Touch panel and manufacturing method thereof

A technology for touch panels and manufacturing methods, applied in the field of information input, capable of solving problems such as increasing production costs of capacitive touch panels, increasing processes, and reducing production efficiency, so as to save raw materials and professional equipment, avoid oxidation and corrosion, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

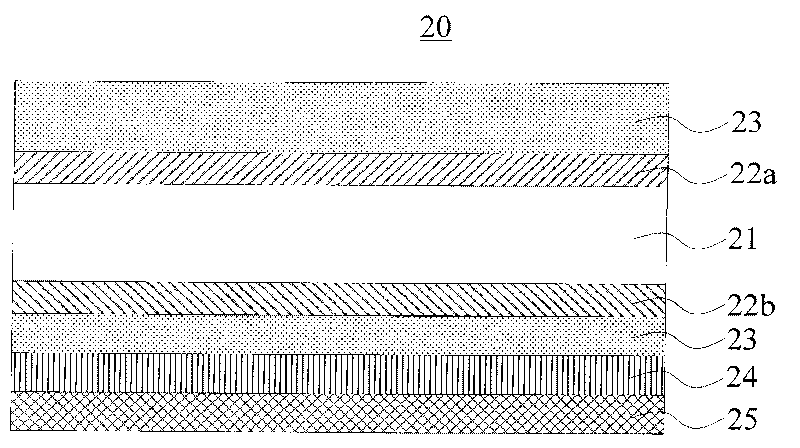

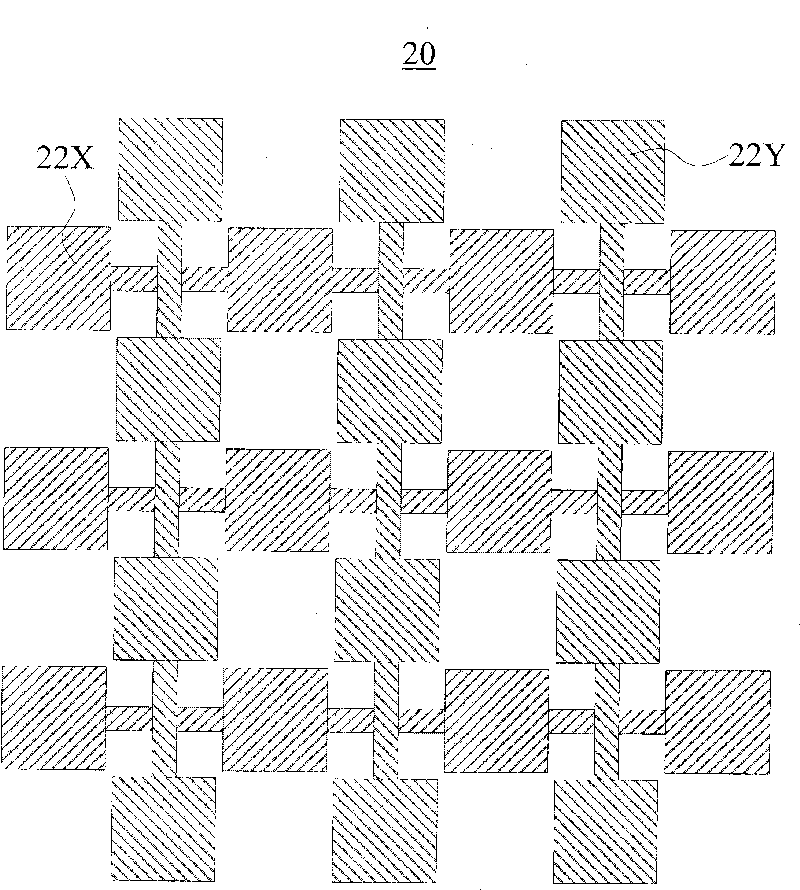

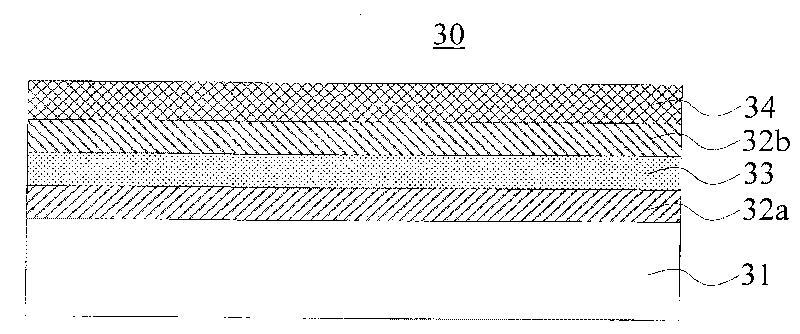

[0043] In order to overcome the problems of low production efficiency and high cost of touch panels in the prior art, the present invention utilizes raw materials for making electrode layers such as transparent oxide ITO (Indium Tin Oxide, indium tin oxide) to make existing single-side single-layer The metal bridge structure in the capacitive touch panel makes the manufacturing equipment and raw materials of the bridge structure the same as the manufacturing equipment and raw materials of the electrode layer, thereby saving the raw materials and professional equipment for making the metal bridge and reducing the production cost of the touch panel. production cost; at the same time, the manufacturing process of the metal bridge can also be saved, and the production efficiency of the touch panel can be improved; at the same time, further, the bridge structure is made using the material for making the electrode layer, such as transparent oxide, which can Avoid the oxidation and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com