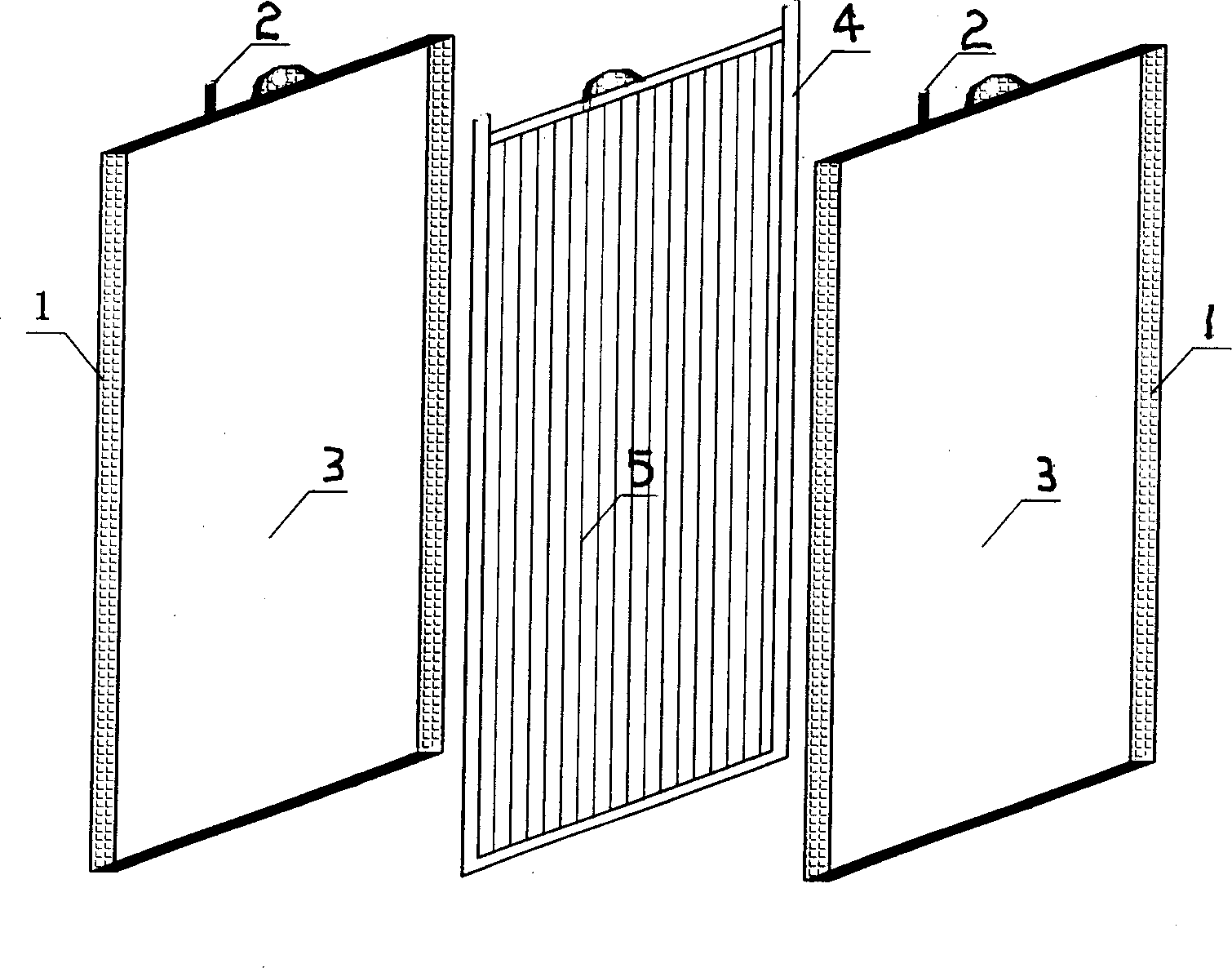

Plate type membrane assembly

A flat-plate membrane and membrane module technology, applied in the field of membrane separation technology research and development and application, can solve the problems of membrane surface pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] Will contain COD 200~500mg / L, BOD 5 100~300mg / L, ammonia nitrogen 50~160mg / L, SS 20~50mg / L domestic sewage enters the activated sludge membrane bioreactor for treatment. 0.4m 3 / hr, temperature 12~29℃, pH 6.5~8.0, stable operation for 6 months. The flat membrane flux in the new membrane module is stable at 25-40L / m 2 h, the operating pressure is 18-22kpa, and the treatment effect is stable. The COD value of the system effluent varies between 10 and 30mg / L, and is generally stable below 20mg / L. 5 The value fluctuates between 1 and 3mg / L, the ammonia nitrogen is stable below 10mg / L, the SS is stable below 0.3mg / L, and the effluent water quality meets the "Urban Sewage Recycling-Urban Miscellaneous Water Quality" (GB / T18920-2002) standard .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com