Paper quality management method and glass substrate backing paper making method

A technology of quality management and backing paper, applied in paper, papermaking, paper machines, etc., can solve problems such as rising costs, high prices, and polluting the surface of glass substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

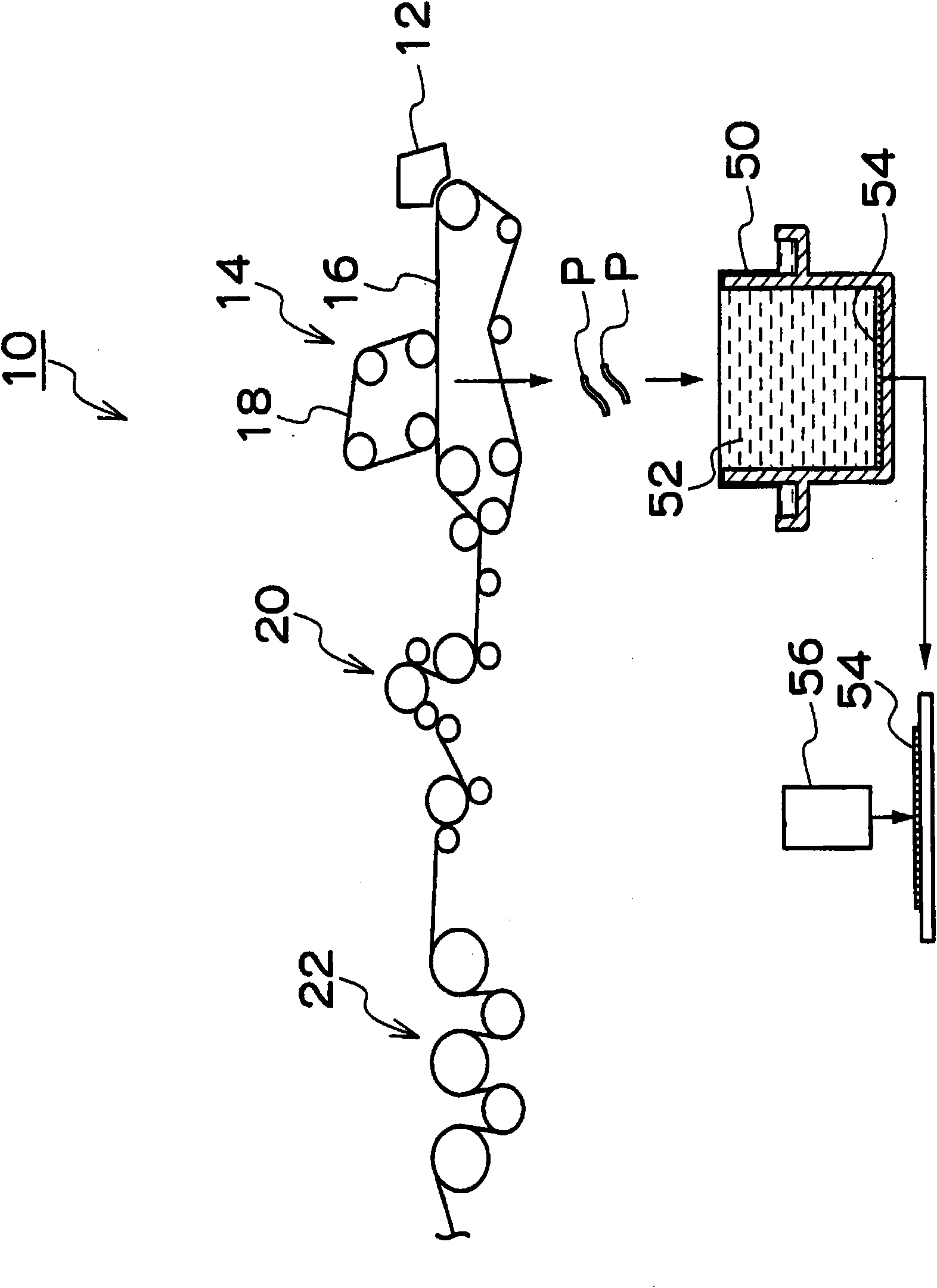

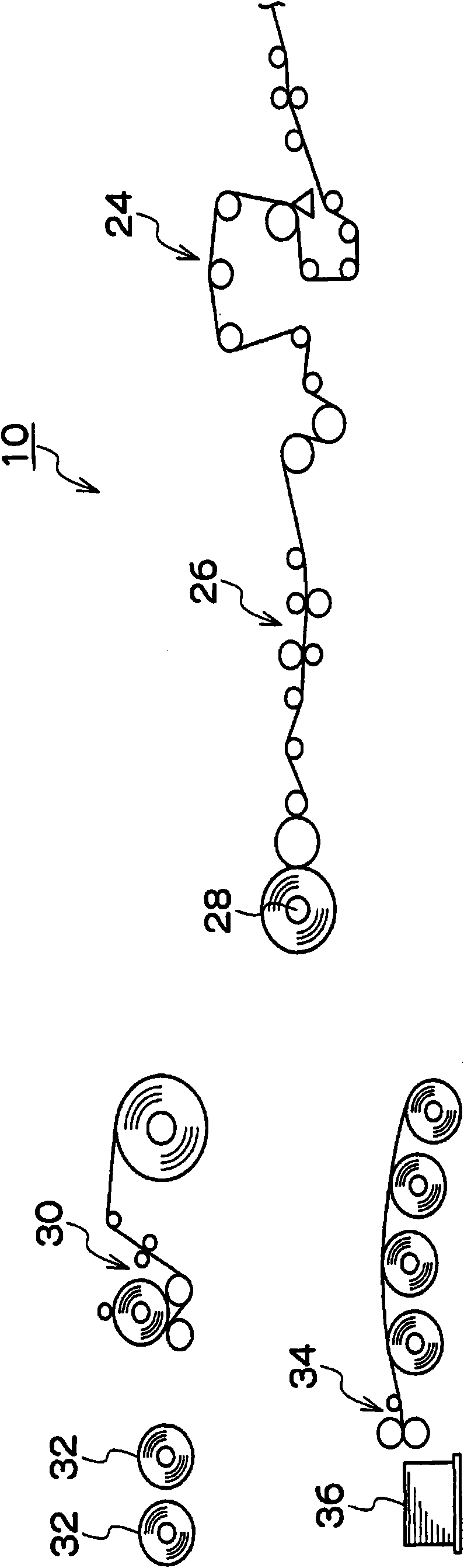

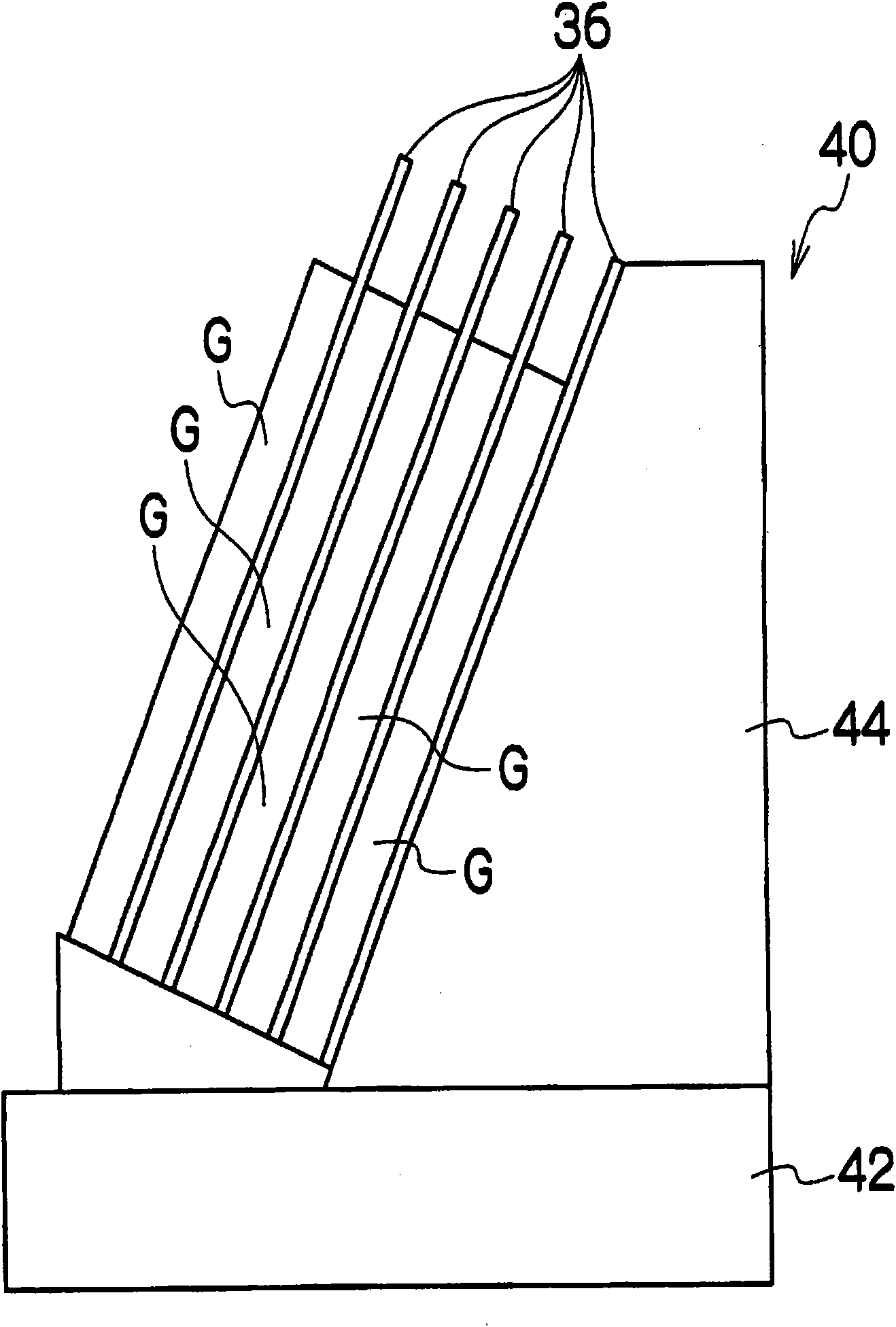

[0028] Next, preferred embodiments of the paper quality control method and the storage liner paper of the glass substrate for flat panel displays and / or the production method of the transport liner paper of the present invention will be described in detail with reference to the drawings.

[0029] figure 1 , figure 2 The structure of the paper machine 10 of a papermaking apparatus is shown. Such as figure 1 As shown, the paper raw material liquid (liquid obtained by diluting pulp with water) sprayed from the headbox 12 is supplied to the lower wire 16 provided in the wire part 14, and thereafter, is sandwiched by the lower wire 16 and the upper wire 18 to perform dehydration. Become wet paper (paper). In addition, a water nozzle (not shown) for cutting the edge P of the wet paper from the main body of the wet paper is arranged above the lower wire 16, and the edge P of the wet paper cut by the water nozzle is used for the production of the lot. Inspection samples for paper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com