A kind of preparation technology and preparation equipment of aerated concrete block

A technology of aerated concrete and blocks, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve the impact of the production efficiency of concrete blocks, affect the production efficiency of concrete blocks, and the heating and mixing processes cannot be carried out continuously, etc. problem, to achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

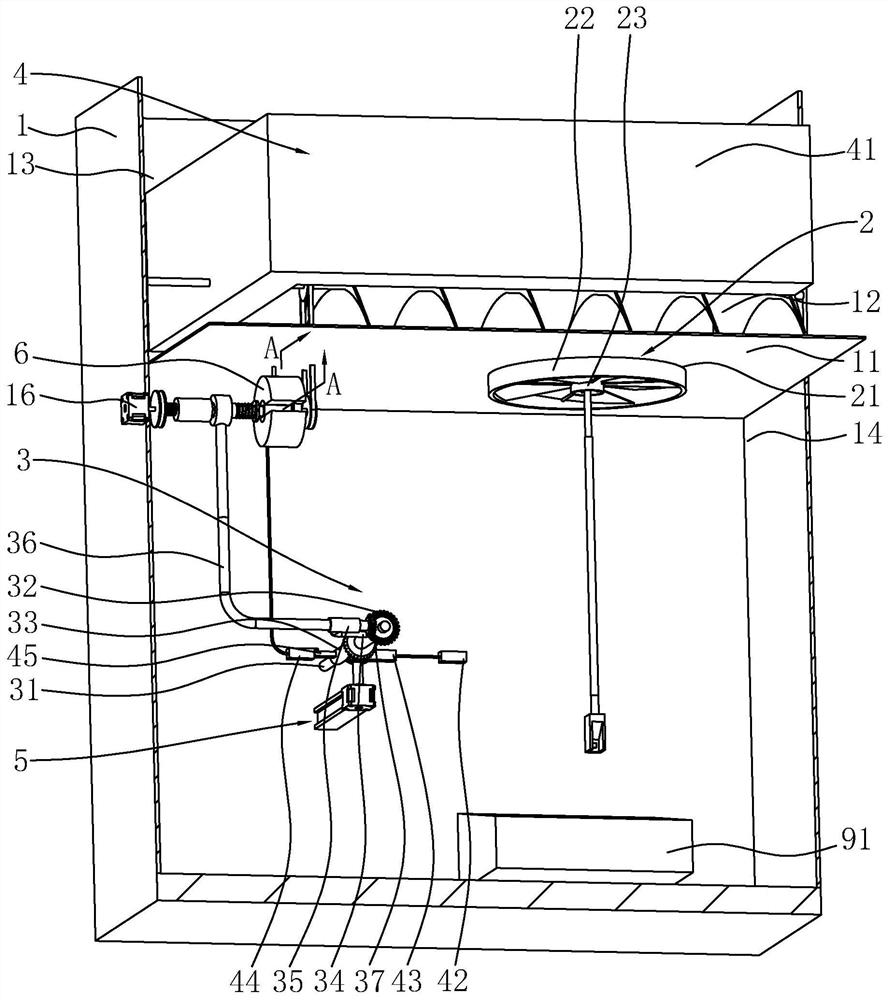

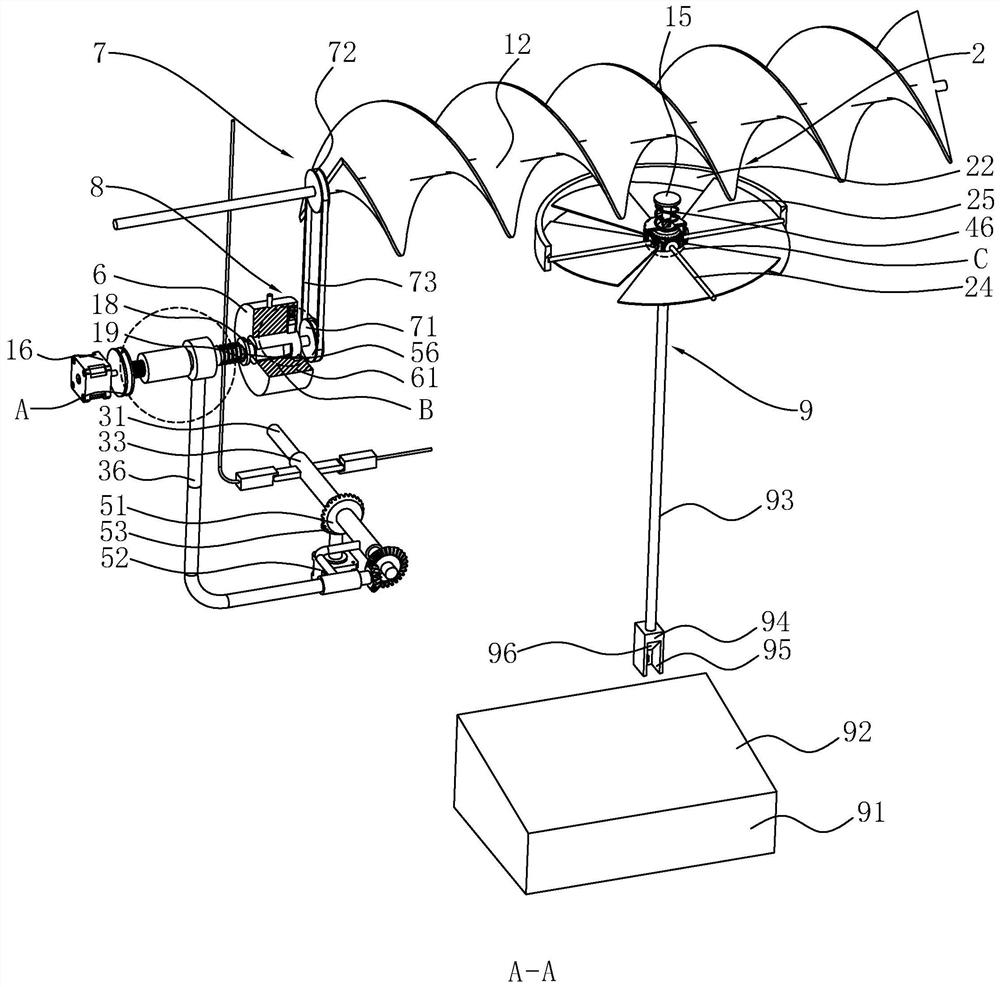

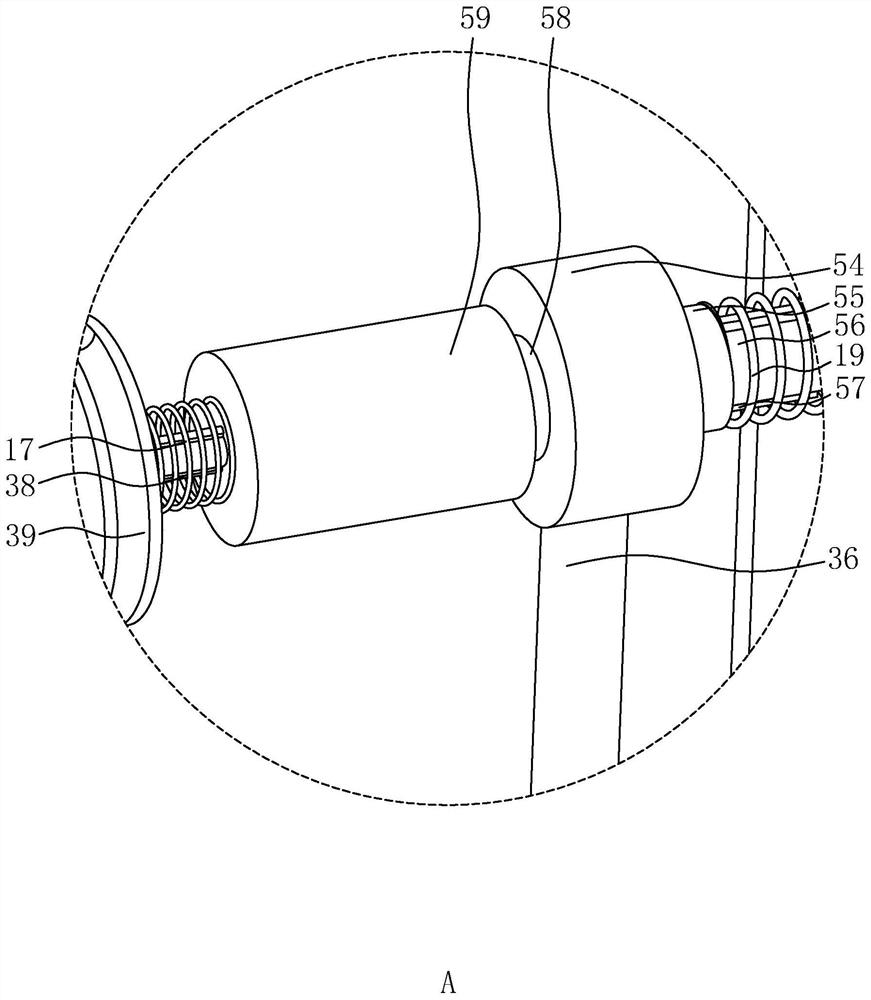

[0042] The embodiment of the present application discloses a preparation process and preparation equipment of an aerated concrete block. refer to figure 1 The preparation equipment includes a square mixing tank 1, a partition 11 fixed to the side wall of the mixing tank 1, a stirring shaft 12 rotatably mounted on the opposite inner side of the mixing tank 1, and a valve device 2 embedded in the partition 11. The partition 11 divides the mixing tank 1 into a mixing bin 13 above the partition 11 and a lower feeding bin 14 below the partition 11 ; the valve device 2 is used to connect the mixing bin 13 and the lower feeding bin 14 . A first motor 16 is fixed on the outer wall of the mixing tank 1 , and a driving device 3 for driving the stirring shaft 12 to rotate is arranged between the first motor 16 and the stirring shaft 12 . The driving device 3 includes a fixed shaft 31 fixed to the inner side wall of the mixing tank 1, a first bevel gear 32 fixed to the end of the fixed s...

Embodiment 2

[0063] A kind of preparation technology of air-entrained concrete block, comprises the steps:

[0064] S1. Mix 12 parts of cement, 3 parts of desulfurized gypsum and 2 parts of aluminum paste into mixing tank 1, add water at 80°C to make slurry, and the ratio of solid to liquid is 1.5;

[0065] S2. Continue to add 70 parts of fly ash and 30 parts of lime to the mixture, after stirring evenly, pour into the mold;

[0066] S3. After resting at 60°C for 3 hours to generate gas, demoulding and cutting to obtain aerated concrete blocks.

Embodiment 3

[0068] A kind of preparation technology of air-entrained concrete block, comprises the steps:

[0069] S1. Mix 11 parts of cement, 2.5 parts of desulfurized gypsum and 1.5 parts of aluminum paste into mixing tank 1, add water at 100°C to make slurry, and the ratio of solid to liquid is 1.45;

[0070] S2. Continue to add 68 parts of fly ash and 25 parts of lime in the mixture, after stirring evenly, pour into the mold;

[0071] S3. After resting at 55°C for 2.5 hours to generate gas, demould and cut to obtain aerated concrete blocks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com