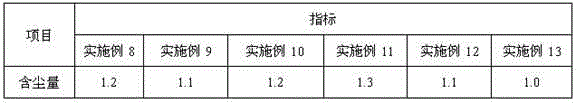

Patents

Literature

211results about How to "Realize online cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

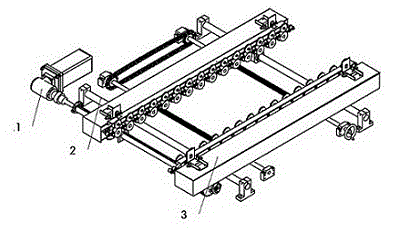

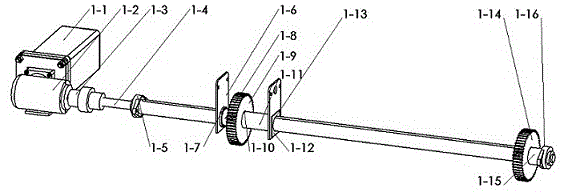

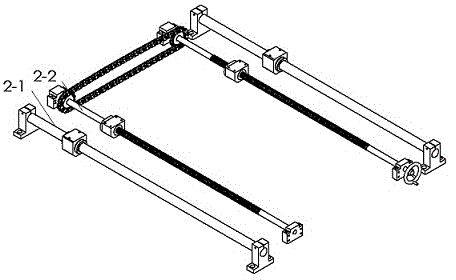

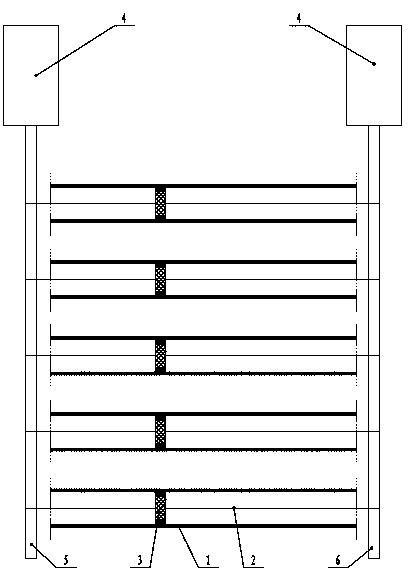

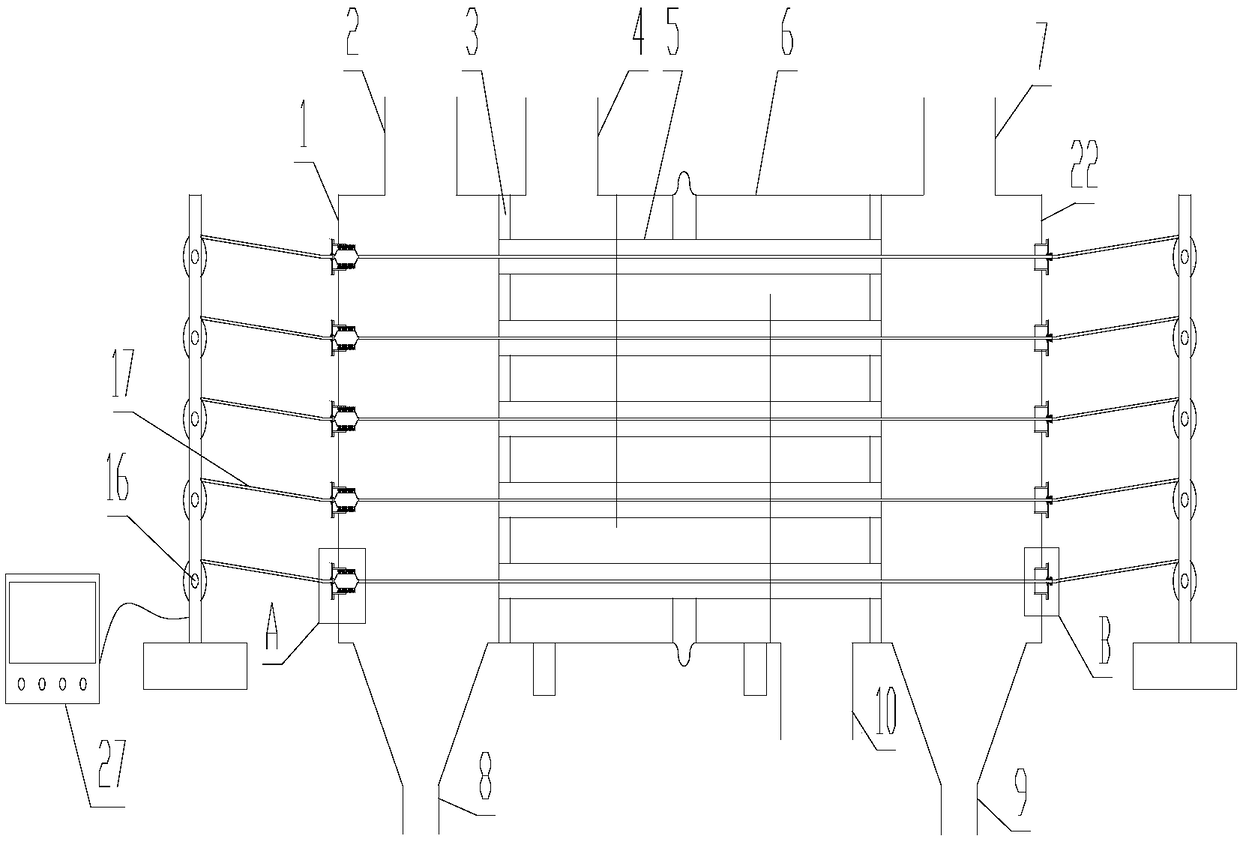

Multifunctional width adjustable conveying device

InactiveCN104401644AAdjustable distanceAchieve cleaningCharge manipulationConveyor partsLinear motionDrive shaft

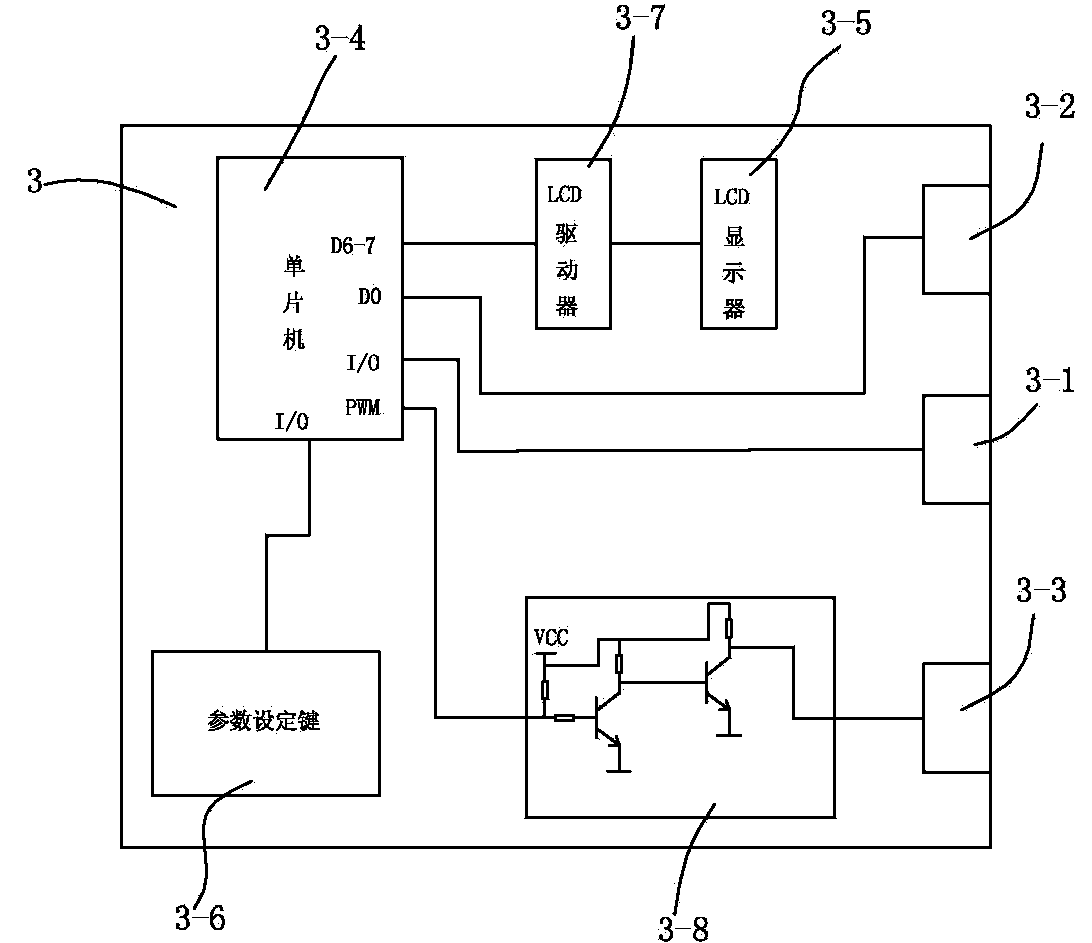

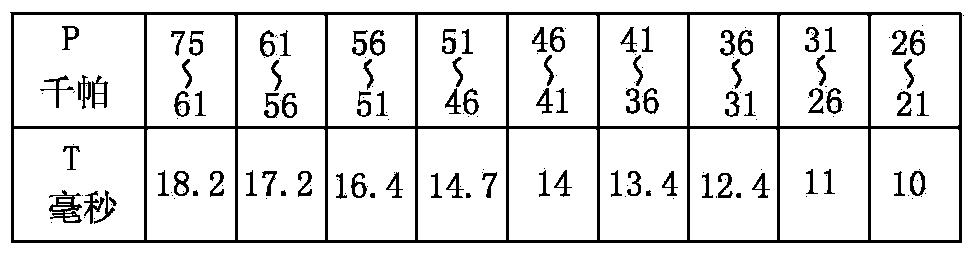

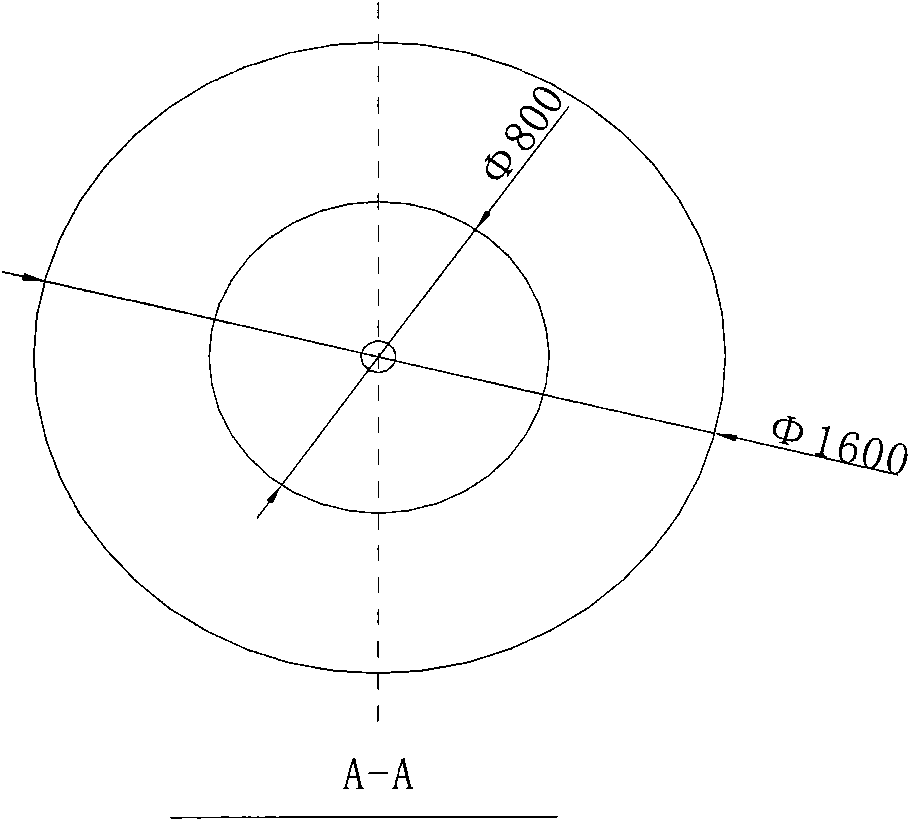

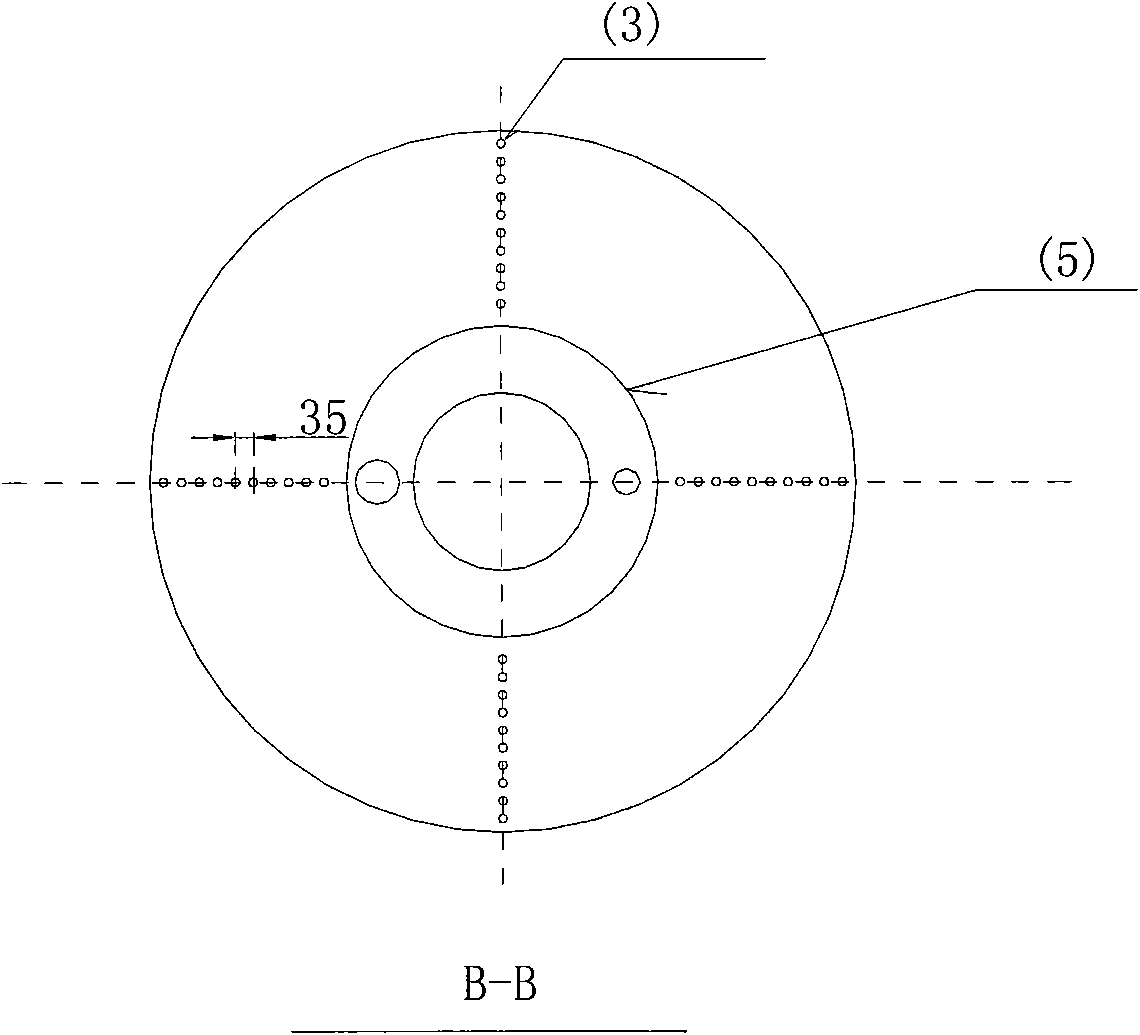

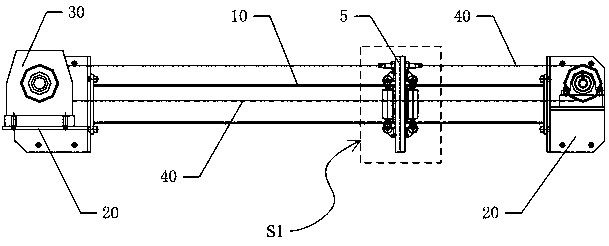

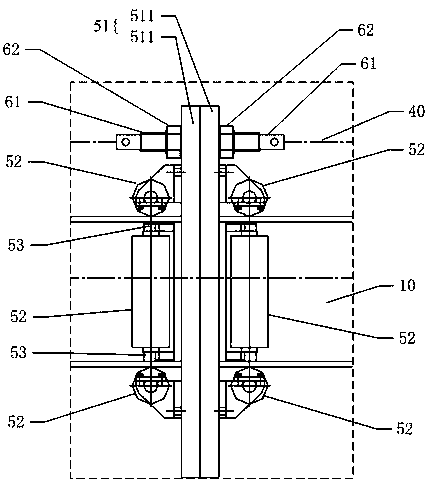

The invention discloses a multifunctional width adjustable conveying device of a PCB (printed circuit board) and machined component washing device, which is a core part of the washing device. The multifunctional width adjustable conveying device consists of a power input device (1), a supporting width adjusting device (2) and a conveying guide rail compression device (3), wherein a motor (1-1) drives a gear of a conveying guide rail (3-1) to rotate through a transmission shaft (1-4), a gear (1-9) and a gear (1-14), and a chain of the conveying guide rail (3-1) drives a large roller and a small roller to rotate together so as to realize the online washing of a PCB; a groove body of the conveying guide rail (3-1) is connected with a slide bearing sleeve and a nut seat of the supporting width adjusting device (2-1), a handle of a ball screw width adjusting device (2-2) is rotated so as to drive a ball screw to rotate through a chain wheel and the chain, the conveying guide rail (3-1) is driven by the linear motion of the nut seat to make linear movement along the axis direction so as to realize the width adjustment of the conveying guide rail, and the online washing of PCBs in different widths can be satisfied.

Owner:SICHUAN UNIV

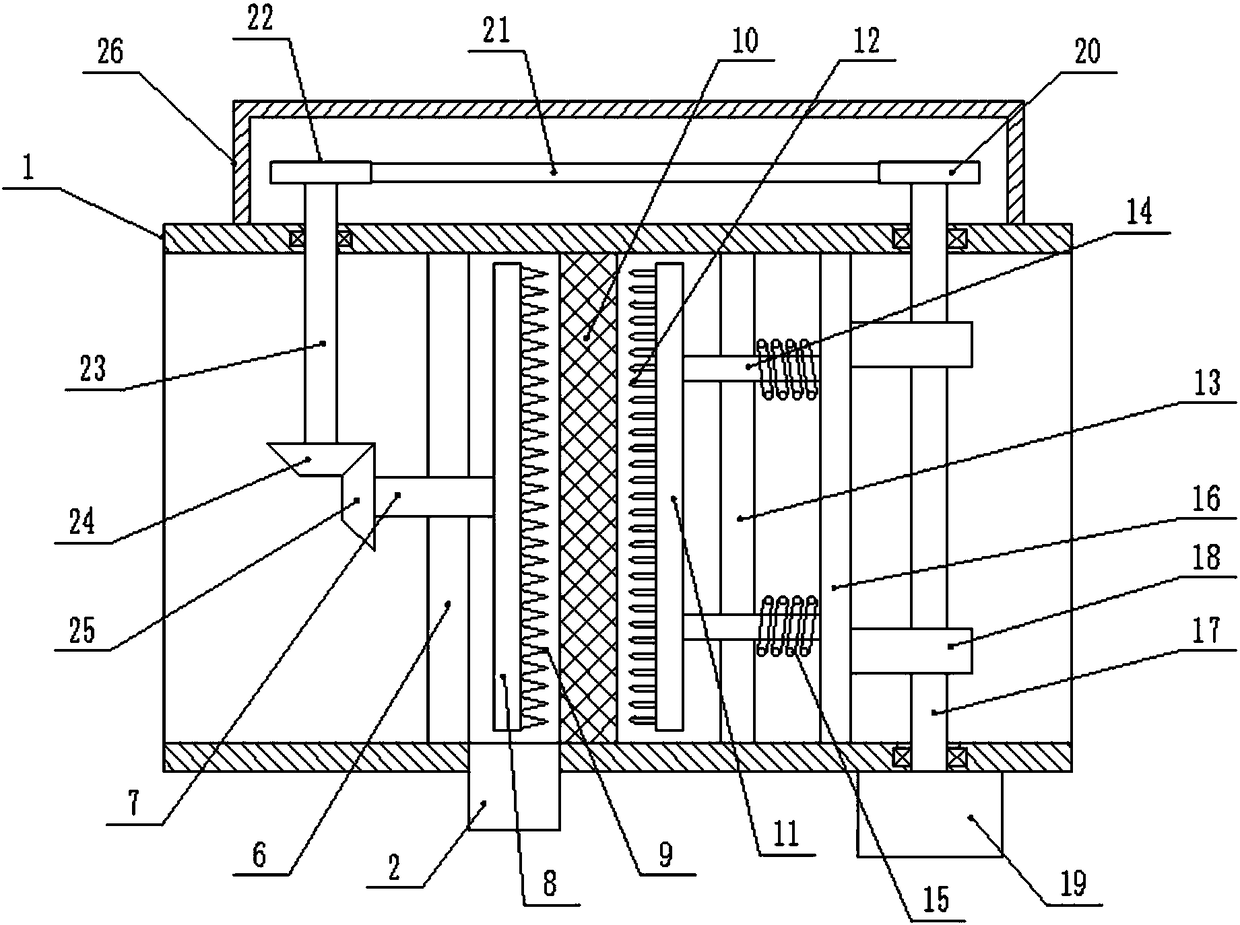

Cam-type dust-removing energy-saving boiler smoke waste heat recovery pipeline

InactiveCN108413425AReasonable structureInnovative designDispersed particle filtrationTransportation and packagingEngineeringCam

The invention discloses a cam-type dust-removing energy-saving boiler smoke waste heat recovery pipeline which comprises a smoke pipeline, wherein a fixing plate is mounted at the inner left end of the smoke pipeline; a rotating shaft is mounted at the middle of the fixing plate; a rotating plate is connected with the right end of the rotating shaft; a smoke dust filtering screen is mounted at theinner middle of the smoke pipeline; a power shaft is mounted at the inner right end of the smoke pipeline; rotating cams are mounted at the middle of the power shaft; a moving plate is in contact with the left sides of the rotating cams; moving rods are connected with the left end of the moving plate; a dust removing plate is fixed at the left ends of the moving rods; a heat recovery tower communicates with the right end of the smoke pipeline; and a snakelike recovery tube is mounted in the heat recovery tower. By adoption of the cam-type dust-removing energy-saving boiler smoke waste heat recovery pipeline disclosed by the invention, smoke dust can be prevented from directly entering the heat recovery tower and being attached to the outer side of the snakelike recovery tube; the recoveryeffect of the snakelike recovery tube on waste heat in smoke can be improved; and meanwhile, the smoke dust accumulated on the smoke dust filtering screen can be removed online, the blockage to the smoke dust filtering screen can be avoided, and the recovery efficiency of the waste heat in the smoke can be further guaranteed.

Owner:HUNAN XIANGXUN ENTERPRISE MANAGEMENT CO LTD

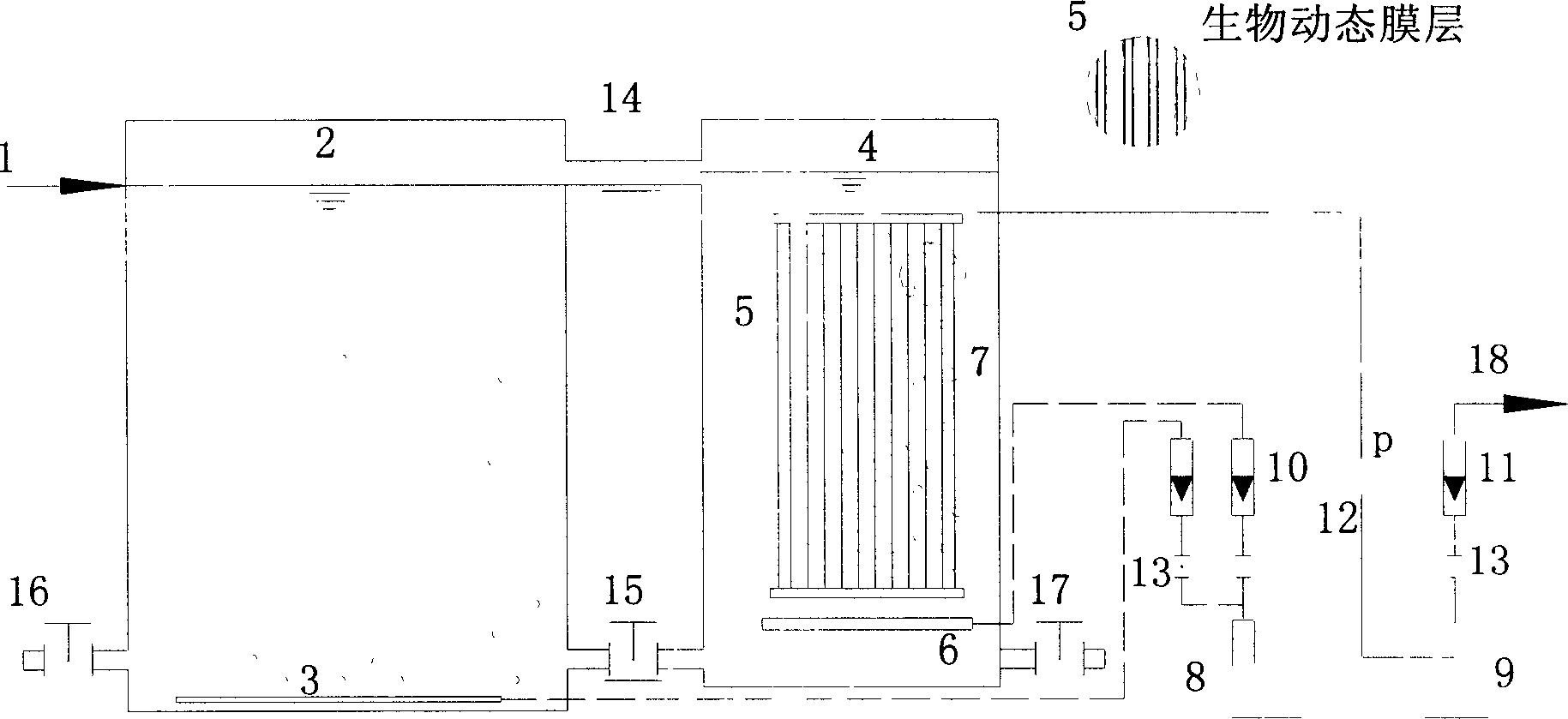

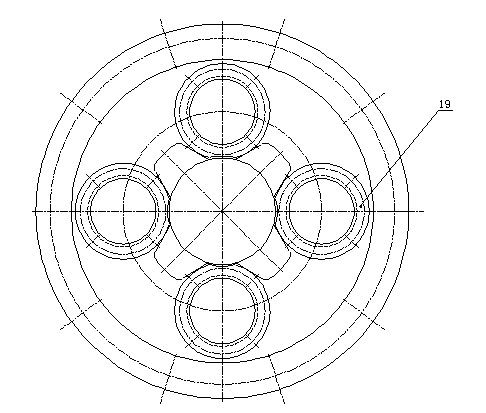

Split-type tube type dynamic membrane bioreactor

InactiveCN1785841AEasy to formRealize online cleaningTreatment using aerobic processesSustainable biological treatmentAeration systemAutomatic control

The present invention relates to a body-separated tubular dynamic membrane biological reactor. It mainly is formed from biological unit, aeration system, membrane unit, suction system and automatic control system. Said invention also provides the working principle of said biological reactor.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

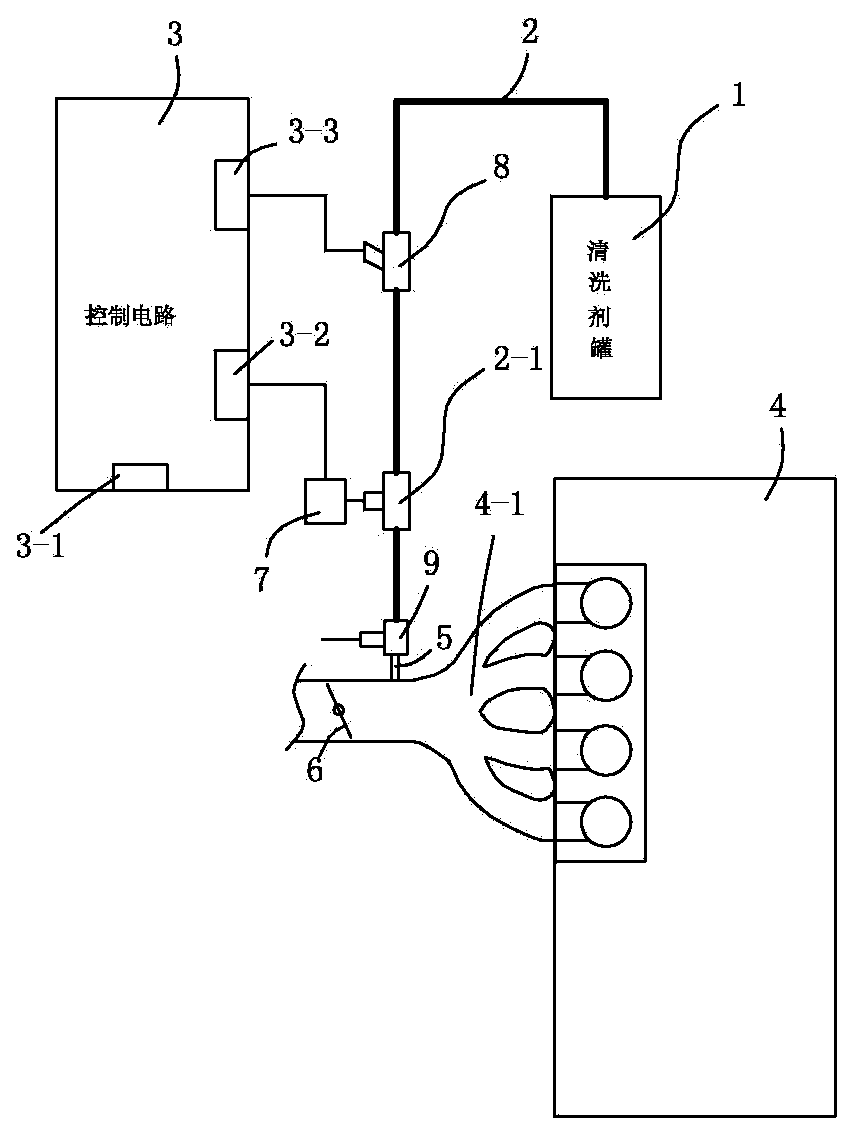

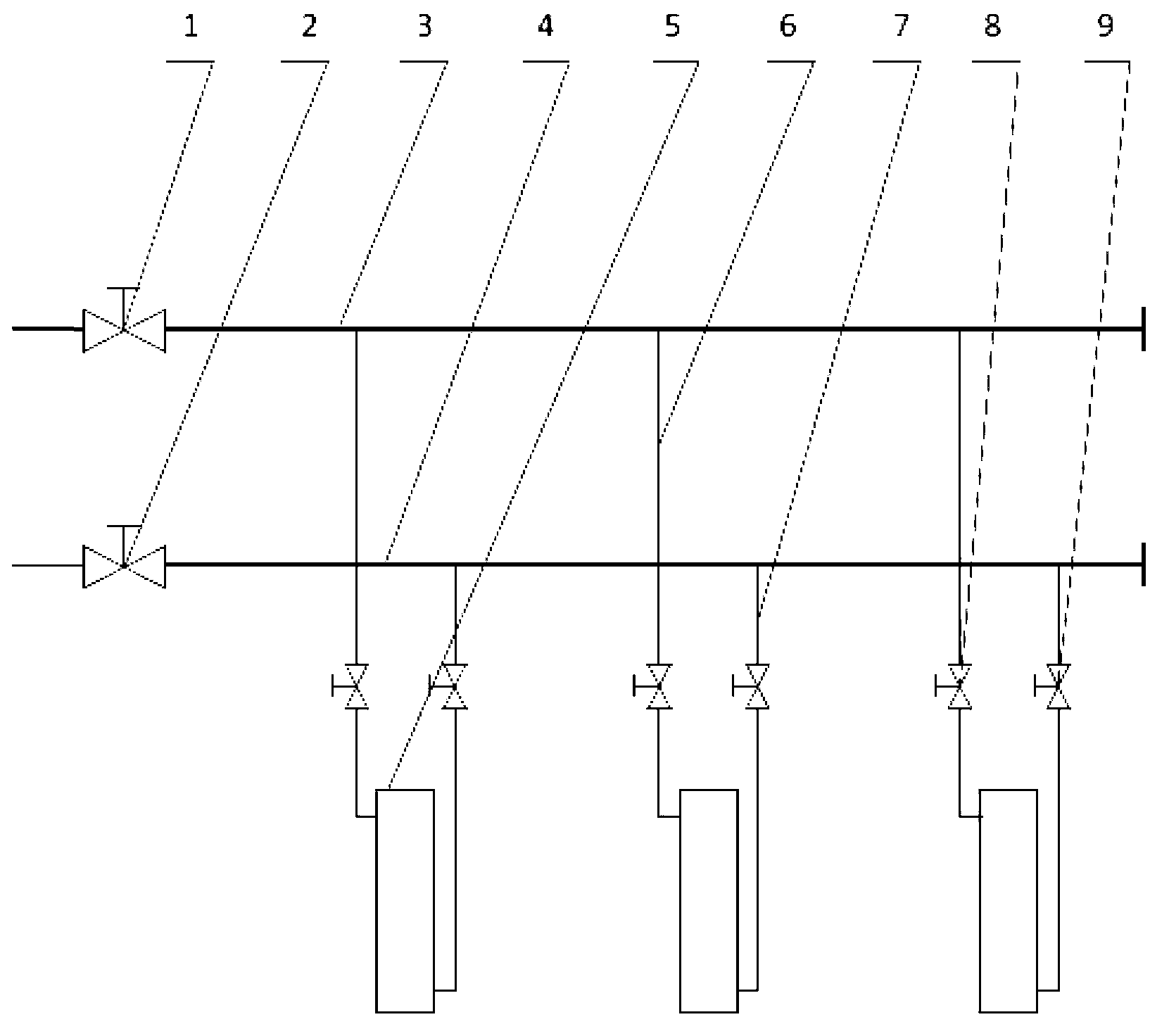

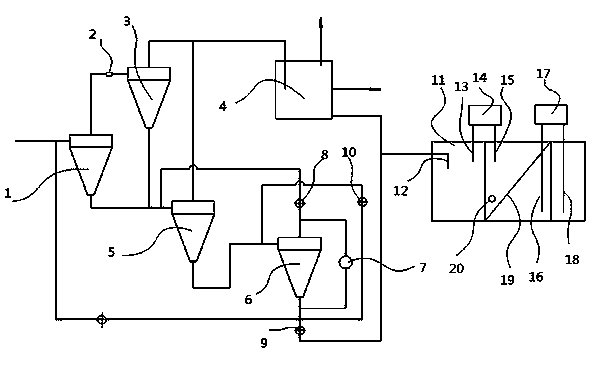

Online carbon deposit cleaning system for air inlet valve and combustion chamber of engine and control method

InactiveCN103422985ARealize online cleaningSimple control methodMachines/enginesEngine componentsCombustion chamberVacuum pressure

The invention discloses an online carbon deposit cleaning system for an air inlet valve and a combustion chamber of an engine and a control method. The system comprises a cleaning agent tank, a cleaning agent charging pipeline and a control circuit, wherein the control circuit comprises a cleaning working procedure; a cleaning starting circuit is arranged in the control circuit; the cleaning agent tank is arranged on a frame in an automotive engine hood; one end of the cleaning agent charging pipeline is connected with the cleaning agent tank, and the other end of the cleaning agent charging pipeline is connected with a vacuum pipeline of the engine; the vacuum pipeline is communicated with the air inlet valve of the automotive engine; a control signal in the running state of the automotive engine is connected with the starting circuit in the control circuit. According to the system and the method, the carbon deposit of the air inlet valve and the combustion chamber of the engine is cleaned on line on the premise of no changes in the conventional basic design of an automobile; the control method is simple and practical; automatic closed loop control over the inflow of a cleaning agent and vacuum pressure is realized; a cleaning process is safe and reliable, and the environment friendliness of engine emissions is improved.

Owner:刘新羽

Rock debris filtering device

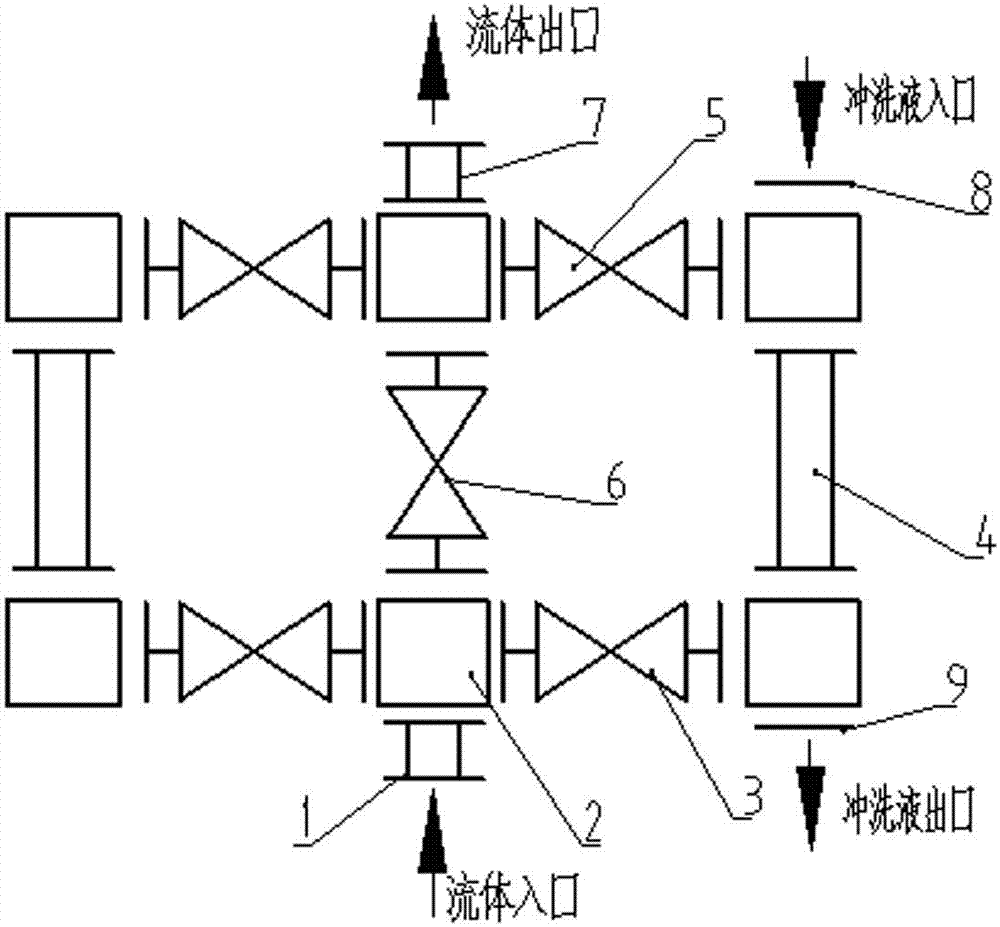

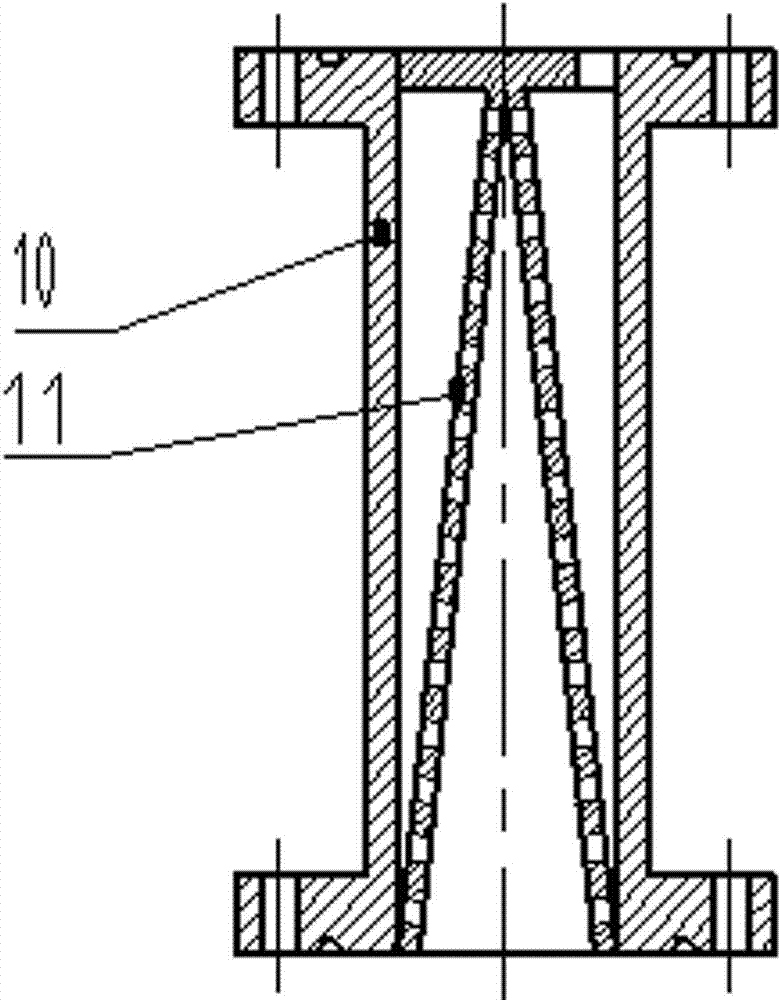

The invention discloses a rock debris filtering device. The rock debris filtering device comprises a stop valve, a connecting pipeline and a filter. The rock debris filtering device is provided with a rock debris filtering channel, a rock debris non-filtering channel and a standby filtering channel; a filter cartridge can be conical, cylindrical or in a round-table shape; an inlet and an outlet of the rock debris filtering device can be respectively installed with a pressure measuring device; and the upstream and the downstream of the filter are connected with an outlet of a flushing pipeline and an inlet of the flushing pipeline. The rock debris filtering device has the advantages of small pressure reduction, strong rock debris filtering capacity, a small number of flushing times for the filter cartridge and on-line cleaning.

Owner:CHINA PETROCHEMICAL CORP +1

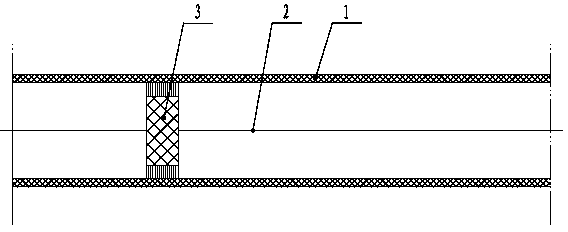

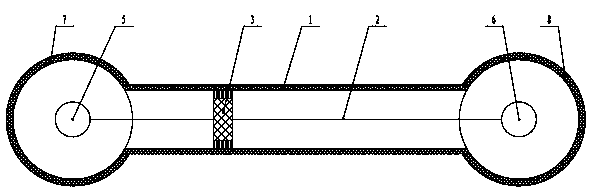

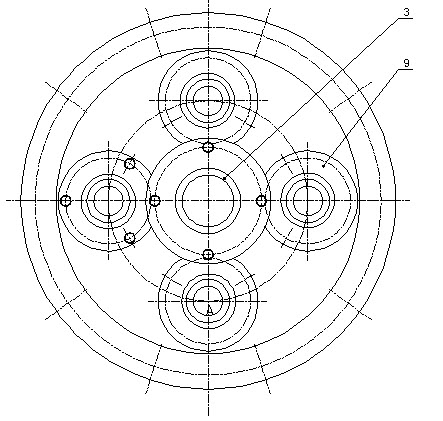

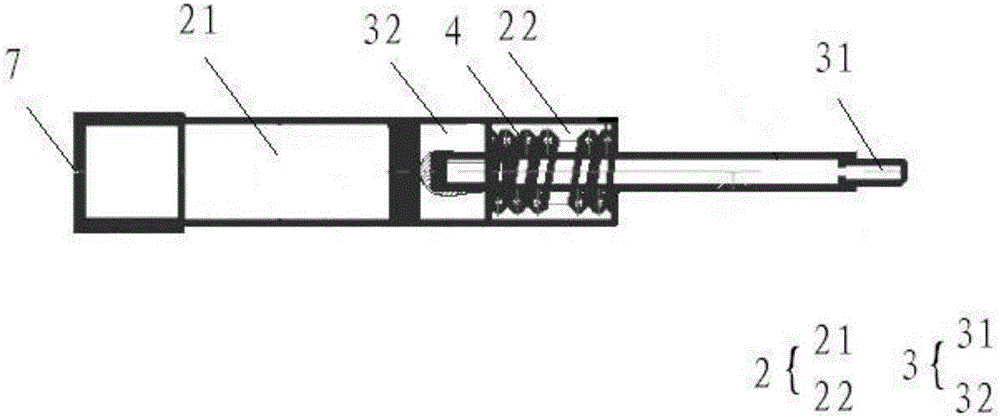

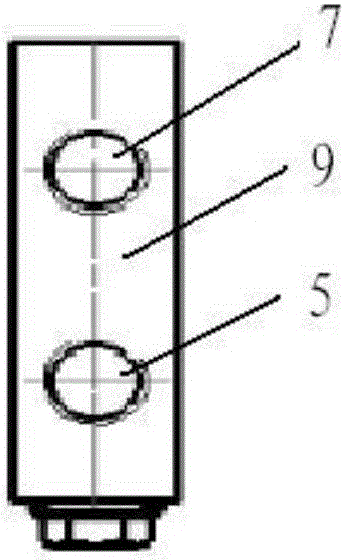

Aeration system capable of being cleaned on line

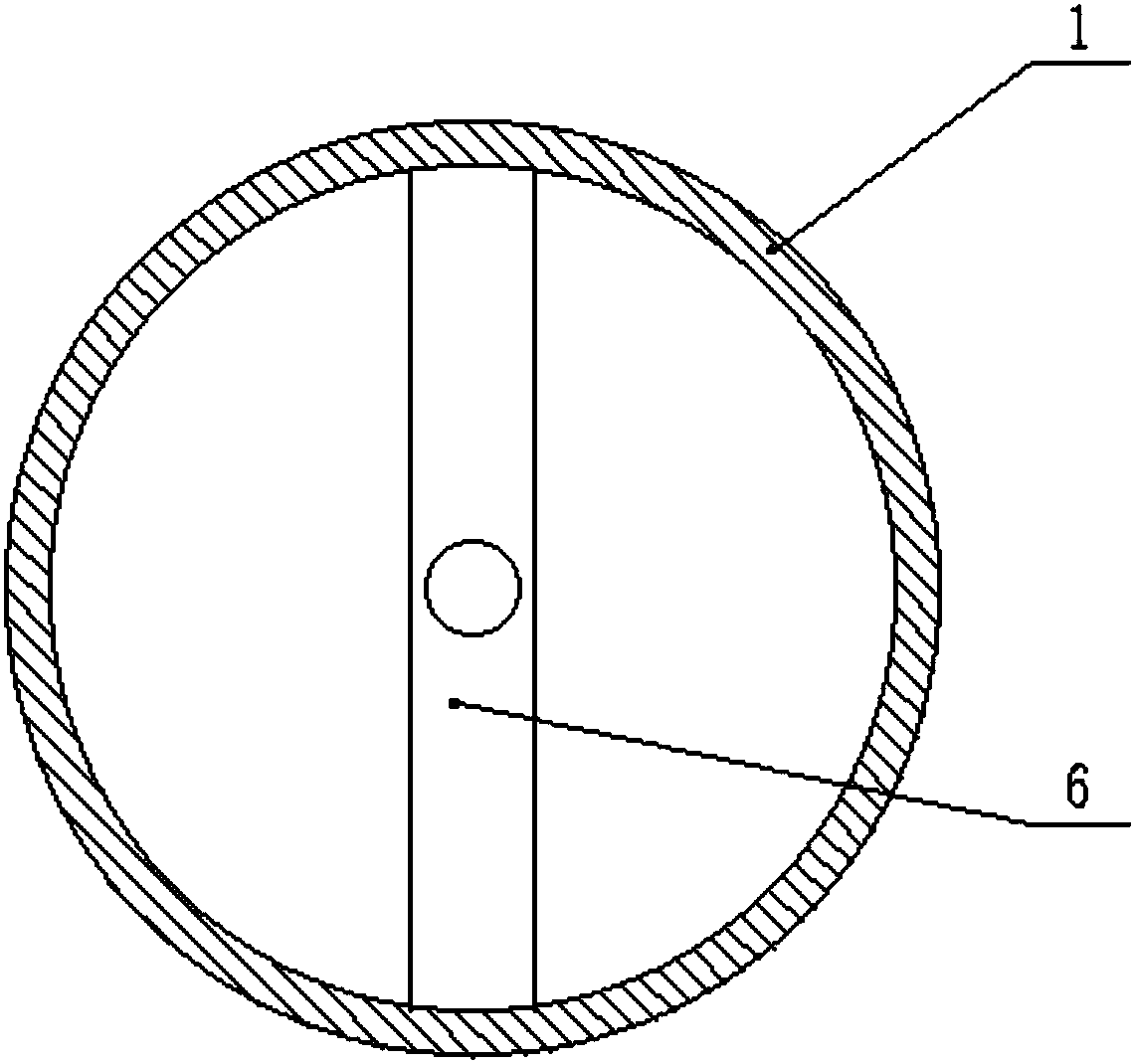

ActiveCN103626309AAvoid cloggingImprove the aeration effectWater aerationCleaning using toolsMembrane configurationTubular membrane

The invention discloses an aeration system capable of being cleaned on line. The aeration system is used in the sewage treatment industry and comprises membranes provided with self-closing micropores, wherein each membrane is of a tube shape, and a pull rope capable of carrying out left-and-right reciprocating motion is arranged in the tubular membrane and is fixedly provided with a hairbrush capable of cleaning the membrane. According to the invention, since each membrane is tubular and the hairbrush capable of carrying out reciprocating motion is arranged in the tubular membrane, on-line cleaning of the interior of each membrane is realized, blockage of the self-closing micropores is prevented, aeration effects are improved, energy consumption is reduced, and the service lives of the membranes are prolonged.

Owner:兴港红环保设备河北有限公司

Aluminum plate washing device

PendingCN107597643ARealize online cleaningImprove efficiencyPretreated surfacesDirt cleaningEngineeringSponge

Owner:NANJING TONGWANG ALMINIUM CO LTD

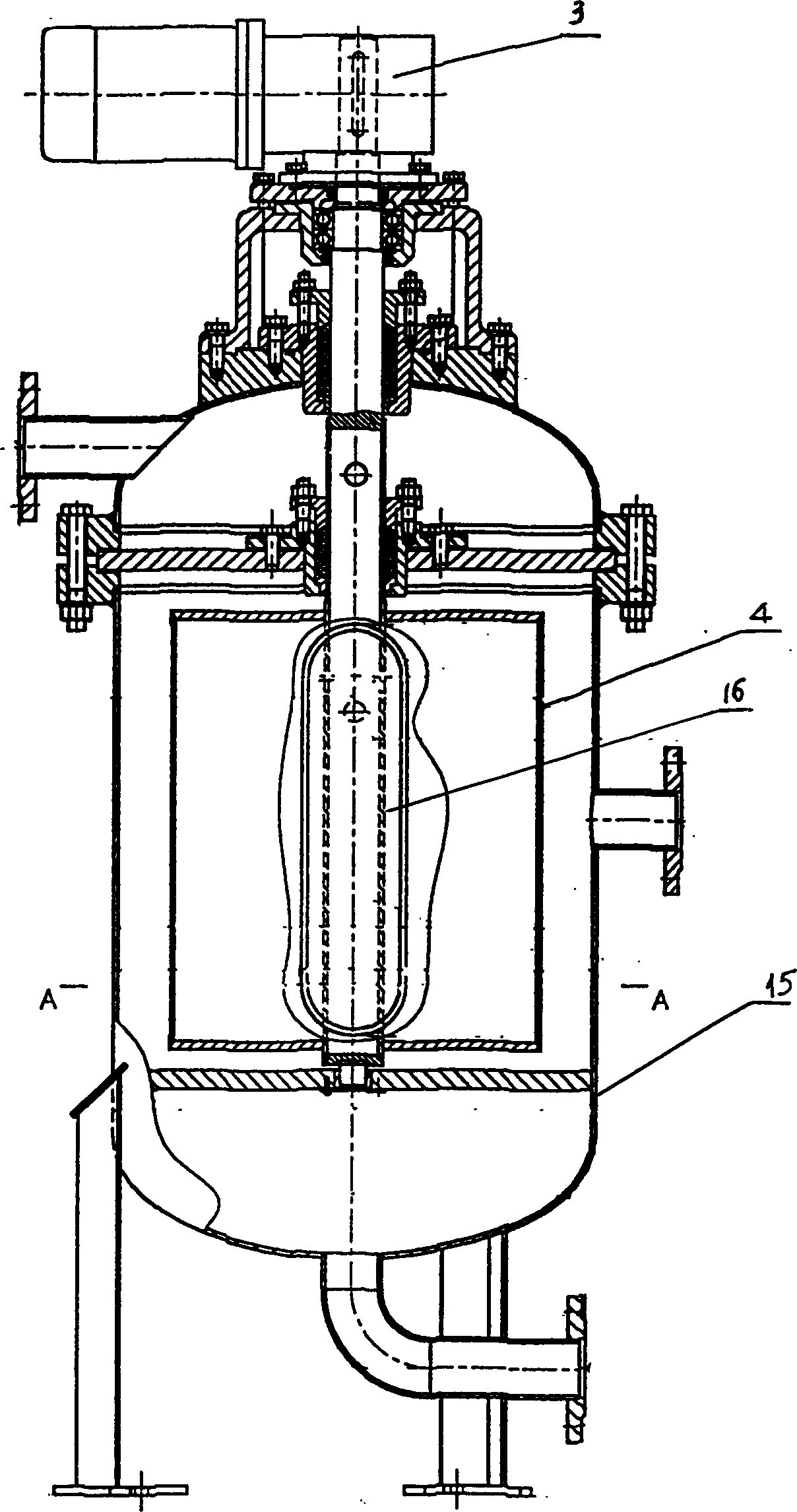

On line autrasonic cleaning and filtering device

InactiveCN1555907AKeep the flow openFast cleaningSemi-permeable membranesStationary filtering element filtersLine tubingDifferential pressure

An in-line ultrasonic washing filter unit is composed of multiple filters with ultrasonic transducer, ultrasonic generator, differential pressure transmitter, PLC autocontroller, pipelines and control valves. Said filter consists of cylindrical body, hollow rotary shaft, drum-type filtering net, speed-reducing motor unit, and at least one ultrasonic transducer. Its advantages are high filtering precision, high automation level and high washing effect.

Owner:SHANGHAI SHENGYU TECH CO LTD

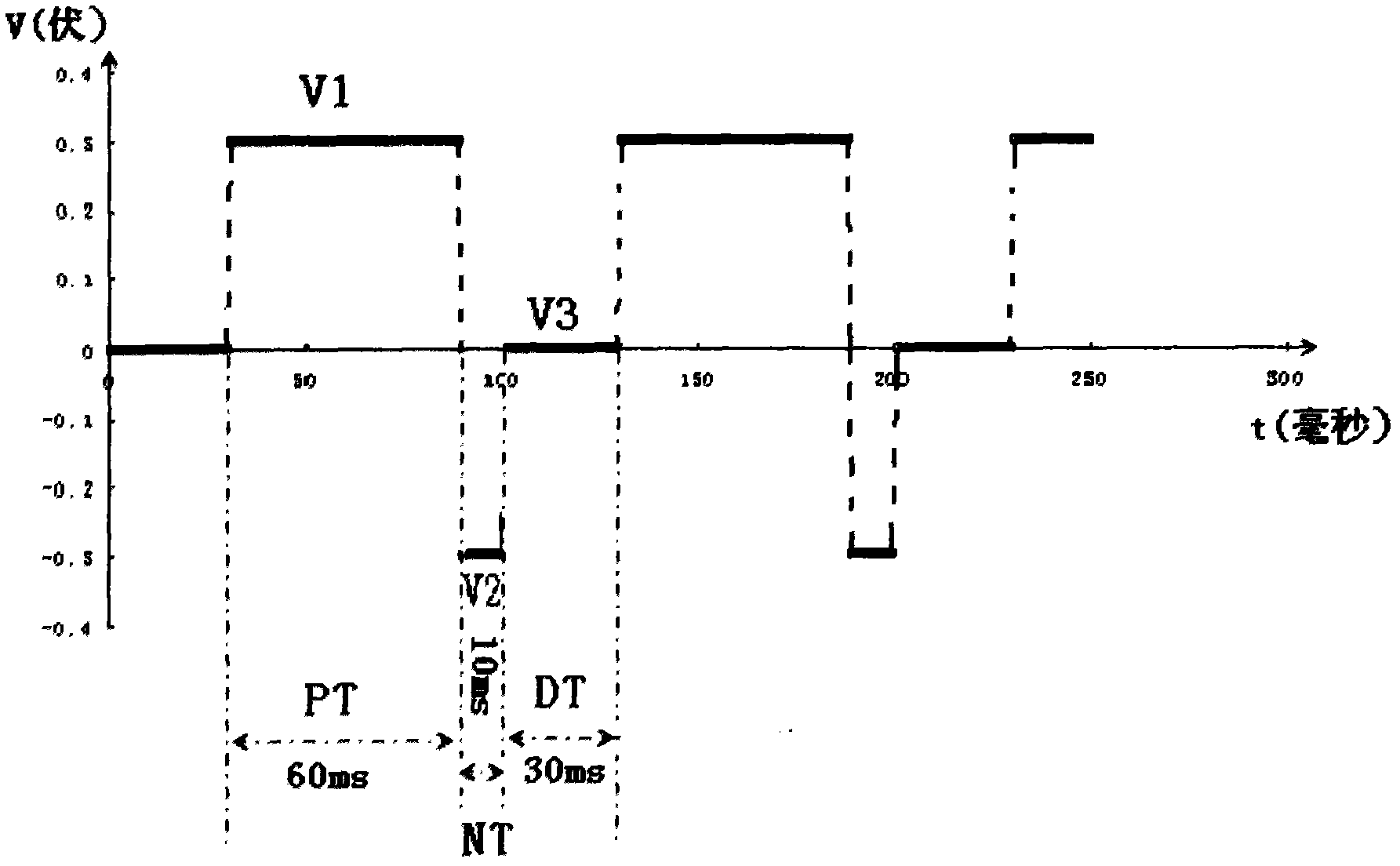

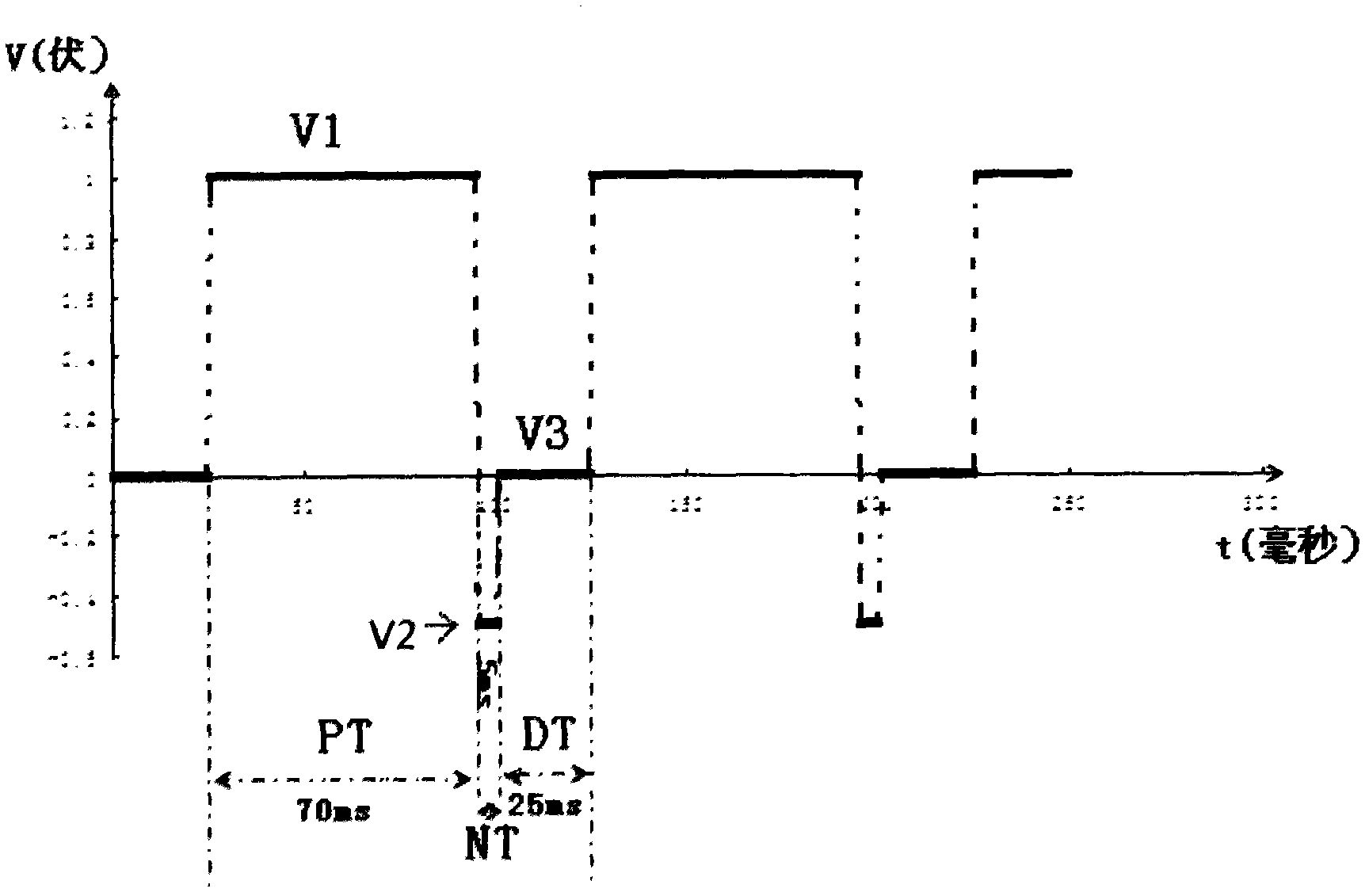

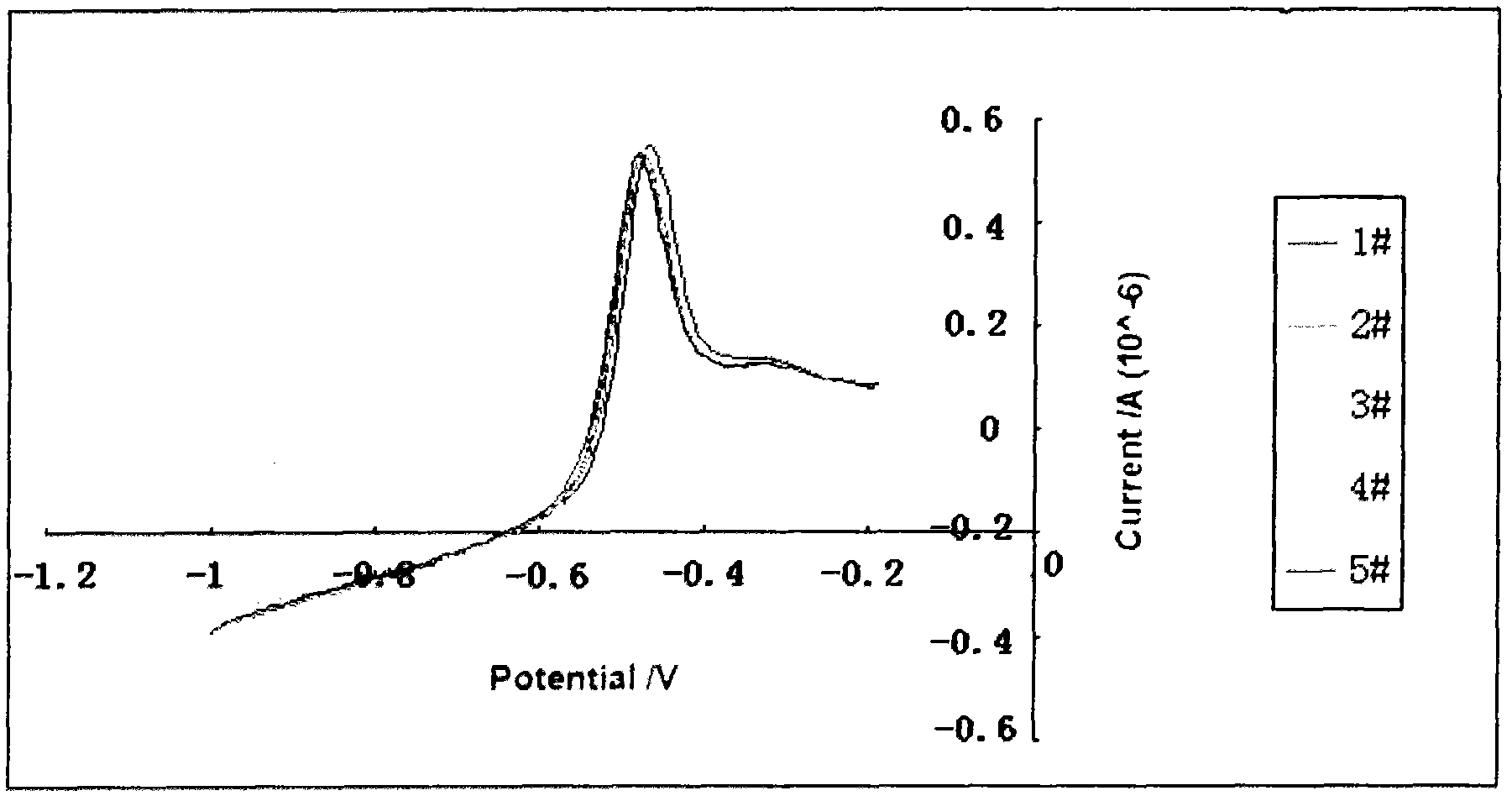

Electrochemistry on-line cleaning method for heavy metal on-line monitor working electrode

ActiveCN102608191ARealize online cleaningBreak through the research and development limitMaterial electrochemical variablesHeavy metalsEngineering

The invention relates to an electrochemistry on-line cleaning method for a heavy metal on-line monitor working electrode based on anodic stripping voltammetry. Each cleaning cycle internally comprises three steps of positive electric potential cleaning, negative electric potential cleaning and initial electric potential recovery for a working electrode, wherein the electric potential (V1) of the positive electric potential cleaning is a positive value; the electric potential (V2) of the negative electric potential cleaning is a negative value; and the initial electric potential (V3) is between the (V1) and the (V2). The electrochemistry cleaning method provided by the invention can clean the working electrode surface fully, the good electrode importance is ensured, the on-line cleaning of the working electrode is realized, and the research and development restriction of the heavy metal automatic on-line monitor based on the anodic stripping voltammetry is broken through.

Owner:QINGDAO JIAMING MEASUREMENT & CONTROL TECH

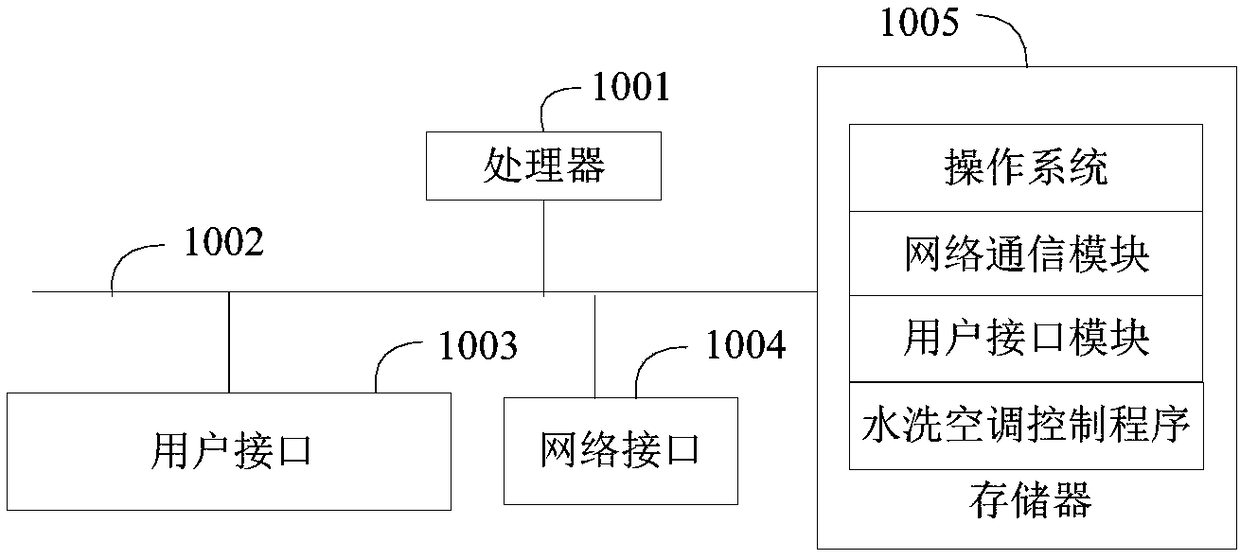

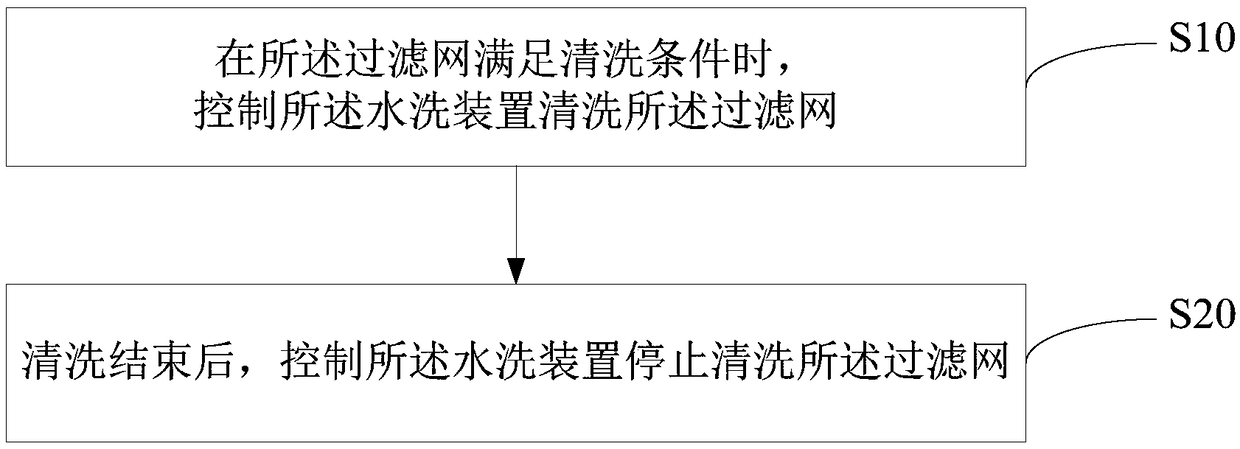

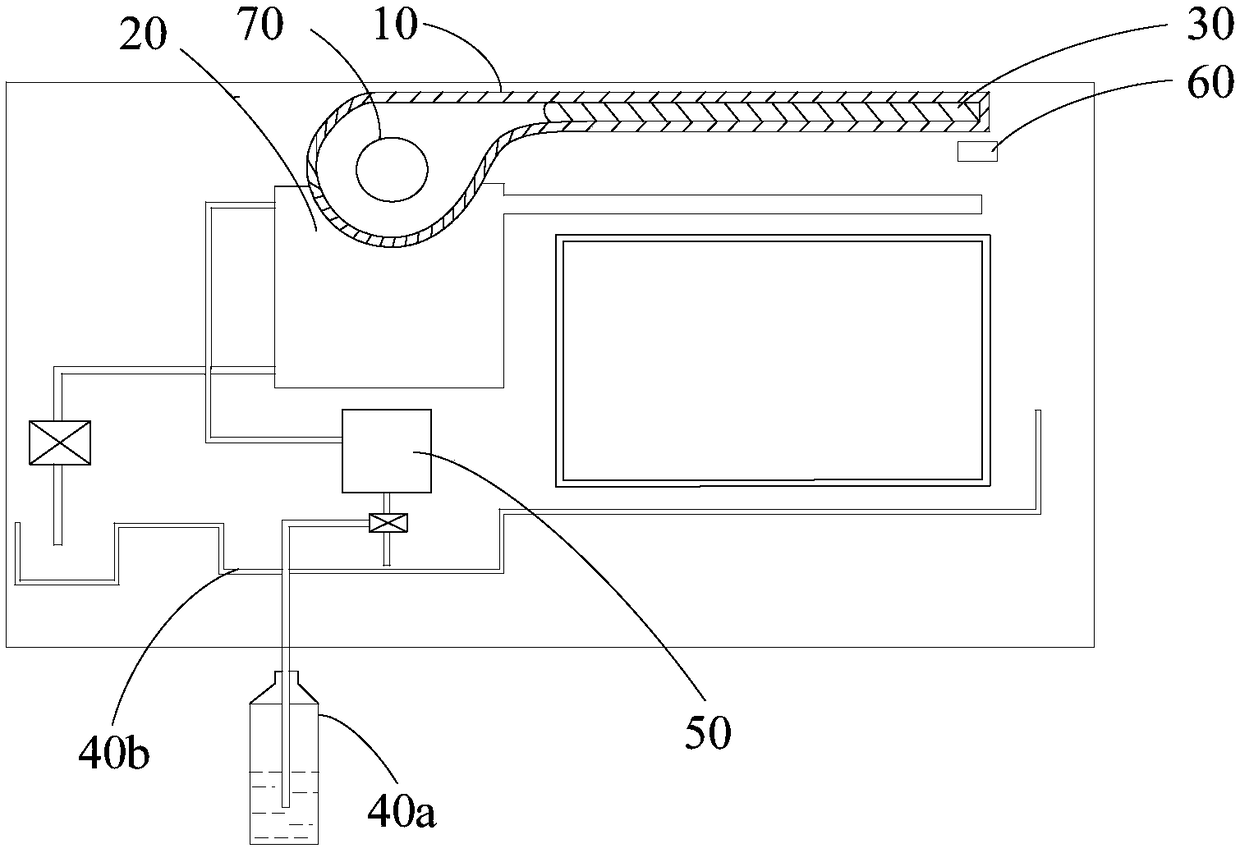

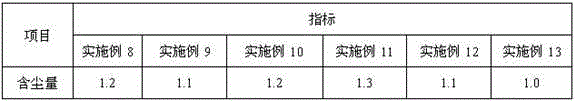

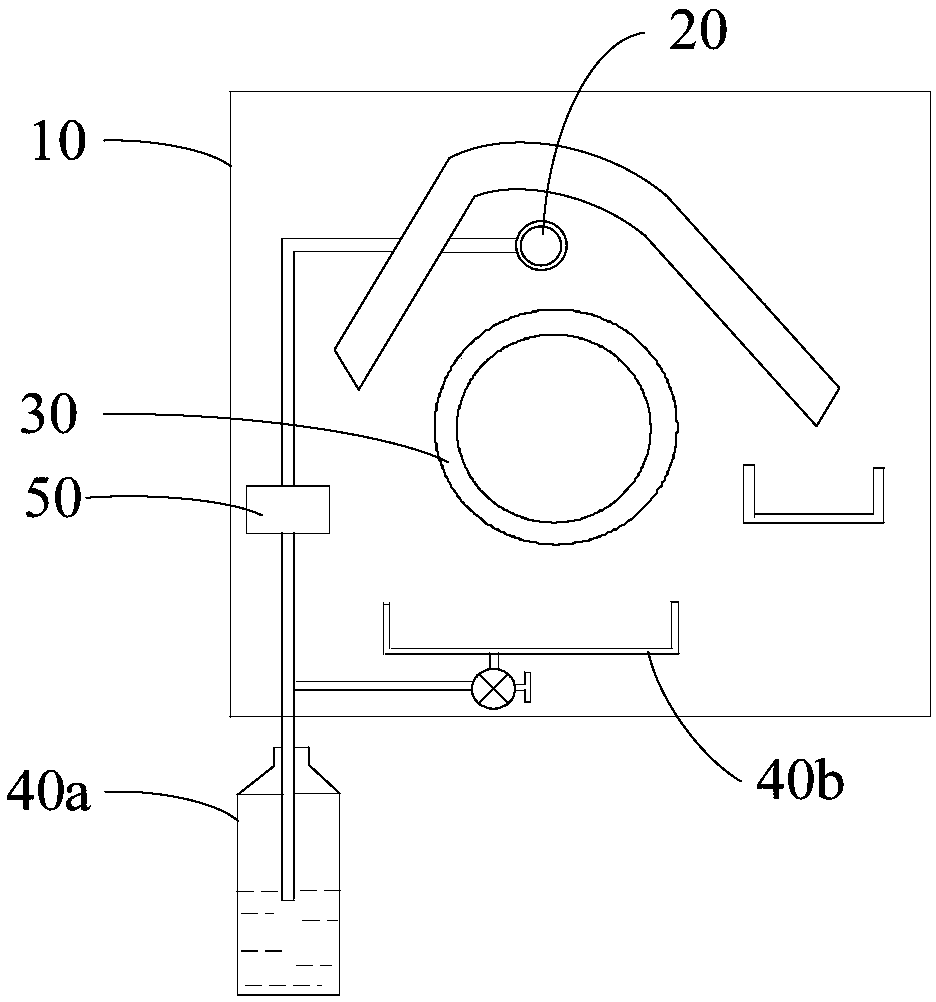

Control method of washable air conditioner, air conditioner and computer readable storage medium

InactiveCN109059182ARealize online cleaningEasy to operateMechanical apparatusLighting and heating apparatusWater sourceEngineering

The invention discloses a control method of a washable air conditioner. An indoor unit of the air conditioner is provided with a shell with an air inlet, and a filter screen arranged at the air inlet;the indoor unit further comprises a water washing device, and the water washing device is connected with a water source through a pipeline to wash the filter screen with water; the control method ofthe washable air conditioner comprises the following steps that when the filter screen meets the washing condition, the water washing device is controlled to wash the filter screen; and after washingis completed, the water washing device is controlled to stop washing the filter screen. The invention also discloses an air conditioner and a computer readable storage medium. According to the indoorunit of the air conditioner provided by the invention, the water washing device is arranged, the water washing device is connected with the water source through the pipeline, the water washing deviceis controlled to directly utilize the water source to supply water to wash the filter screen, so that on-line washing is realized; dismounting or hand washing is not needed, the automatic washing is carried out when the filter screen meets the washing condition, and operation is convenient.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Ultrasonic cleaning process for copper surface

InactiveCN104588349AImprove decontamination abilityImprove rust resistanceCleaning using liquidsWater basedEngineering

The invention provides an ultrasonic cleaning process for a copper surface. The process comprises the following steps of 1, precleaning, wherein contaminants on a workpiece are softened, separated and dissolved through a hot dipping or spray-washing method; 2, rough cleaning, wherein dirt on the surface of the workpiece is stripped to fall off through ultrasonic cleaning under the action of water-based cleaning agents; 3, fine cleaning, wherein ultrasonic rinsing is adopted, and cleaning media left on the surface of the workpiece are washed off through pure water; 4, high-pressure flushing, wherein high-pressure pure water spraying is carried out in an omnibearing mode from top to bottom so as to flush away contaminating media in small blind holes and clearances, and hot air drying is carried out. The water-based cleaning agents are composed of 0.8 g / l to 1.2 g / l of surface active agents KE-1, 2.0 g / l to 2.5 g / l of surface active agents AES, 2.2 g / l to 2.6 g / l of surface active agents NP-10, 0.5 g / l to 0.6 g / l of auxiliary detergent, 0.8 g / l to 1 g / l of compound corrosion inhibitor and solvent of water.

Owner:成都川硬合金材料有限责任公司

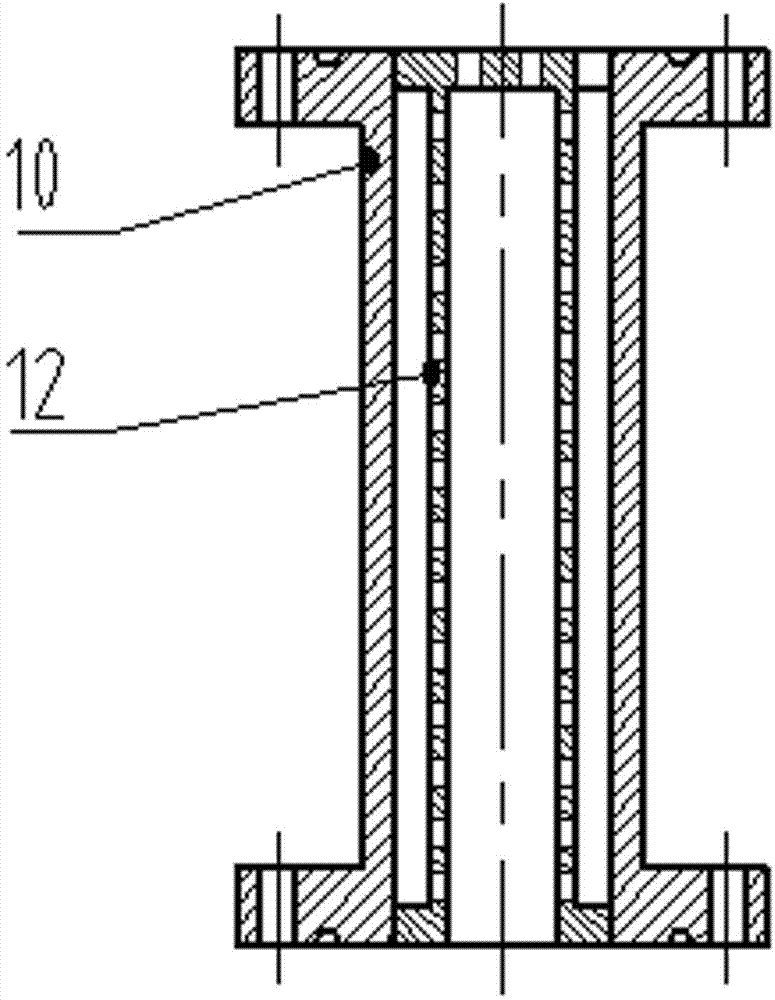

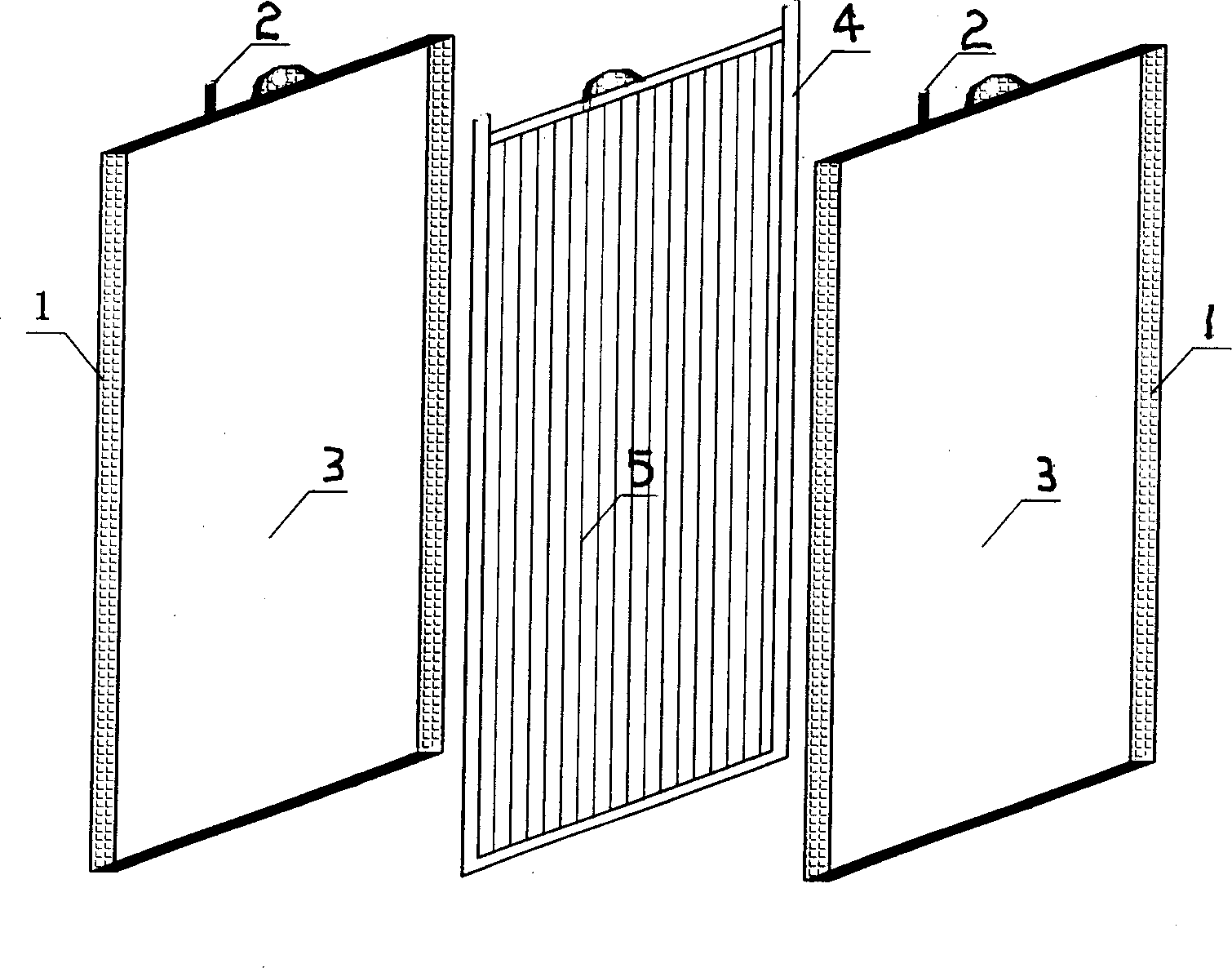

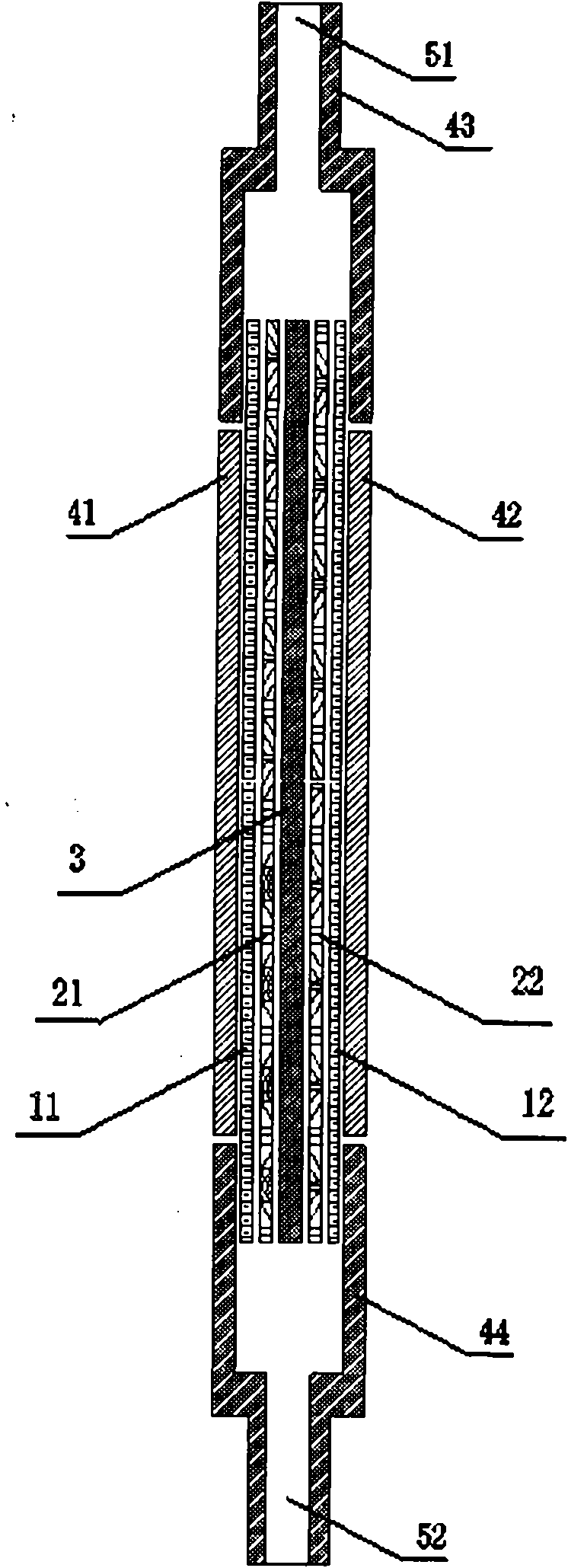

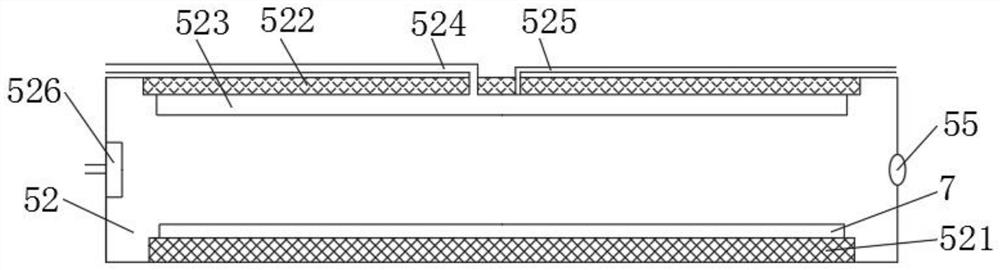

Plate type membrane assembly

InactiveCN1814557ARealize the role of mechanical cleaningFacilitated DiffusionCleaning using toolsSustainable biological treatmentEngineeringMechanical engineering

The invention relates to a new type flat film component that is made up of sheet frame film component, and sheet frame mechanism cleaning brush. The sheet frame film is made up of pressing film, raw net supporting material, supporting board, raw new supporting material, film. And the mechanism cleaning brush is made up of brushing and brush frame. The feature is that it enhances the mechanism cleaning brush to realize the removal of the main pollution of flat film and keeps the advantage of traditional flat film component. The component installs mechanism cleaning brush in the interval clearance between the traditional flat film component to realize online washing, and enhances the yield and useful life of the film component.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

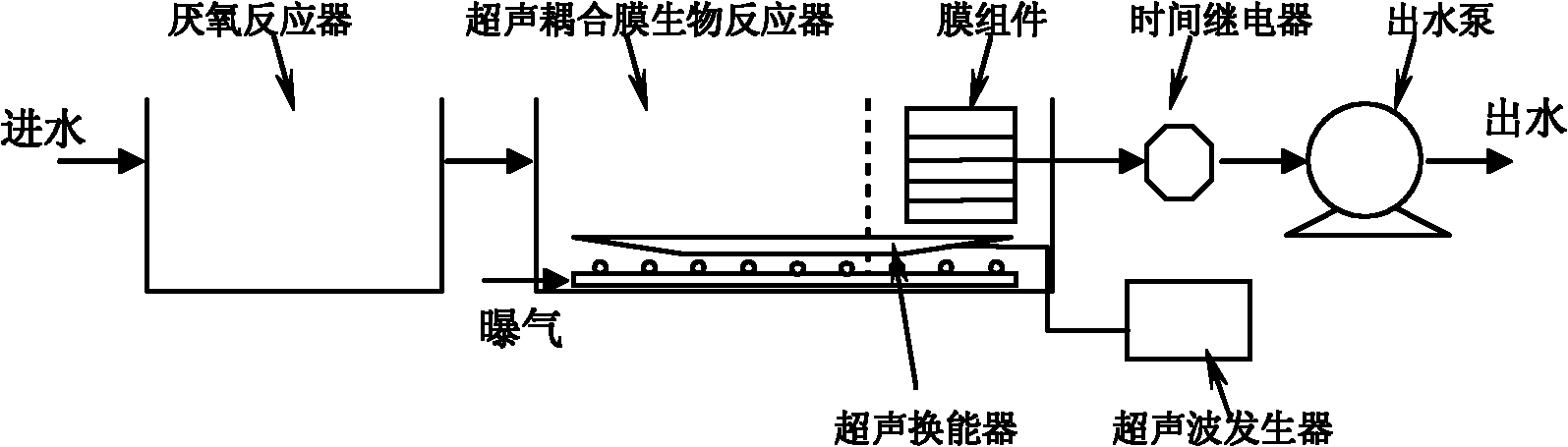

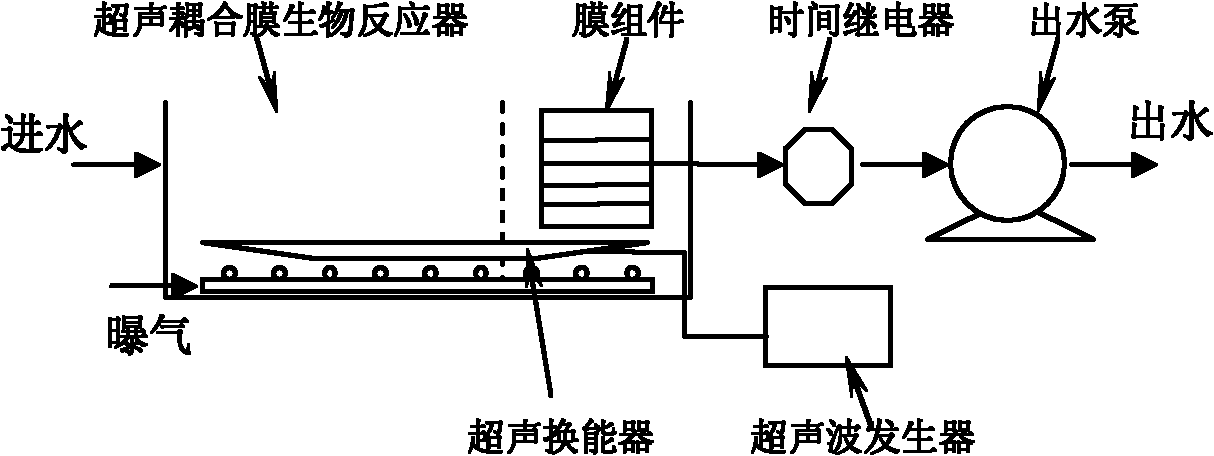

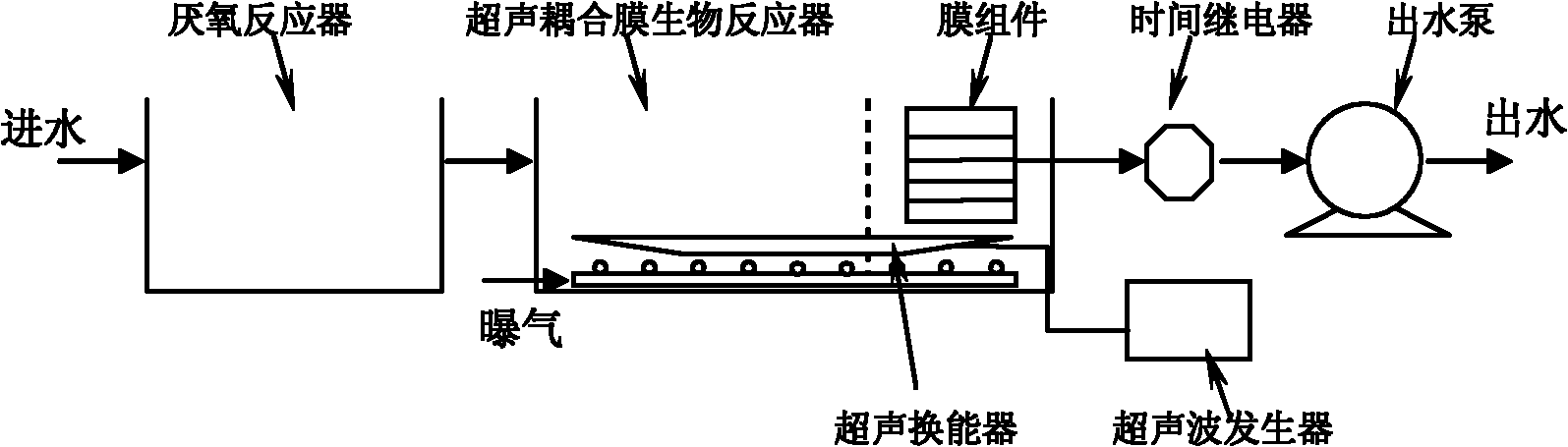

Ultrasonic coupled membrane bioreactor for treating difficultly-degradable organic waste water

InactiveCN102145962AImprove permeabilityImprove degradation efficiencyWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentUltrasonic radiationDrug biological activity

The invention discloses an ultrasonic coupled membrane bioreactor for treating difficultly-degradable organic waste water, belonging to the technical field of sewage treatment. The bioreactor is characterized in that: the bottom of a membrane bioreactor is provided with an ultrasonic transducer; the ultrasonic transducer is connected with an ultrasonic generator and is used for converting a high-frequency oscillation signal transmitted by the ultrasonic generator into high-frequency mechanical oscillation and transmitting the high-frequency mechanical oscillation to the ultrasonic coupled membrane bioreactor; the frequency of ultrasonic waves is between 10 KHz and 35 KHz; the ultrasonic radiation intensity is between 0.05 W / cm<2> and 0.2 W / cm<2>; the radiation time is between 2 minutes and 20 minutes; the radiation period is between 12 hours and 48 hours; and the sludge concentration of the ultrasonic coupled membrane bioreactor is between 2 g / L and 10 g / L. By adopting the ultrasonic coupled membrane bioreactor, the biological activity and mass transfer capability are enhanced, the degradation efficiency of a difficultly-degradable organic matter is increased, the membrane pollution is reduced, online cleaning of a membrane component is realized, and the running cost of the membrane bioreactor is lowered.

Owner:DALIAN UNIV OF TECH

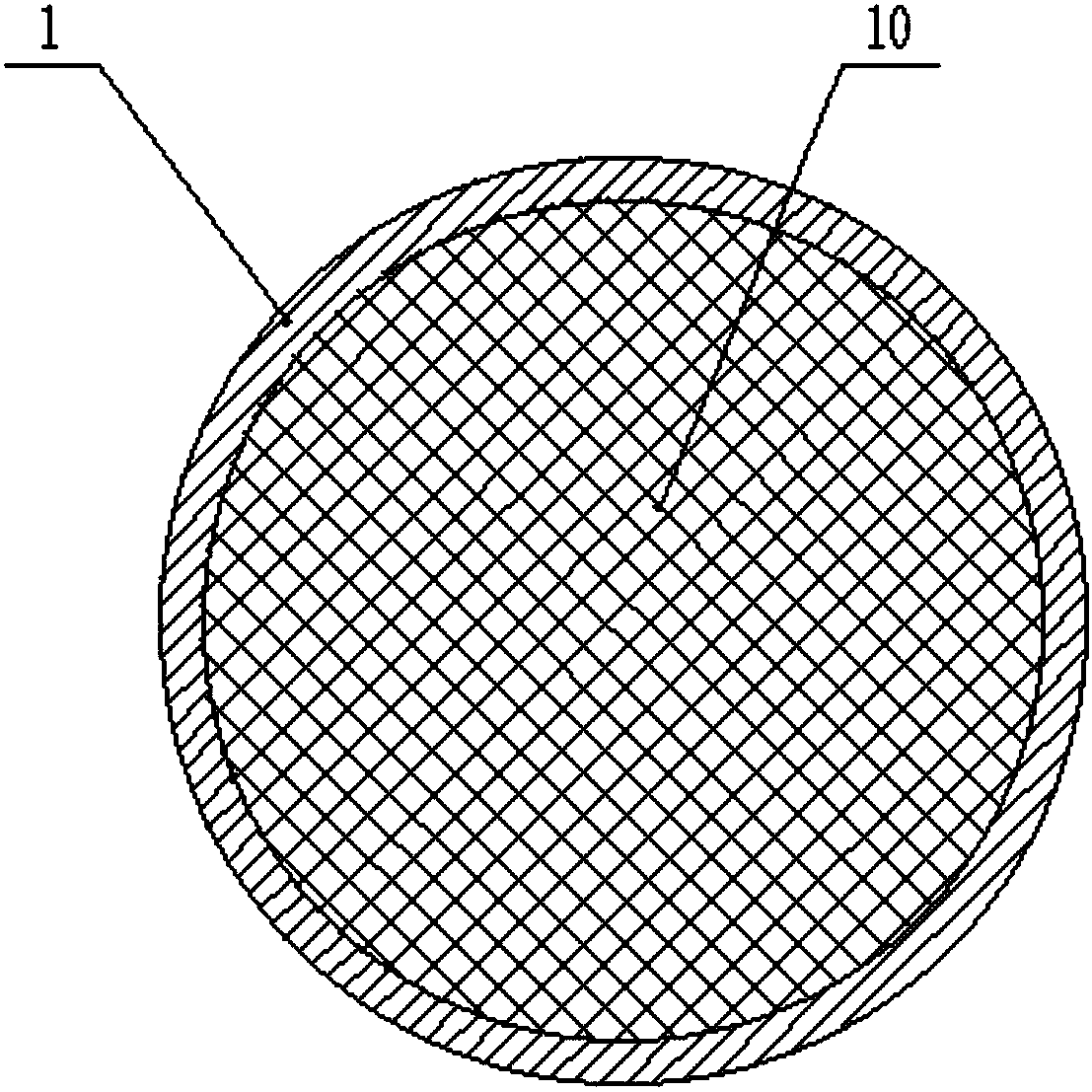

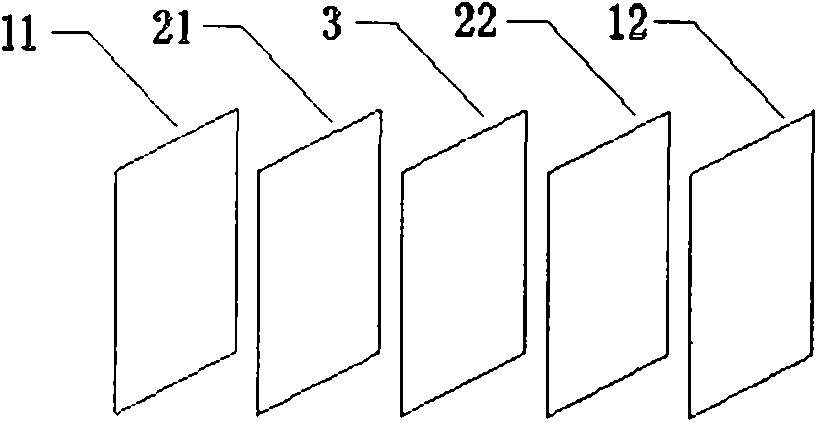

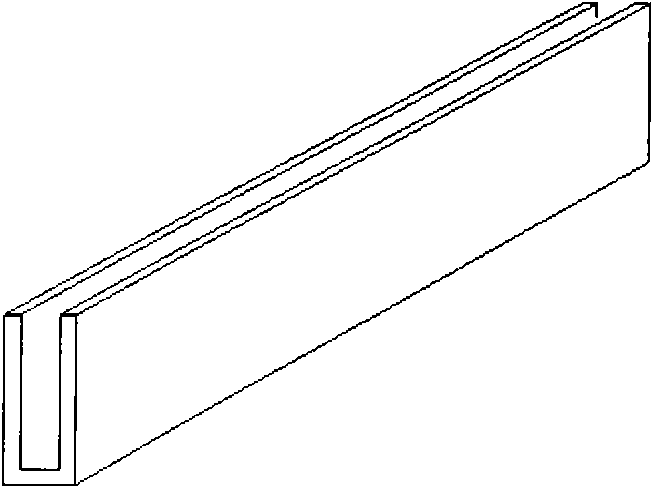

Back-washable flat membrane element

ActiveCN101829504AGuaranteed uptimeSimple structureSemi-permeable membranesBiological water/sewage treatmentMembrane bioreactorEngineering

The invention discloses a back-washable flat membrane element, belonging to the field of flat membrane element, which is characterized in that the flat membrane element is formed by superposing a first backwashing protecting screen, a first flat membrane, a first stream guidance screen, a backing plate, a second stream guidance screen, a second flat membrane and a second backwashing protecting screen in sequence, namely a back-washable flat membrane main body is formed after superposition, and the periphery of the main body is sealed by a U-shaped seal groove, wherein, the upper and lower sides of the U-shaped seal groove are respectively provided with a stream guidance groove, an opening and a fixed ring. The back-washable flat membrane element of the invention has convenient operation and simple structure, realizes on-line cleaning, leads a membrane bioreactor to operate continuously, and is especially suitable for water processing fields, such as life, chemical engineering, biological engineering and environmental protection and the like.

Owner:BEIJING CRYSTEC TECH

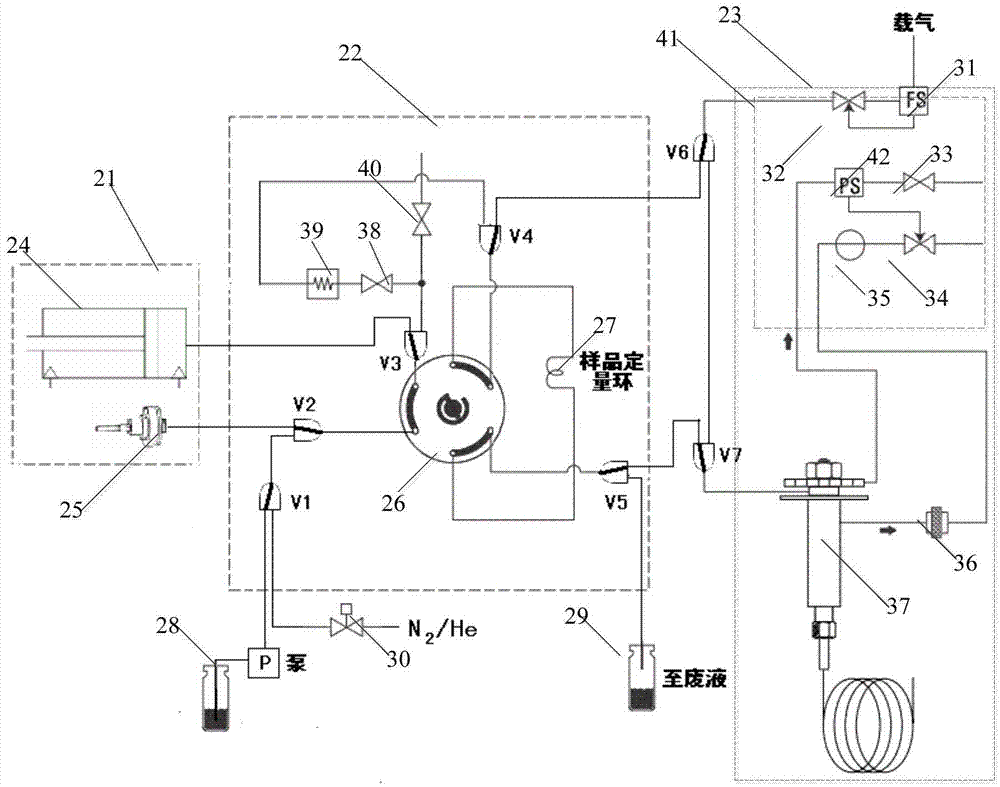

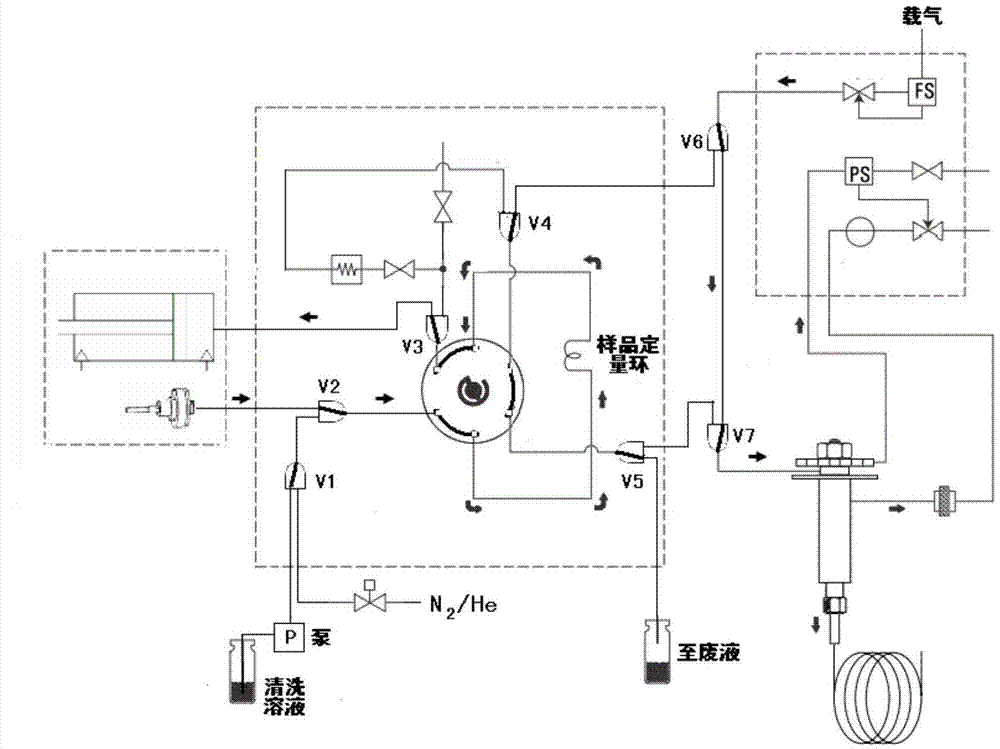

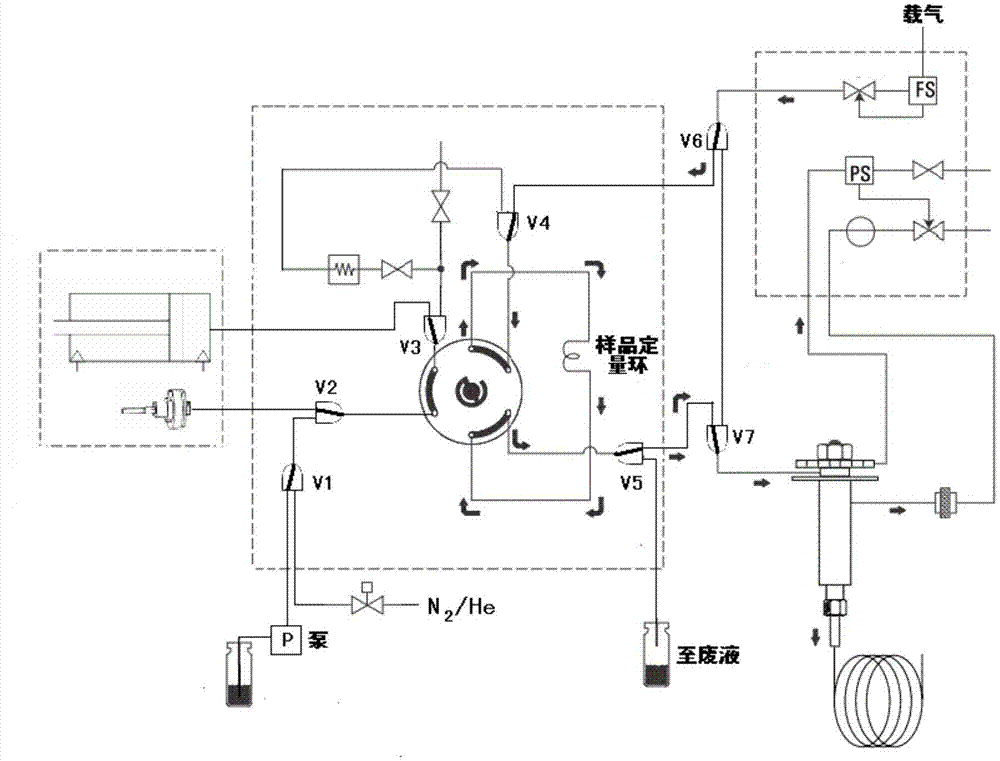

On-line real-time analysis method for tobacco smoke

ActiveCN104713959AOvercoming discriminationRealize online collection, real-time analysis and detectionComponent separationReal time analysisFiltration

The invention discloses an on-line real-time analysis method for tobacco smoke. The method adopts an on-line real-time analyzer for tobacco smoke, and the analyzer comprises a smoking machine, a feeding and cleaning module, a smoke analysis module, a smoke holding device, a deactivated pipeline system and an external controller. A gas chromatograph or gas-mass spectrometer is used for realizing detection of sample components; the temperature-controllable smoke holding device is used for realizing selective gas filtration or total smoke analysis without filter disc through various special adsorption materials and temperature setting; the external controller is used for realizing synchronous control of the smoking machine, an on-line pollution cleaning sampler and the gas chromatograph; thus, the real-time collection and analysis of tobacco smoke is completed. The method has the characteristics of controllable suction, controllable smoke volume, controllable temperature, real-time cleaning of smoke pollution and no residues, realizes real-time on-line analysis, directly analyzes the gas components generated by tobacco burning, and avoids chemical change or loss of components in the sample processing process.

Owner:CHINA TOBACCO HUNAN INDAL CORP +1

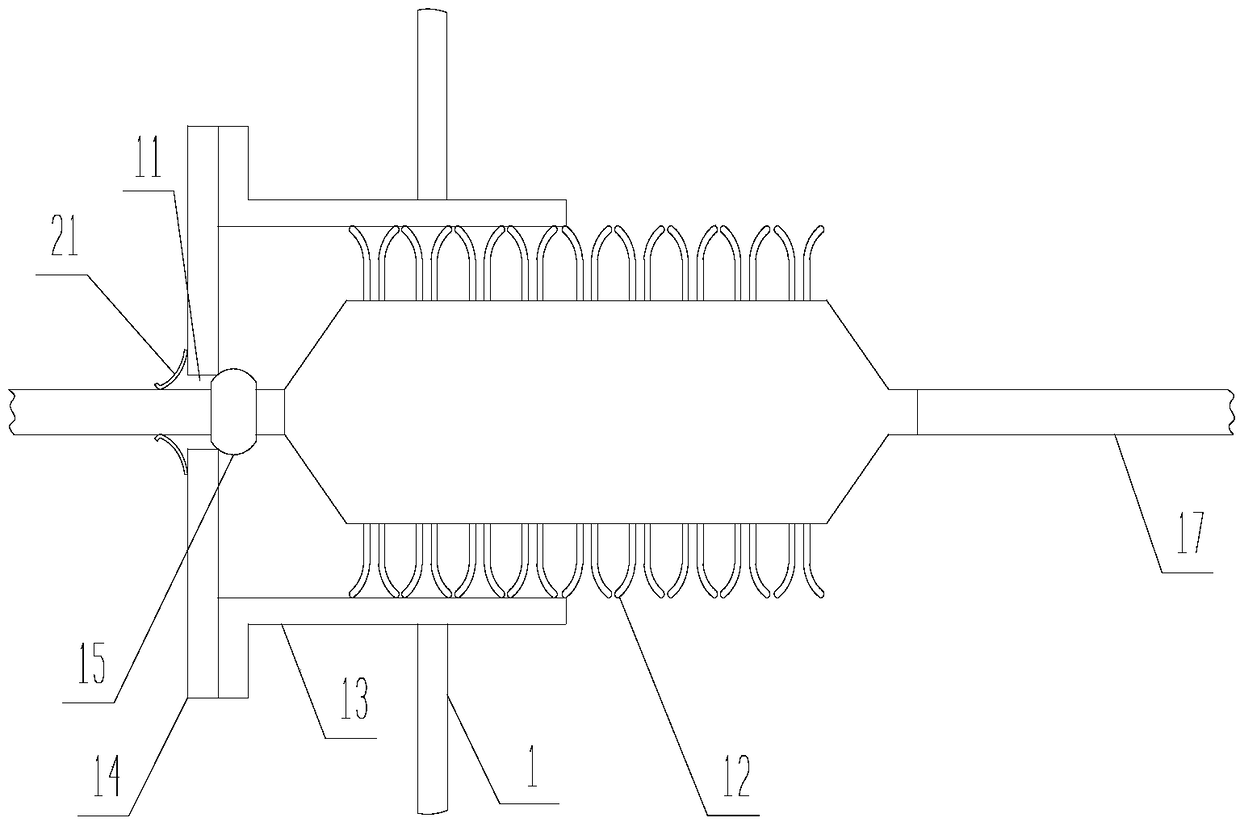

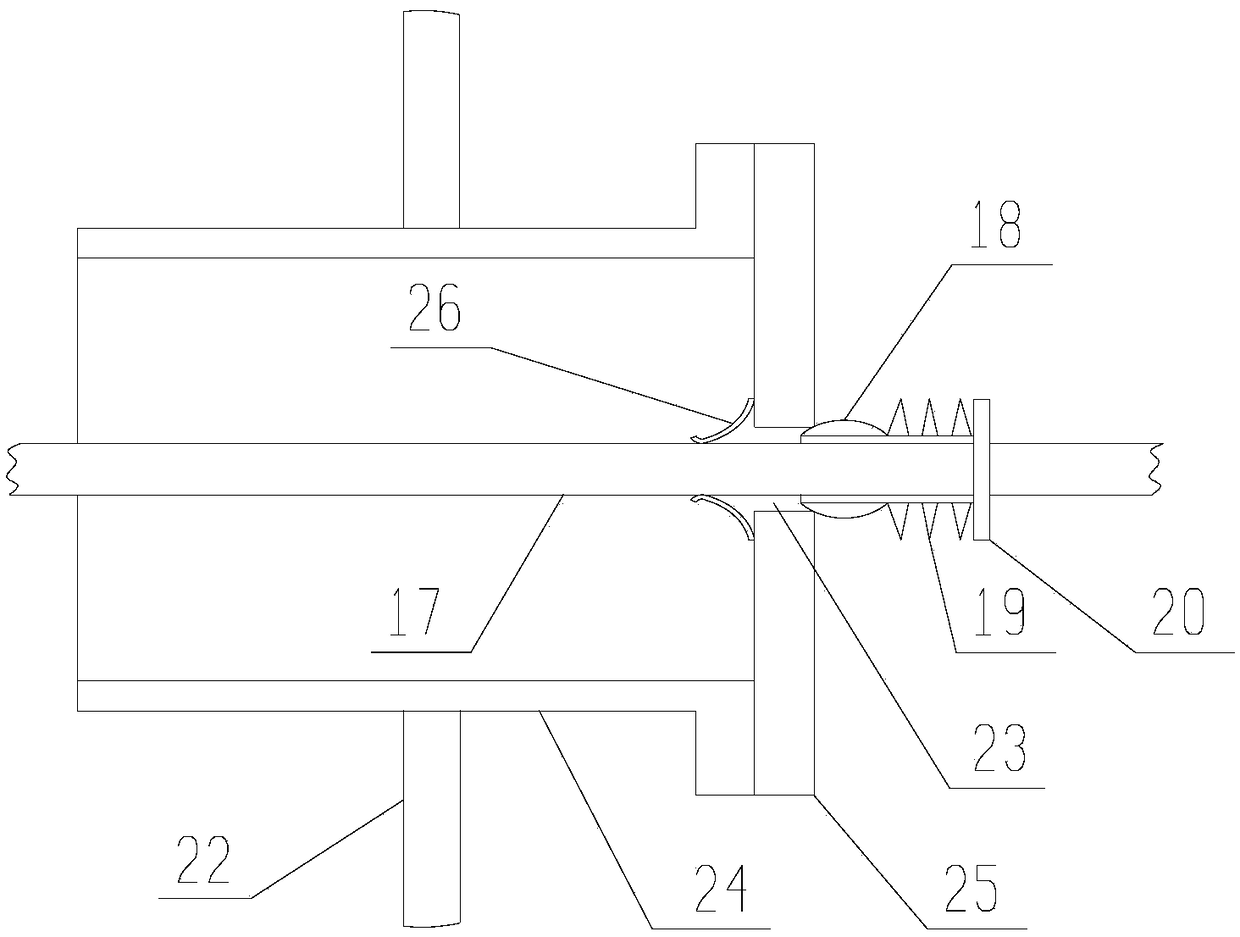

Online ash removing device and heat exchanger with same

InactiveCN108844397AGood cleaning effectImprove efficiencyNon-rotary device cleaningHeat transfer efficiencyThermal efficiency

The invention discloses an online ash removing device and a heat exchanger with the same. The online ash removing device is mainly composed of traction devices, metal wire ropes, an ash remover, a front-end guider, a rear-end guider and a controller. The metal wire ropes penetrate through the front-end guider and the rear-end guider, and the two ends of the metal wire ropes are each connected withone traction device; the ash remover is fixed to the metal wire ropes and conducts reciprocating movement along with the metal wire ropes between the front-end guider and the rear-end guider; and thecontroller is connected with the traction devices. The online ash removing device and the heat exchanger with the same are high in heat transfer efficiency, adjustable in heat exchange load and highin adaptability, and can achieve online ash removal and ensure long-term operation of equipment.

Owner:SINOPEC GUANGZHOU ENG +1

Ultrasonic washing process applicable to aluminum surface

InactiveCN104399694AImprove decontamination abilityImprove rust resistanceCleaning using liquidsWater basedMegasonic cleaning

The invention provides an ultrasonic washing process applicable to an aluminum surface. The process comprises the steps of 1) pre-washing, namely, softening, separating and dissolving pollutant on a component by hot dipping or spraying; 2) rough washing, namely, ultrasonically washing to enable dirt to be separated and fallen from the surface of the component under the effect of a water-based detergent; 3) fine washing, namely, ultrasonically rinsing, and washing to remove the washing medium residual on the surface of the component with pure water; 4) showering under high temperature, namely, spraying pure water under high pressure from top to bottom in all directions so as to remove pollution mediums from small blind holes and gaps, and drying with hot air; the water based detergent comprises 0.8-1.2g / l of surface active agent KE-1, 2.0-2.5g / l of surface active agent SDBS, 2.2-2.6g / l of surface active agent NP-10, 0.5-0.6g / l of builder, and 0.8-1g / l of compound corrosion inhibitor; water serves as a solvent.

Owner:成都川硬合金材料有限责任公司

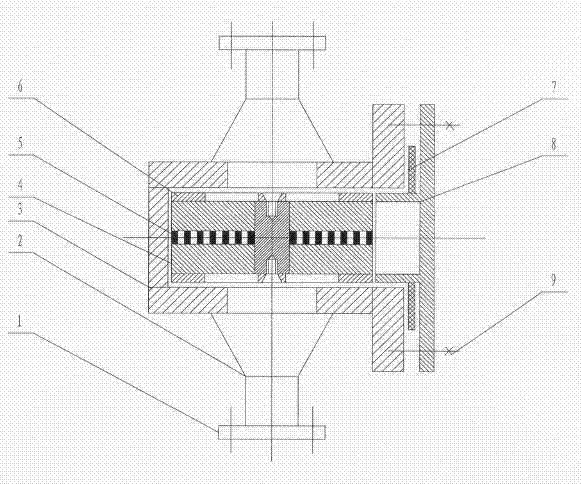

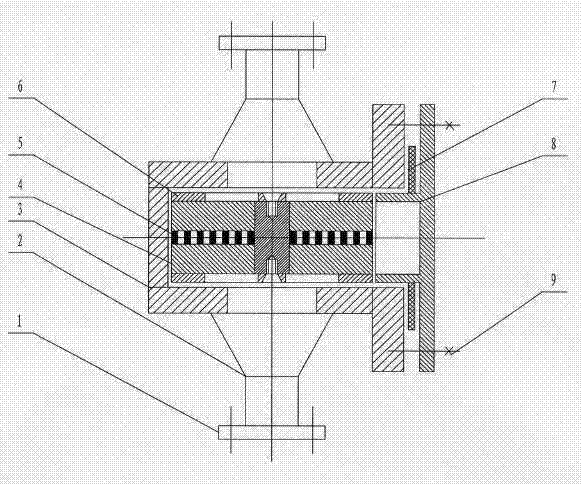

Drawer Flame Arrester

The invention relates to a drawer-type flame arrester, comprising a housing, a fire resistant component, barrier filler material, upper and lower press rings, a gland and screws, wherein, the housing is provided with a rectangular base and a drawer-type cavity, the upper portion and lower portion of the housing are both provided with inlets and outlets, the edge of the opening of the drawer arranged at the side portion of the housing is provided with a bulge; the fire resistant component comprises a plurality of sheet materials and is arranged in the cavity of the housing, the interlayer of the fire resistant component is provided with rectangular barrier filler materials, and the top and the bottom of the fire resistant component are provided with the upper and lower press rings; the glands are arranged on the edge of the housing and fixed on the bulge which is arranged on the edge of the housing with the screws; and reducers are arranged at the inlets and outlets of the housing, andthe end portions of the reducers are provided with flanges. According to the invention, the fire resistant component, the barrier filler materials and the upper and lower press rings are fixed as a whole with countersunk head screws, so that the problem of blockage of holes is solved, the materials are saved half, and when repairing and replacing the fire resistant component, the online cleaning,replacing the other work can be realized with only removing the screws to take the fire resistant component out.

Owner:WUXI HUAERTAI MACHINERY MFG

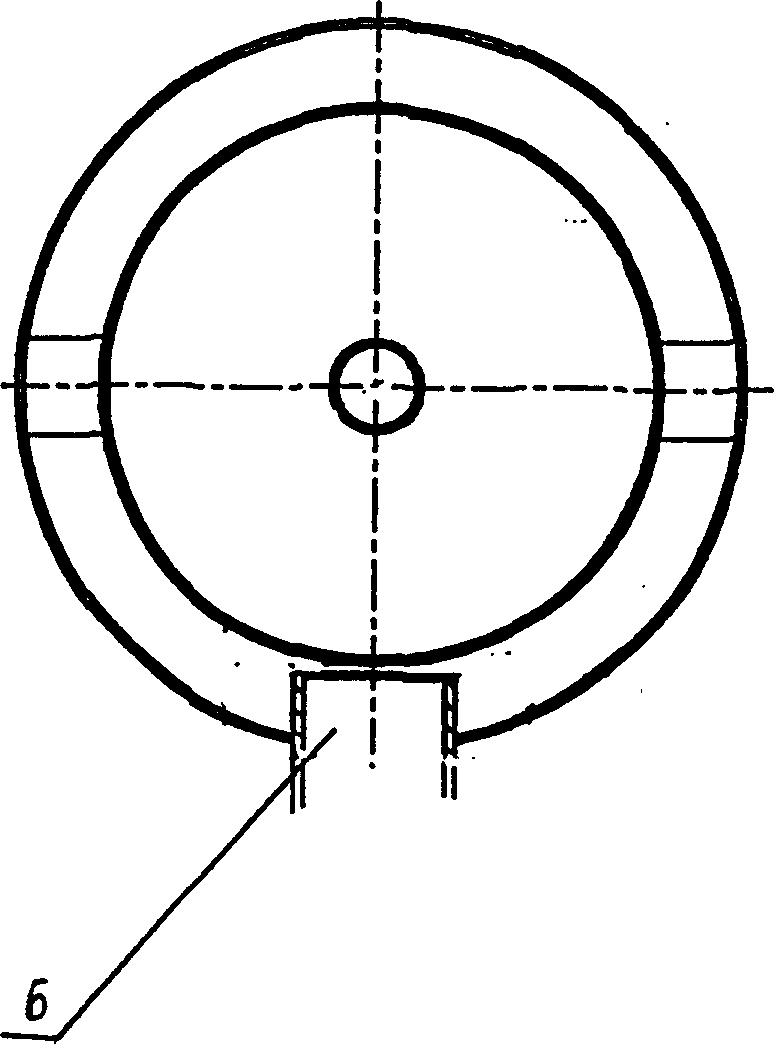

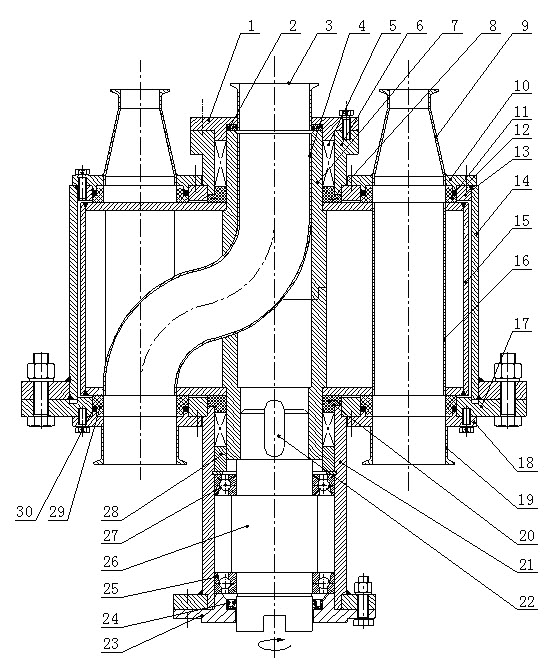

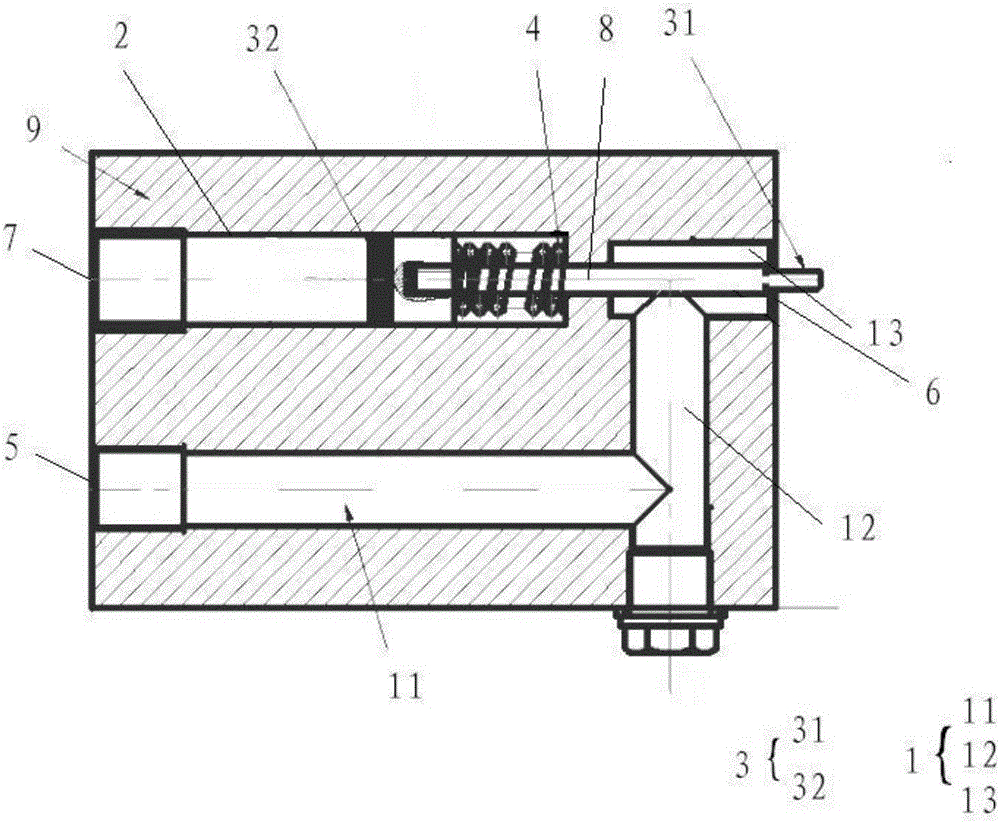

Integrated multidirectional distribution valve for liquid delivery

InactiveCN101782155AImplementation of multi-directional distributionRealize online cleaningOperating means/releasing devices for valvesMultiple way valvesLiquid mediumDrive shaft

The invention relates to an integrated multidirectional distribution valve for liquid delivery, comprising a valve body and a drum-shaped valve plug, wherein the valve body comprises a casing and a main end cover fixedly arranged on the lower part of the casing; a main liquid inlet is fixedly arranged in the middle of the upper end face of the casing; a plurality of liquid outlets are annularly and uniformly distributed and fixedly arranged on the main end cover on the lower part; the drum-shaped valve plug is coaxially rotatably arranged in the valve body and comprises rotating boxes, hollow mandrels and S-shaped liquid pipes; transmission boxes are coaxially and fixedly arranged outside the main end cover of the valve body; a drive shaft is coaxially arranged in the transmission boxes and is coaxially linked with the lower ends of the hollow mandrels of the drum-shaped valve plug. The multidirectional distribution valve is compact in structure and scientific and reasonable in design and realizes multichannel switching and butting of the pipes by utilizing the electrodynamic drum-shaped valve plug, thus ensuring the liquid media to be accurately and selectively delivered to the specified directions without residues and leakage in the device, and the multidirectional distribution valve has the advantages of simple operation, steady operation, good leak tightness, etc.

Owner:TIANJIN UNIV OF SCI & TECH

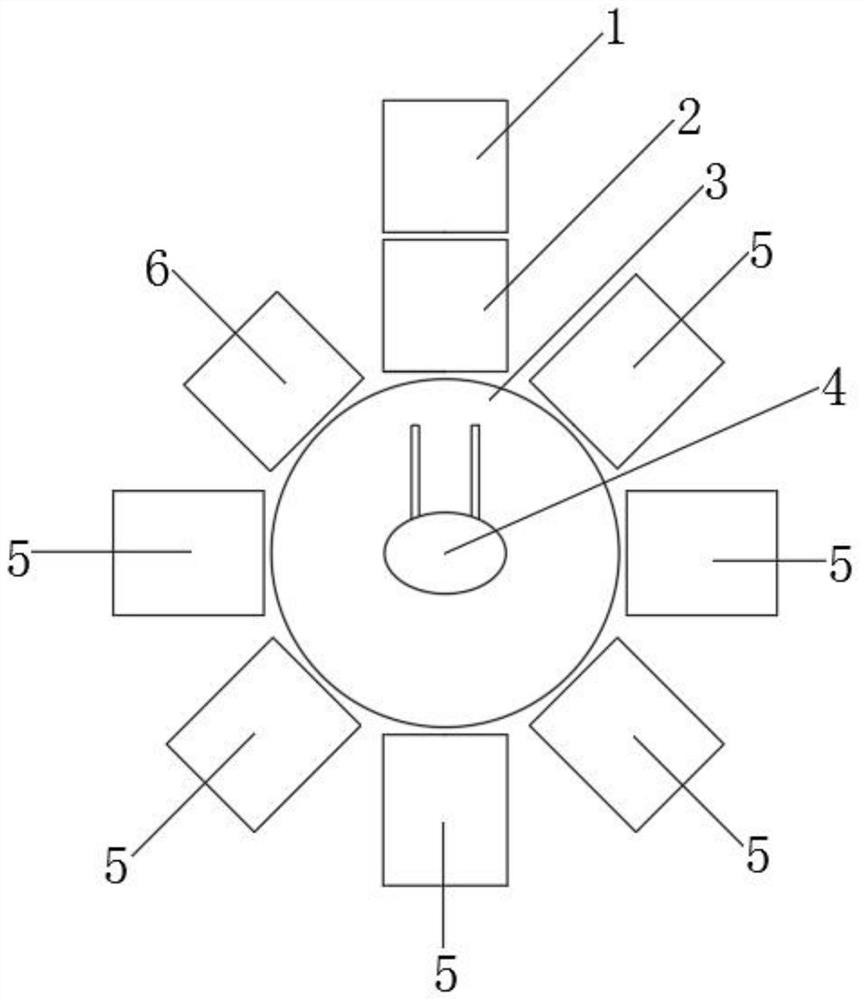

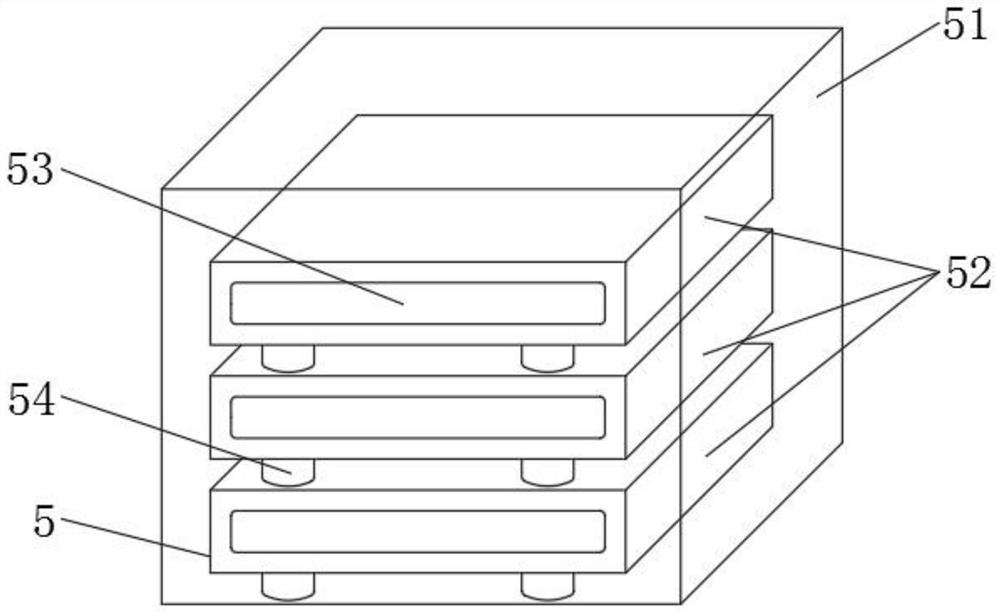

Device for preparing Topcon battery passivation film layers and technological process thereof

PendingCN112159973AReduce the problem of poor uniformityAvoid damageFinal product manufactureChemical vapor deposition coatingFilm-coated tabletBattery cell

The invention discloses a device for preparing Topcon battery passivation film layers. The device comprises a loading cavity, a preheating cavity, a vacuum transmission cavity, film coating modules and an unloading cavity, wherein the loading cavity is connected with the preheating cavity, the preheating cavity is arranged at one side of the vacuum transmission cavity, and the plurality of film coating modules are arranged along the periphery of the vacuum transmission cavity. The plurality of film coating modules are arranged in a cluster mode, the unloading cavity is connected with the vacuum transmission cavity, a mechanical hand is arranged in the vacuum transmission cavity, and each film coating module comprises an outer vacuum cavity body and a film coating cavity. The device has thebeneficial effects that by means of the cluster type multi-layer stacked film coating cavities, the productivity can be improved, the occupied area is reduced, the cost is reduced, and the film coating uniformity drop is reduced; and a film coating mode of a plate-type ALD and PECVD combination or a plate-type PEALD and PECVD combination is adopted, so that online doping is realized, the film coating speed is increased, the productivity is improved, and the performance quality requirements of different passivation film layers of Topcon batteries are met.

Owner:盛远

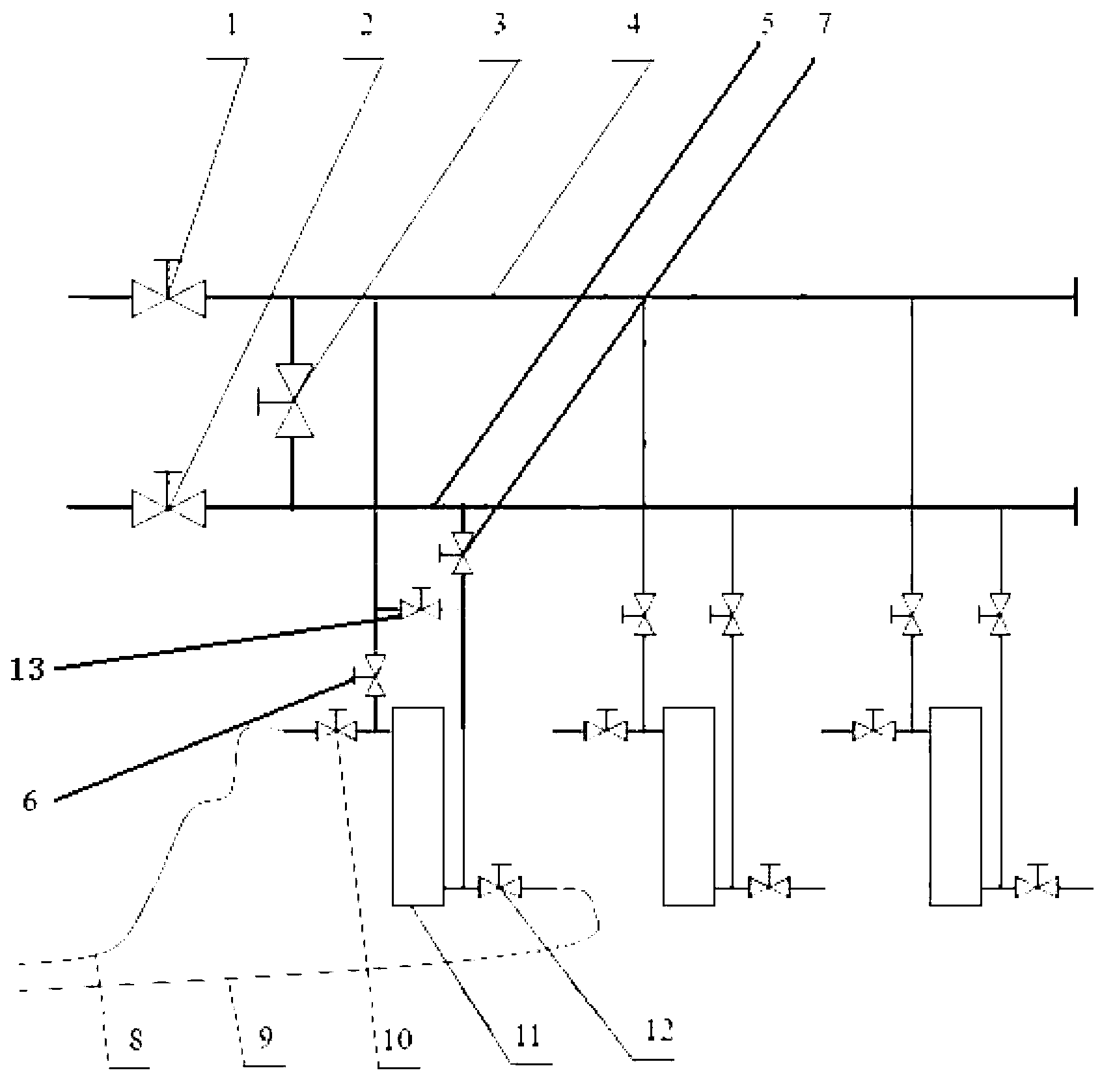

Method for cleaning phosphoric acid delivery pipelines

The invention discloses a method for cleaning phosphoric acid delivery pipelines. The method is implemented as follows: after respectively configuring a 5-8% sulfuric acid solution as an acid cleaning solution and a 4-10% sodium hydroxide solution as an alkaline cleaning solution, a transport pipeline, an acid supply pipe, a spare acid supply pipe, a cleaning solution configuration tank, a cleaning solution receiving tank, a solution supply pump and a solution return pump are connected together so as to form a circulatory cleaning system, and through starting the solution supply pump and the solution return pump, the circulatory cleaning can be performed in the pipes by a cleaning solution; and the alkali cleaning is performed firstly and then the acid cleaning is performed, or the acid cleaning is performed firstly and then the alkali cleaning is performed, and the acid cleaning solution and the alkaline cleaning solution are recycled respectively by using an acid cleaning solution recovery tank and an alkali cleaning solution recovery tank. The method disclosed by the invention is simple, quick, short in cleaning time, convenient in cleaning solution preparation, and low in cleaning cost; an effect of performing on-line cleaning on the phosphoric acid delivery pipelines can be achieved, and no damage is caused on the pipelines; after the phosphoric acid delivery pipelines are cleaned, the scale removal rate can be up to above 99%; and the method not only improves the cleaning efficiency, but also reduces the labor intensity of workers, and reduces potential safety hazards.

Owner:GUIZHOU KAILIN GRP CO LTD

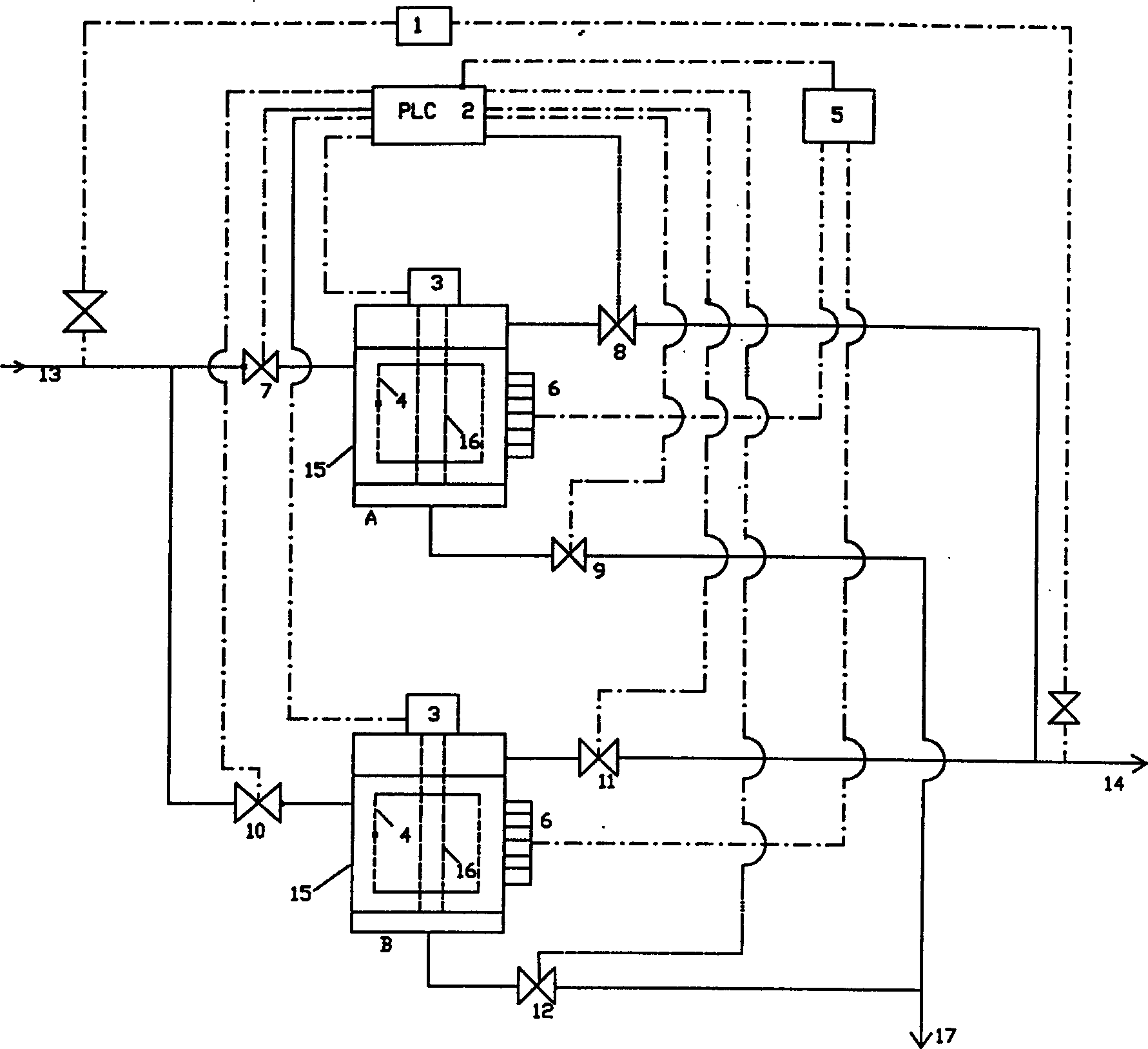

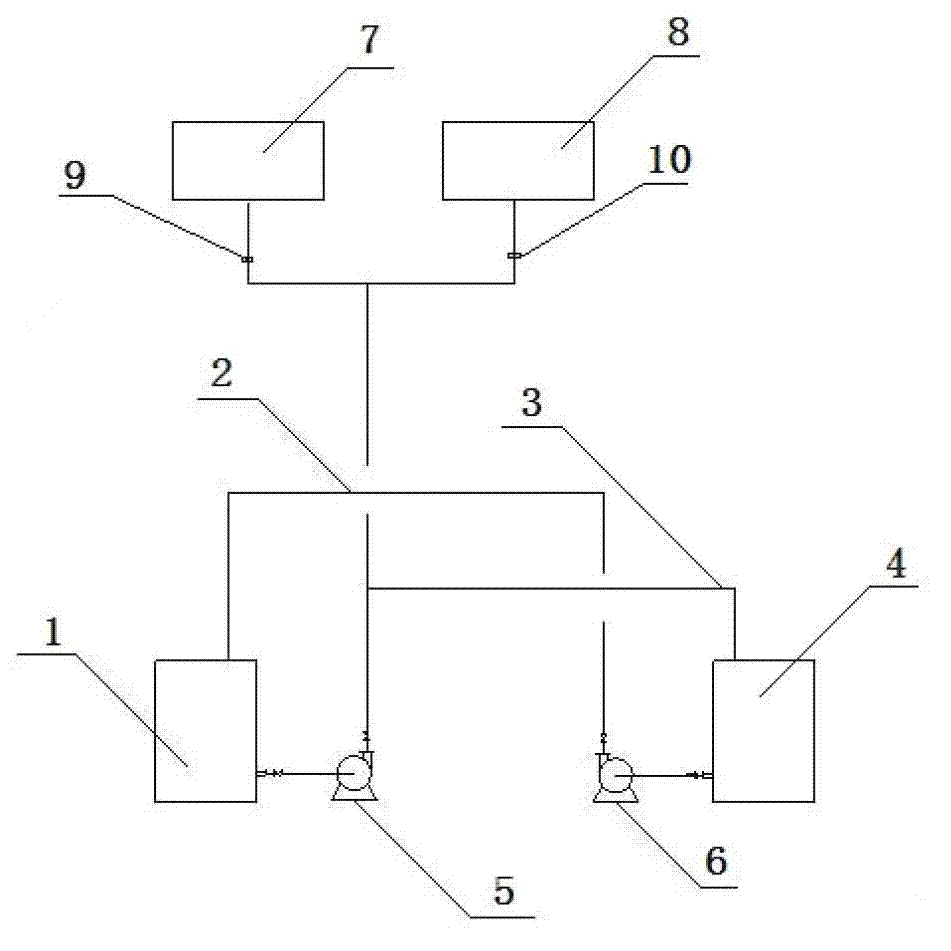

Cooling system capable of on-line cleaning heat exchanger and cleaning method thereof

ActiveCN102798317ARealize online cleaningAvoid Offline CleaningFlush cleaningInlet valveCleaning methods

The invention discloses a cooling system capable of on-line cleaning a heat exchanger, which comprises at least two branches. Each branch comprises a heat exchanger and a water inlet drain valve. Both ends of the heat exchanger are respectively connected with a trunk water inlet pipeline and a trunk backwater pipeline through branch pipes, the trunk backwater pipeline is provided with a trunk backwater valve, and branch pipes on both sides of the heat exchanger are respectively provided with a water inlet valve and a backwater valve; the water inlet drain valve is arranged on the branch pipe between the heat exchanger and the water inlet valve; and the water inlet drain valve is connected with a drain pipe. According to the invention, the drain pipe and the drain valve are arranged on the branch pipeline, so that the cooling system capable of on-line cleaning the heat exchanger can on-line clean the heat exchanger by utilizing the original pipeline and valve of the cooling system so as to avoid offline cleaning, which is labor-consuming and time-consuming. In addition, the cleaning manner with the complicated water inlet or backwater pipeline switch equipment or the cleaning manner of adding a cleaning pipeline pump in the prior art is not required.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Oil-water separation method

ActiveCN103830934AImprove sorting efficiencySorting is simpleLiquid separationChemistrySeparation process

The invention discloses an oil-water separation method. An oil-water separating part is used for separating an oil-water mixture into oil and intermediate water, the intermediate water enters a water processing part and is further separated into heavy impurities and water, a coarse separation hydrocyclone of the oil-water separating part is used for separating the oil-water mixture into two branches of light phase and heavy phase, and separated heavy products of the light phase are introduced into the branch of the heavy phase for enrichment, namely the separation efficiency is improved for the light phase, and the separation precision is improved for the heavy phase; for the light phase, although the separation precision is sacrificed, a part of oil runs out from the bottom flow of a first hydrocyclone, only the first hydrocyclone is used in the whole separation process of the light phase, and other hydrocyclones are not used for recleaning and return separation, and thus the separation of the light phase is extremely simple and easy to control; however, for the heavy phase, the adjustability of closed-loop return separation consisting of a second hydrocyclone and a third hydrocyclone can overcome the oil leakage defect of the light phase, and all separation errors are solved in closed-loop return separation.

Owner:SUZHOU YOUDAN INTERNET TECH CO LTD

Blockage clearing device

InactiveCN105772304ANo secondary clogging problemTo achieve the purpose of online blockage removalSpraying apparatusWater flowWater pipe

The invention discloses a blockage clearing device which is used for online blockage clearing of a water pipe. The blockage clearing device comprises a first water supply channel, a second water supply channel, a blockage clearing assembly and a reset assembly. The first water supply channel comprises a first branch way, a second branch way and a third branch way which are connected in sequence in a communication manner. The tail end of the third branch way is provided with a nozzle opening used for being connected with a nozzle. The blockage clearing assembly comprises a piston and an ejector rod. The piston is located in the second water supply channel. One end of the ejector rod penetrates to the third branch way and reciprocates along with the piston. When the piston is pushed to move along the second water supply channel through water flow flowing into the second water supply channel, the ejector rod can be driven to move towards the nozzle opening, and therefore the ejector rod penetrates the nozzle opening to enter the nozzle so as to remove dirt in the nozzle. The reset assembly is located in the second water supply channel and abuts against the piston and the second water supply channel in the movement direction of the piston. By the adoption of the scheme of the blockage clearing device, the dirt on the nozzle can be automatically removed online.

Owner:SHANGHAI TIANSHUN ENVIRONMENTAL PROTECTION EQUIP

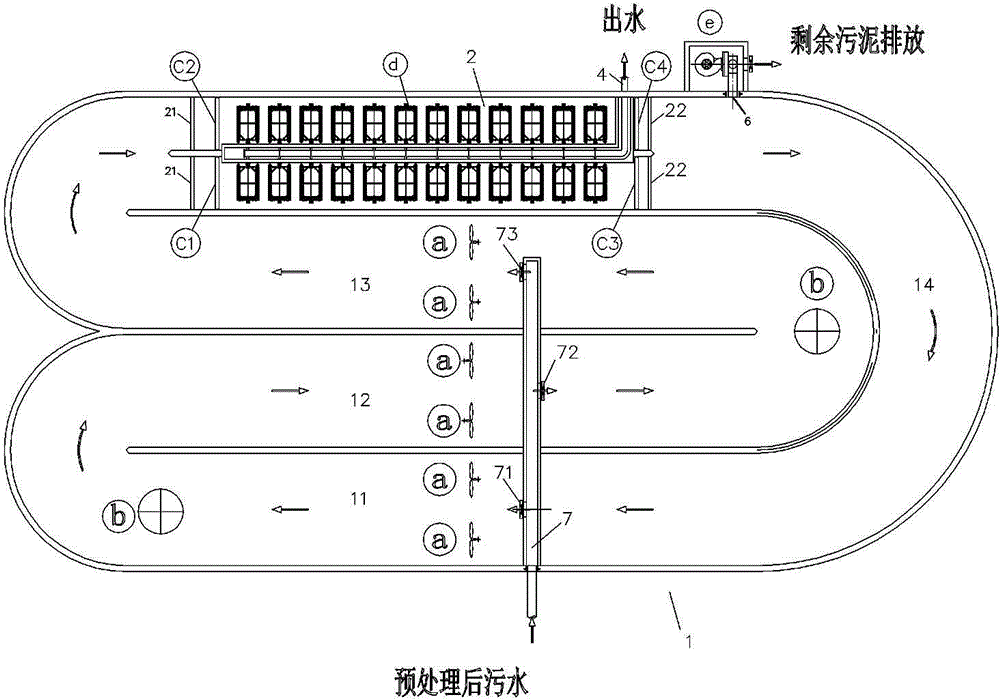

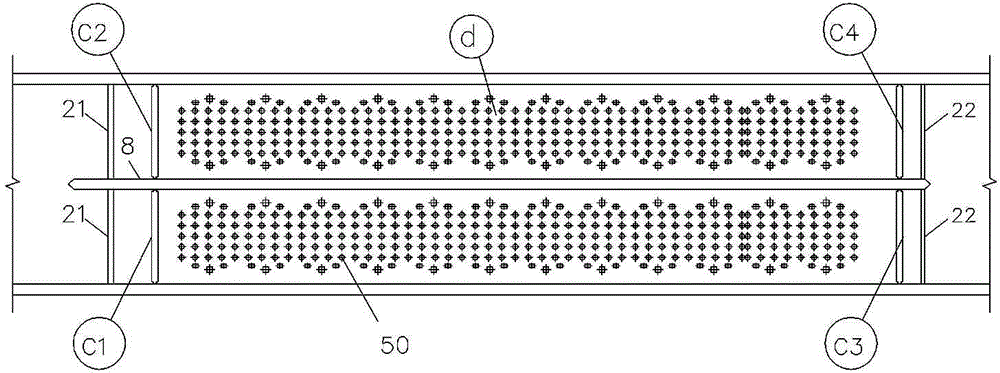

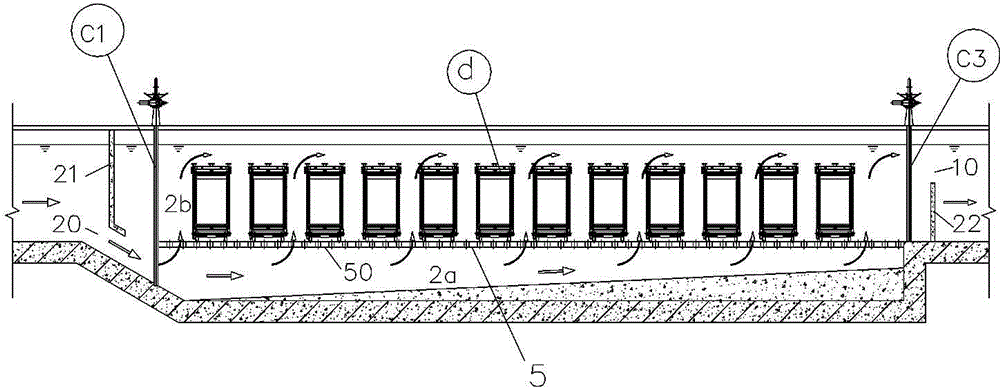

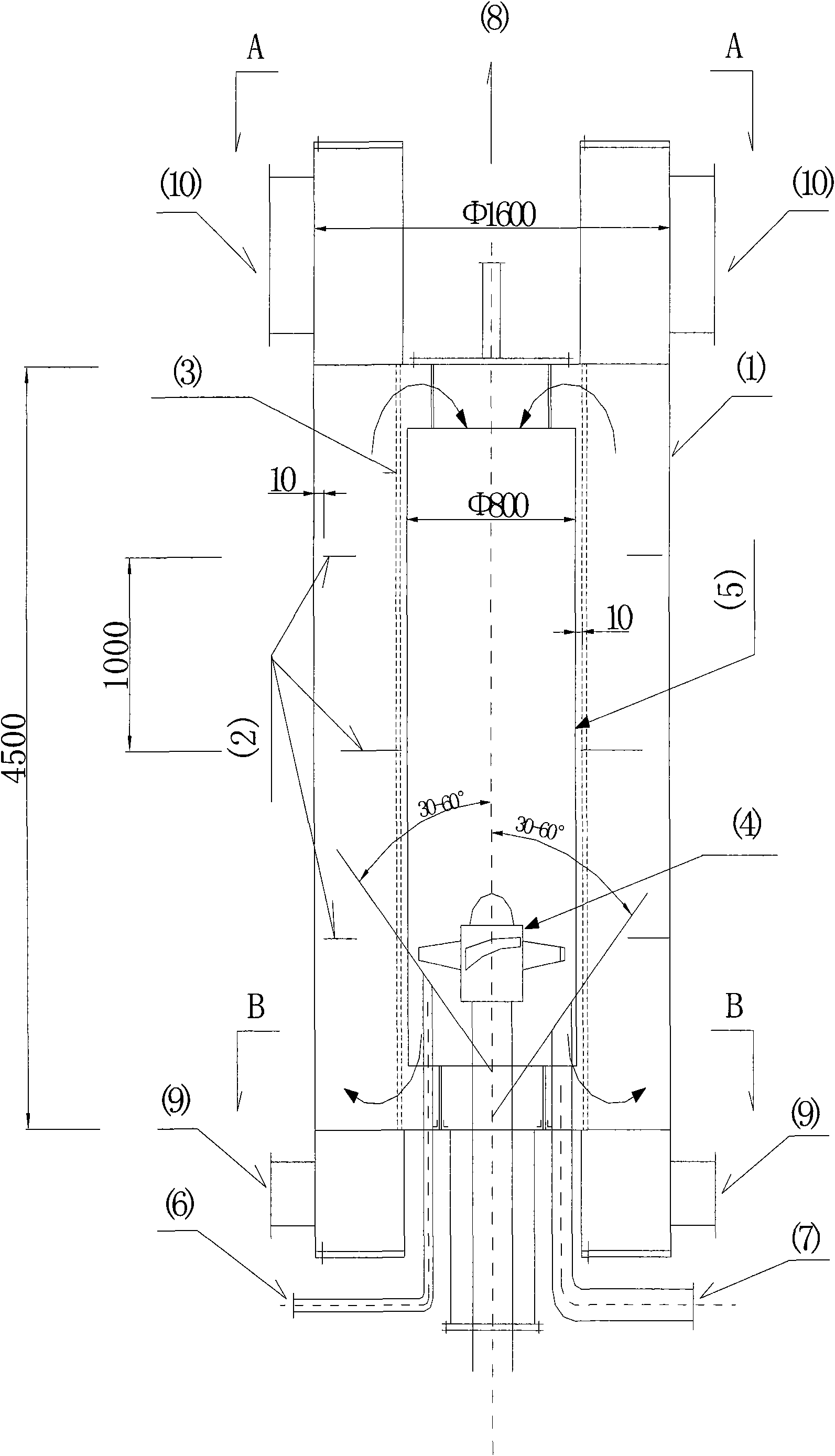

Energy-saving type treatment device for MBR (membrane biological reactor) oxidation ditch sewage

ActiveCN103951063AEliminates adverse transverse shearExtended service lifeTreatment with aerobic and anaerobic processesButt jointSmall footprint

The invention relates to the technical field of treating sewage by utilizing a biological technology and discloses an energy-saving type treatment device for MBR (membrane biological reactor) oxidation ditch sewage. The energy-saving type treatment device comprises an oxidization ditch biochemical reaction region and a membrane region, wherein a straight gallery of the membrane region and an S-shaped gallery of the oxidization ditch biological reaction region are in butt joint from the beginning to the end to form a circulating gallery; a penetrating tracery wall flat plate is overhead arranged on the bottom of the membrane region and used for dividing the membrane region into a membrane tank and a water distribution region from top to bottom; water distribution holes are uniformly distributed in the penetrating tracery wall flat plate; a membrane region water inlet is formed in the front end of the water distribution region; a membrane assembly and a water outlet tube are arranged in the membrane tank; the oxidization ditch biological reaction region is equipped with a water inlet device, a residual sludge outlet, a pushing device and an aeration device. According to the energy-saving type treatment device disclosed by the invention, the oxidization ditch process is organically combined with the membrane biological reactor; by utilizing hydraulic operation characteristics of large-flow circulating plug-flow state of the oxidization ditch process, mixed liquor in a groove is circulated and quickly flows through an MBR membrane set to realize solid-liquid separation, and therefore, the energy-saving type treatment device has the advantages of simple and compact structure, low operation energy consumption, small floor area, less investment, high pollutant removing efficiency and the like.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

High-efficiency polymerization reactor

ActiveCN101920182AIncrease the heat exchange areaReduce volumeChemical industryChemical/physical/physico-chemical processesAxial-flow pumpChemical industry

The invention provides a high-efficiency polymerization reactor, belonging to the field of chemical industry. The reactor comprises a reactor cylinder body, a guide cylinder, an annularly arranged ring heat pipe, a special deflection baffle, an axial-flow pump and a feed port with special charging. The reactor can solve the problem of uniform and quick heat exchange of a polymerization reaction, changes the heat exchange mode of the traditional reactor, has the advantages of high yield in unit volume, uniform heat exchange, no dead angle low energy consumption, low investment and simple and convenient operation, greatly reduces the size of the reactor by improving the heat exchange efficiency and is applicable to all polymerization processes, in particular to rubber production.

Owner:CHINA PETROCHEMICAL CORP +1

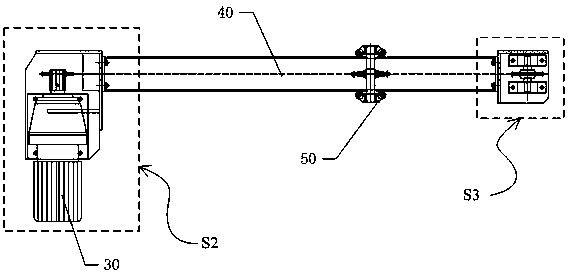

Strip steel spraying device and walking device thereof

PendingCN107716567ARealize online cleaningSimple structureWork cleaning devicesMetal rolling arrangementsBeam directionSprocket

The invention discloses a strip steel spraying device and a walking device of the strip steel spraying device. The walking device comprises a beam, two support seats correspondingly arranged at the two ends of the beam and a moving mechanism arranged on the beam and capable of doing reciprocating motion in the length direction of the beam. A drive motor is arranged on one of the support seats. A spindle of the drive motor is sleeved with a driving chain wheel. The other support seat is rotationally connected with a driven chain wheel. A chain is wound around the driving chain wheel and the driven chain wheel. The two ends of the chain are connected with the moving mechanism. The walking device is simple in structure and capable of being adaptive to the poor working environment containing alot of impurities and dirt, and it can be guaranteed that the strip steel spraying device operates stably for a long time.

Owner:佛山市高明基业冷轧钢板有限公司

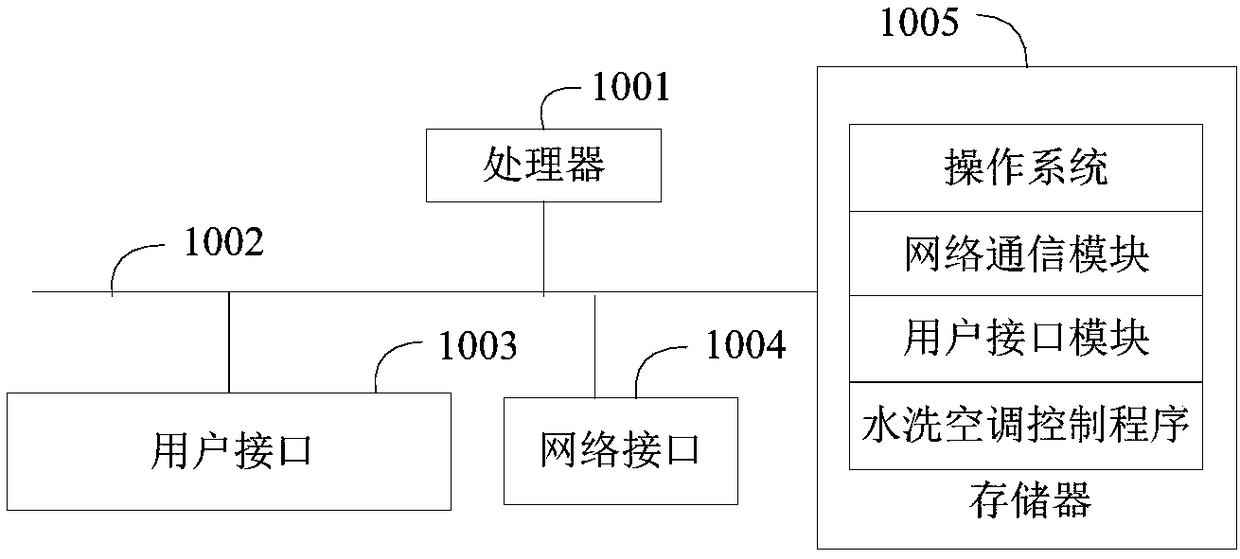

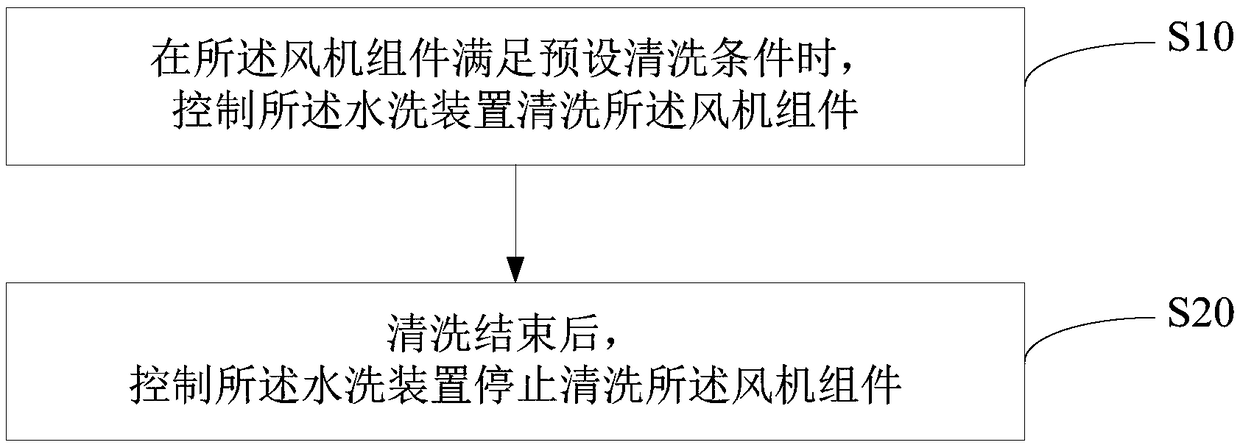

Control method of washing air conditioner, air conditioner and computer readable storage medium

InactiveCN108692430ARealize online cleaningEasy to operateMechanical apparatusSpace heating and ventilation safety systemsWater sourceEngineering

The invention discloses a control method of a washing air conditioner. An indoor unit of the air conditioner comprises a shell, and a washing device arranged in the shell; the indoor unit further comprises a fan assembly; the fan assembly comprises at least one of an air flue and a wind wheel; the washing device is connected with a water source through a pipeline so as to clean the fan assembly inthe indoor unit; and the control method of the washing air conditioner comprises the steps of when the fan assembly meets a preset cleaning condition, controlling the washing device to clean the fanassembly, and after finishing cleaning, controlling the washing device to stop cleaning the fan assembly. The invention further discloses the air conditioner and a computer readable storage medium. The washing device is arranged in the indoor unit of the air conditioner and is connected with the water source through the pipeline, and the washing device is controlled to clean the fan assembly by directly utilizing water supplied by the water source, so that on-line cleaning is realized, and no disassembling and hand washing is required; and automatic cleaning is started when the fan assembly meets the cleaning condition, so that the convenience in operation is realized.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

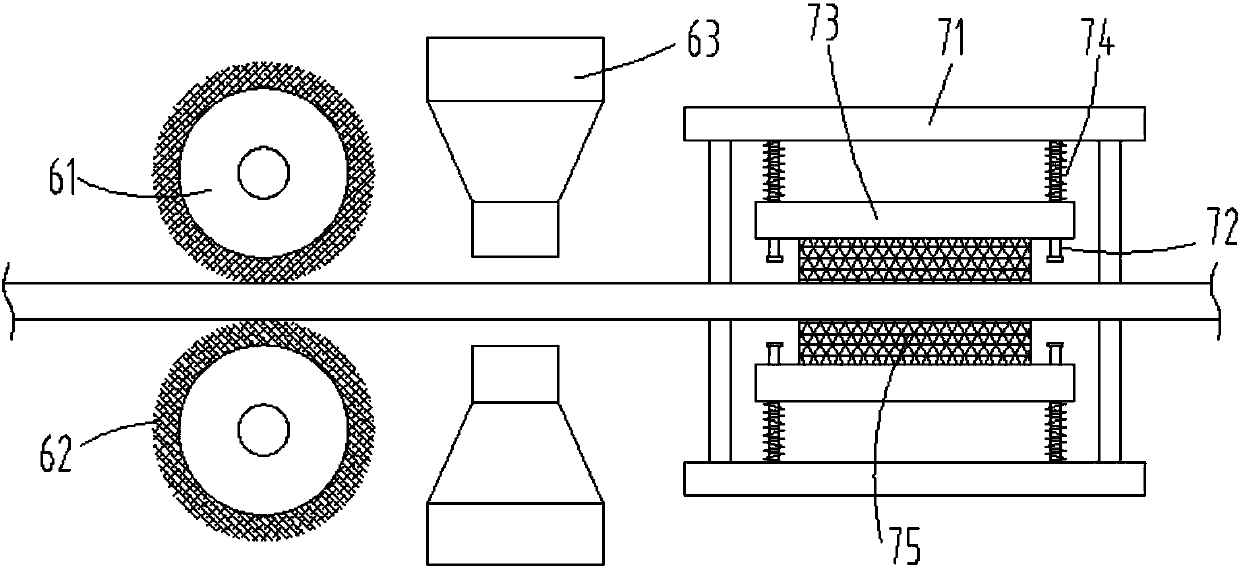

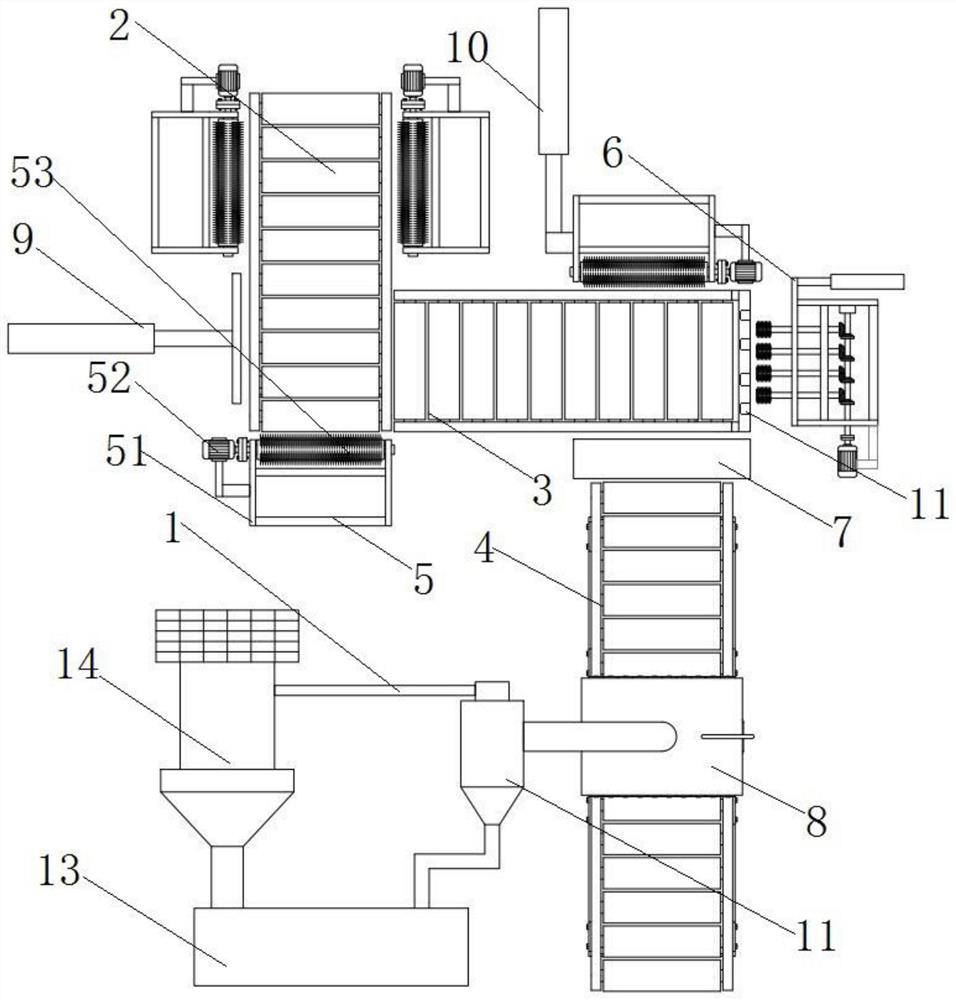

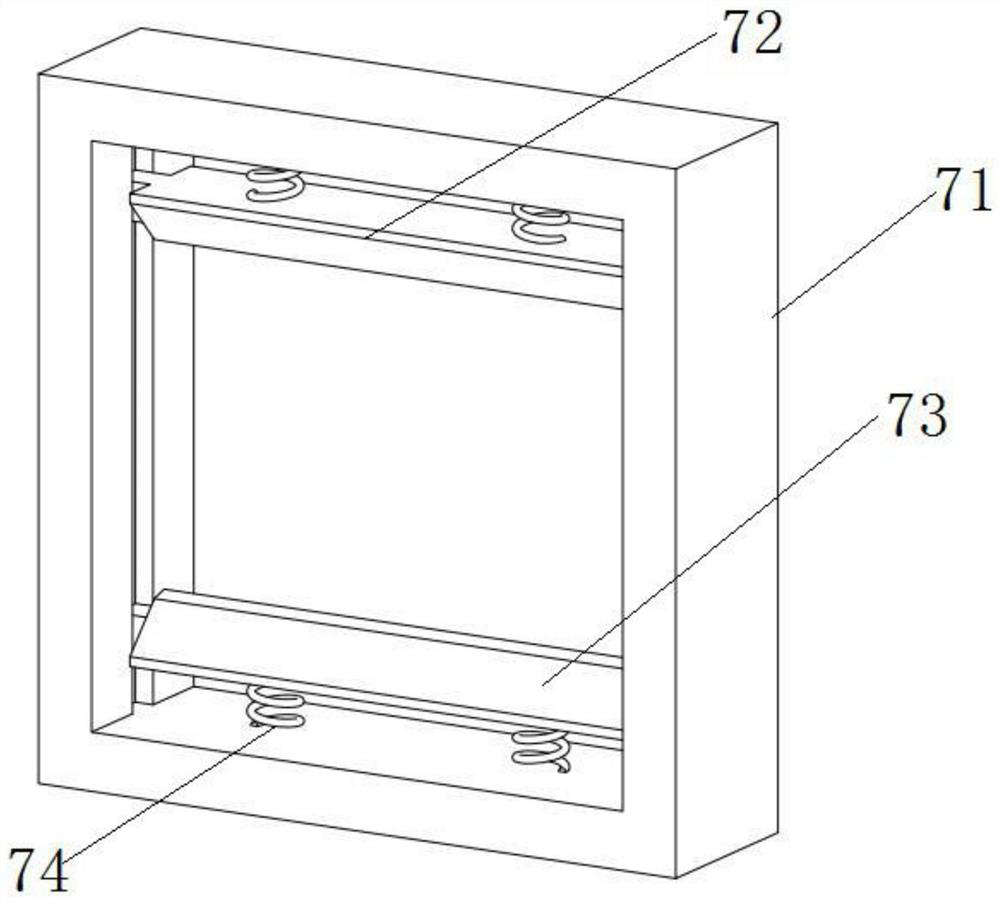

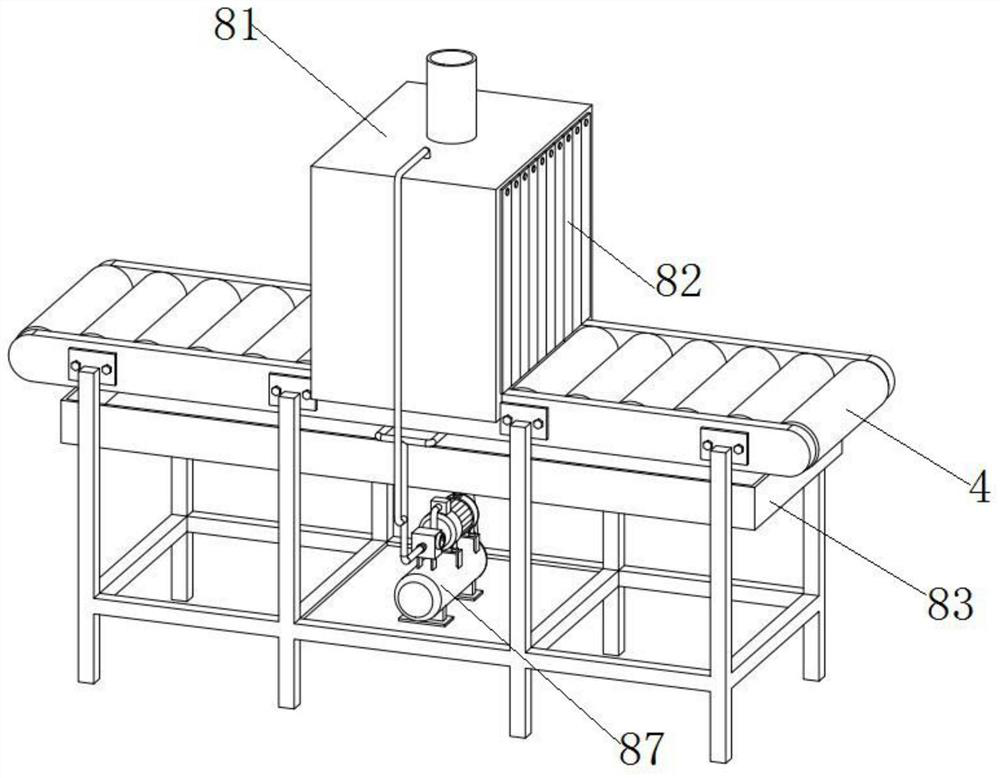

Environment-friendly cleaning equipment for prebaked anode carbon bowls for aluminum

PendingCN112775059AQuick clean upSuck away in timeCombination devicesCleaning using toolsDust controlProcess engineering

The invention discloses environment-friendly cleaning equipment for a prebaked anode carbon bowl for aluminum. The environment-friendly cleaning equipment comprises a conveying device, a cleaning device and a dust removal device, wherein the cleaning device and the dust removal device are installed on the conveying device. The conveying device comprises a first carrier roller conveyor, a second carrier roller conveyor and a third carrier roller conveyor. The cleaning device comprises a side face cleaning mechanism, a carbon bowl cleaning mechanism, a scraper mechanism and a high-pressure airflow cleaning mechanism. According to the environment-friendly cleaning equipment for the prebaked anode carbon bowl for aluminum, online cleaning of prebaked anode carbon blocks can be completely achieved, manual operation can be replaced, automatic production is achieved, the equipment integrates electric operation and hydraulic operation, the working efficiency can be improved, and the production cost can be reduced. The carbon bowl can be rapidly cleaned, and automatic cleaning is achieved. Due to the fact that the dust removal device is arranged in the equipment, cleaned powder can be sucked away in time and does not fly, and therefore environment pollution can be reduced.

Owner:SUNSTONE DEV

Cleaning method of polypropylene filter cloth

InactiveCN105597391AEasy to operateShort processFiltration separationChemicalsAfter treatmentCleaning methods

The invention provides a cleaning method of a polypropylene filter cloth. The cleaning method is characterized by being implemented on line and comprising acid pickling performed at least once, sterilization performed at least once and alkali washing performed at least once. According to the on-line cleaning method, operation is easy, the process is short, no additional labor cost or operation cost is needed, water consumption is greatly reduced, the effect is obvious, the polypropylene filter cloth is not damaged, the water flux is increased after treatment, the treatment cost is low, and the cost performance is high.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com