Oil-water separation method

A technology of oil-water separation and oil-water mixture, which is applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., to achieve the effects of dynamic adjustment, simple sorting, and reduced layout difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

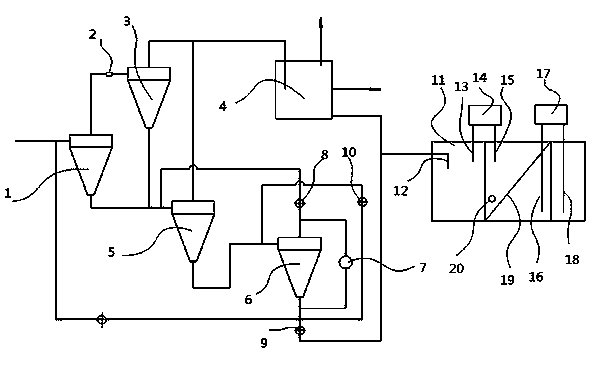

[0017] The following is a further explanation in conjunction with the drawings:

[0018] The oil-water separation part in this embodiment is mainly composed of the coarse separation cyclone 1 and the first to third cyclones. The coarse separation cyclone 1 coarsely separates the oil-water mixed stock solution. Because of the overflow, there is a cyclone separation. Therefore, the overflow of the coarse cyclone is not as pure as the oil. Considering the fluidity and separability of the overflow, it is preferable that 70%-75% of the oil in the original liquid enters the overflow term and enters the first In the cyclone 3, the remaining oil, water and most of the heavy impurities enter the underflow into the second cyclone 5. If the purity of the overflow of the coarse cyclone 1 is only one-sidedly pursued, the oil is too thick to be swirled. Flow separation, and the volume of the entire separation system is greatly reduced. Therefore, the separation concept in this application beli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com