Dust removing device for optical fiber diameter measuring instrument

A technology of dust removal device and caliper, which is applied in the field of optical fiber and core rod manufacturing, and can solve problems such as cost loss, miscutting of optical fiber, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

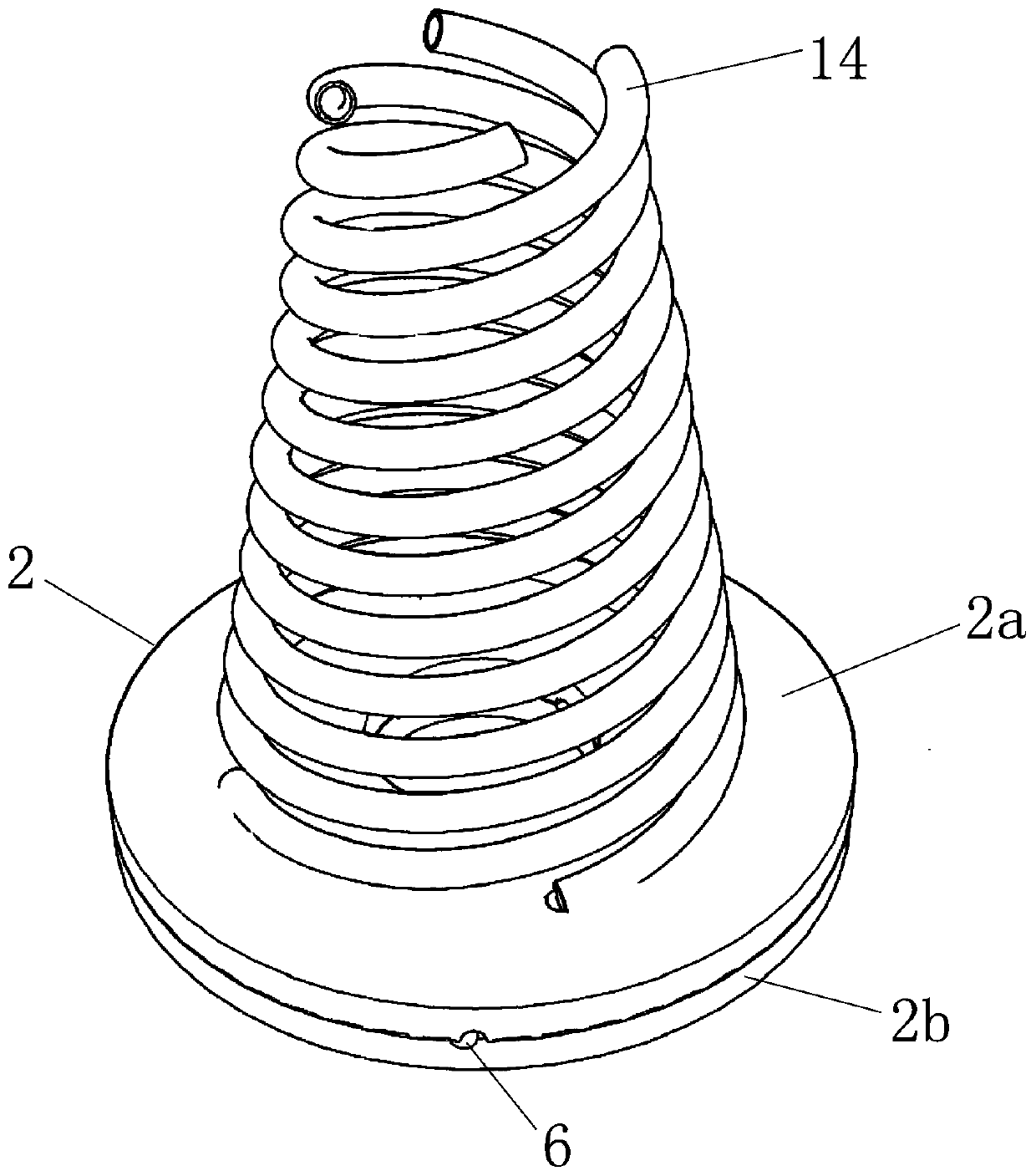

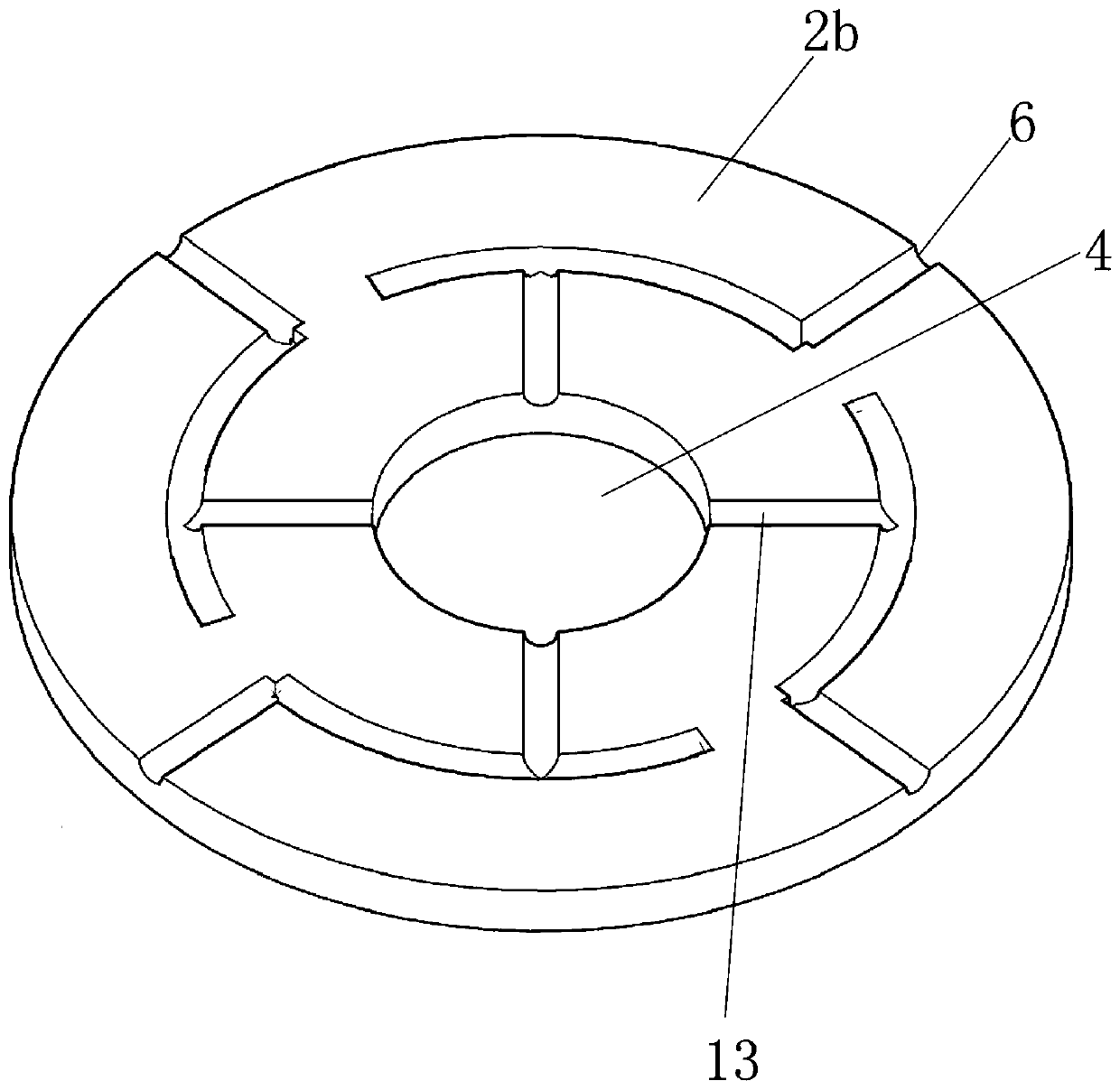

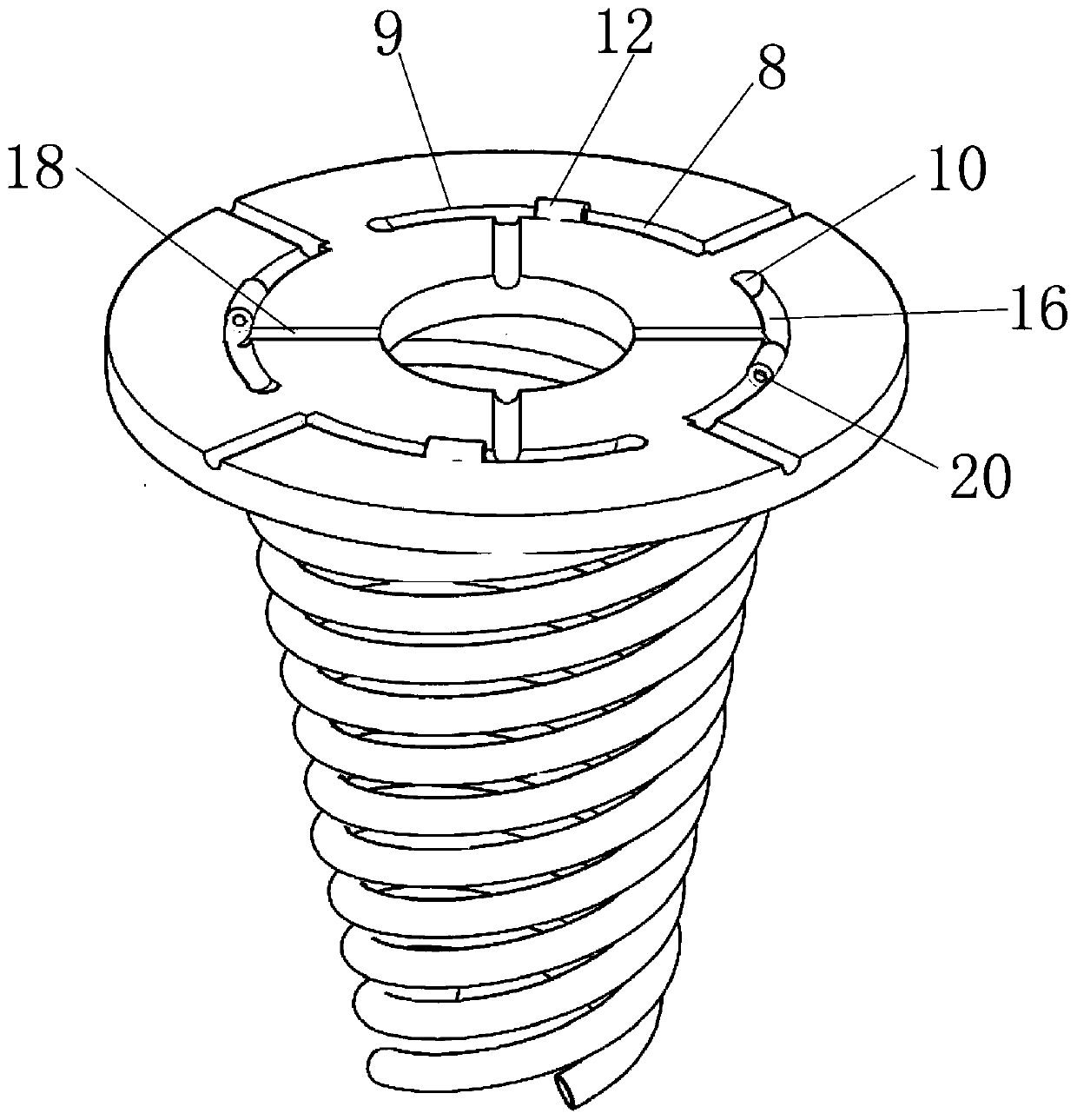

[0023] This embodiment discloses a dust removal device for an optical fiber caliper. The dust removal device includes an end cover 2, which is assembled with the optical fiber caliper through the bottom surface of the end cover 2; refer to Figure 1~3 As shown, the center of the above-mentioned end cap 2 is provided with a fiber hole 4; the flat bottom surface of the above-mentioned end cap 2 is assembled on the optical fiber caliper, and the bare fiber after fiber drawing passes through the fiber hole 4 and enters the fiber caliper .

[0024] The outer wall of the above-mentioned end cover 2 is provided with at least two groups of air inlets 6, and the above-mentioned air inlets 6 communicate with the air flow channel inside the end cover 2, and the end of the above-mentioned air flow channel communicates with the air outlet 10; The air port 6 is independently configured with an air flow channel, and a group of air outlets 10 is independently configured on the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com