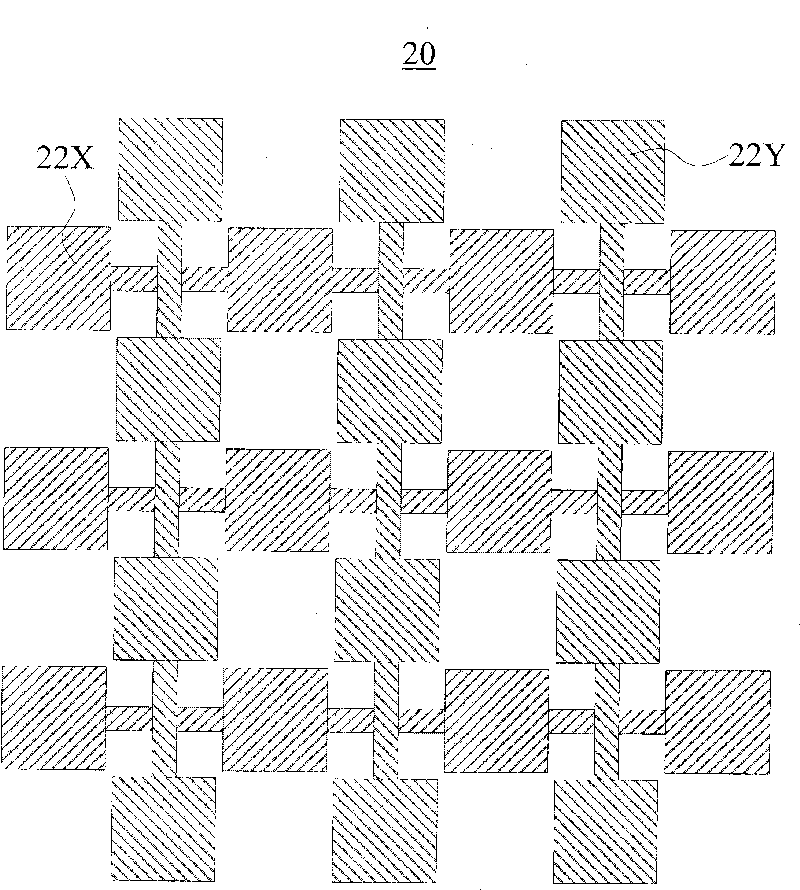

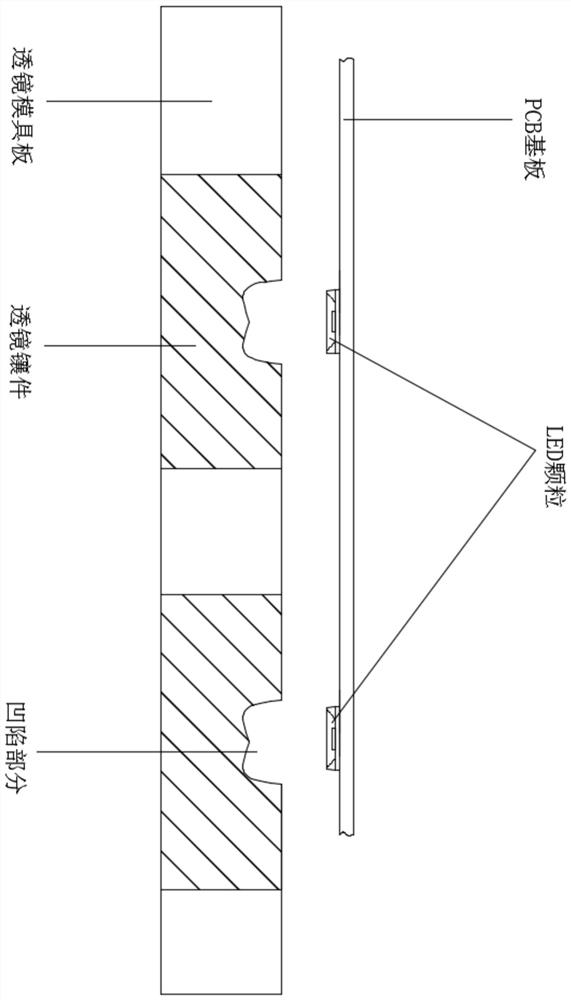

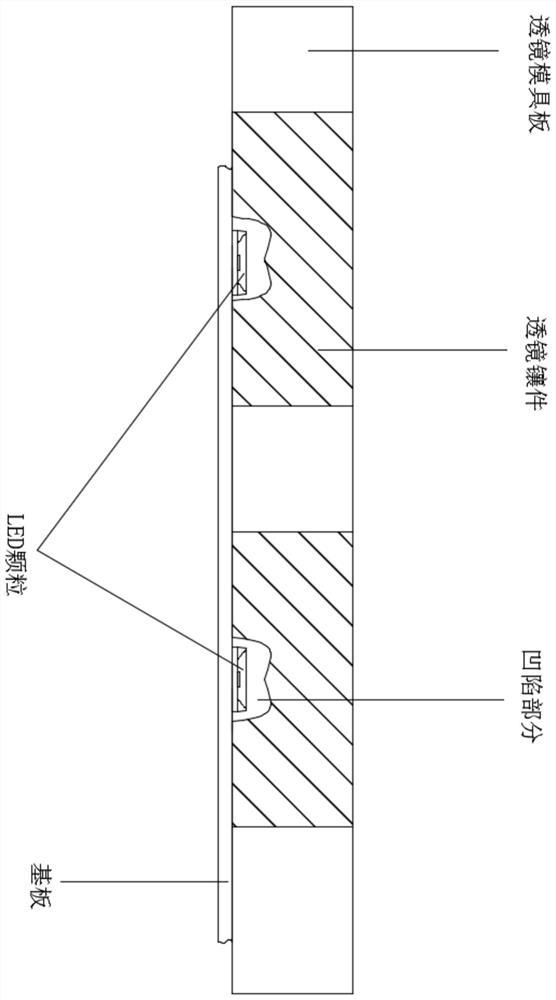

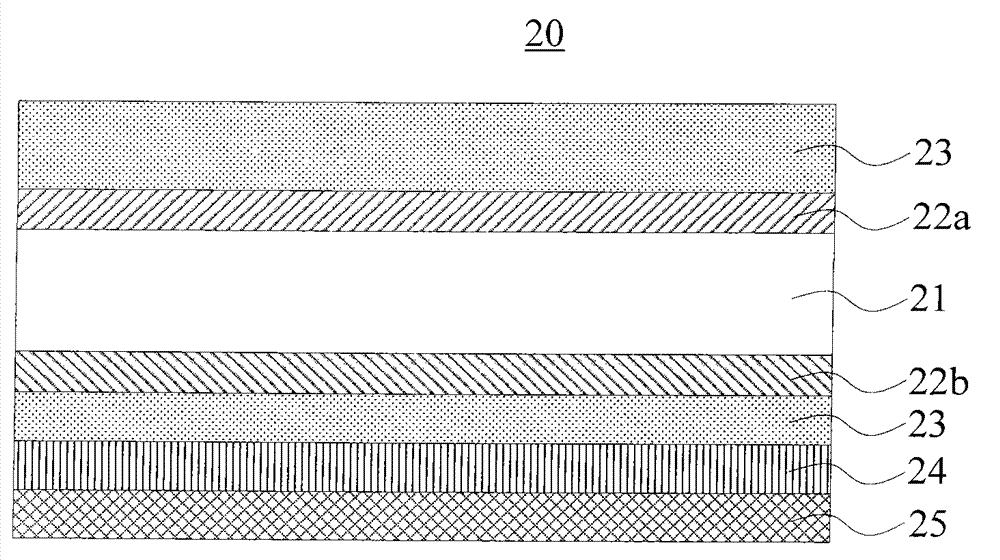

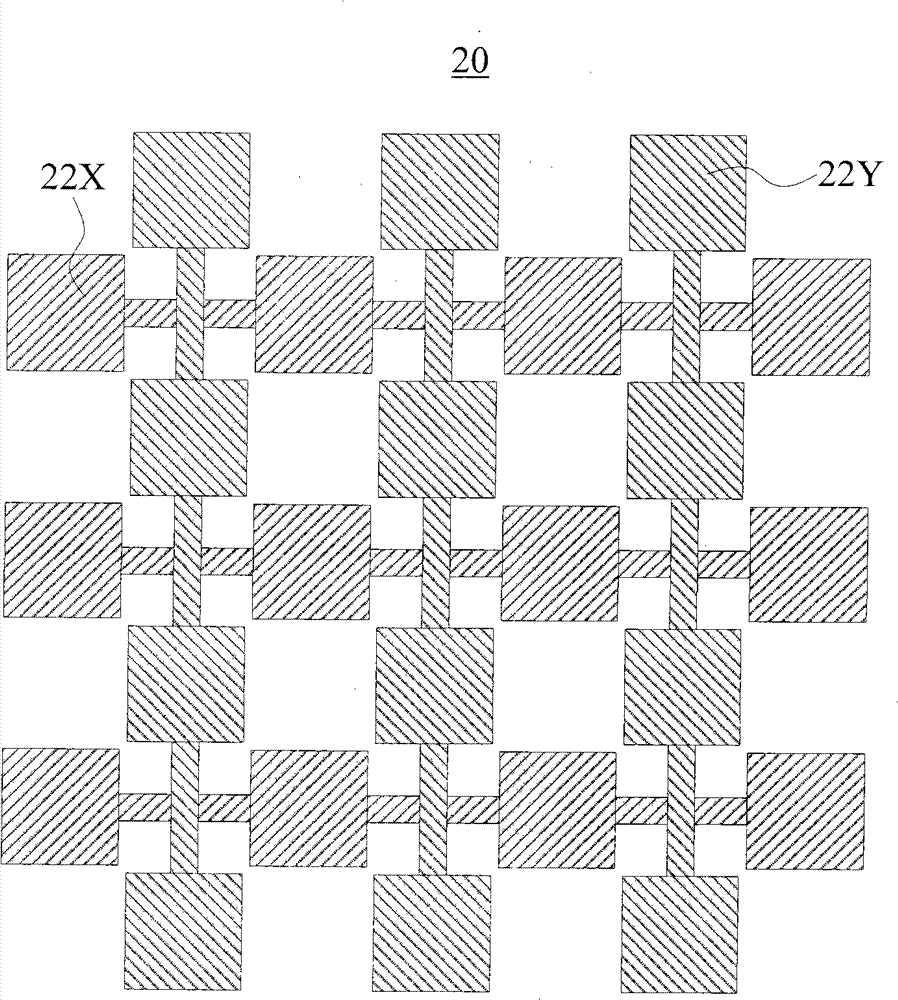

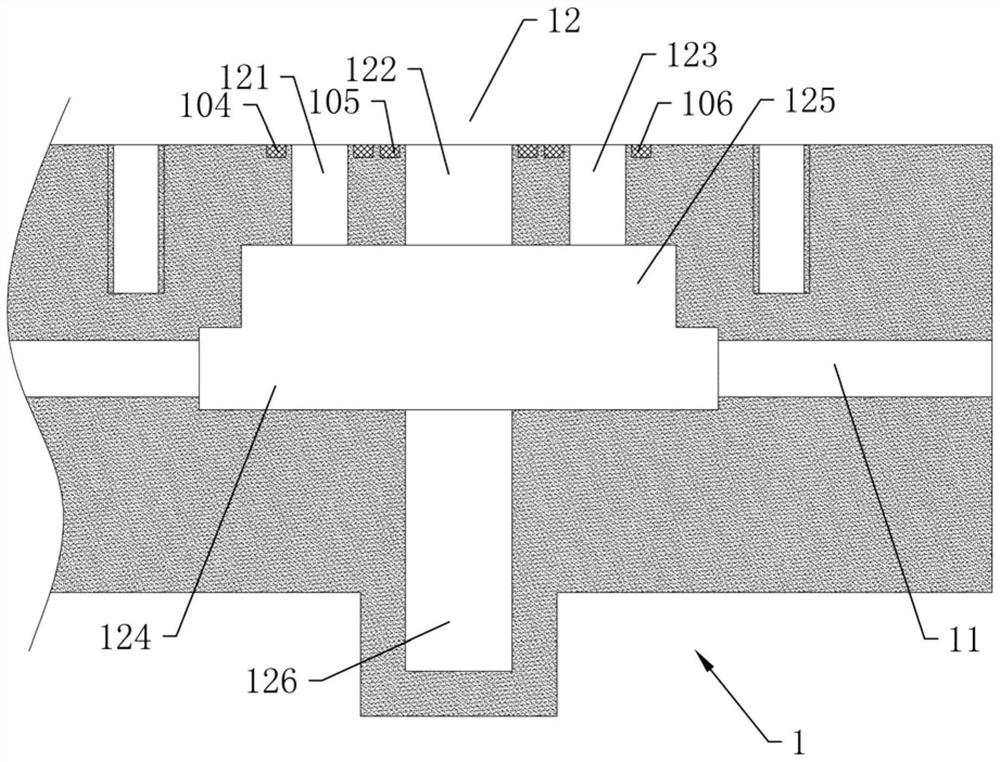

Touch panel and manufacturing method thereof

ActiveCN101751178AReduce manufacturing costIncrease productivityInput/output processes for data processingEngineeringTouch panel

The invention relates to information input technology, in particular to a touch panel and a manufacturing method thereof. The touch panel comprises a substrate and an electrode layer. The electrode layer is formed on the substrate and comprises a plurality of parallel X-axis traces, a plurality of parallel Y-axis traces, a plurality of bridge structures and a plurality of insulation blocks. The plurality of X-axis traces intersect with the plurality of Y-axis traces, and the plurality of Y-axis traces are partitioned into a plurality of units by the plurality of X-axis trances. The bridge structures are positioned at intersections of the X-axis traces and the Y-axis traces and are used for connecting adjacent two units which are positioned on the two sides of the same X-axis trace and belong to the same Y-axis trace. The bridge structures are formed on the substrate; the insulation blocks are arranged on the bridge structures; the overlapped parts of the X-axis traces and the bridge structures are positioned on the insulation blocks; and the X-axis traces are insulated from the bridge structures through the insulation blocks. A manufacturing material and a process of the bridge structures are the same as the manufacturing material and the process of the X-axis traces and the Y-axis traces.

Owner:SHENZHEN LAIBAO HI TECH

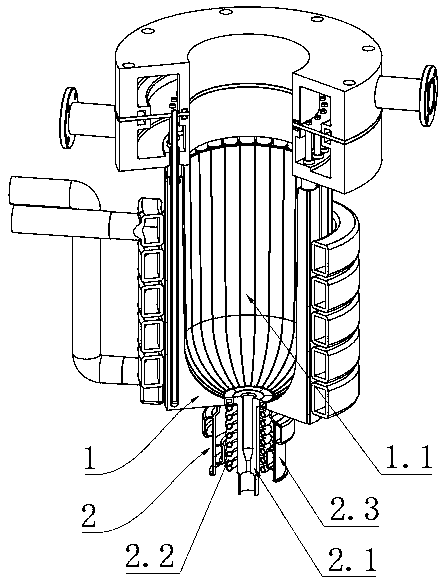

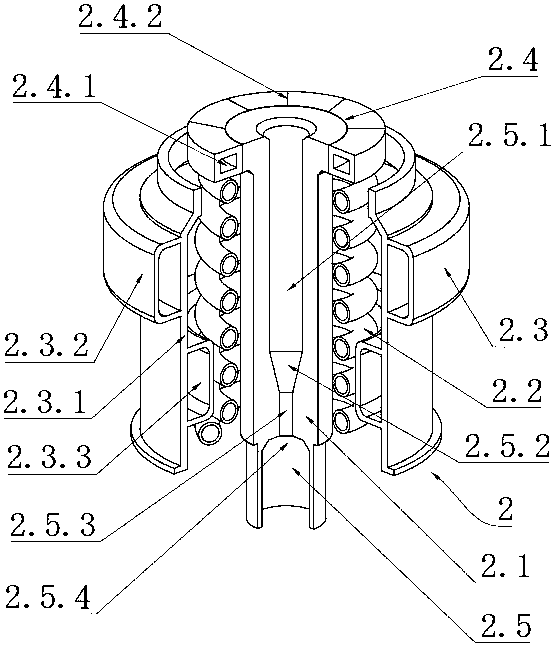

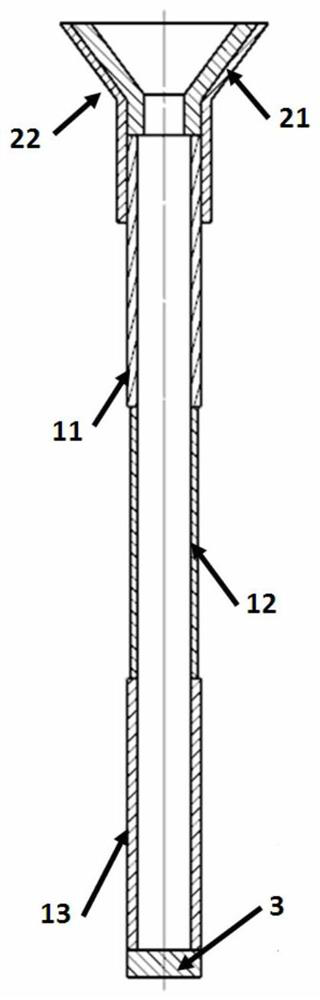

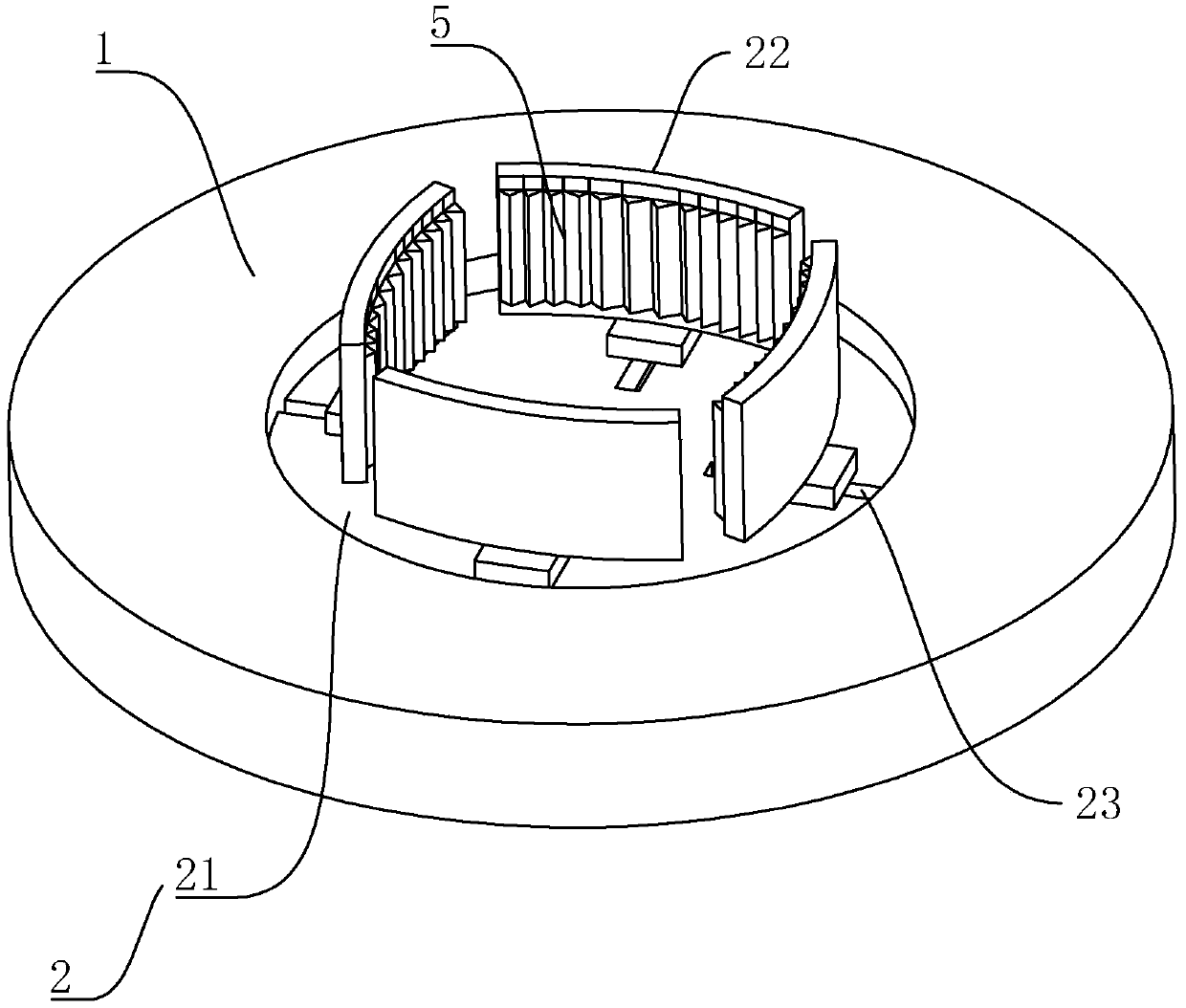

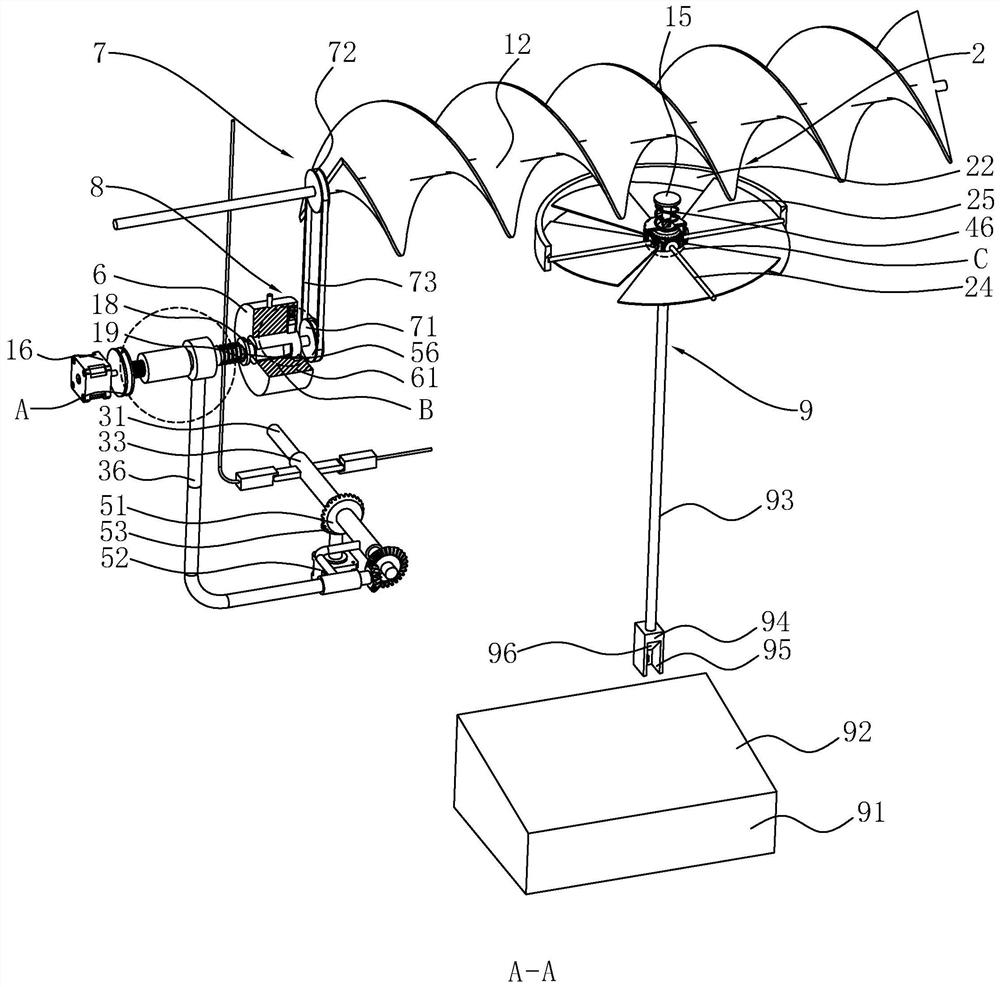

Titanium alloy smelting atomization powder manufacturing equipment and manufacturing technology thereof

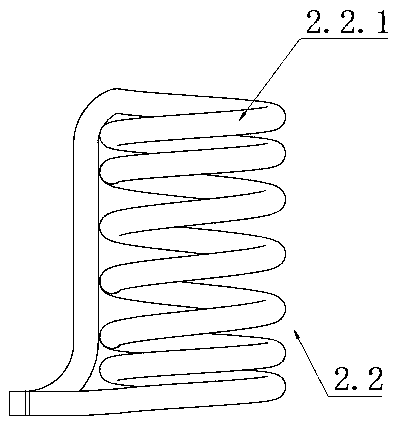

The invention discloses titanium alloy smelting atomization powder manufacturing equipment and a manufacturing technology thereof. The titanium alloy smelting atomization powder manufacturing equipment comprises a crucible body (1); a smelting cavity (1.1) is formed in the crucible body (1); a pouring hole (1.2) through which smelted titanium alloy liquid flows out is formed in the lower end of the crucible body (1); a heating mechanism (2) is arranged at the lower part of the crucible body (1); the heating mechanism (2) comprises a heating pipe (2.1), an auxiliary heating coil (2.2) and a water cooled hood (2.3); the heating pipe (2.1) is arranged at the lower part of the pouring hole (1.2); the auxiliary heating coil (2.2) sleeves the heating pipe (2.1); the water cooled hood (2.3) sleeves the auxiliary heating coil (2.2). The titanium alloy smelting atomization powder manufacturing equipment and the manufacturing technology have the advantages that kish in the crucible body is little, the probability of blocking is low, the liquidity of titanium alloy liquid flowing from the smelting cavity to an atomization cavity is good and the titanium alloy liquid is not prone to being interrupted, and the atomization powder manufacturing efficiency is high.

Owner:宁波中物力拓超微材料有限公司

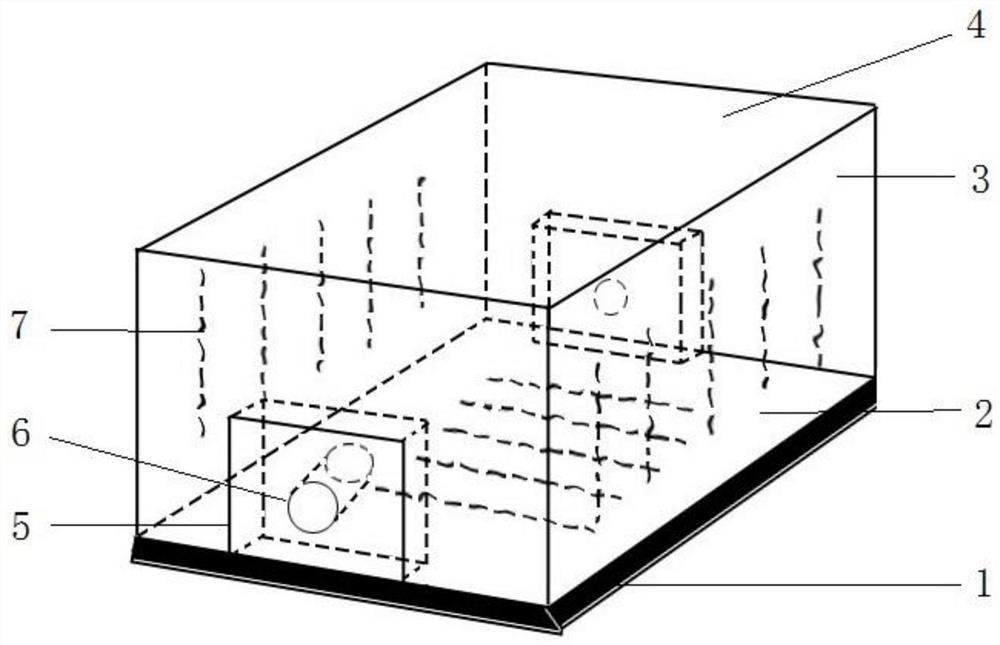

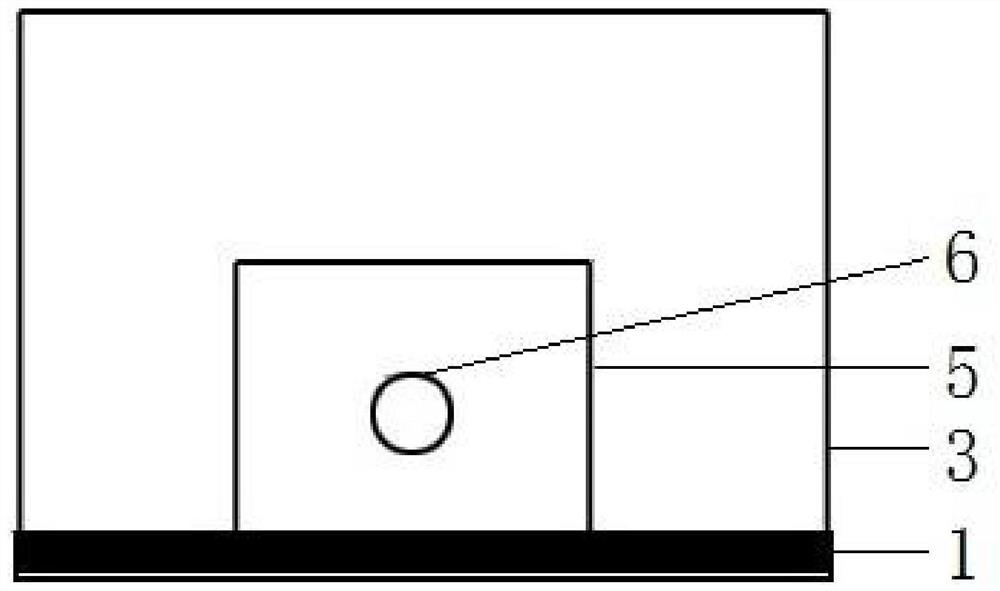

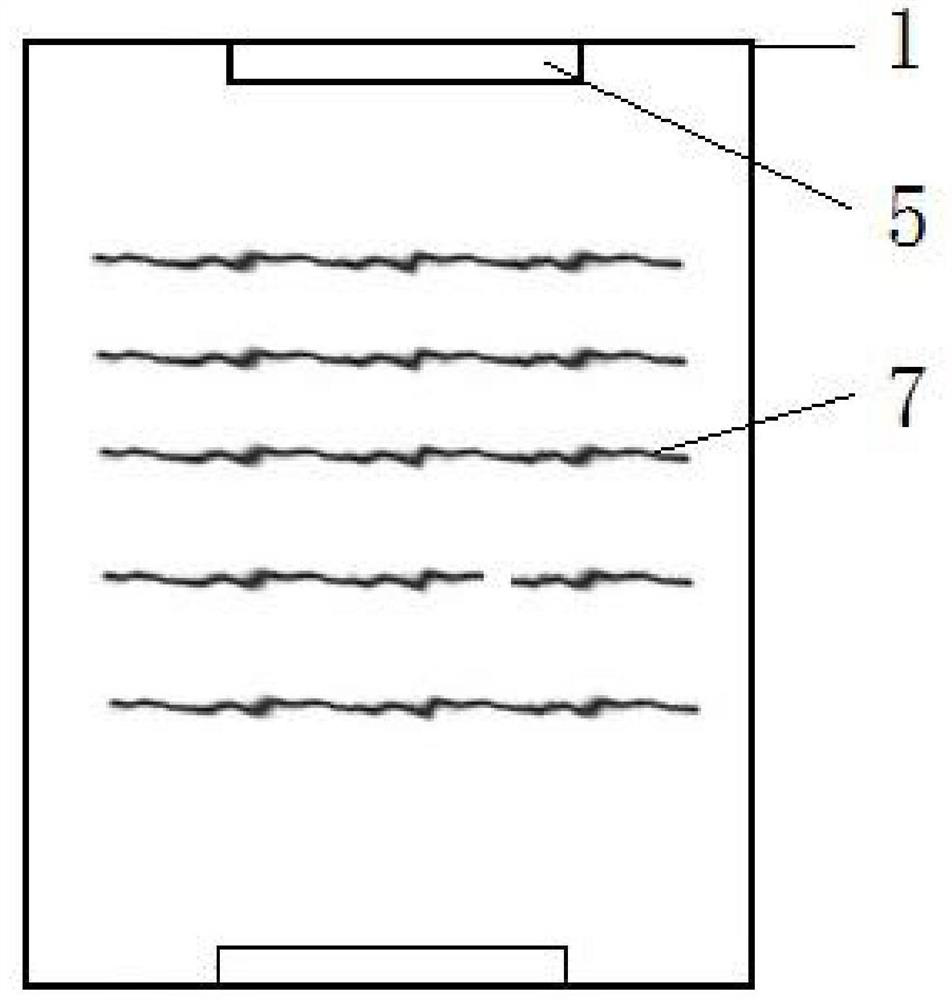

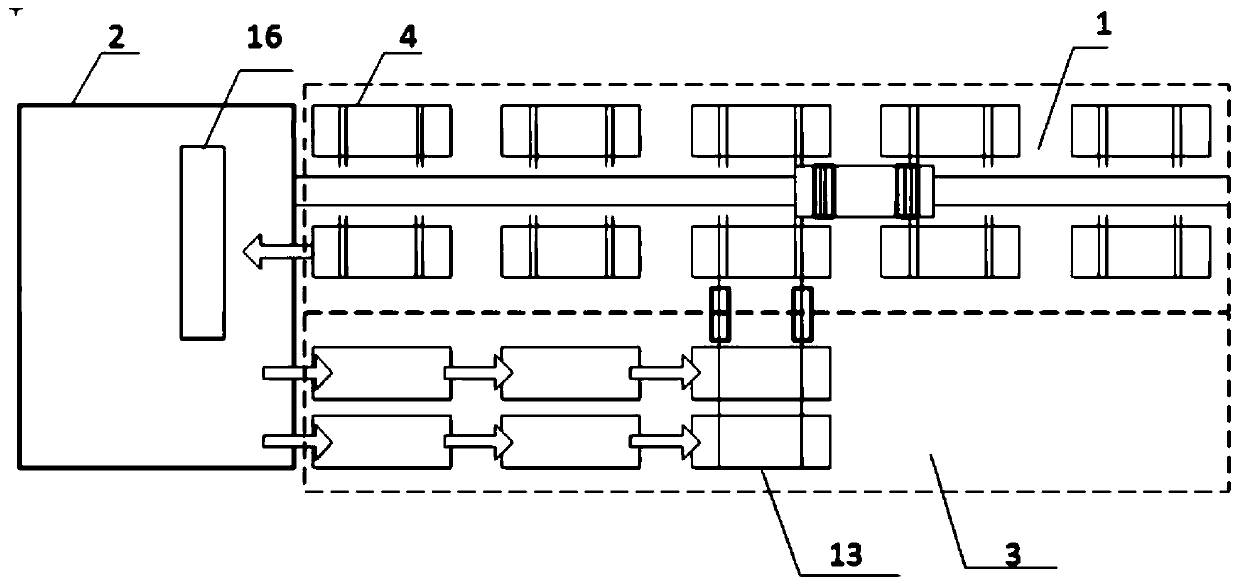

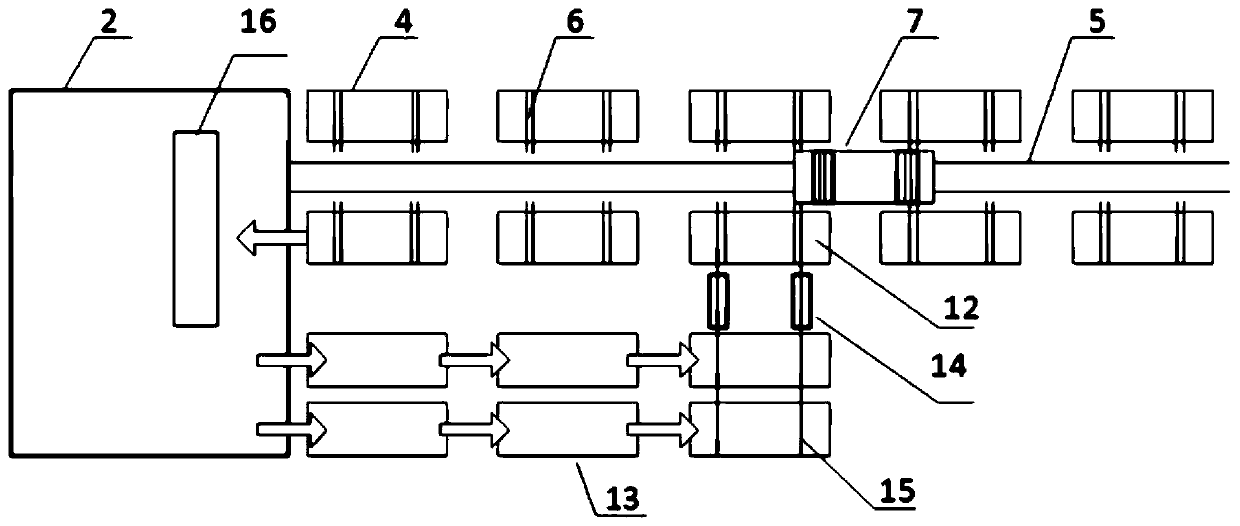

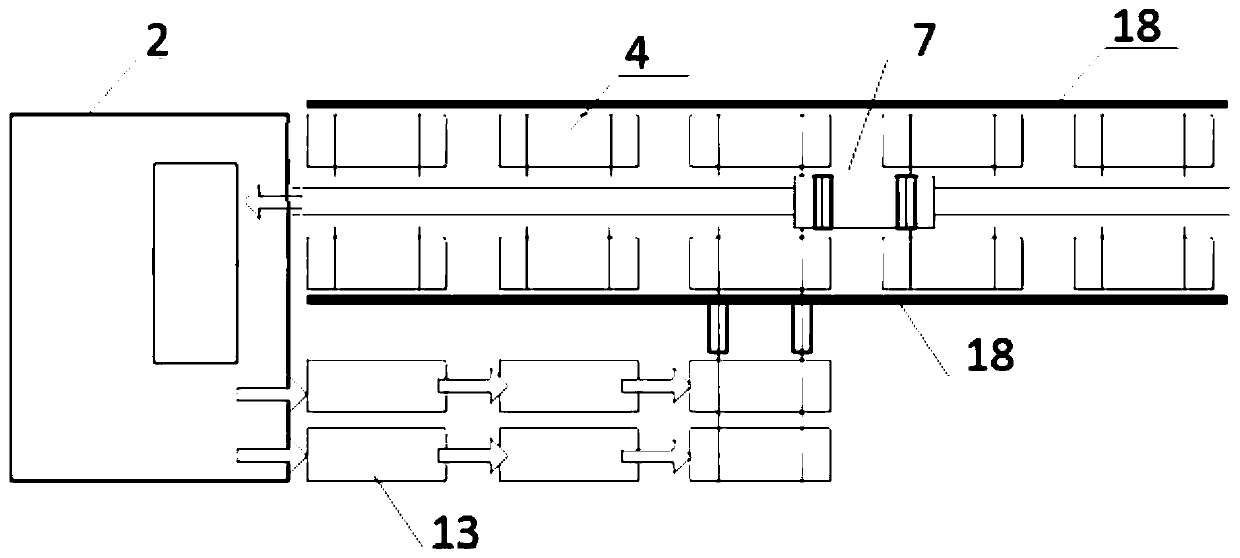

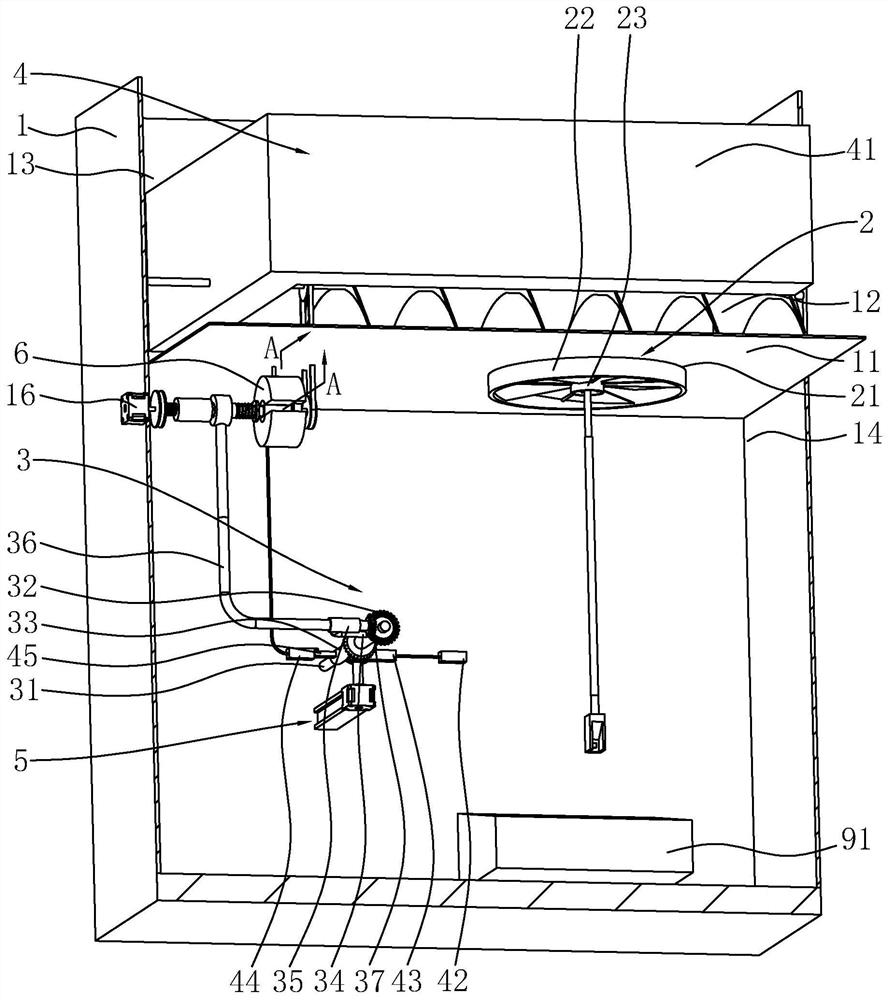

Prefabricated component production line

The invention provides a prefabricated component production line. The prefabricated component production line comprises a first area, a second area and curing kilns, and the curing kilns are arrangedat one ends of the first area and the second area in an adjoining neighbor mode side by side; the first area comprises a plurality of fixed stations arrayed in rows, bench formworks placed on the upper parts of the fixed stations, a horizontal track parallel to the fixed stations, a vertical track arranged on each fixed station and perpendicular to the horizontal track, and a child-mother vehicle,and the child-mother vehicle conveys the bench formworks into the curing kilns through the horizontal track and the vertical tracks; and the second area comprises a plurality of flowing stations anda transverse conveying line connecting the multiple flowing stations, and the bench formworks subjected to curing procedures in the curing kilns are circulated on all the flowing stations along the transverse conveying line. The prefabricated component production line can be suitable for production of prefabricated components with different structural types, has flexible production and organization modes, and can also achieve assembly line operation, the bench formworks enter the curing kilns for three-dimensional storage and curing, and the advantages of both a fixed bench formwork productionline process and an assembly line production process are achieved.

Owner:筑友智造智能科技有限公司

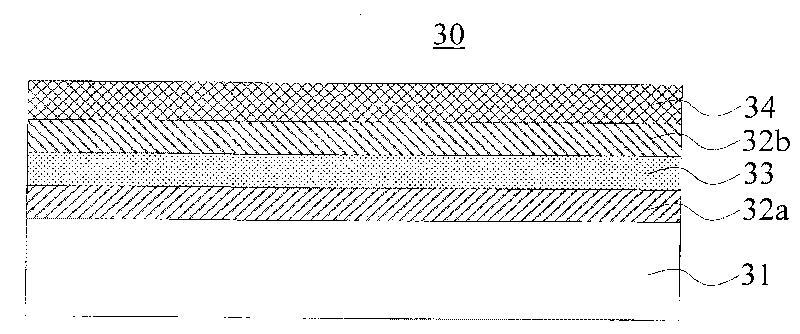

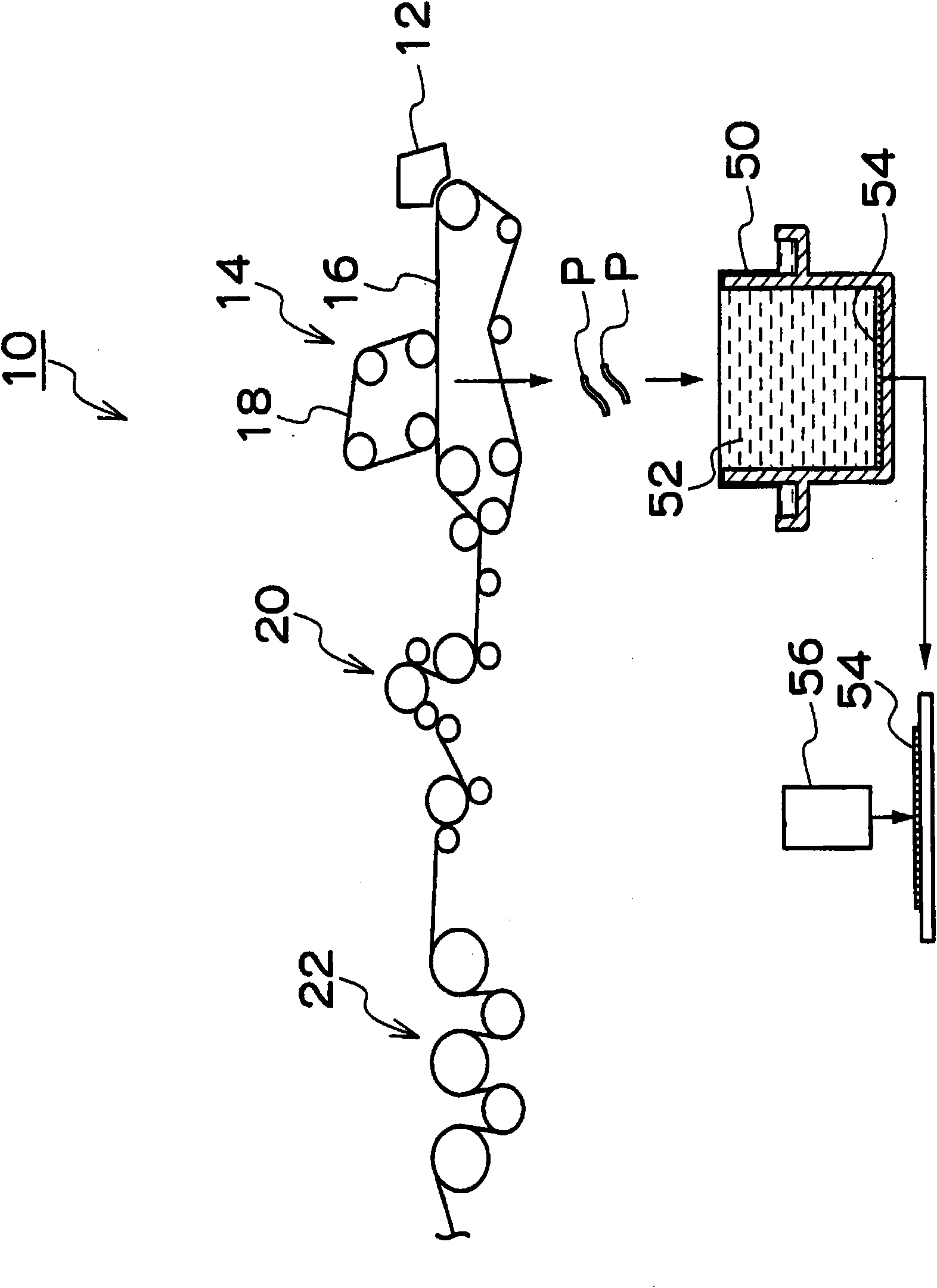

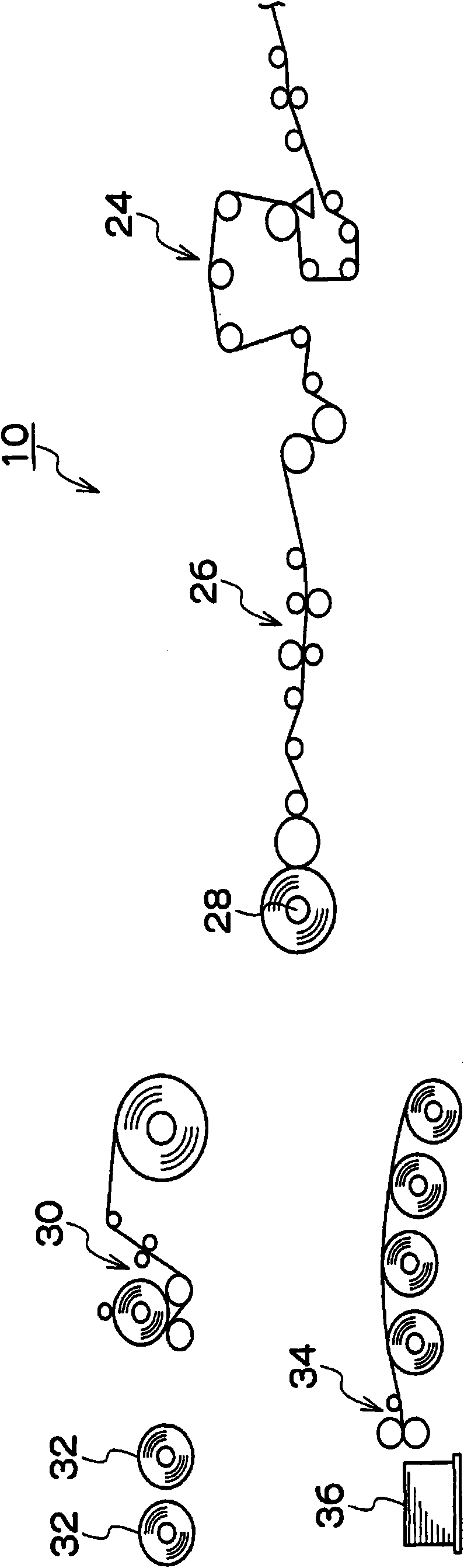

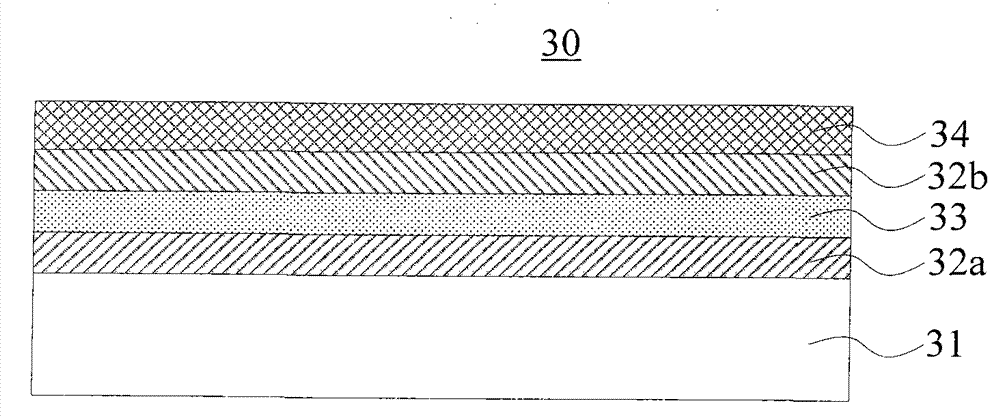

Paper quality management method and glass substrate backing paper making method

InactiveCN102418298AProductivity impactAvoid flawsSpecial paperPaper/cardboardFlat panel displayPapermaking

The invention provides a paper quality management method and a glass substrate backing paper making method. The paper quality management method is characterized in that a water spray nozzle is used for cutting off paper to selectively make the edge part (P) of the paper on a paper machine (10) at a papermaking process, the size of foreign matters contained in the edge part (P) is detected and determined, and quality management is conducted to the paper (36) made by the paper machine (10) according to the inspection result of the size of the foreign matters contained in the edge part (P). In other words, the specific size of the foreign matters causing flaws to a glass substrate (G) is taken as a threshold and classification management is conducted to the paper (36) batch by batch. The threshold, i.e. the threshold of the specific size of the foreign matters causing the flaws to the glass substrate (G) is 200mum according to experiments. Therefore, the selected paper with the edge part (P) containing the foreign matters with the size being below 200mum can be used as transport backing paper for the glass substrate (G) for a flat panel display, and the backing paper and other paper can be managed batch by batch.

Owner:ASAHI GLASS CO LTD

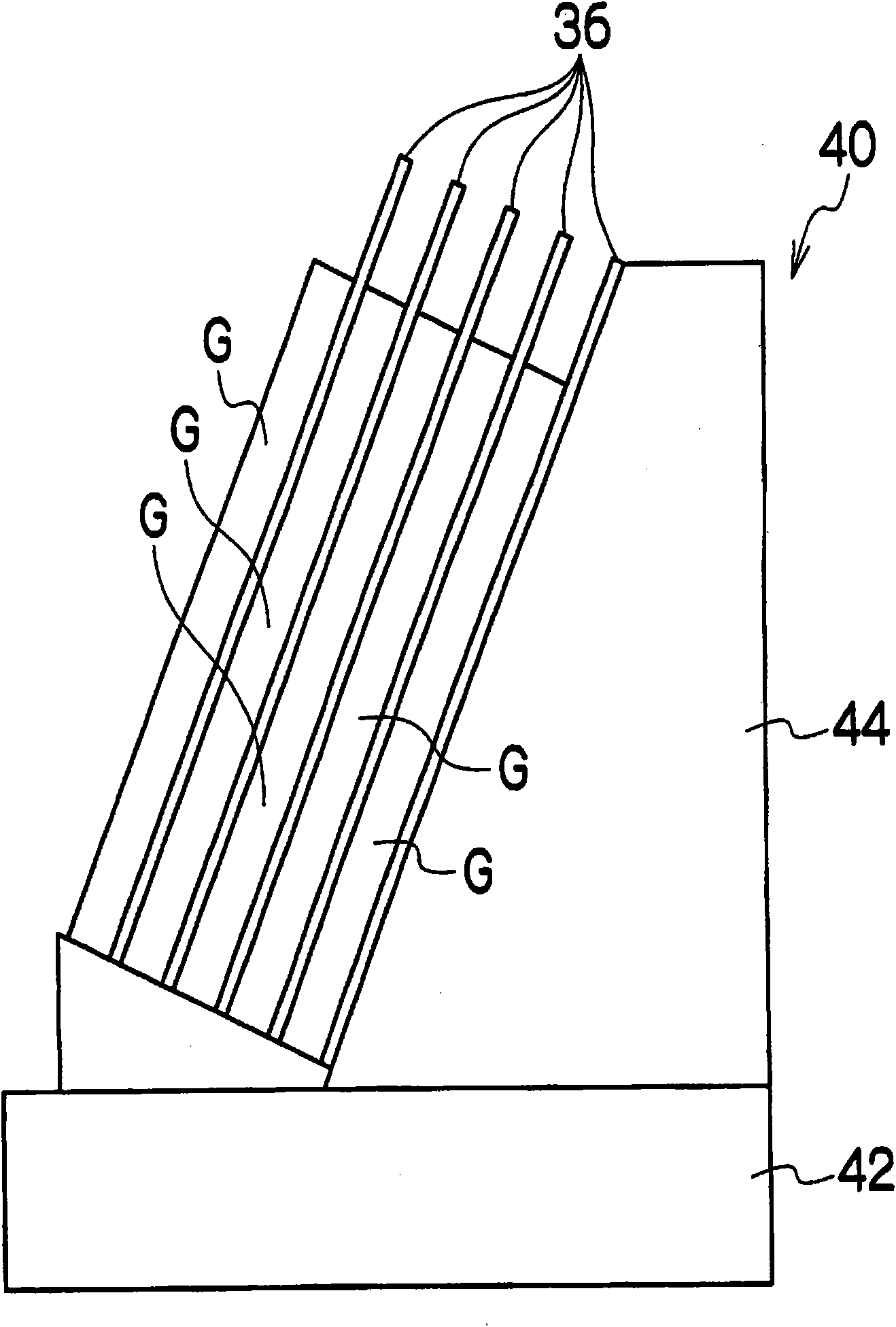

Preparation method of LED light-emitting device, and LED light-emitting device

InactiveCN112259660AIncrease productivityGood zoom effectNon-linear opticsSemiconductor devicesCompression moldingMaterials science

The invention provides a preparation method of an LED light-emitting device. The preparation method comprises the steps that S1, LED particles or LED chips are attached to a substrate of a LED light-emitting device; S2, the concave part of a lens insert on a lens mold plate is filled with a curing glue; S3, the substrate obtained in the step S1 is inversely pressed on the lens mold plate obtainedin the step S2, wherein the positions of the LED particles or the LED chips correspond to about the middle position of the concave part of the lens insert; and S4, the substrate and the lens mold plate which are pressed together in the step S3 are cured, after the curing glue is cured, the curing glue, the LED particles or the LED chips and the substrate are fixed together, and after mold opening,a LED light-emitting device is obtained. The invention further provides an LED light-emitting device, which is characterized in that LED particles or LED chips are located at the position about the middle of a lens, the lens is only provided with one optical face, and the lens is directly formed in a compression molding mode through a curing glue.

Owner:苏州东岩电子科技有限公司

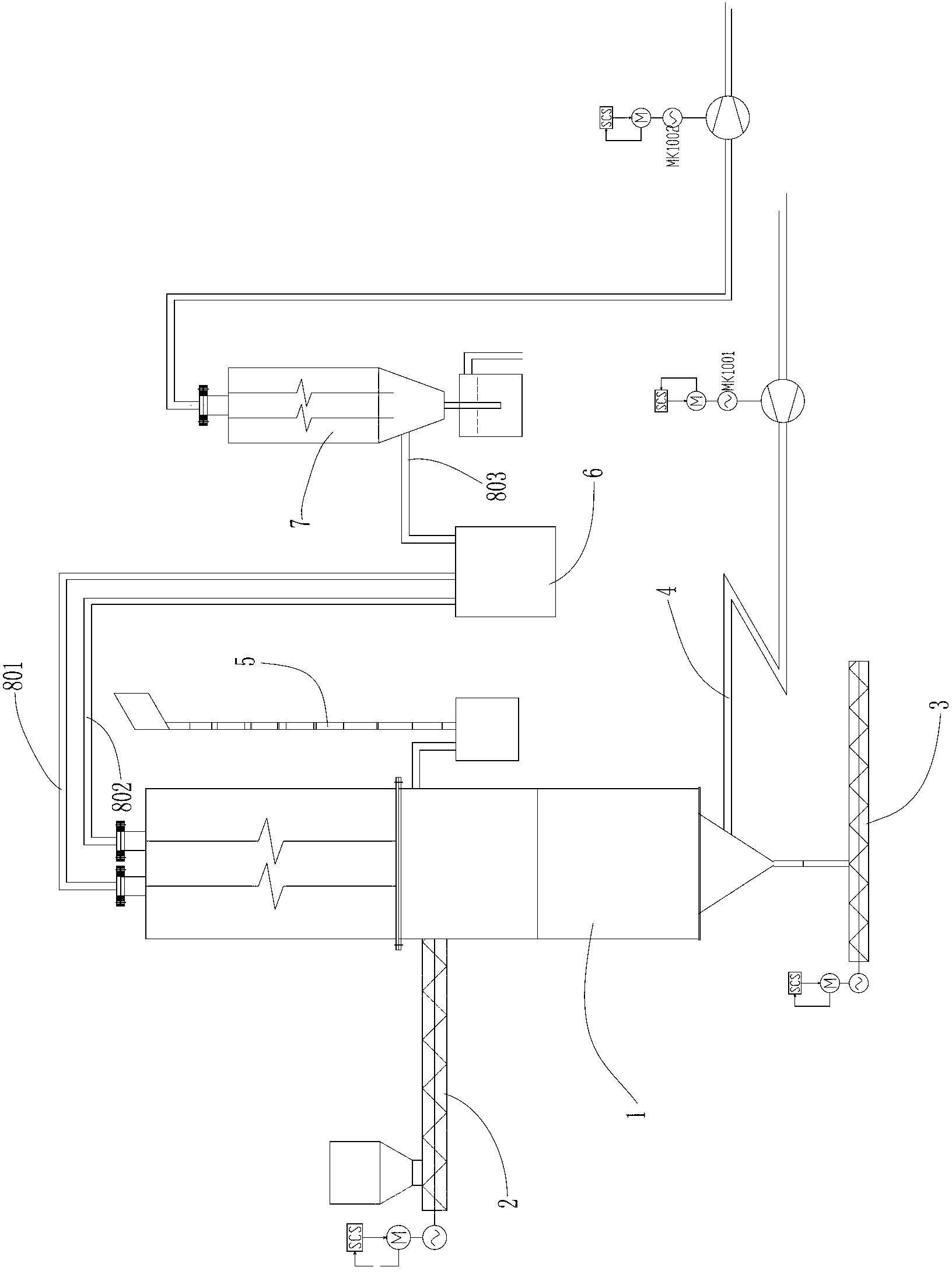

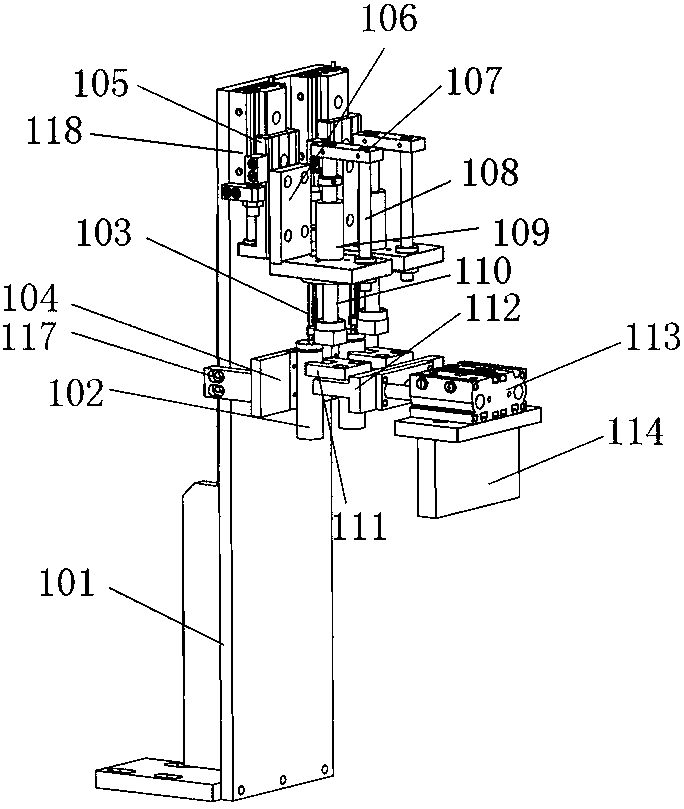

Method for automatically removing tar oil from fixed-bed biomass gasification furnace

ActiveCN103173251AProductivity impactCreate pollutionChemical industryFixed-bed gasificationTarProcess engineering

The invention provides a method for automatically removing tar oil from a fixed-bed biomass gasification furnace. The lower section of the gasification furnace produces biomass gas, the upper section of the gasification furnace is provided with a gas channel, the space in the gas channel is cooled, and the temperature of the gas produced by the lower section of the gasification furnace is reduced when the gas passes through the gas channel from bottom to top, so that tar oil in the gas is separated out. According to the method, the production efficiency of the gas is not influenced, and no pollution is caused to an external environment and circulating water; one part of the heat produced by gas cooling is used for drying fuel on a drying layer in the furnace, so that little heat is taken away through cooling of the circulating water; during cooling of the gas, a great amount of tar oil is recycled and participates in gasification again, so that the energy utilization rate is greatly improved, and the saved heat is more than the lost heat caused by cooling; and furthermore, as the temperature of the gas is low, the requirement on an auxiliary machine, an instrument, pipelines and the like is greatly reduced, and thus the investment cost is saved.

Owner:GUANGZHOU XINGUANGHE ENVIRONMENTAL PROTECTION TECH

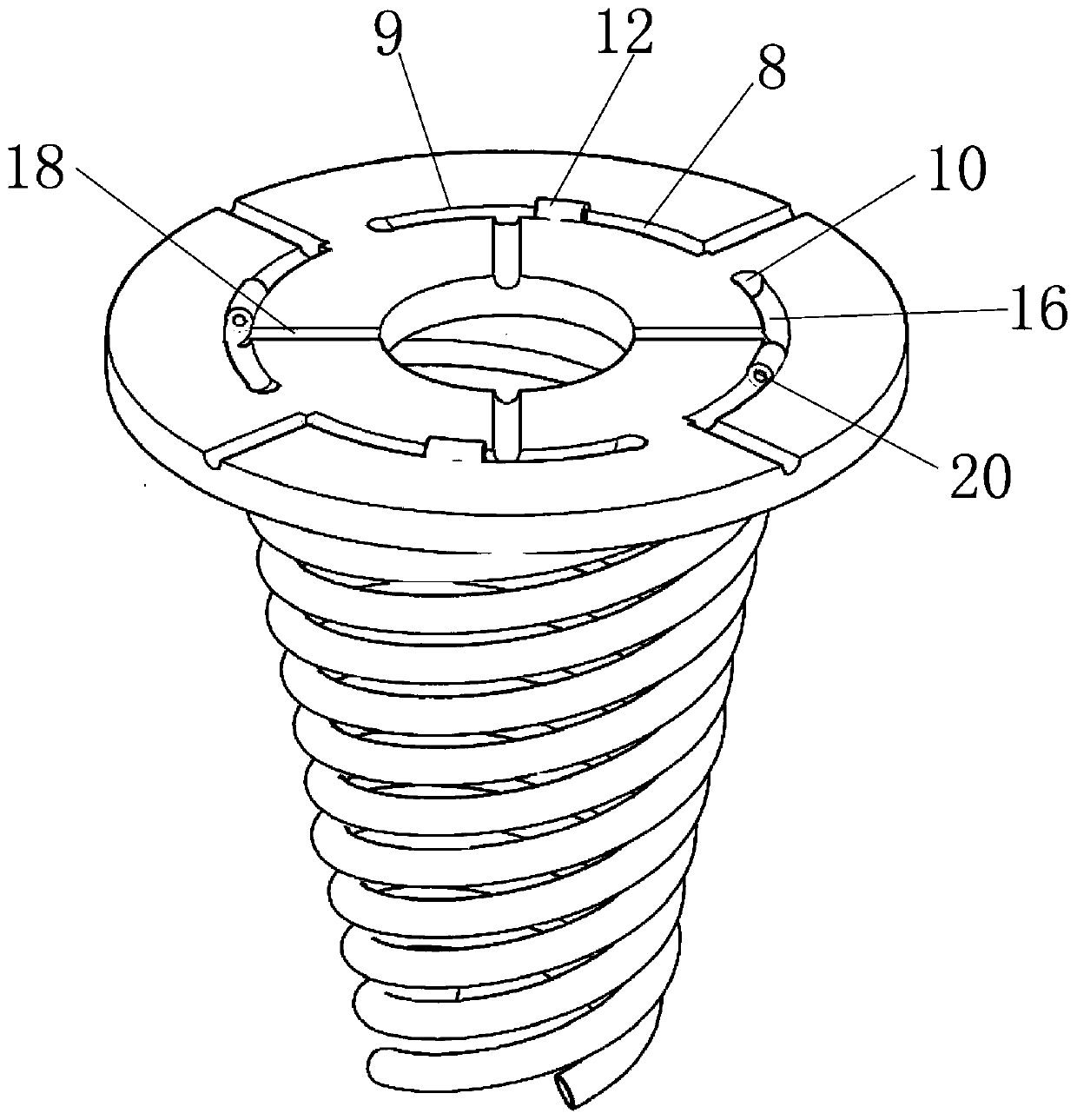

Injection mold mounting equipment

PendingCN109571865AReduce disassembly efficiencyReduce replacement efficiencyProduction lineEngineering

The invention discloses injection mold mounting equipment, and relates to the technical field of mold matched equipment. The injection mold mounting equipment comprises a base; the base is fixed to the ground through a plurality of bolts; the base is provided with a mounting part used for being connected with and fixing a mold; the mounting part comprises a mounting groove formed in the base; thewhole mounting groove is square; the mold is arranged inside the mounting groove; the mounting groove is further provided with clamping boards used for fixing the square mold; the clamping boards arearranged around the mounting groove and used for clamping and fixing the mold; the base is internally provided with a drive part used for driving the clamping boards to slide towards the mold synchronously or slide away from the mold synchronously; and by arranging the mounting base fixed to the ground to be matched with molds of different types and sizes, the molds are fixed in a movable connection mode, so that the situation that after the molds are stressed and deformed, the dismounting and replacing efficiency is reduced is avoided, and influence on the production efficiency of vehicle parts on a production line is prevented.

Owner:无锡艾赛特科技有限公司

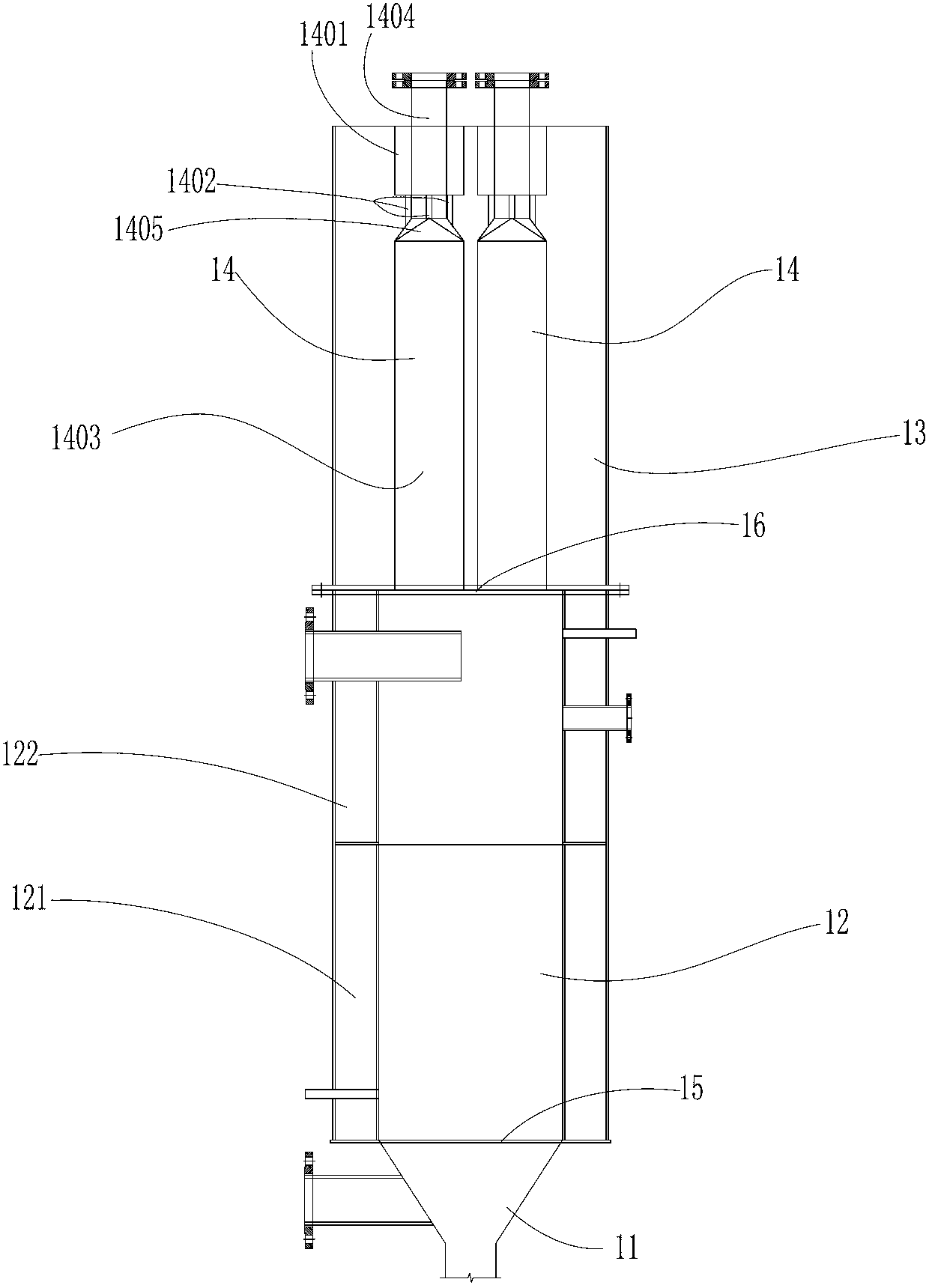

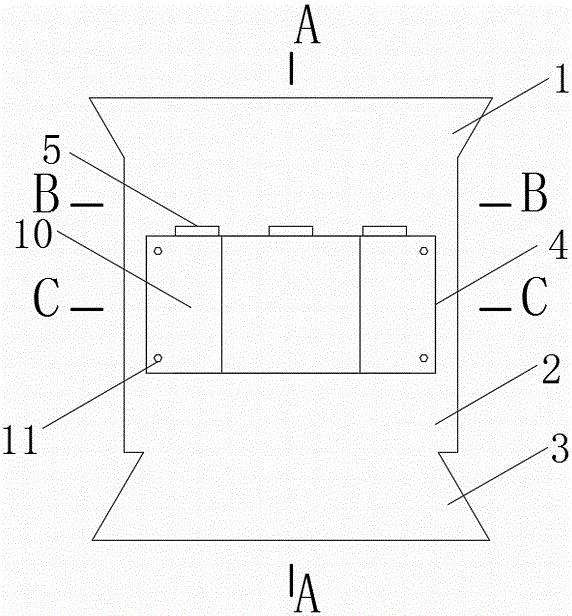

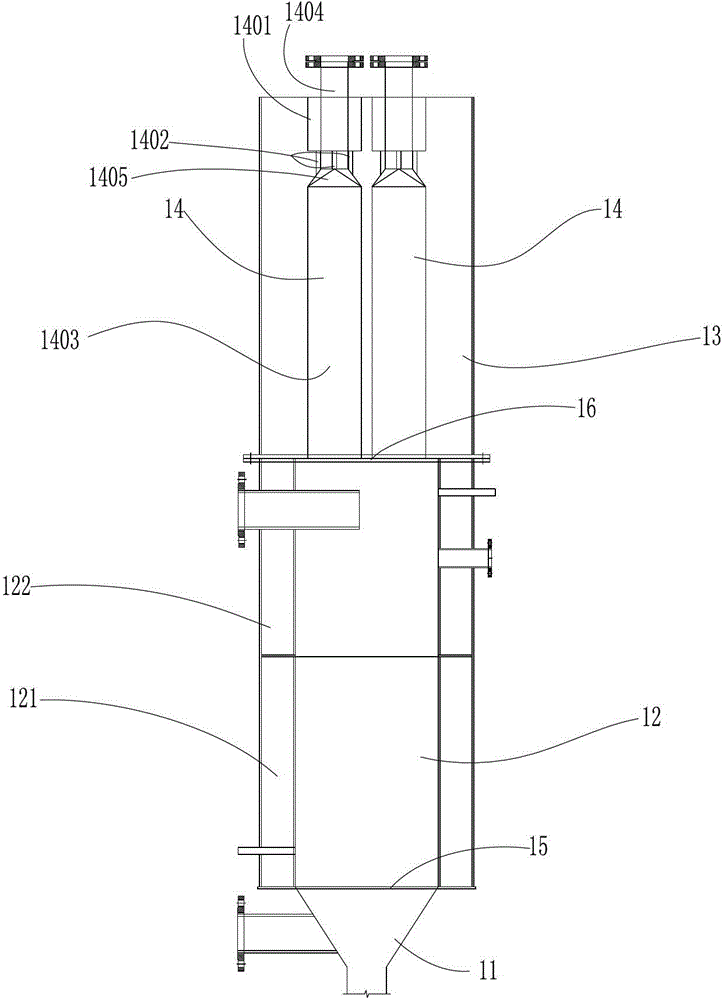

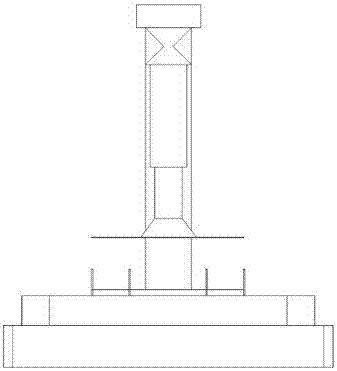

Casting mold for high-temperature alloy cast ingot with large height-diameter ratio and application

The invention provides a casting mold for a high-temperature alloy cast ingot with the large height-diameter ratio and application. The casting mold comprises a hollow casting mold unit, an opening is formed in the upper end of the casting mold unit, the casting mold unit is sleeved with a riser unit, the riser unit is sequentially provided with a casting head layer and a heat preservation layer from inside to outside, and the casting mold unit is sequentially provided with a first section, a second section and a third section from top to bottom; and the inner walls of the first section, the second section and the third section are flush in the vertical direction, and the outer wall of the second section retracts inwards relative to the first section and the third section in the horizontal direction. The invention further provides application of the casting mold for the high-temperature alloy ingot with the large height-diameter ratio. According to the casting mold for the high-temperature alloy cast ingot with the large height-diameter ratio and the application, the shrinkage porosity in the center of a casting can be remarkably reduced, the cast ingot quality and the product yield are improved, large-scale production is easy, and no adverse effect is generated on the production efficiency.

Owner:SHANGHAI JIAO TONG UNIV

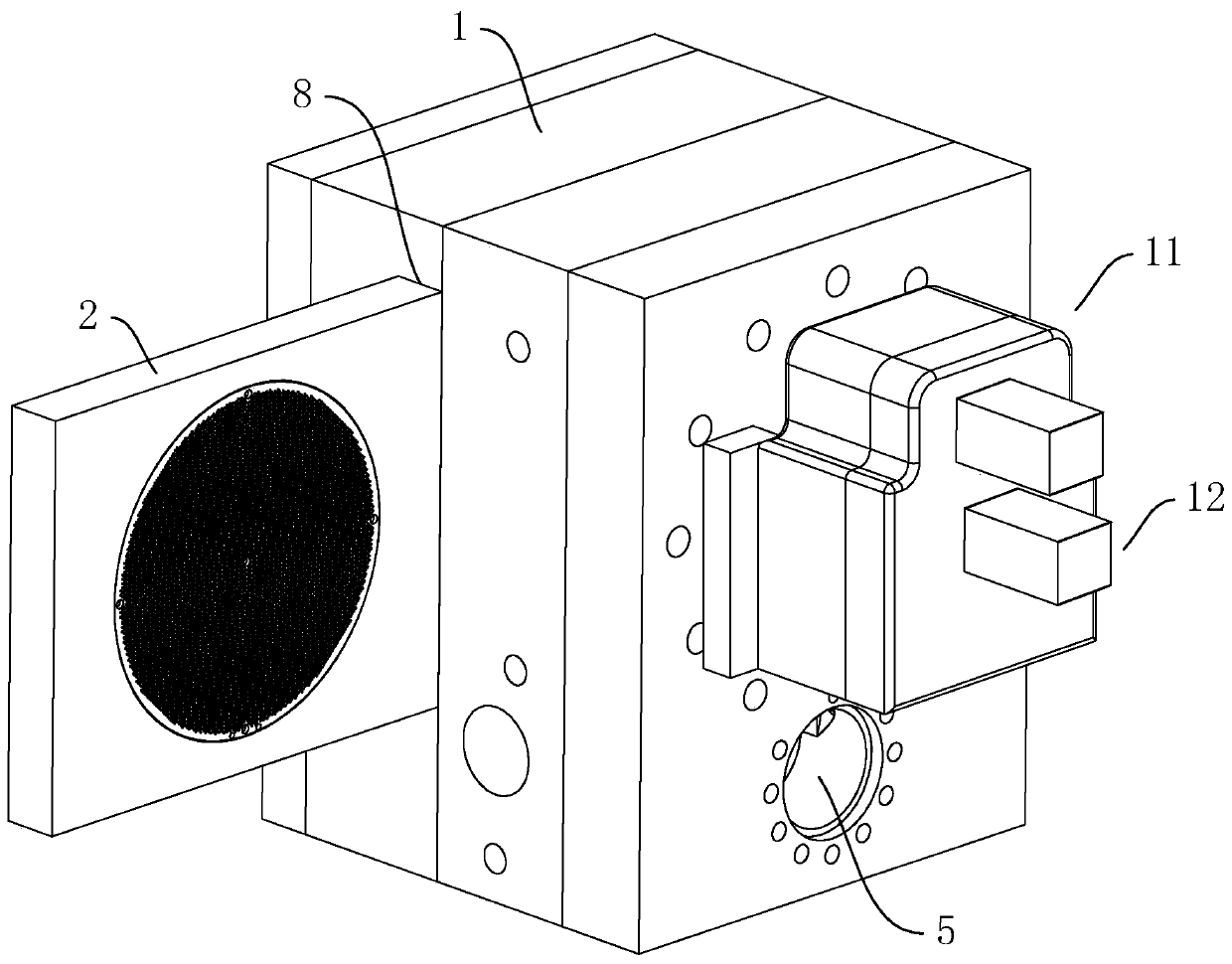

Recycled plastic melt filter

The invention discloses a recycled plastic melt filter and relates to the technical field of filtering devices. The key point of the technical scheme is that the recycled plastic melt filter comprisesa box body with a chamber inside, a filtering part and an impurity discharging part; the filtering part comprises a filtering screen plate arranged in the a cavity; the filtering screen plate partitions the cavity into a material feeding cavity and a material discharging cavity; a material inlet, an impurity discharging opening and a material outlet are formed in the box body; the impurity discharging part is arranged in the impurity discharging opening; a through groove communicating with the cavity is formed in the external wall of the box body; and the filtering screen plate is slidingly connected to the interior of the through groove. When the filtering screen plate needs to be washed or changed, the filtering screen plate can move to the external side of the box body only by applyinga tension to the filtering screen plate; and therefore, the washing and changing process of the filtering screen plate becomes more convenient and faster without detaching the box body and a scrapingknife; and moreover, the production efficiency of the recycled plastic melt filter is uneasily affected due to washing or changing the filtering screen plate.

Owner:ZHEJIANG LEENY TECH

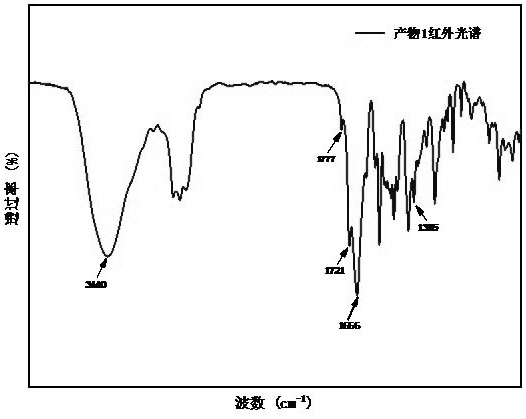

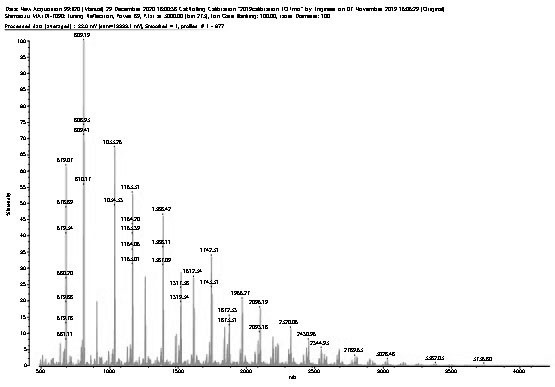

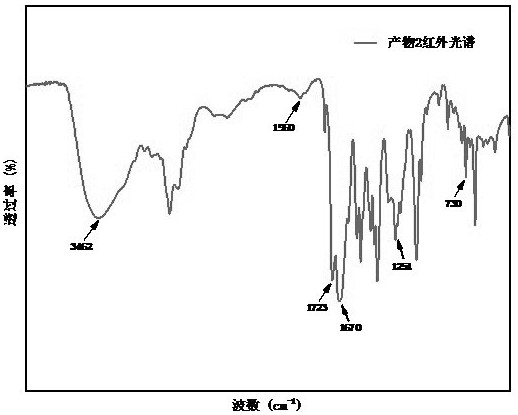

Polyamide-imide prepared by adopting microchannel reactor and preparation method of polyamide-imide

The invention discloses polyamide-imide prepared by adopting a microchannel reactor and a preparation method of the polyamide-imide, and the polyamide-imide is obtained by carrying out solution polycondensation on diisocyanate monomers and difunctional acid anhydride or carboxyl compounds in a continuous flow microchannel reactor according to a certain proportion under a certain condition. The polyamide-imide prepared by the invention has the advantages of high reaction efficiency, simplicity and convenience in operation, good safety, easiness in control, continuous production, cost saving and the like, is beneficial to large-scale production, and has wide application prospects.

Owner:LANZHOU UNIVERSITY

Square outer shell drying device used for electronic product production

InactiveCN111790583ADry evenlyEasy to fixPretreated surfacesCoatingsEngineeringMechanical engineering

The invention belongs to the technical field of electronic product production, and particularly provides a square outer shell drying device used for electronic product production. Based on the problemthat in the drying process of an existing drying device, the surface of an outer shell cannot be evenly heated and the outer shell is fixed from the outer surface so the drying effect of some parts is poor, the following scheme is proposed: the square outer shell drying device used for electronic product production comprises an air inlet disc; air inlets are evenly formed in the outer wall of theperiphery of the air inlet disc; air inlet structures are arranged on the inner walls of the air inlets; electrothermal films are fixed on the inner walls on one sides, near the air inlet structures,of the air inlets via screws; an installation opening is formed in the outer wall at the top of the air inlet disc; and a drying case is arranged on the inner wall of the installation opening. According to the device, airflow direction can be changed via air guiding holes formed in hollow triangular plates, hot air can be blown to the side surface of the outer shell and paddles, the drying effectof the outer shell is significantly improved, the outer shell can be fixed from the inside, and the outer shell drying quality is improved.

Owner:SUZHOU CHUANGMING SOFTWARE TECH CO LTD

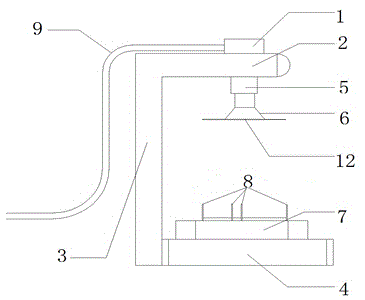

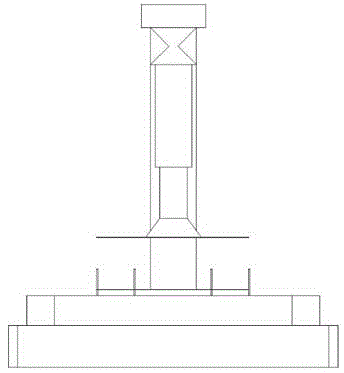

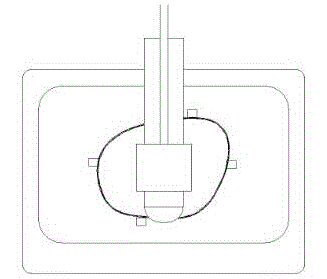

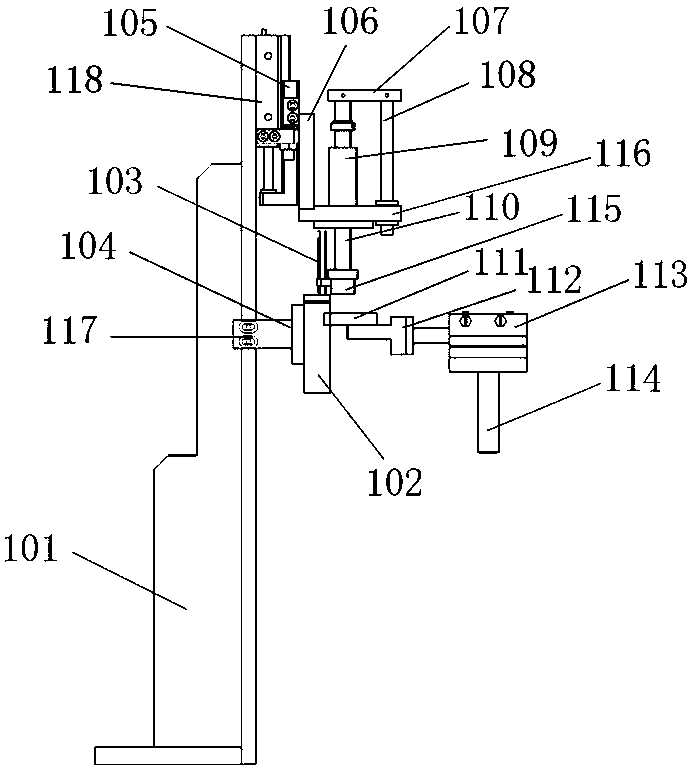

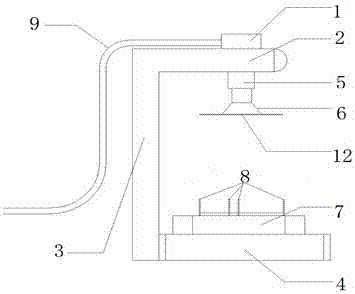

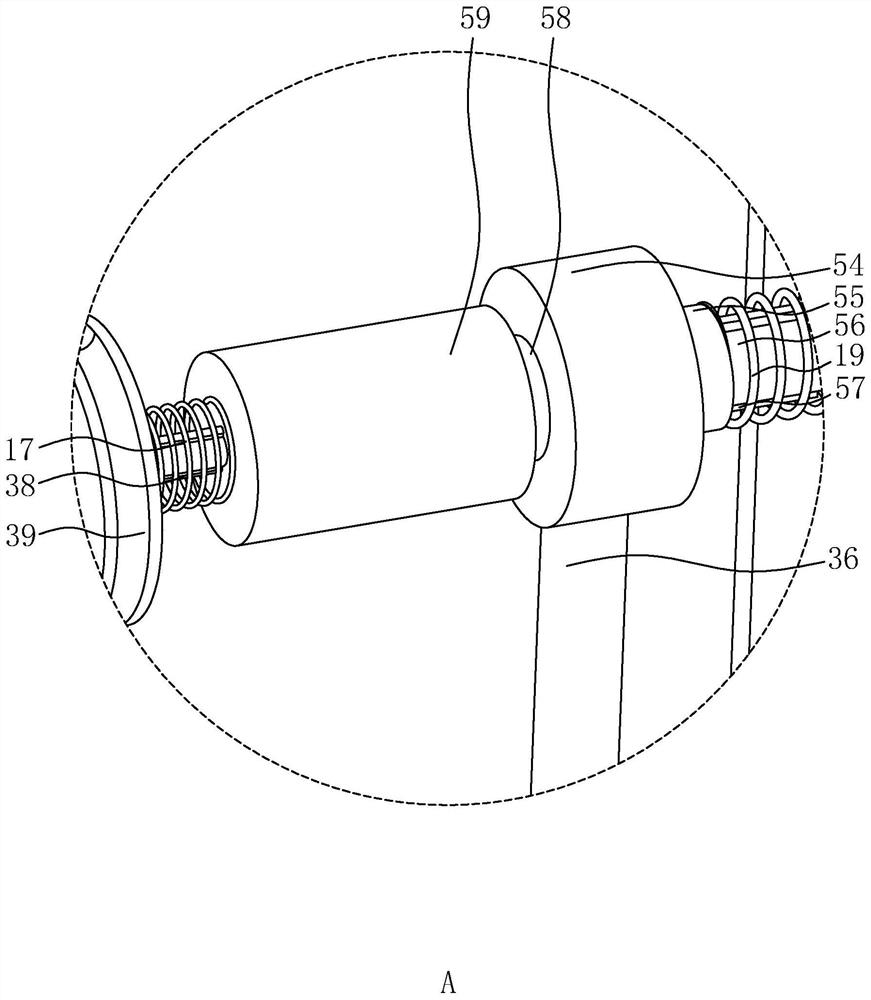

Outside rear-view mirror sheet pressure connecting tool

InactiveCN104874976AEven by forceImprove product qualityVehicle componentsMetal working apparatusReciprocating motionEngineering

The invention provides an outside rear-view mirror sheet pressure connecting tool which comprises a workbench, a cylinder, a press fit mechanism and a strong sponge body. The workbench is composed of a cantilever beam arranged horizontally, a base platform and a connection beam arranged vertically. The lower end of the connection beam is fixed to the base platform, one end of the cantilever beam is fixedly connected with the upper end of the connection beam, and the cantilever beam and the base platform are located on the same side of the connection beam. The cylinder is fixedly mounted on the cantilever beam and used for driving the press fit mechanism. The press fit mechanism comprises a press-down rod and a suction cup, the suction face of the suction cup is downward and used for sucking a mirror sheet, and the other face of the suction cup is connected with the lower end of the press-down rod. The upper end of the press-down rod is fixedly connected to the cylinder, and achieves vertical reciprocating motion under driving of the cylinder. The strong sponge body is fixed to the upper surface of the base platform, located below the suction cup, and used for placing and supporting a mirror frame. The outside rear-view mirror sheet pressure connecting tool has the advantages that the quality of product and the quality stability of the products are improved, the labor intensity is lowered, and the production efficiency is improved.

Owner:力帆科技(集团)股份有限公司

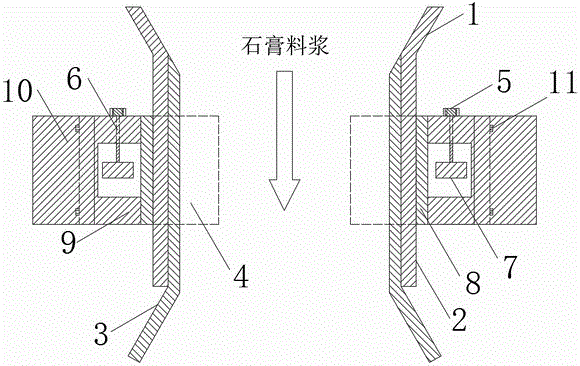

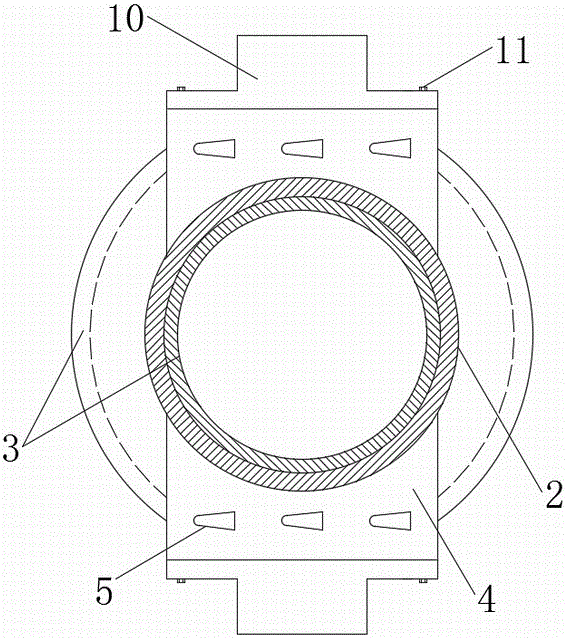

Device for preventing blockage of discharging opening of building plaster slurry blender

The invention discloses a device for preventing blockage of a discharging opening of a building plaster slurry blender. The device comprises a sleeve film, a fixing part and a vibration part. The sleeve film is closely attached to the inner wall of the discharging opening and is fixed to the outer wall through the fixing part according to the magnetic principle, and the sleeve film can be replaced at regular intervals according to needs. The vibration part is installed on the fixing part through a bolt, the vibration frequency can be adjusted according to the slurry viscosity, smooth discharging is guaranteed, and slurry attachment is prevented. The device has the beneficial effects of being simple in structure, efficient, stable, good in durability, easy to replace and the like, and the extremely-high application and popularization value is achieved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

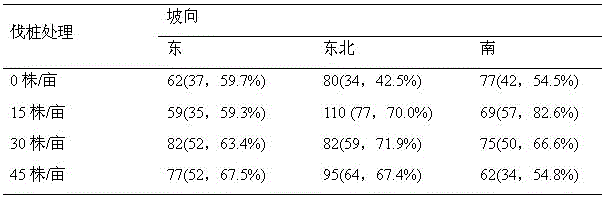

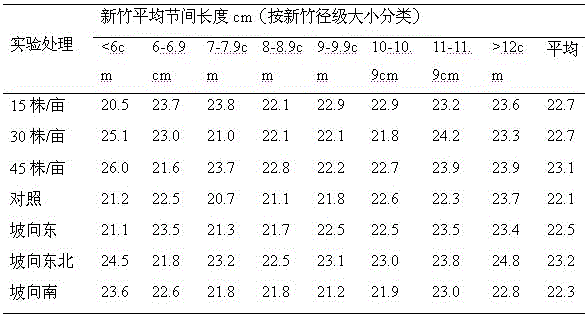

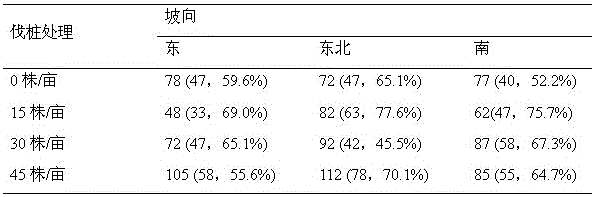

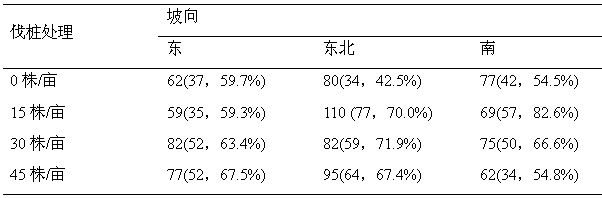

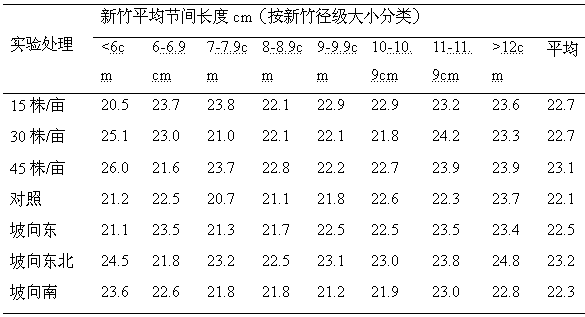

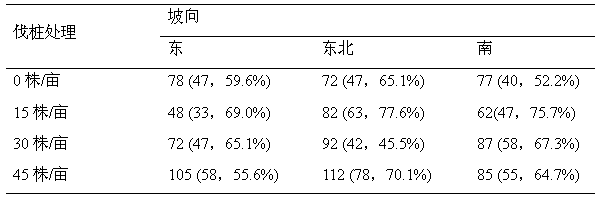

Water-saving phyllostachys edulis irrigation method

ActiveCN106106051ASustainable water supplyProductivity impactWatering devicesCultivating equipmentsWater storageWater saving

The invention discloses a water-saving phyllostachys edulis irrigation method. The water-saving phyllostachys edulis irrigation method comprises the following steps that 1, phyllostachys edulis forest land is selected, and horizontal ditches are dug; 2, PVC pipes with the diameter of 6-8 cm are sawed open from the middles and are respectively divided into two parts to establish horizontal water collecting ditches; 3, fixing columns are evenly distributed and arranged on two sides of each horizontal water collecting ditch in the length direction; 4, water collecting containers are arranged at the lower ends of the horizontal water collecting ditches and are covered with plastic films; 5, old phyllostachys edulis different in ground diameter are selected and are felled at the end of February, stump joints spacers are made through, stumps are fully filled with water every 15-30 days according to the weather condition, and water-saving irrigation is conducted on the phyllostachys edulis. The water-saving phyllostachys edulis irrigation method applies a field runoff field rainwater collecting method to establish an efficient and economical anti-drought technology of a water storage system using phyllostachys edulis stumps as cores, and provides sustainable water supply for phyllostachys edulis water-starved for a long time in middle-slope, upper-slope and remote regions so as to reduce the influence on phyllostachys edulis productivity of extreme or continuous drought.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

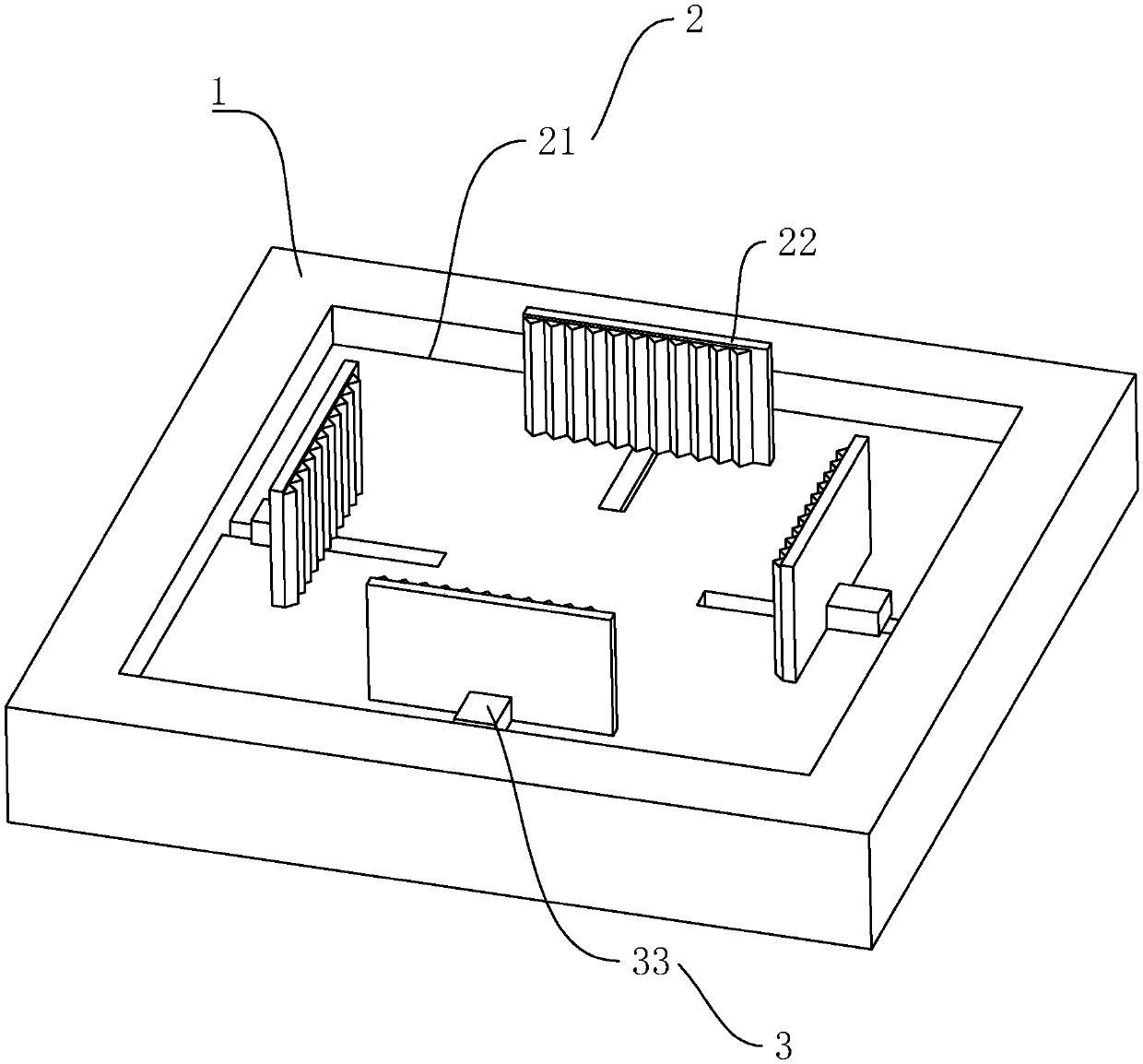

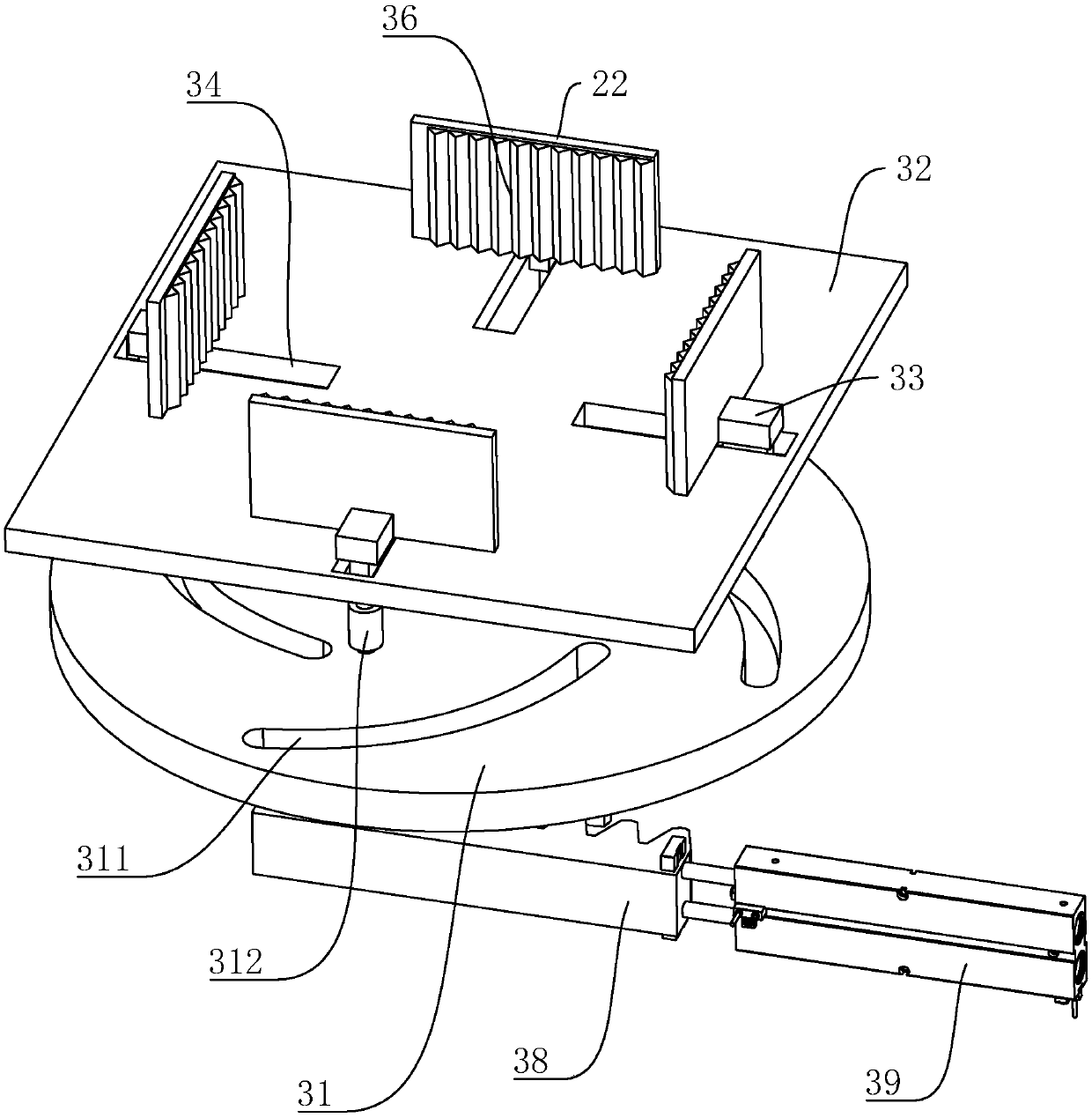

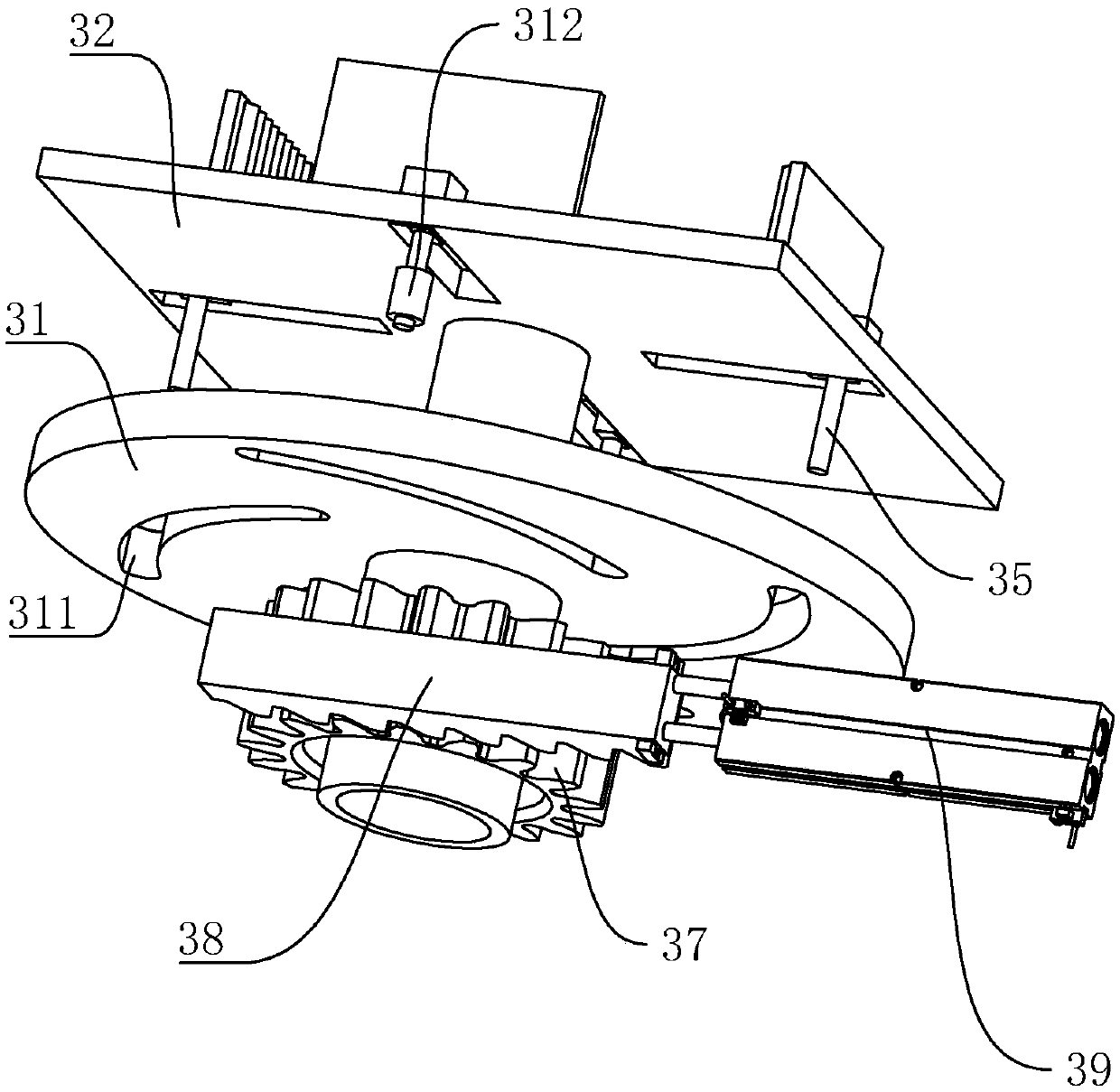

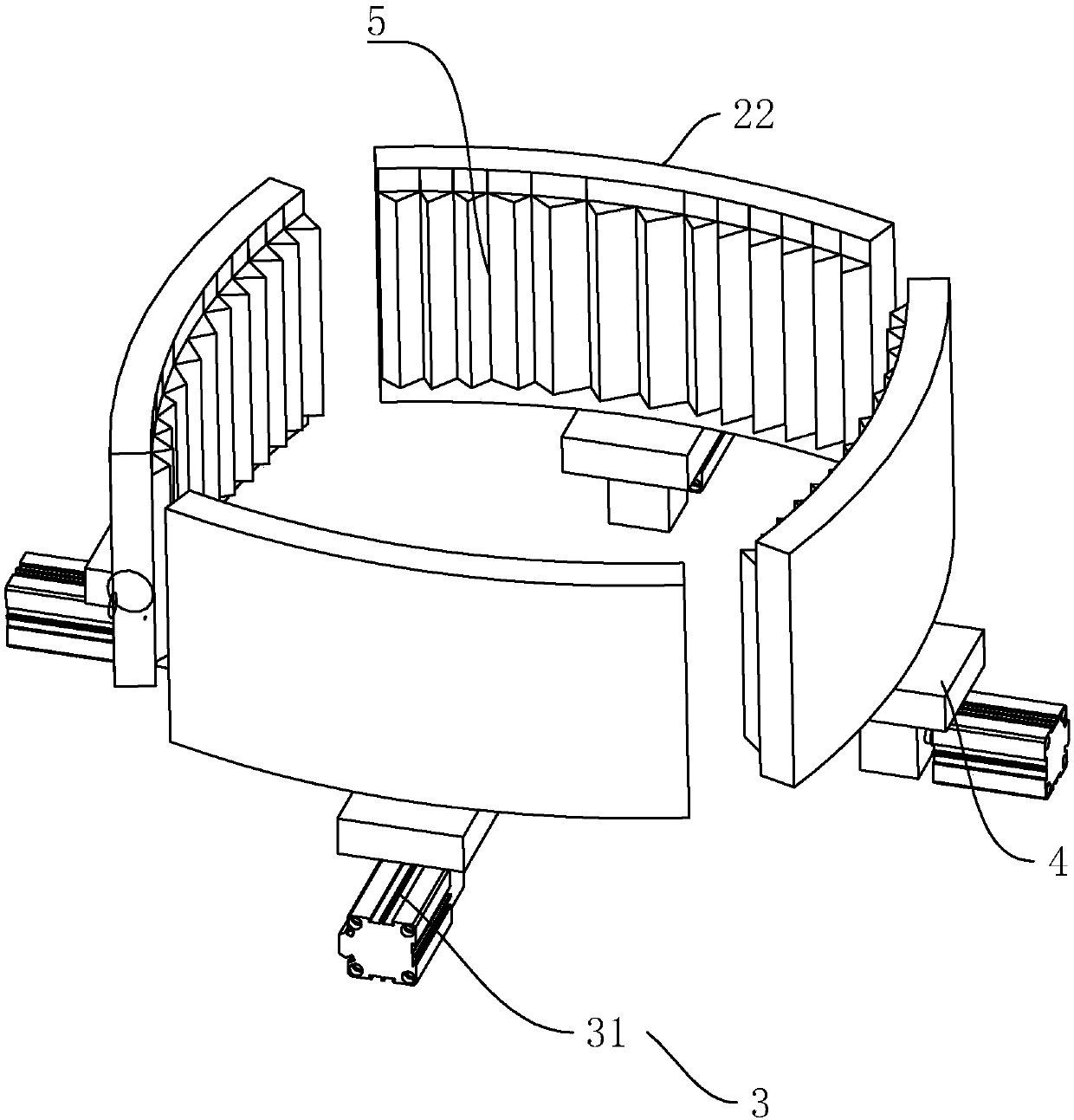

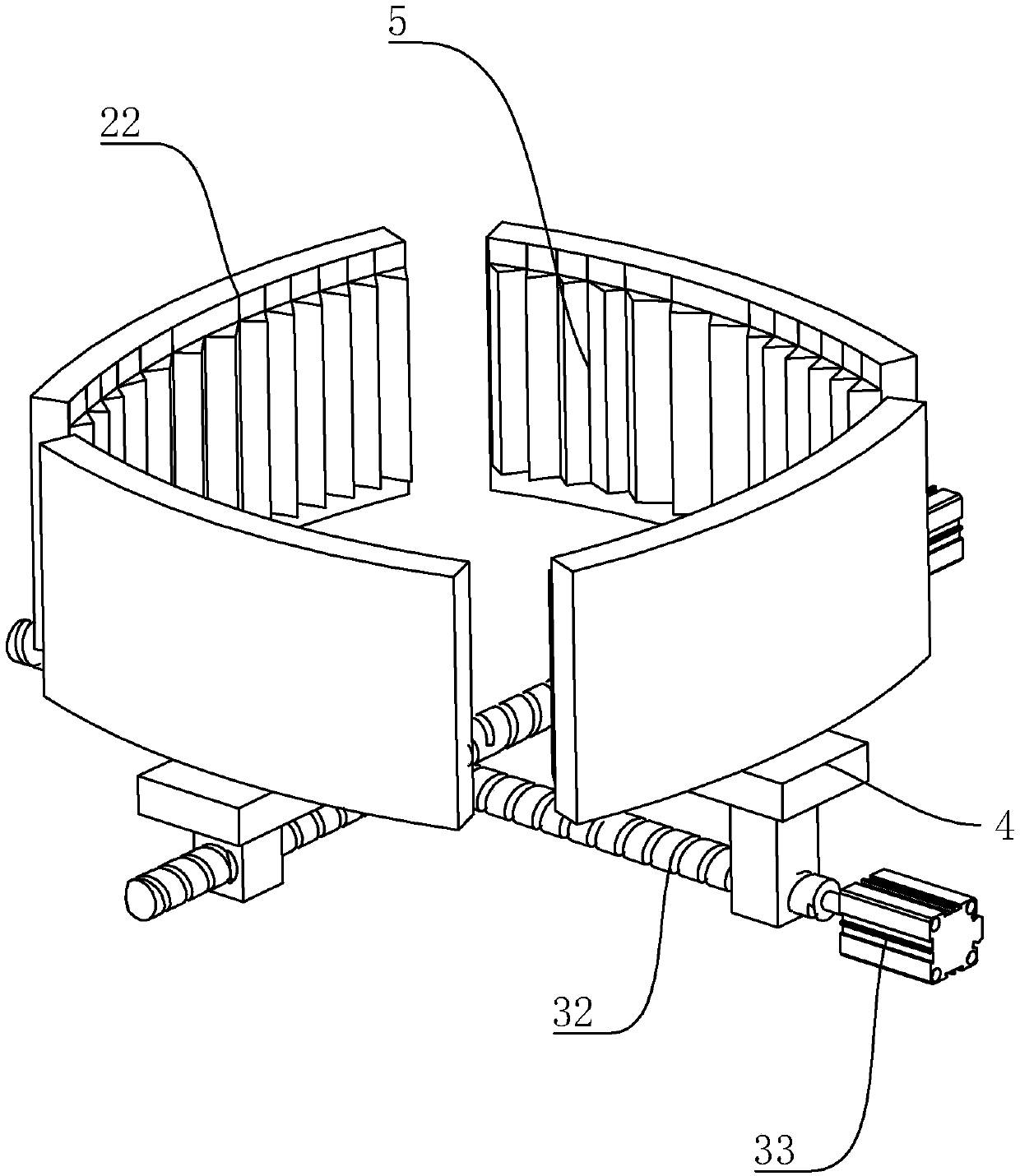

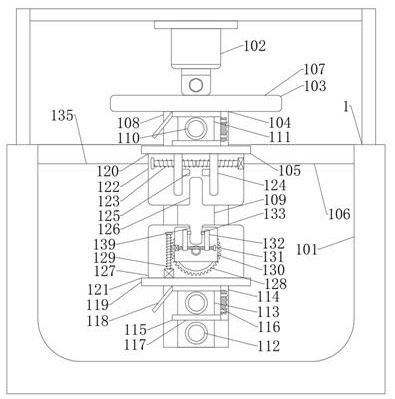

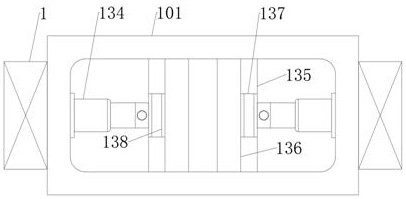

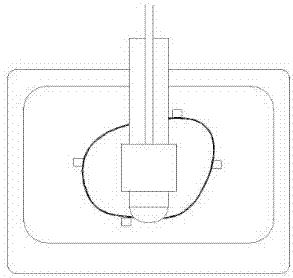

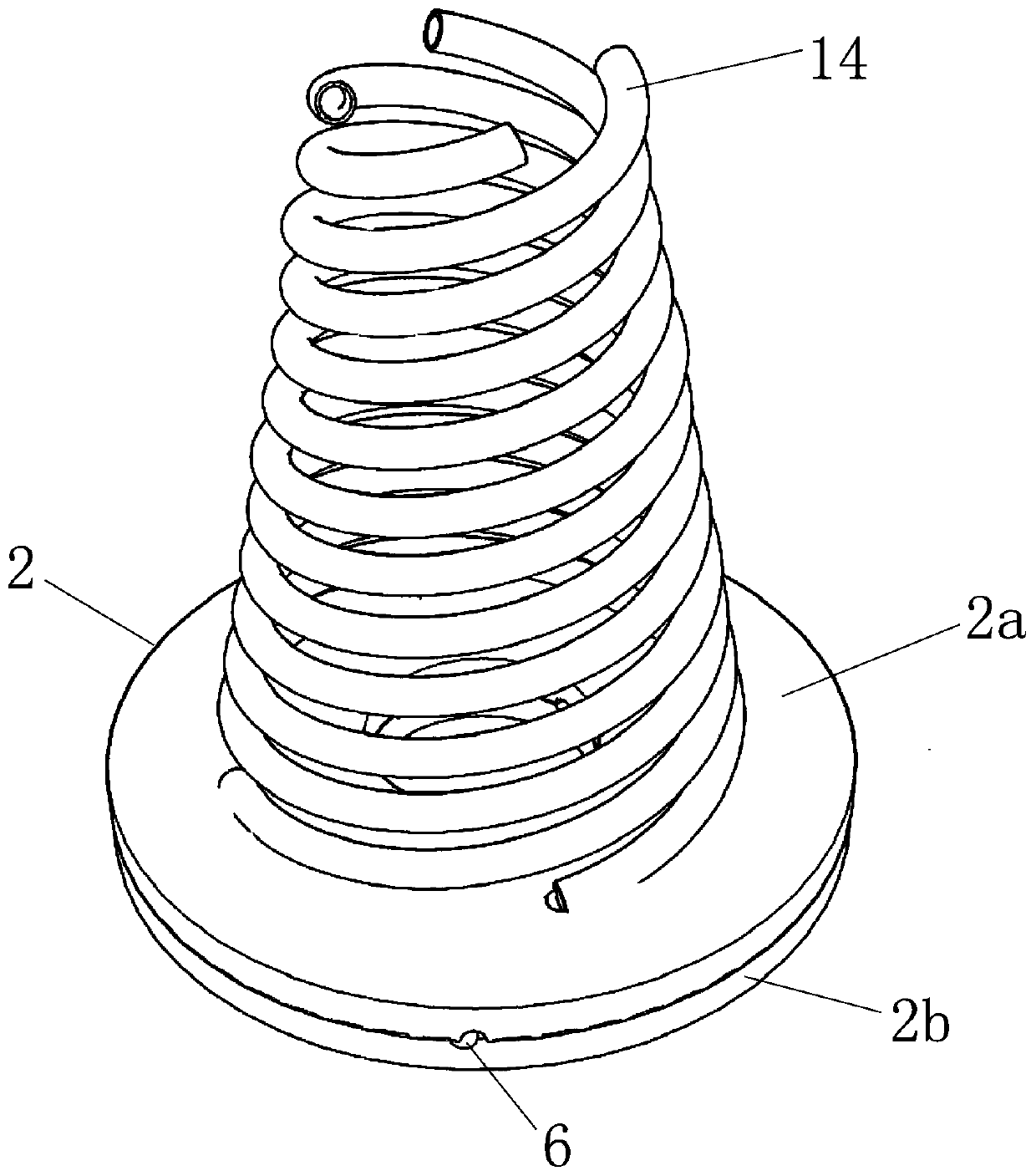

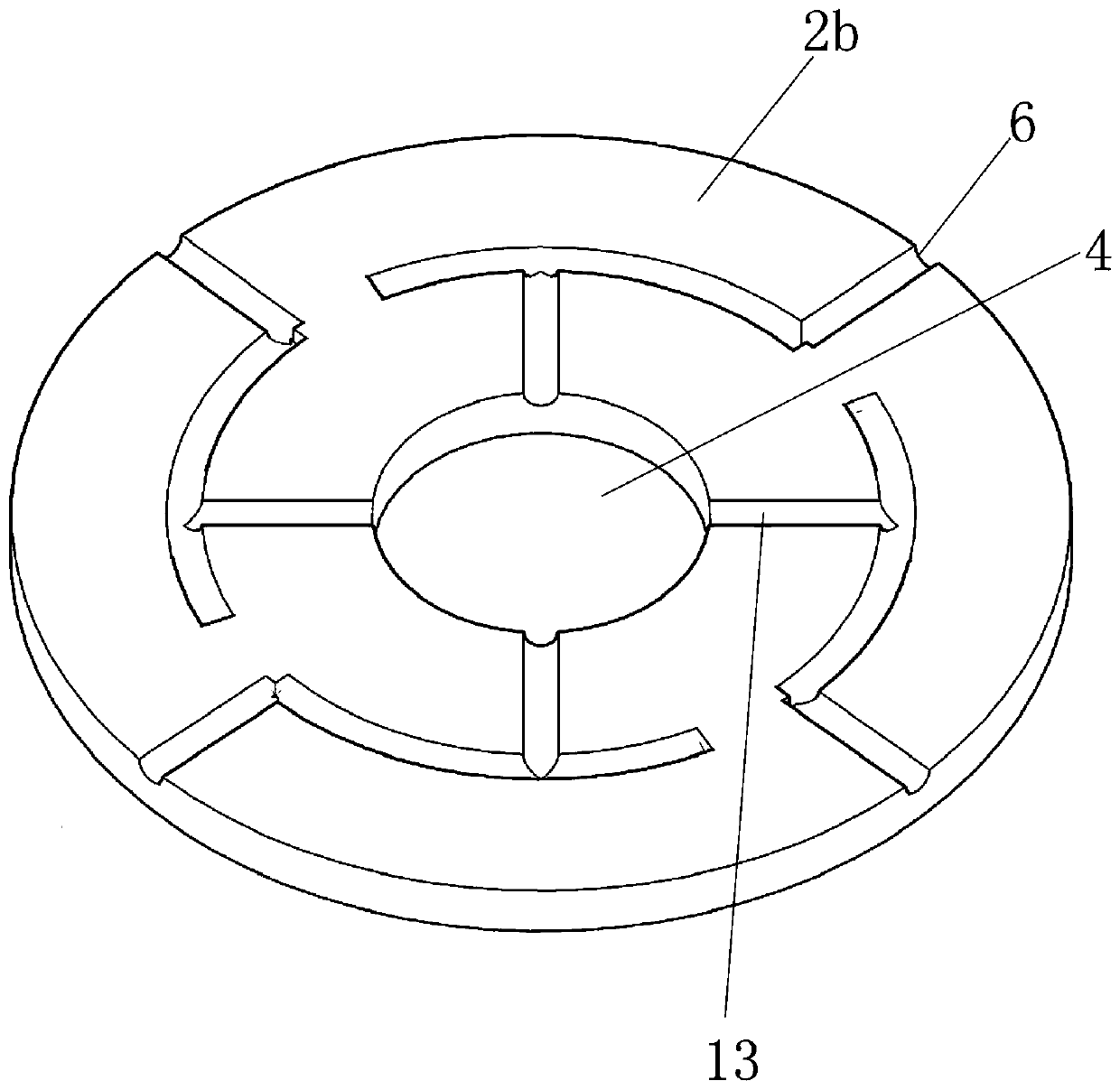

Mold mounting equipment

PendingCN109571866AFor the purpose of fixing the moldReduce disassembly efficiencyProduction lineEngineering

The invention discloses mold mounting equipment, and relates to the technical field of mold matched equipment. The mold mounting equipment comprises a base; the base is fixed to the ground through a plurality of bolts; the base is provided with a mounting part used for being connected with and fixing a mold; the mounting part comprises a mounting groove formed in the base; the whole mounting groove is circular; the mold is arranged inside the mounting groove; the mounting groove is further provided with movable boards used for fixing the circular mold; the movable boards are in an arc shape; the multiple movable boards are arranged along the circumference array of the circle center of the mounting groove; the base is internally provided with a drive part used for driving the multiple movable boards to slide towards the circle center of the mounting groove at the same time synchronously; and by arranging the mounting base fixed to the ground to be matched with molds of different types and sizes, the molds are fixed in a movable connection mode, so that the situation that after the molds are stressed and deformed, the dismounting and replacing efficiency is reduced is avoided, and influence on the production efficiency of vehicle parts on a production line is prevented.

Owner:无锡艾赛特科技有限公司

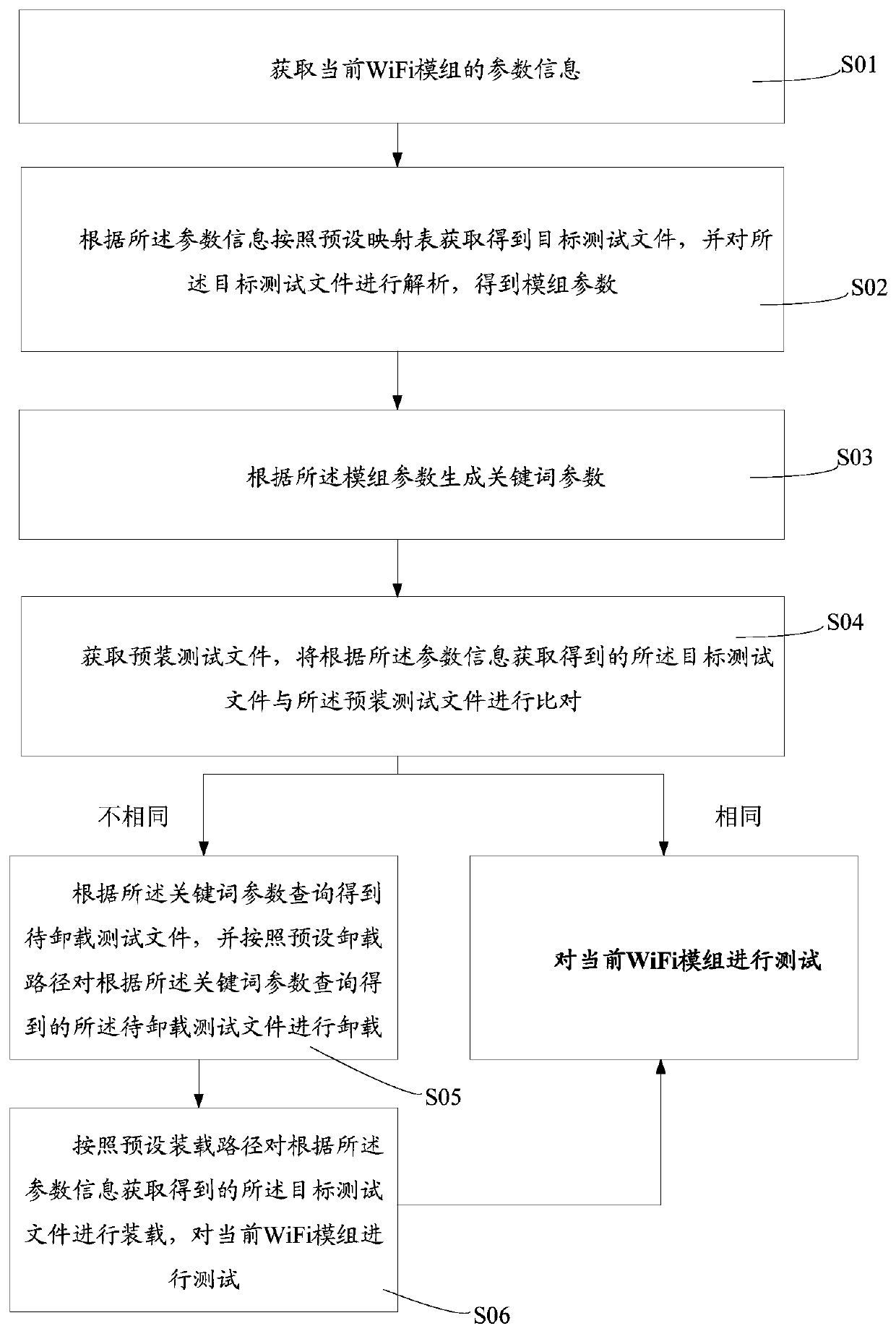

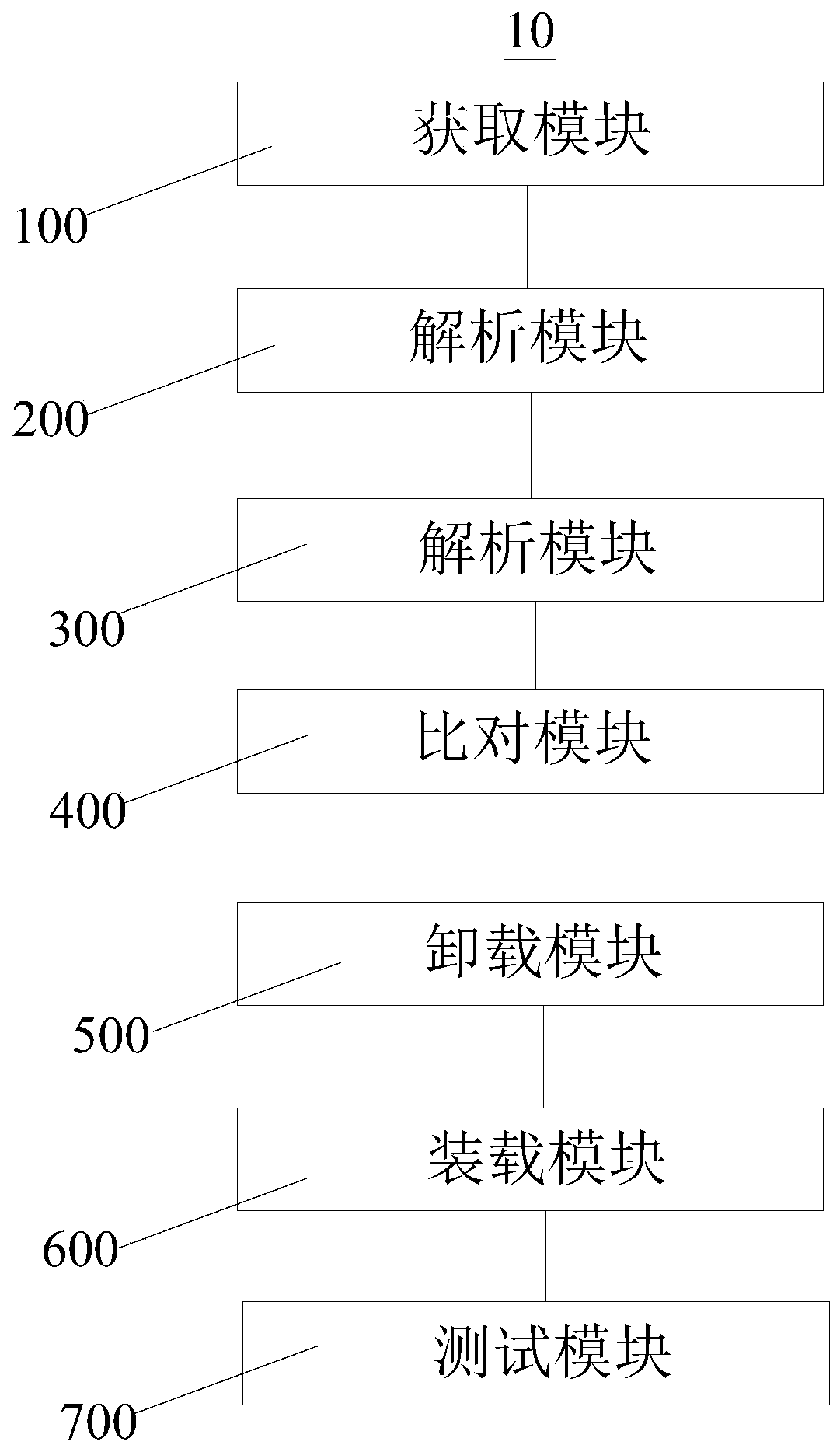

WiFi module testing method and system and storage medium

ActiveCN110896333AQuick testIncrease productivityTransmitters monitoringReceivers monitoringMaterial resourcesReliability engineering

The invention discloses a WiFi module testing method and system and a storage medium. The method comprises the following steps: acquiring parameter information of a current WiFi module; utilizing theparameter information to correspondingly obtain a target test file; analyzing the target test file to obtain module parameters; generating keyword parameters by utilizing the module parameters, judging whether the current WiFi module is the same as the previous batch of WiFi modules or not by comparing the pre-installed test file with the target test file, and if so, directly testing the current WiFi module by utilizing the pre-installed test target file; and if not, unloading the related to-be-unloaded test file by utilizing the keyword parameters, and testing the current WiFi module after the target test file is loaded. According to the method, the WiFi module can be quickly tested, related test files do not need to be manually unloaded, the production efficiency of enterprises is greatly improved, a large amount of manpower and material resources are saved, and the WiFi module can be quickly tested.

Owner:HUIZHOU GAOSHENGDA TECH CO LTD

High-efficiency cooling device used before cable plastic molding

ActiveCN114334292AImprove the effect of cooling protectionAvoid lifeCable/conductor manufactureEngineeringElectric cables

The invention discloses an efficient cooling device before cable plastic molding, which comprises traction mechanisms arranged at the two ends of a contact type cooling mechanism and used for pulling a thick wire to continuously pass through the contact type cooling mechanism, and the cooling mechanism comprises a cooling groove, a lifting device and a reverse twisting type contact device, through the winding effect that the reverse twisting type contact device reversely rotates around the twisting direction of the thick wire to temporarily make contact with the thick wire, the surface of a small wire on the thick wire makes complete contact with talcum powder, the cooling protection effect on the thick wire is improved, the thickness of the thick wire is reduced, and the service life of the thick wire is prolonged. The problems that the service life of the cable is shortened and the use safety is reduced due to the fact that the thick wire is heated and adhered during plastic molding are solved, and the reverse twisting type contact device and the thick wire move synchronously, so that the influence on the production efficiency of cable processing is avoided.

Owner:南通永祥机电有限公司

Touch panel and manufacturing method thereof

ActiveCN101751178BReduce manufacturing costIncrease productivityInput/output processes for data processingTouch panelElectrical and Electronics engineering

The invention relates to information input technology, in particular to a touch panel and a manufacturing method thereof. The touch panel comprises a substrate and an electrode layer. The electrode layer is formed on the substrate and comprises a plurality of parallel X-axis traces, a plurality of parallel Y-axis traces, a plurality of bridge structures and a plurality of insulation blocks. The plurality of X-axis traces intersect with the plurality of Y-axis traces, and the plurality of Y-axis traces are partitioned into a plurality of units by the plurality of X-axis trances. The bridge structures are positioned at intersections of the X-axis traces and the Y-axis traces and are used for connecting adjacent two units which are positioned on the two sides of the same X-axis trace and belong to the same Y-axis trace. The bridge structures are formed on the substrate; the insulation blocks are arranged on the bridge structures; the overlapped parts of the X-axis traces and the bridge structures are positioned on the insulation blocks; and the X-axis traces are insulated from the bridge structures through the insulation blocks. A manufacturing material and a process of the bridge structures are the same as the manufacturing material and the process of the X-axis traces and the Y-axis traces.

Owner:SHENZHEN LAIBAO HI TECH

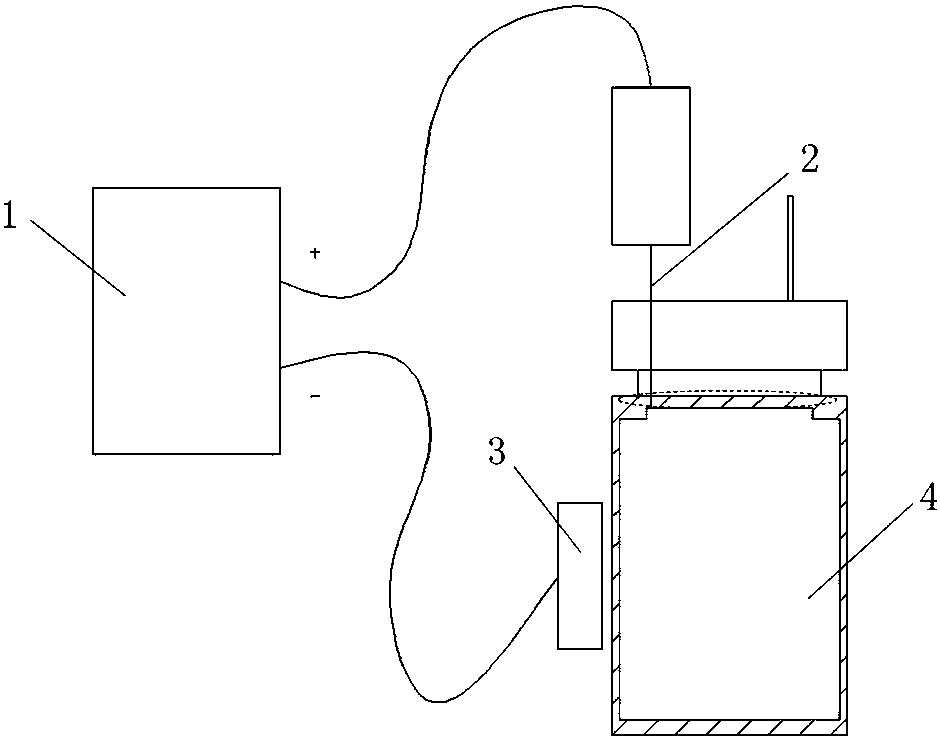

Lithium ion battery floating liquid detection device and floating liquid detection method

PendingCN107703455APrevent flowProductivity impactResistance/reactance/impedenceElectrical testingProduction lineInternal resistance

The invention discloses a lithium ion battery floating liquid detection device, which comprises an internal resistance detector, a positive electrode probe connected with a positive electrode of the internal resistance detector, and a negative electrode stopper connected with a negative electrode of the internal resistance detector. The lithium ion battery floating liquid detection device furtherincludes a support base and a positive electrode probe position control component. The positive electrode probe is fixedly mounted on the positive electrode probe position control component. The positive electrode probe position control component comprises a positive electrode cylinder and is slidably connected onto the support base. The positive electrode cylinder drives the positive electrode probe position control component to move so as to drive the positive electrode probe to move. The lithium ion battery floating liquid detection device of the invention uses the positive electrode probeand the negative electrode stopper of the internal resistance tester to test the internal resistance of lithium ion batteries so as to distinguish and eliminate floating liquid batteries, has a simpleand reasonable structure, forms an integrated production line with the existing lithium-ion battery manufacturing line, effectively sorts out the floating batteries without affecting the current production efficiency of the lithium-ion batteries, and prevents poor batteries with a floating liquid inside from flowing to the next station.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

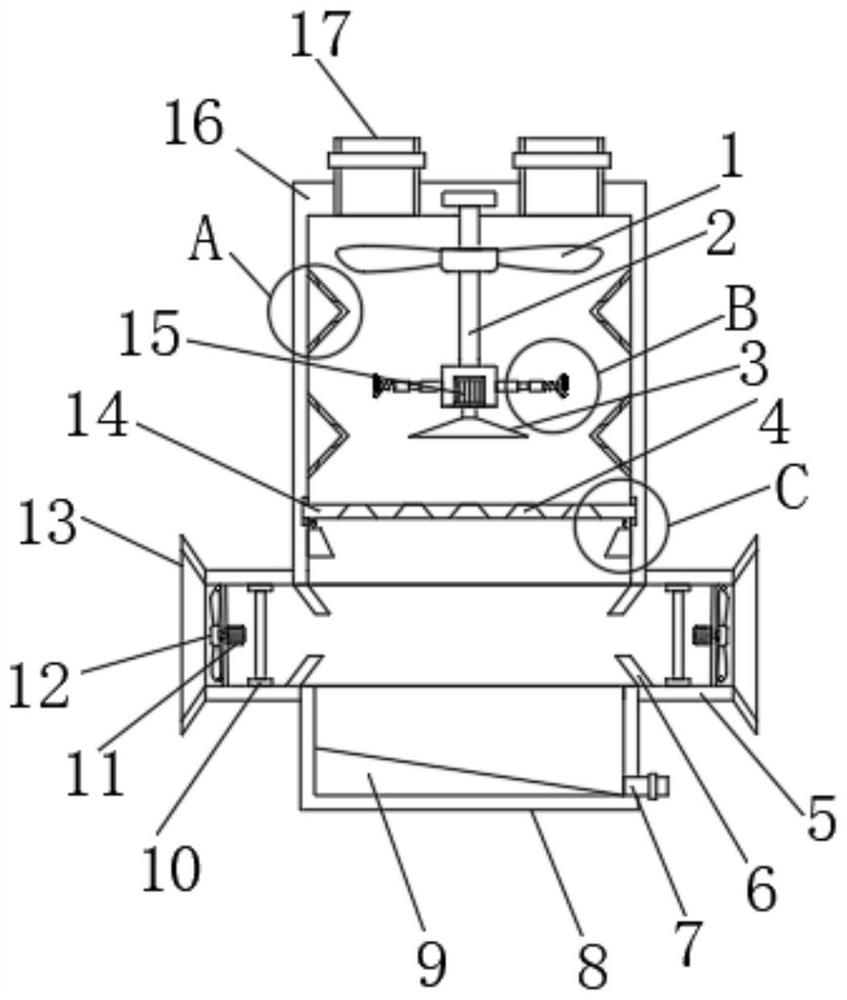

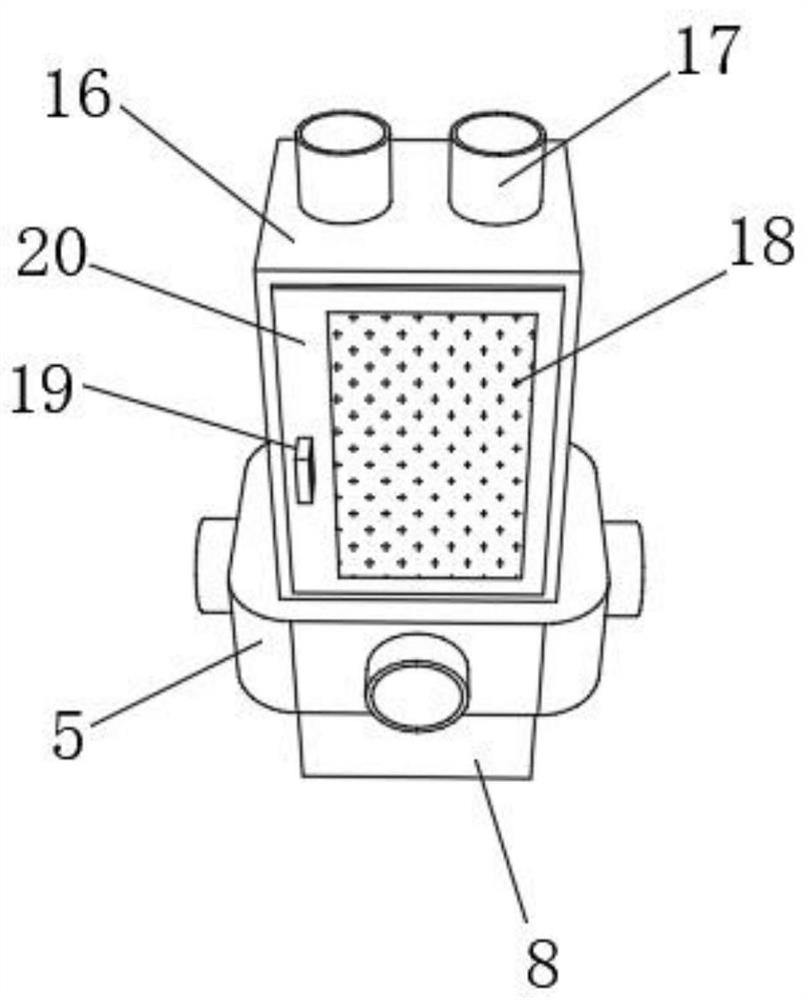

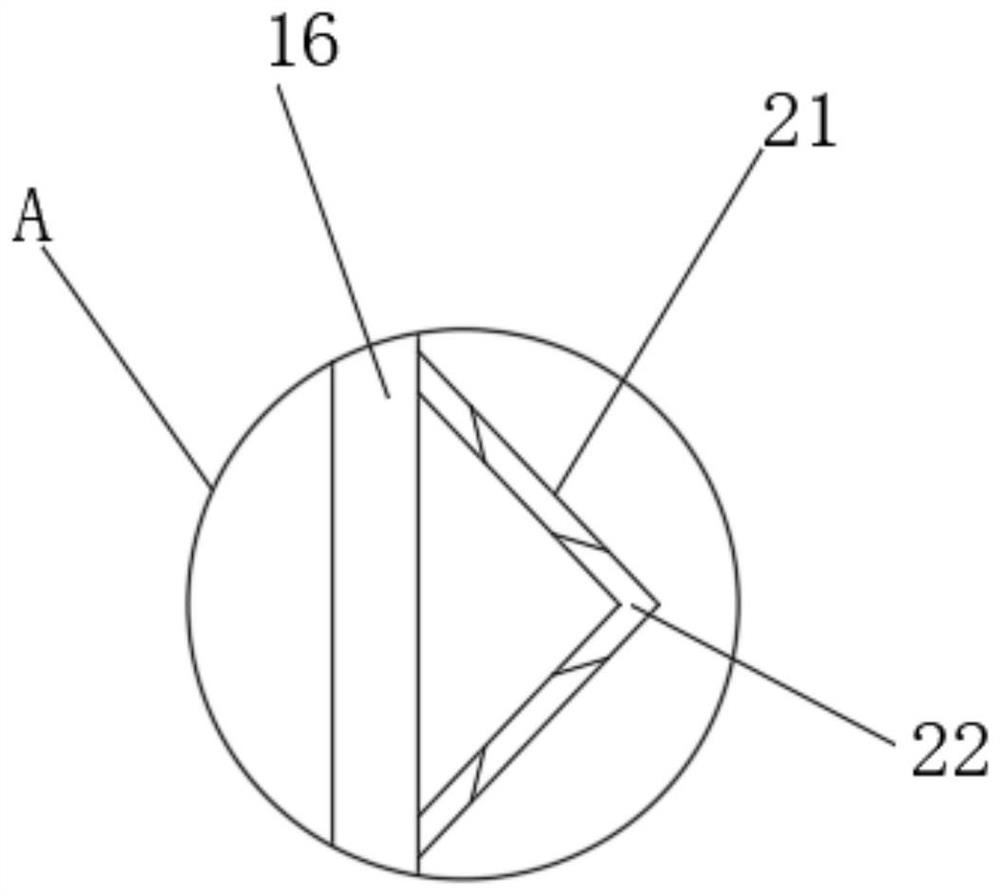

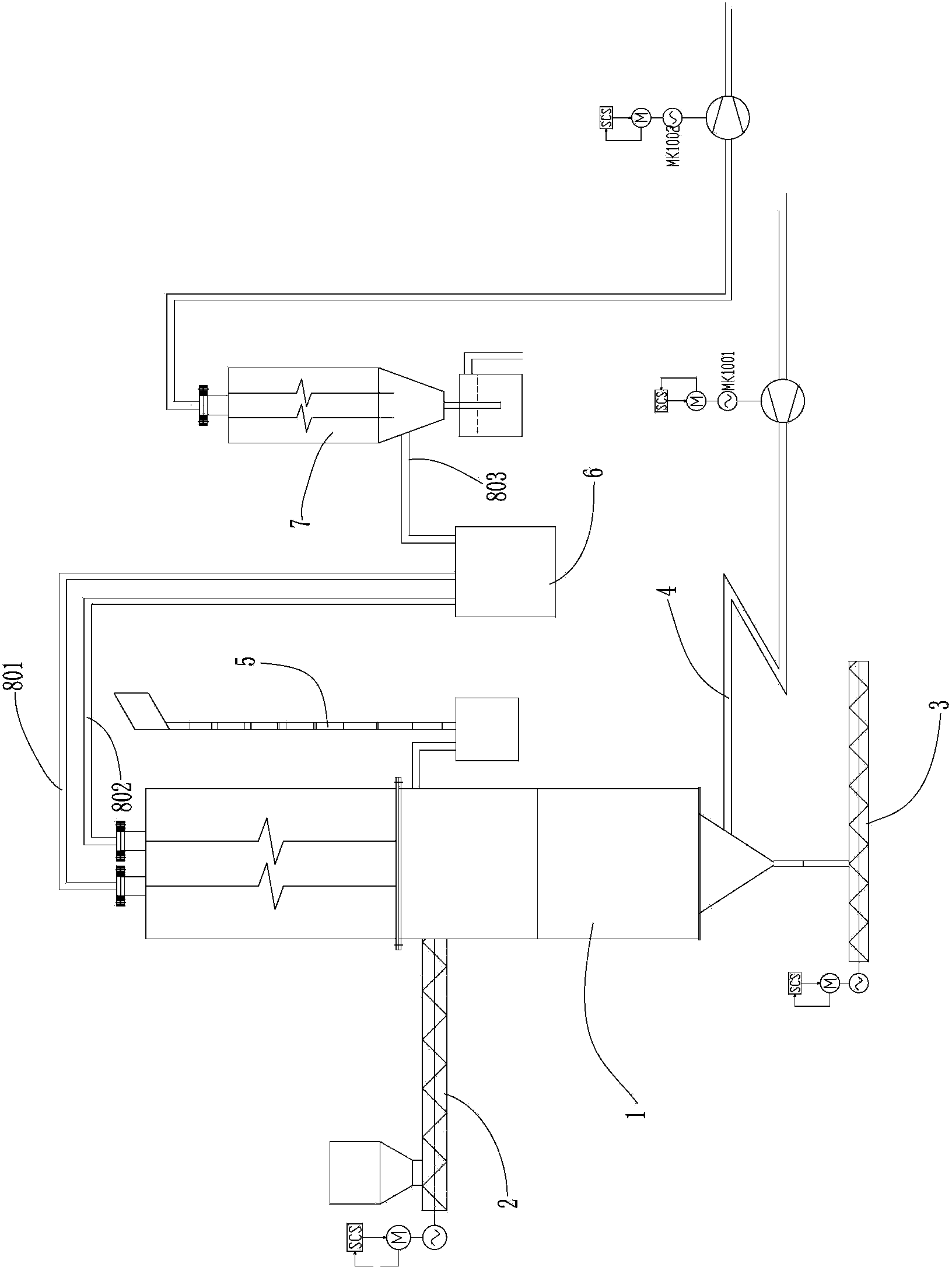

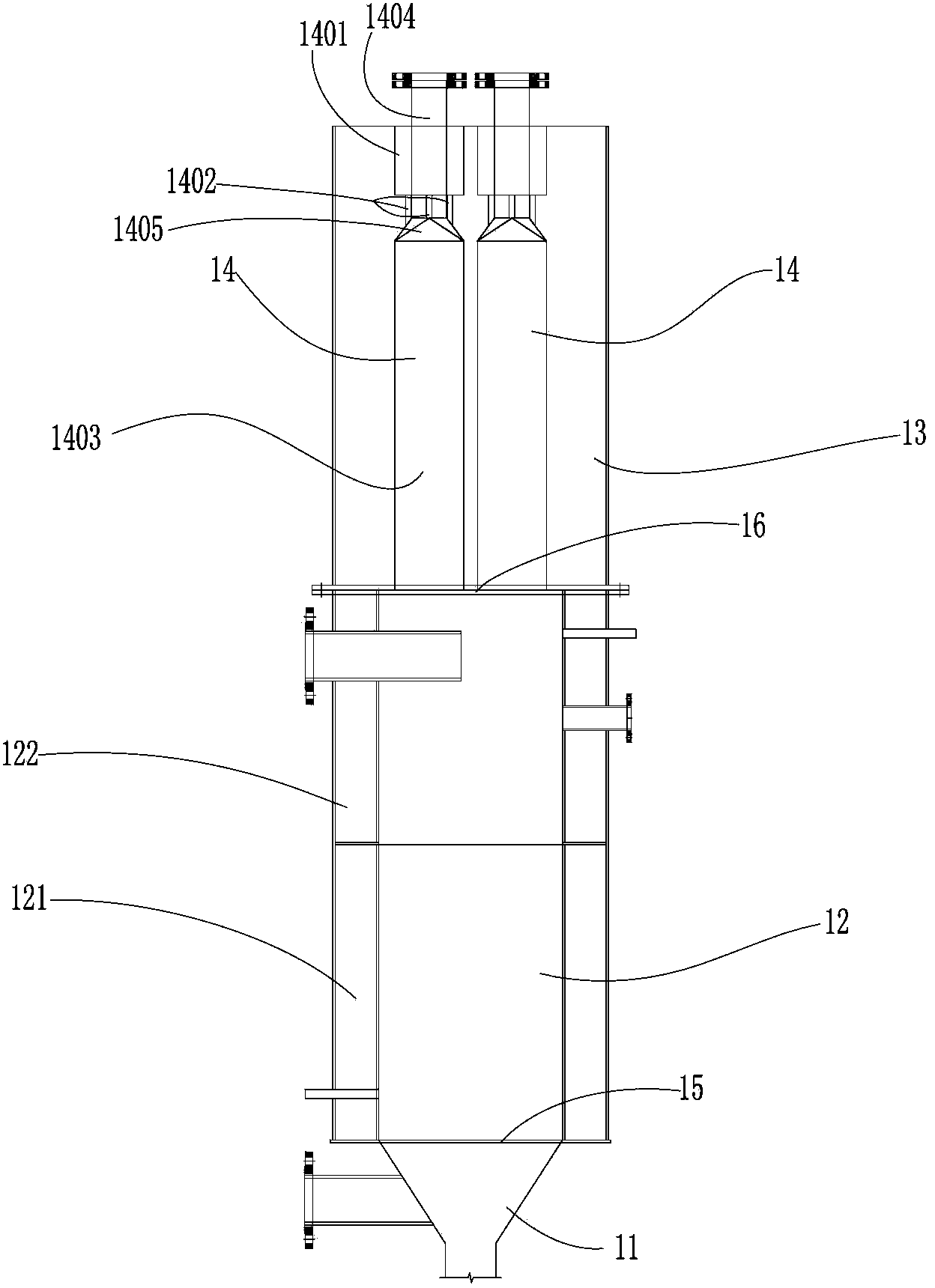

A self-tar removing biomass fixed bed gasifier system

The present invention provides a self-tar removing biomass fixed bed gasifier system. The system comprises a self-tar removing biomass fixed bed gasifier which comprises a gasifier body arranged in a longitudinal direction, and the gasifier body comprises a cone hopper-shaped tail ash portion, a cylindrical reaction portion, and a tar removing portion from bottom to top. The top of the tar removing portion is provided with a fuel gas outlet; the bottom of the tail ash portion is provided with a taphole; the side portion of the tail ash portion is provided with at least one gasifying medium inlet; the side of the top of the reaction portion is provided with a feeding inlet; a separating plate is arranged between the reaction portion and the tar-removing portion, and a fuel gas inlet communicating with the reaction portion is provided on the separating plate; a tar removing device is arranged inside the tar removing portion, the tar removing device comprises a condensing tube which comprises a cylindrical housing with two ends open, and the lower end opening of the cylindrical housing is connected to the fuel gas inlet on the separating plate; the gasifier wall of the tar removing portion, the separating plate, and the housing of the tar removing device form a space where the fuel gas can not enter; and multiple pipe bundles made from cooling pipes are arranged inside the cylindrical housing.

Owner:GUANGZHOU XINGUANGHE ENVIRONMENTAL PROTECTION TECH

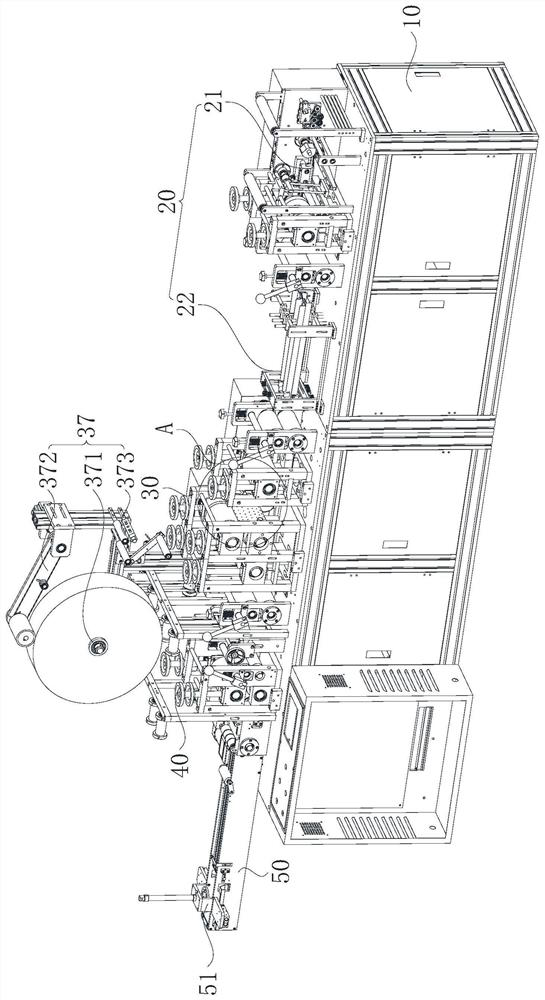

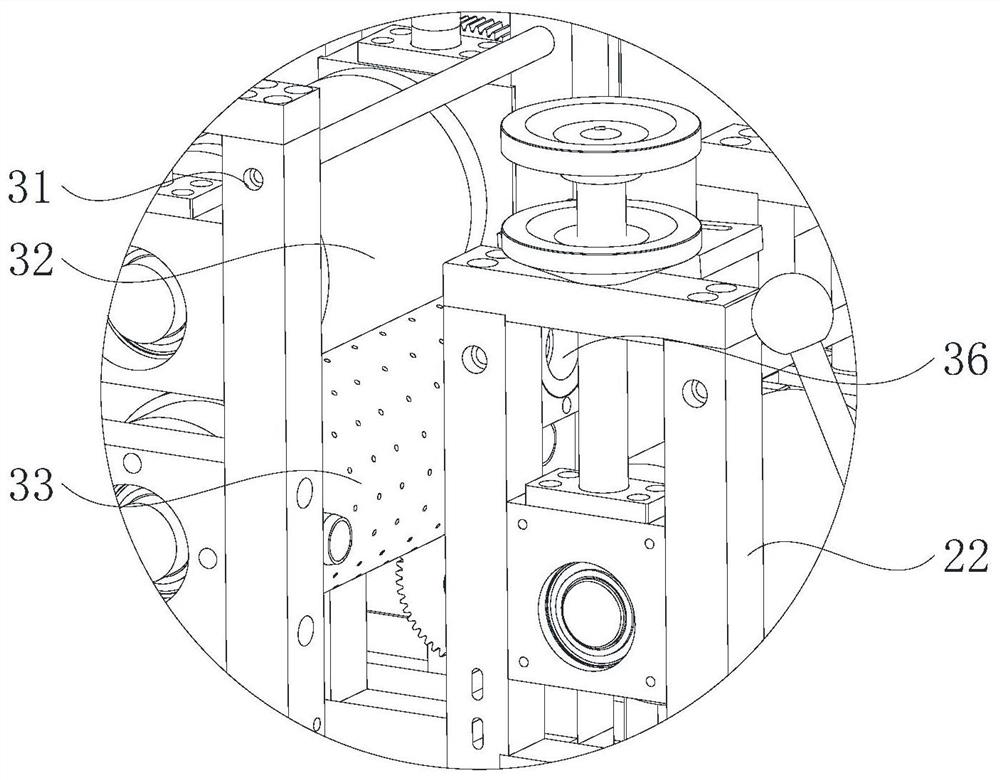

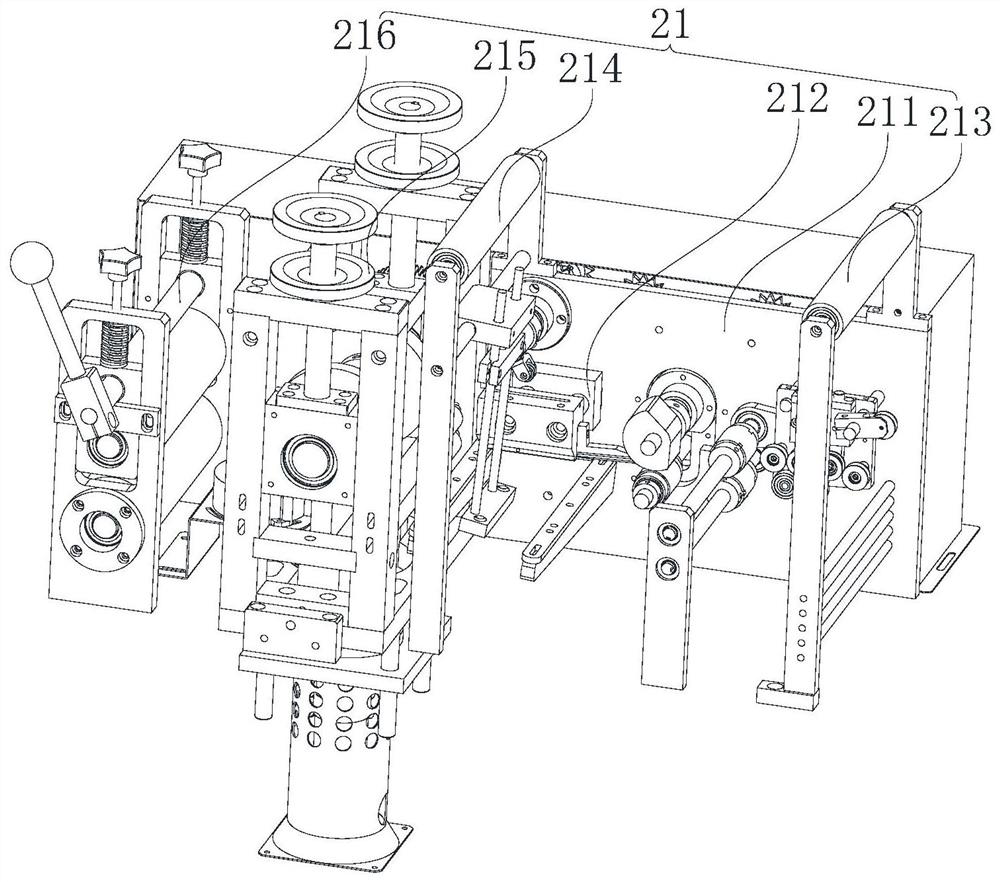

Planar elastic cloth mask machine

PendingCN112515273AProductivity impactProtective garmentClothes making applicancesStructural engineeringWaste material

The invention belongs to the technical field of mask production equipment, and particularly relates to a planar elastic fabric mask machine which comprises a rack, and a planar mask forming device, anelastic fabric welding device and a mask cutting and forming device which are sequentially arranged on the rack; the elastic fabric welding device comprises two vertical plates, a roll cutting shaft,a supporting shaft, a first welding rolling shaft, a first welding machine, a negative pressure extraction mechanism, an elastic fabric input mechanism and a first driving mechanism; the two verticalplates are oppositely arranged on the rack; the roll cutting shaft and the supporting shaft are oppositely arranged between the two vertical plates up and down; a cutter part is arranged on the rollcutting shaft; the suction end of the negative pressure extraction mechanism extends to one side of the supporting shaft; the first welding rolling shaft is arranged between the two vertical plates, the first welding machine is arranged in the rack, and the welding part extends to the bottom of the first welding rolling shaft; the elastic fabric input mechanism is arranged on the rack; and the first driving mechanism is connected with the roll cutting shaft and the first welding rolling shaft. Through the arrangement, waste materials of the elastic cloth will not influence the production efficiency of masks.

Owner:东莞快裕达自动化设备有限公司

Method for automatically removing tar oil from fixed-bed biomass gasification furnace

ActiveCN103173251BProductivity impactCreate pollutionChemical industryFixed-bed gasificationFixed bedTar

The invention provides a method for automatically removing tar oil from a fixed-bed biomass gasification furnace. The lower section of the gasification furnace produces biomass gas, the upper section of the gasification furnace is provided with a gas channel, the space in the gas channel is cooled, and the temperature of the gas produced by the lower section of the gasification furnace is reduced when the gas passes through the gas channel from bottom to top, so that tar oil in the gas is separated out. According to the method, the production efficiency of the gas is not influenced, and no pollution is caused to an external environment and circulating water; one part of the heat produced by gas cooling is used for drying fuel on a drying layer in the furnace, so that little heat is taken away through cooling of the circulating water; during cooling of the gas, a great amount of tar oil is recycled and participates in gasification again, so that the energy utilization rate is greatly improved, and the saved heat is more than the lost heat caused by cooling; and furthermore, as the temperature of the gas is low, the requirement on an auxiliary machine, an instrument, pipelines and the like is greatly reduced, and thus the investment cost is saved.

Owner:GUANGZHOU XINGUANGHE ENVIRONMENTAL PROTECTION TECH

Crimping tooling for outside rearview mirror lens

InactiveCN104874976BEven by forceImprove product qualityVehicle componentsMetal working apparatusReciprocating motionEngineering

The invention provides an outside rear-view mirror sheet pressure connecting tool which comprises a workbench, a cylinder, a press fit mechanism and a strong sponge body. The workbench is composed of a cantilever beam arranged horizontally, a base platform and a connection beam arranged vertically. The lower end of the connection beam is fixed to the base platform, one end of the cantilever beam is fixedly connected with the upper end of the connection beam, and the cantilever beam and the base platform are located on the same side of the connection beam. The cylinder is fixedly mounted on the cantilever beam and used for driving the press fit mechanism. The press fit mechanism comprises a press-down rod and a suction cup, the suction face of the suction cup is downward and used for sucking a mirror sheet, and the other face of the suction cup is connected with the lower end of the press-down rod. The upper end of the press-down rod is fixedly connected to the cylinder, and achieves vertical reciprocating motion under driving of the cylinder. The strong sponge body is fixed to the upper surface of the base platform, located below the suction cup, and used for placing and supporting a mirror frame. The outside rear-view mirror sheet pressure connecting tool has the advantages that the quality of product and the quality stability of the products are improved, the labor intensity is lowered, and the production efficiency is improved.

Owner:力帆科技(集团)股份有限公司

Welded structure of rear wheel hub assembly, rear floor and rear longitudinal beam of automobile

InactiveCN102530099AGood sealing performanceImprove sealingSuperstructure subunitsWeldingEngineering

The invention discloses a welded structure of a rear wheel hub assembly, a rear floor and a rear longitudinal beam of an automobile, the rear wheel hub assembly, the rear floor and the rear longitudinal beam are lapped and welded into a whole, and at the lapped and welded part of the rear wheel hub assembly, the rear floor and the rear longitudinal beam, the rear longitudinal beam is positioned between the rear floor and the rear wheel hub assembly and respectively welded with the rear floor and the rear wheel hub assembly, the rear floor is further welded with the rear wheel hub assembly, the rear floor is positioned on the inner side and the rear wheel hub assembly is positioned on the outer side. The welded structure can prevent water from flowing into the automobile from the lapped and the welded part of the rear wheel hub assembly, the rear floor and the rear longitudinal beam on the premise of maintaining current welding quality and coating and glue-squeezing speed.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A kind of water-saving irrigation method of moso bamboo forest

ActiveCN106106051BSustainable water supplyProductivity impactWatering devicesCultivating equipmentsWater storageWater saving

The invention discloses a water-saving phyllostachys edulis irrigation method. The water-saving phyllostachys edulis irrigation method comprises the following steps that 1, phyllostachys edulis forest land is selected, and horizontal ditches are dug; 2, PVC pipes with the diameter of 6-8 cm are sawed open from the middles and are respectively divided into two parts to establish horizontal water collecting ditches; 3, fixing columns are evenly distributed and arranged on two sides of each horizontal water collecting ditch in the length direction; 4, water collecting containers are arranged at the lower ends of the horizontal water collecting ditches and are covered with plastic films; 5, old phyllostachys edulis different in ground diameter are selected and are felled at the end of February, stump joints spacers are made through, stumps are fully filled with water every 15-30 days according to the weather condition, and water-saving irrigation is conducted on the phyllostachys edulis. The water-saving phyllostachys edulis irrigation method applies a field runoff field rainwater collecting method to establish an efficient and economical anti-drought technology of a water storage system using phyllostachys edulis stumps as cores, and provides sustainable water supply for phyllostachys edulis water-starved for a long time in middle-slope, upper-slope and remote regions so as to reduce the influence on phyllostachys edulis productivity of extreme or continuous drought.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Aluminum alloy heat dissipation device with automatic sealing mechanisms

PendingCN111829381AImprove convenienceAvoid affecting productivityIndirect heat exchangersHeat exhanger sealing arrangementPhysicsHeat sink

The invention relates to an aluminum alloy heat dissipation device with automatic sealing mechanisms. The aluminum alloy heat dissipation device with the automatic sealing mechanism is characterized by comprising a heat dissipation base, a plurality of cooling fins, the plurality of automatic sealing mechanisms and a plurality of screws, wherein a first water guide hole and a plurality of auxiliary cavity holes are formed in the heat dissipation base, the auxiliary cavity holes comprise left vertical holes, middle vertical holes, right vertical holes and inner cavities, second water guide holes and jacking columns are arranged on the cooling fins, all the automatic sealing mechanisms are mounted in the inner cavities in a one-to-one correspondence manner, the automatic sealing mechanisms comprise sealing parts and jacking springs, the sealing parts comprise sealing pressing plates, flow guide blocks, guide columns, left flow guide cylinders and right flow guide cylinders, and all the cooling fins are arranged on the top surface of the heat dissipation base. According to the aluminum alloy heat dissipation device, enterprises can select a proper number of cooling fins according to actual heat dissipation requirements, the use is more flexible, and the cost input of the enterprises can be greatly reduced; and the aluminum alloy heat dissipation device further has the advantages of being simple in structure, high in reliability, good in heat dissipation effect, low in maintenance cost and the like.

Owner:佛山市伟卓铝业有限公司

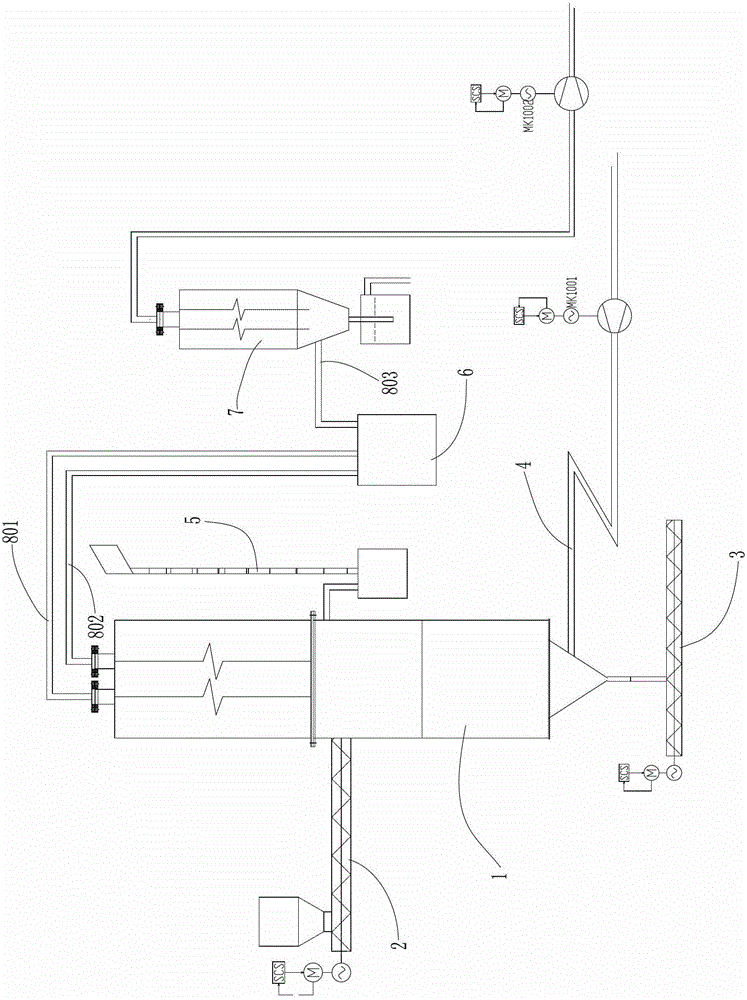

A kind of preparation technology and preparation equipment of aerated concrete block

ActiveCN112207949BEasy to controlProductivity impactFeeding arrangmentsAuxillary shaping apparatusElectric machineEngineering

This application relates to a preparation process and equipment for aerated concrete blocks. The preparation equipment includes a mixing tank, a partition, a first motor, a stirring shaft and a valve device; a driving device is arranged between the first motor and the stirring shaft; The device includes a fixed shaft, a first bevel gear, a rotating circular tube, a first L-axis, a fixed circular tube, a second L-axis and a second bevel gear; a heating mechanism is provided on one side of the rotating circular tube; a power assembly is provided in the mixing cylinder ; There is a connecting mechanism between the second L axis and the stirring shaft. The preparation process includes the following steps: mixing cement, desulfurized gypsum and aluminum paste, adding water to make slurry; continuing to add fly ash and lime to the mixture, stirring evenly, pouring into the mold; Air-entrained concrete blocks. The application has the effect of improving the production efficiency of concrete blocks.

Owner:上海阜阜建材有限公司

Dust removing device for optical fiber diameter measuring instrument

The invention discloses a dust removing device for an optical fiber diameter measuring instrument. The dust removing device comprises an end cover, wherein a fiber through hole is formed in the centerof the end cover. At least two air inlets are formed in the outer wall of the end cover, the air inlets communicate with air flow channels in the end cover, and the air flow channels communicate withair outlets. The end cover is internally provided with the air flow channels corresponding to the air inlets respectively and provided with the air outlets corresponding to the air flow channels respectively. Each air flow channel is internally provided with an air flow conversion component, and the air flow conversion components divide the airflow channels into first air flow channel bodies andsecond air flow channel bodies. The first air flow channel bodies and the second air flow channel bodies communicate with the air inlets and the air outlets respectively. The end cover is internally provided with adsorption channels communicating with the second air flow channel bodies and communicating with the fiber through hole. The ventilation aperture of the air flow conversion components issmaller than that of the first air flow channel bodies. The dust removing device for the optical fiber diameter measuring instrument is used for removing dust and impurities on the surface of the optical fiber diameter measuring instrument online, performs two-step cleaning on online drawn optical fibers and core rods in the extending process, and reduces the influence of the dust and the impurities on the production efficiency and quality of the optical fibers.

Owner:JIANGSU HENGTONG OPTICAL FIBER TECH +1

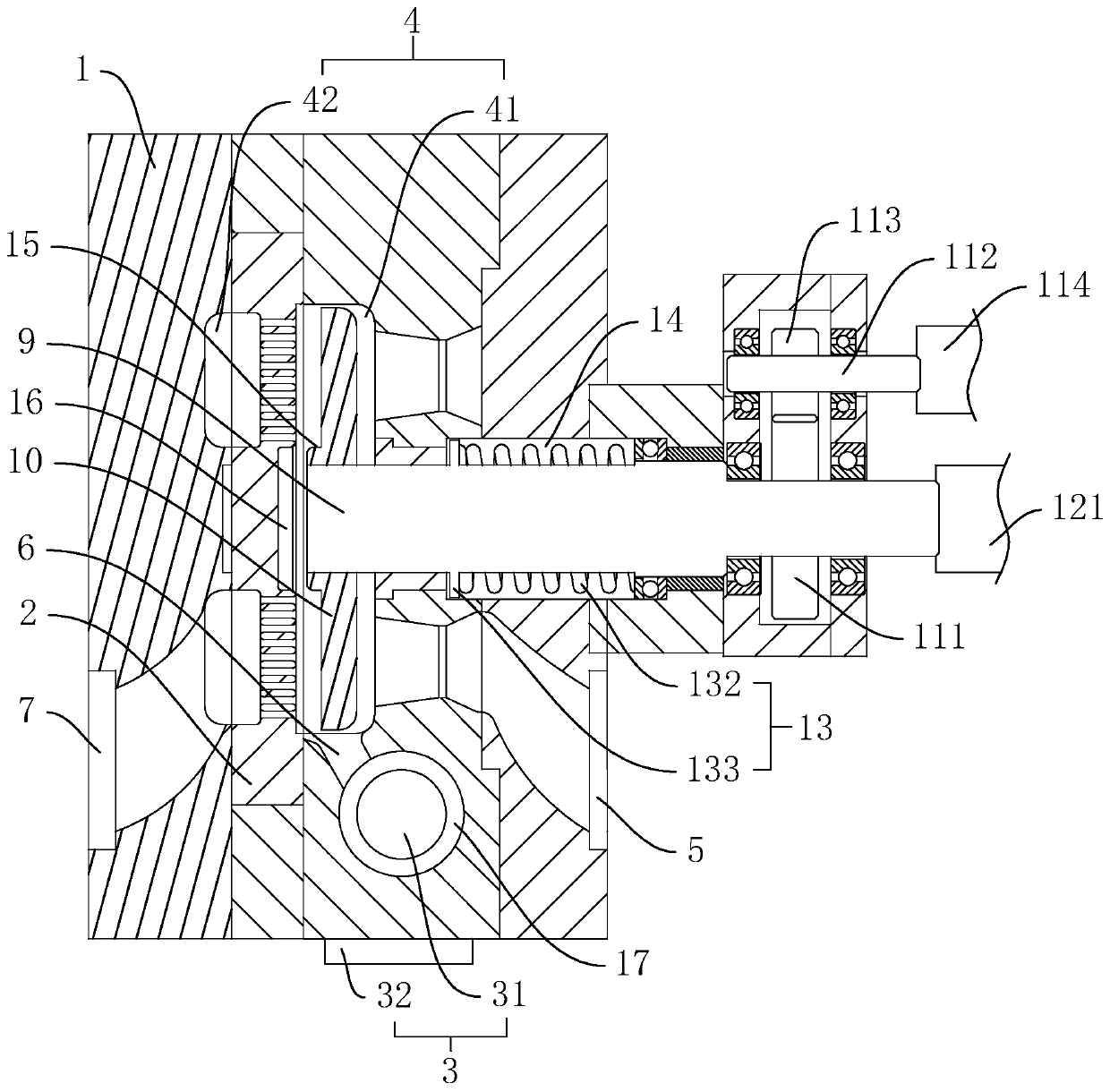

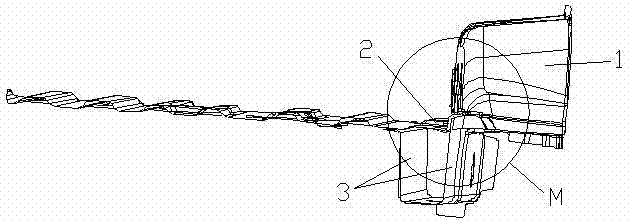

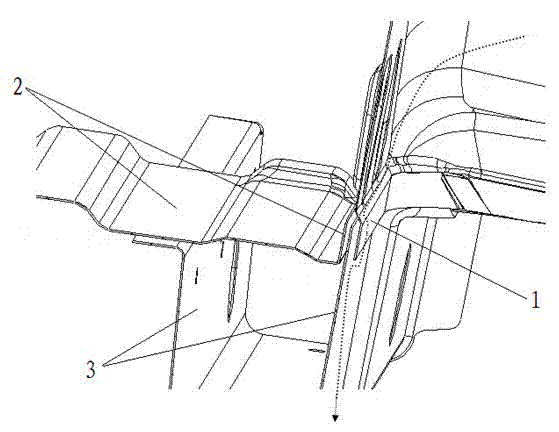

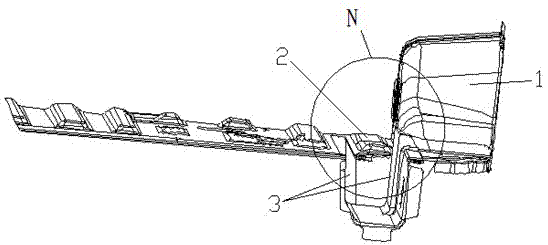

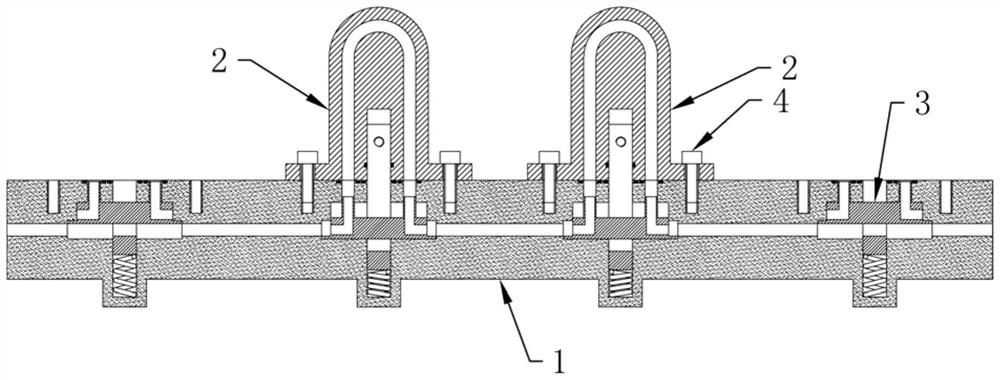

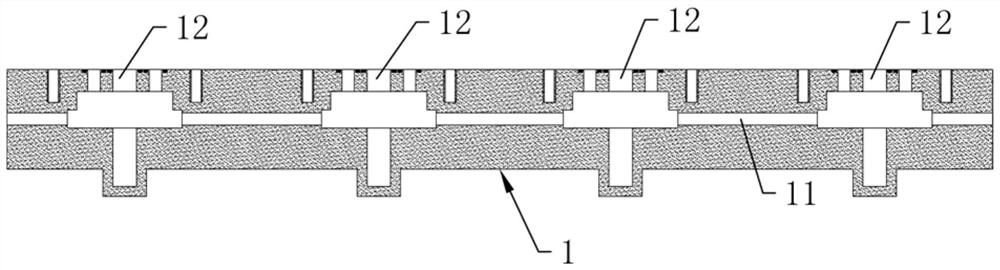

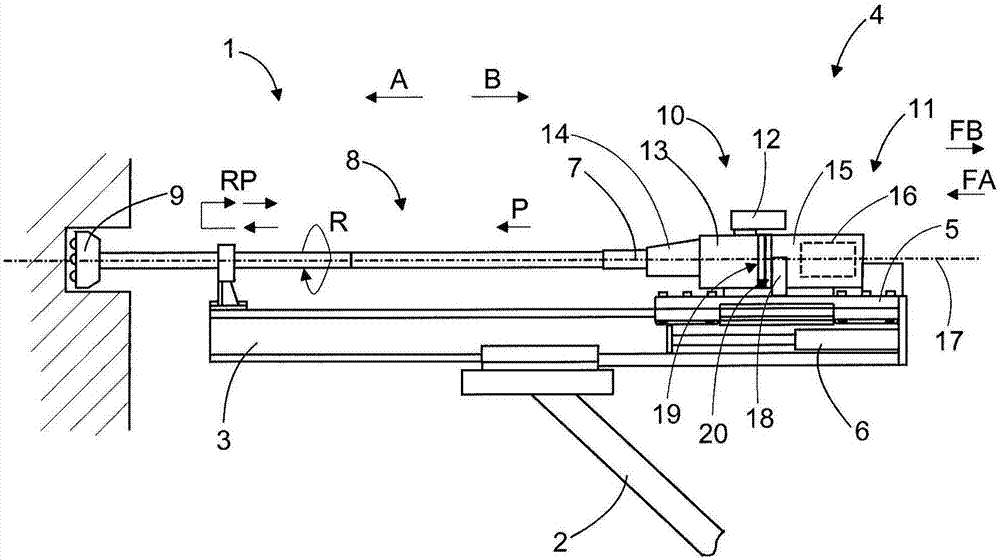

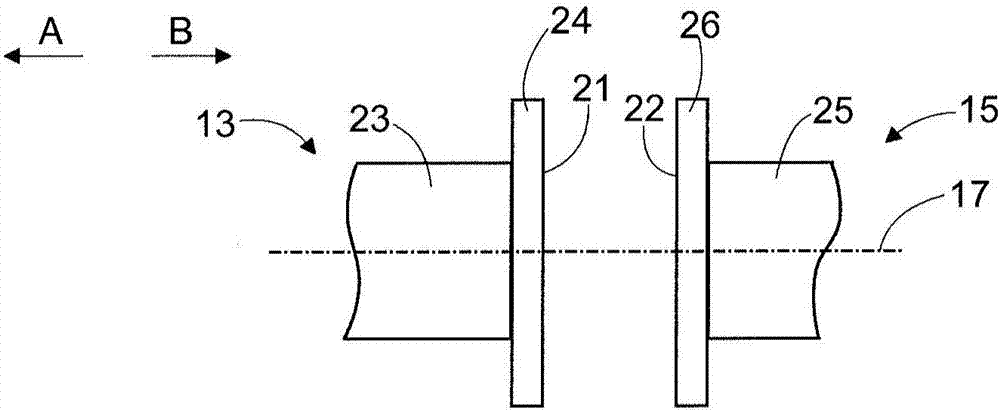

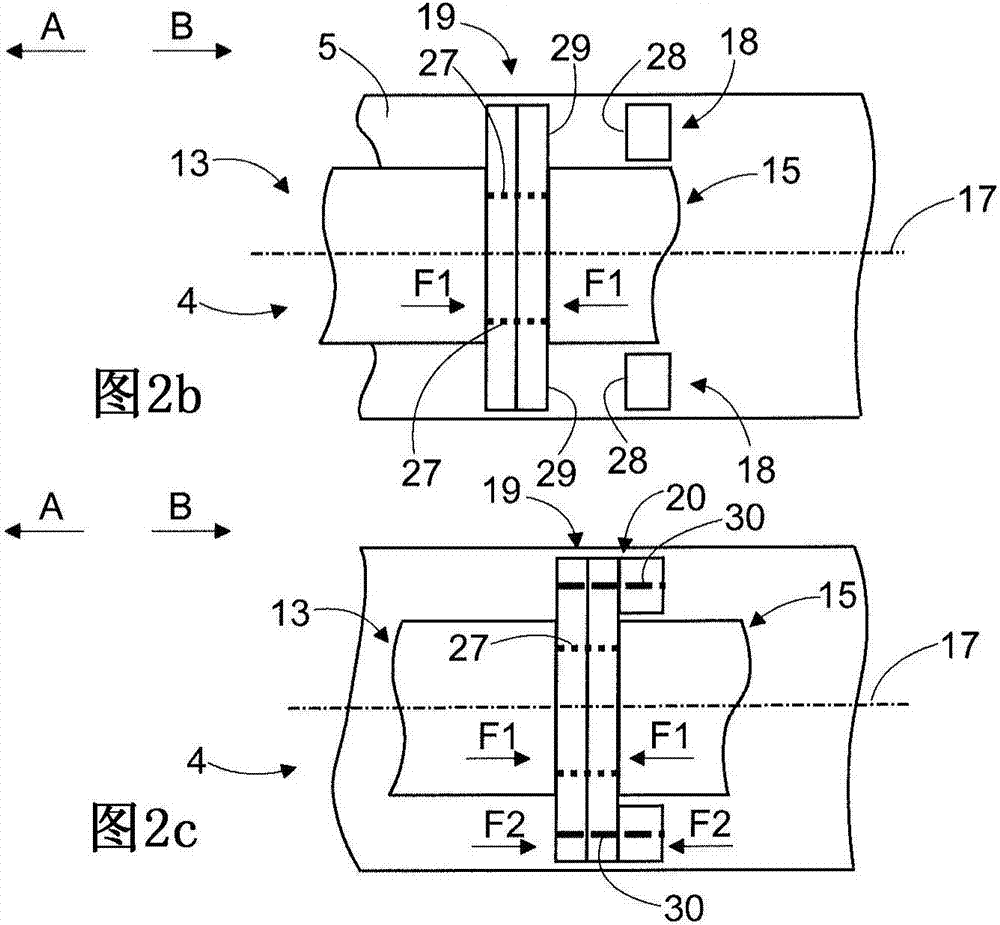

Arrangement in rock drilling machine and method of mounting same

ActiveCN106948754AExtended service lifeReduce wearDrilling drivesDriving meansEngineeringSupport surface

The invention relates to an arrangement in a rock drilling machine and to a method of mounting the same. The rock drilling machine (4) comprises a gear module (13) and a percussion module (15), which are arranged on a same axial line (17). The modules are pressed towards each other by means of several first connecting means (27) and several second connecting means (30). The connecting means generate first axial connecting forces (F1) and second axial connecting forces (F2) which receive axial operational forces of the rock drilling machine. The second connecting means also fasten the rock drilling machine to a carriage (5) provided with support surfaces (28).

Owner:SANDVIK MINING & CONSTR OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com