Patents

Literature

38results about How to "Sorting is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Improved wood-plastic composite material and preparation method thereof

InactiveCN102250482AGood physical and mechanical propertiesImprove toughnessThermoplasticUltimate tensile strength

The invention relates to an improved wood-plastic composite material and a preparation method thereof. The improved wood-plastic composite material consists of the following components in part by mass: 30 to 80 parts of thermoplastic plastics, 30 to 70 parts of plant fiber powder, 5 to 30 parts of vermiculite powder, and 2 to 10 parts of interface modifying agent, wherein the vermiculite powder is non-expanded natural vermiculite powder and has the fineness of 100 to 500 meshes; and the thermoplastic plastics are new thermoplastic plastics or waste thermoplastic plastics. The components are premixed, plasticized and granulated to form the improved wood-plastic composite material. The vermiculite powder has the function of a common filler, and also can obviously improve the toughness, strength and rigidity of the wood-plastic composite material, so that the application range of the wood-plastic composite material is widened. The product is low in cost and meets the environmental protection requirement.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

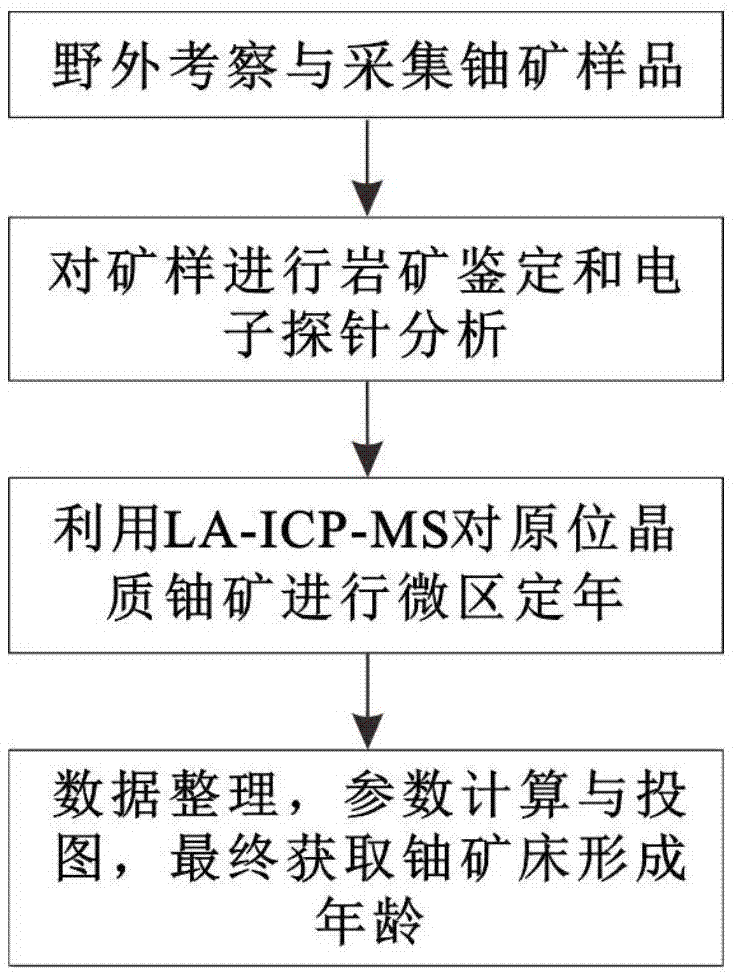

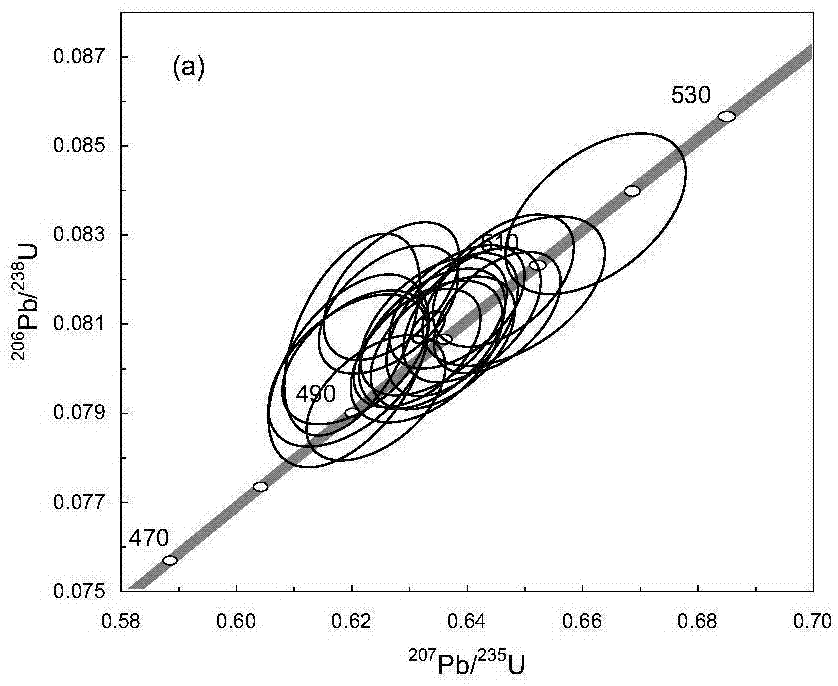

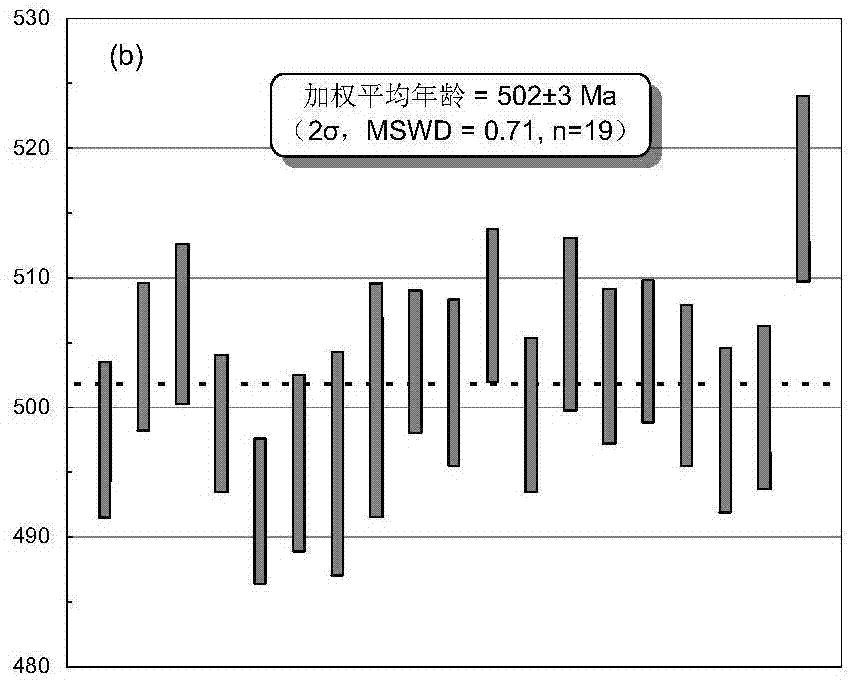

Method of testing uraninite formation age

InactiveCN106932837AAnalytical testing requirements are clearEasy to operateGeological measurementsUraniniteElectron probe microanalysis

The invention belongs to the technical field of uranium ore, and specifically relates to a method for testing the formation age of crystalline uranium ore; The age of uranium deposits and the role of metallogenic evolution analysis, decomposing the key elements and main ore-controlling factors of each metallogenic period from complex geological phenomena, providing ideas for uranium deposit exploration, and guiding specific ore-prospecting work to test crystal quality The method for the formation age of uranium ore; including the following steps: Step 1, field investigation and collection of uranium ore samples; Step 2, rock ore identification and electronic probe analysis on the ore samples; Step 3, using LA-ICP-MS Micro-zone dating of crystalline uranium ore; step 4, data collation, parameter calculation and mapping, and finally the formation age of uranium ore is obtained.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

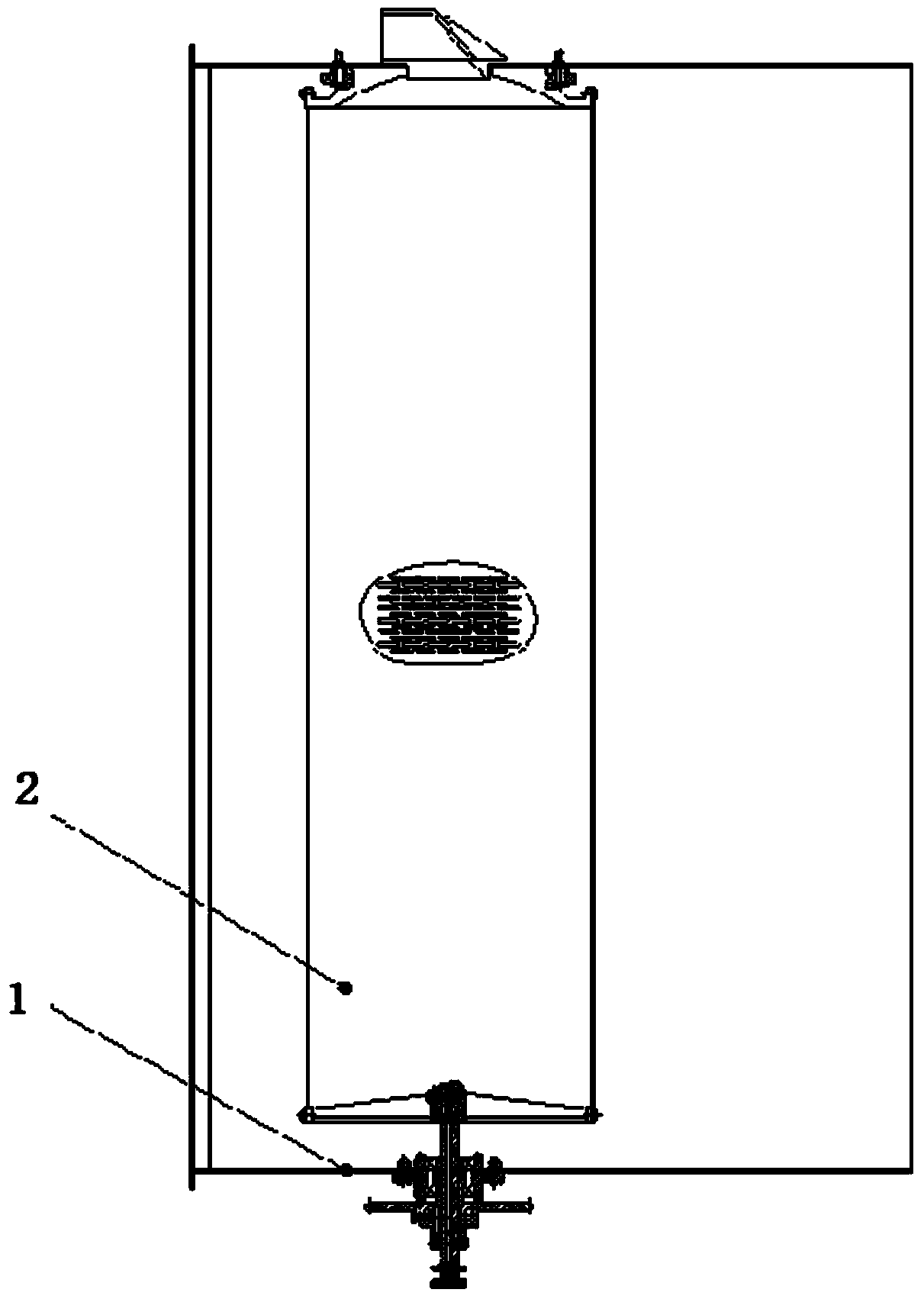

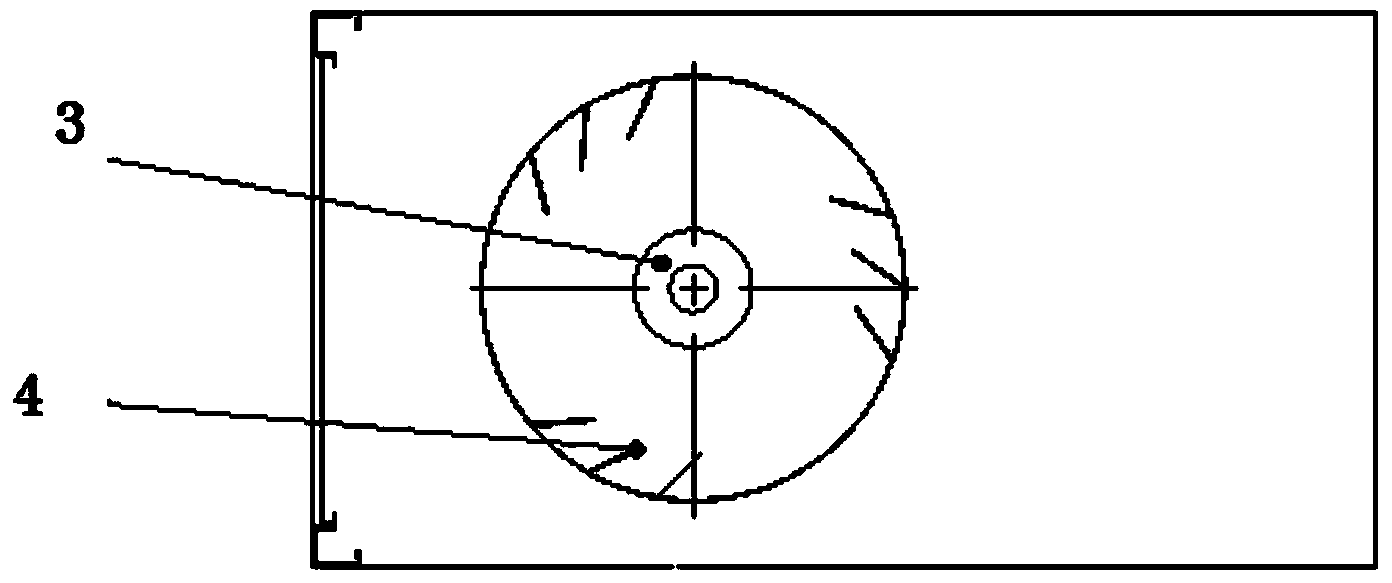

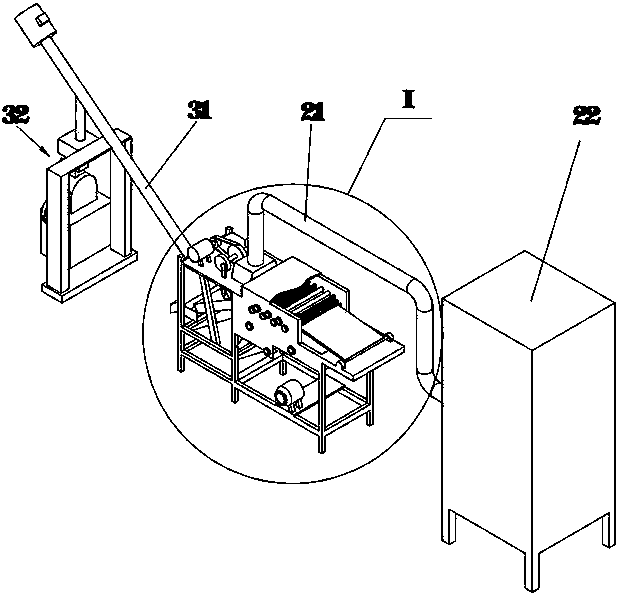

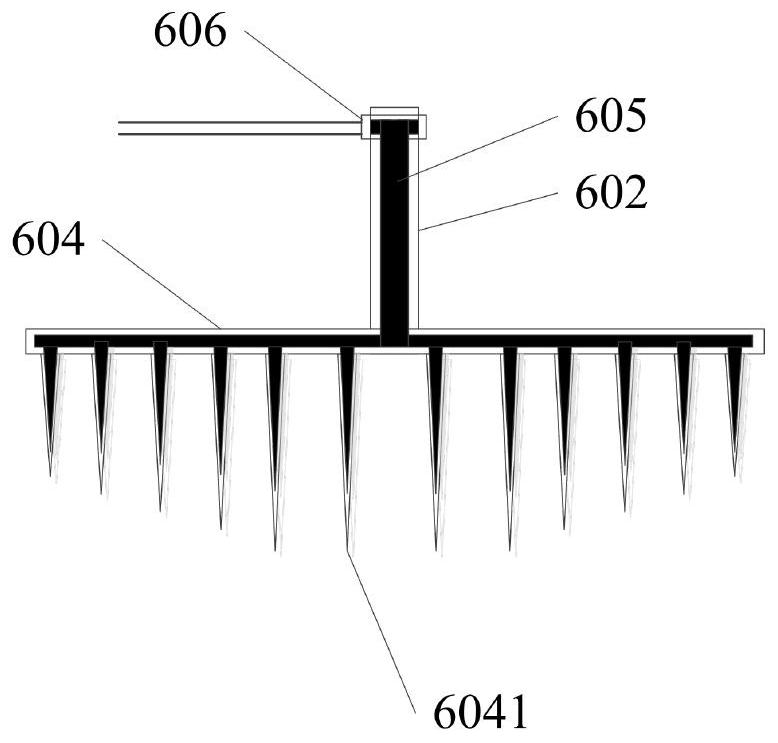

Roller for mung bean huller capable of evenly stirring, shovelling and screening materials in real time

ActiveCN103798935AImprove work efficiencyReduce overgrindingFood treatmentRelative displacementMechanical engineering

Provided is a roller for a mung bean huller capable of evenly stirring, shovelling and screening materials in real time. The roller comprises a roller body, one end of the roller body is arranged on a rack bearing pedestal, the other end of the roller body is arranged on a rack mounting seat, the roller body can rotate around the axial center of the roller body, a mesh screen is arranged on the surface of the roller body, the inner wall of the roller body stretches out of a shovelling plate, and a hulling grinding wheel is arranged in the axial center of the roller body. The roller is characterized in that round holes or long round holes are formed in the mesh screen of the surface of the roller body, the shovelling plate on the inner wall of the roller body is divided into a plurality of sets in the circumferential direction at intervals, and three pieces form one set and are evenly distributed on the inner wall of the circumferential roller body at intervals. The round holes or the long round holes are adopted as mesh screen holes of the roller, completely-hulled whole mung beans or half mung beans can be screened conveniently, the built-in shovelling plate bodies are evenly distributed on the circumference of the roller, the materials are stirred and shoveled in the work process, relative displacement can be generated between the materials and the roller, and small-size materials are easier to screen. The whole device guarantees the milled rice rate and improves equipment production efficiency.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

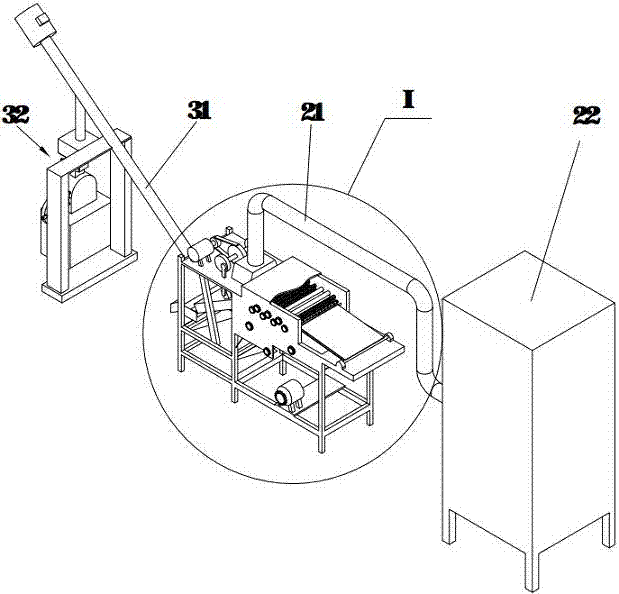

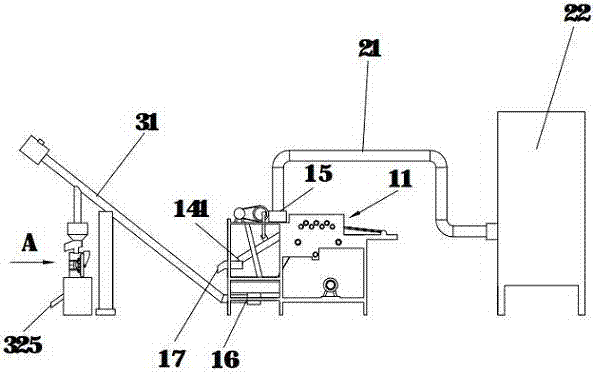

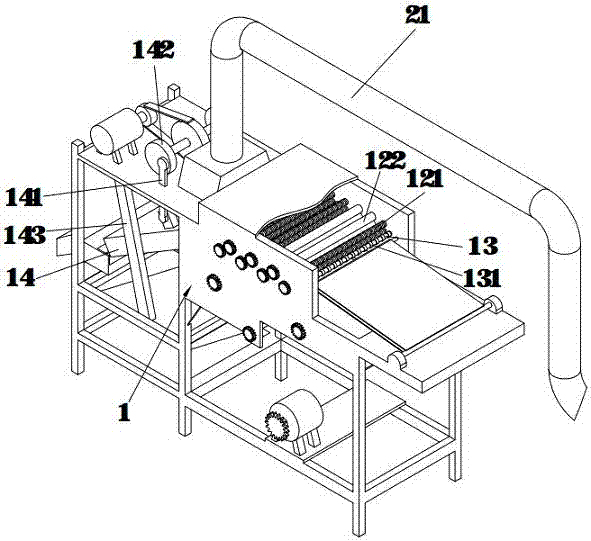

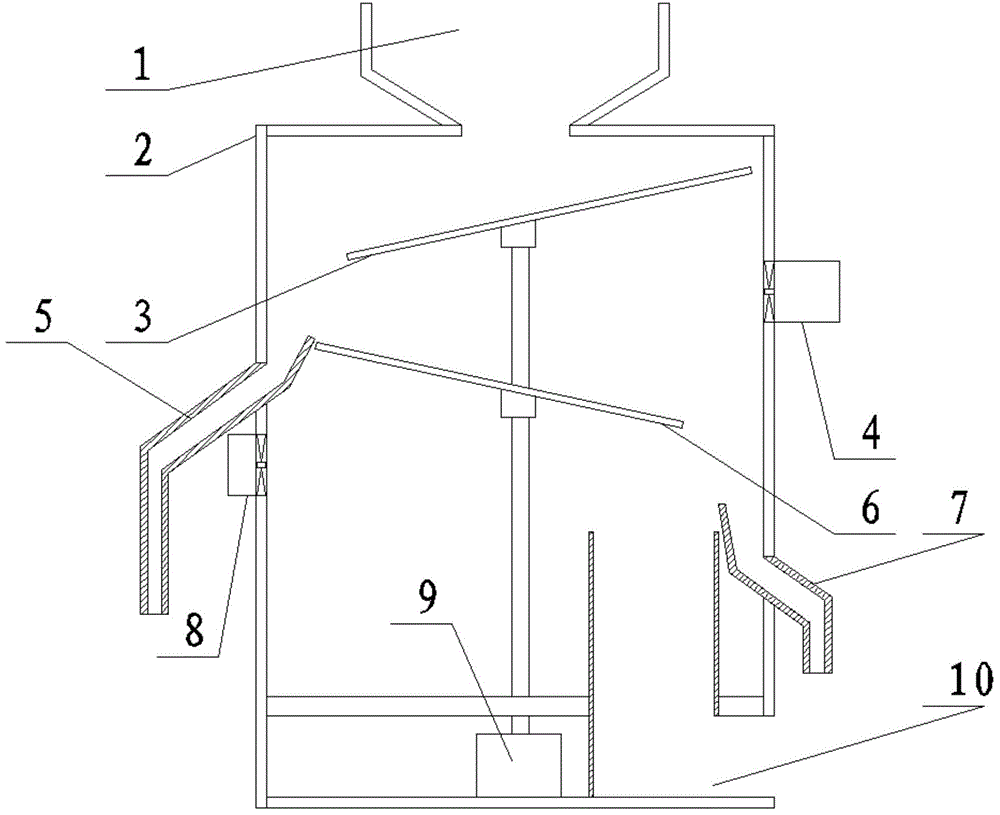

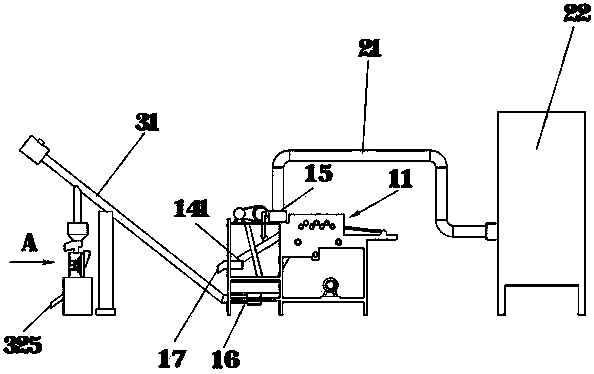

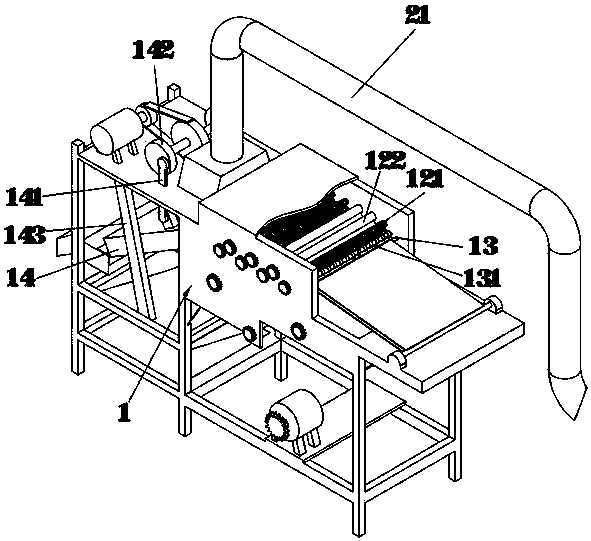

Recovery system of accumulator plate

InactiveCN102315503AReduce pollutionNot harmful to healthSolid waste disposalWaste accumulators reclaimingParticulatesEngineering

The invention discloses a recovery system of an accumulator plate. The recovery system comprises a plate breaking part, a dust recovery part and a PM (particulate matter) recovery part, wherein the plate breaking part comprises a feed port and a machine case; a roller and a transition roller are arranged behind the feed port; the machine case is internally provided with a vibration box, a dust outlet is arranged at the upper part of the machine case and a PM outlet is arranged at the lower part of the machine case; the dust recovery part comprises a feed pipe which is communicated with the dust outlet and is connected to a dust remover; and the PM recovery part comprises a feeding pipe which is communicated with the PM outlet, and the feeding pipe is also connected with a crusher. The plates recovered by the recovery system are separated thoroughly and recovered products are refined. The recovery process generates little pollution to the environment, does not need manual operation and is not harmful to human health.

Owner:长兴巨沃机电科技有限公司

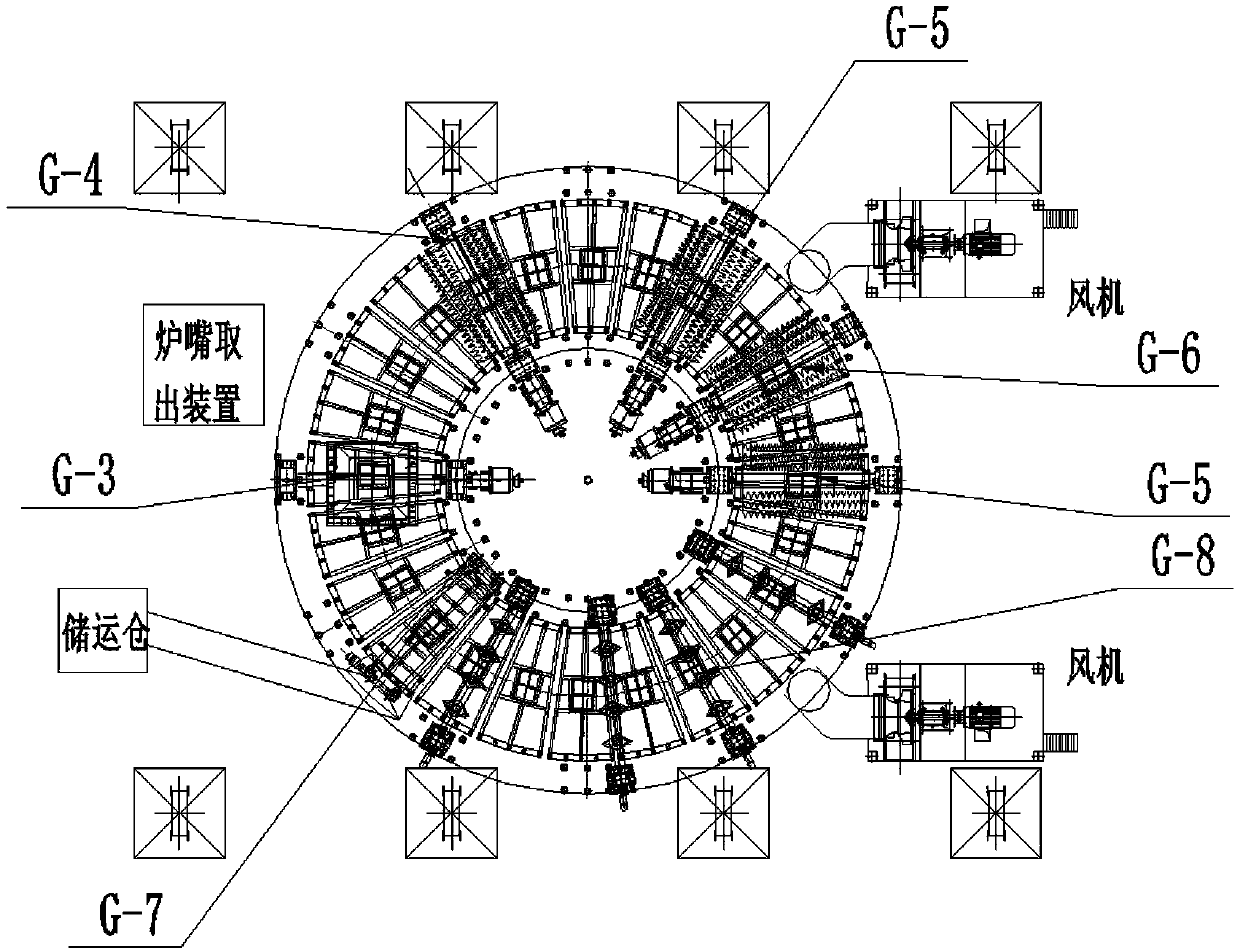

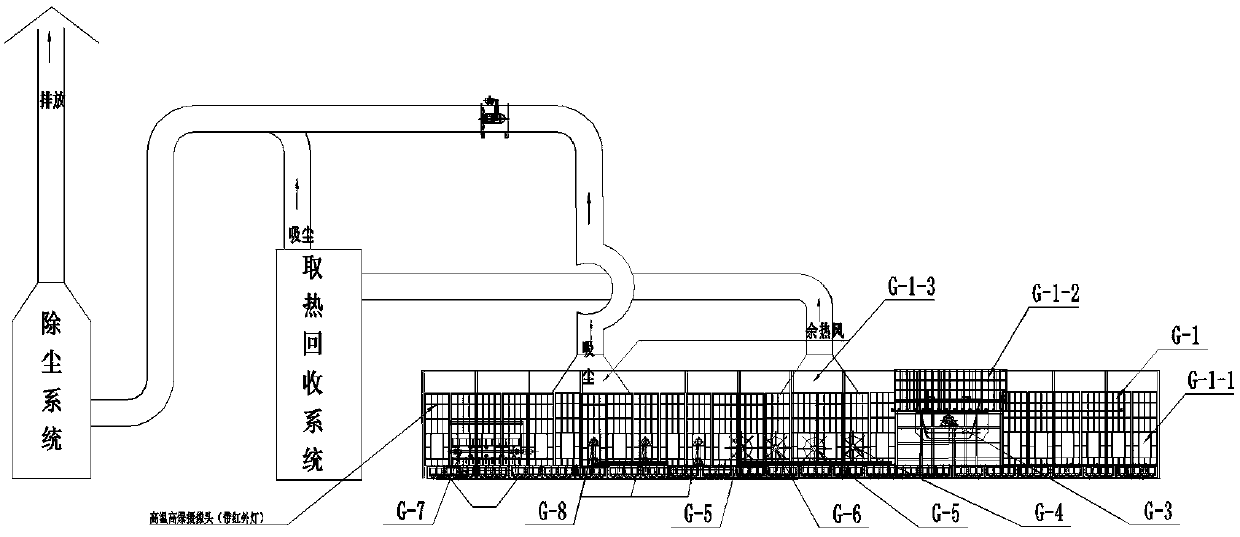

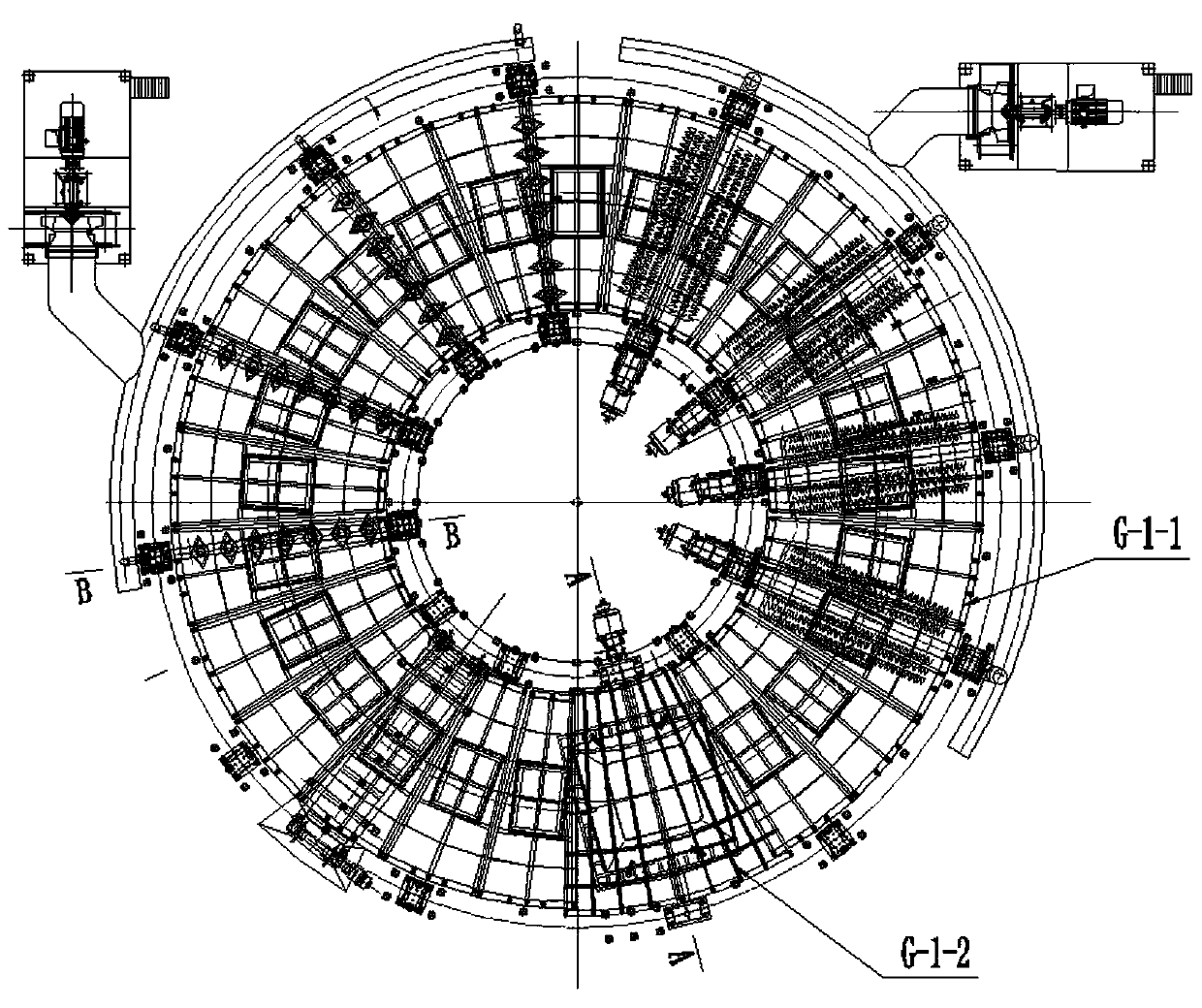

Environment cleaning, heat extraction and dry treatment system and process for high-temperature metallurgical slag

PendingCN111518971ALow Concentrated Emission ConcentrationAvoid explosionRecycling and recovery technologiesProcess efficiency improvementChemistryPlough

The invention relates to an energy-saving, environment-friendly and safe environment cleaning, heat extraction and dry treatment system and an energy-saving, environment-friendly and safe environmentcleaning, heat extraction and dry treatment process for high-temperature metallurgical slag. The system comprises a sealed cabin, an annular rotating platform board, a slag ladle tipping machine, a steel slag flattening machine, a rotating chopper machine, a steel slag raising machine, a suspended slag discharging scraper machine and an air distribution plough, wherein the sealed cabin and the annular rotating platform board form a closed annular tunnel type closed space through rigid sealing and flexible sealing, the slag ladle tipping machine, the steel slag flattening machine, the rotatingchopper machine and the steel slag raising machine are sequentially arranged in the closed space, are connected and fixed with ground foundation via bolts through bearing seats and supports, stretch across two sides of the width direction of the annular rotating platform board and serve as main slag treatment equipment of the system; the suspended slag discharging scraper machine is fixed on a bracket upright post of the sealed cabin through a truss, stretches across the width position of the annular rotating platform board, and serves as tail slag discharging equipment of the system; and theair distribution plough is arranged in front of the suspended slag discharging scraper machine. The system has the advantages of high power, few faults, small maintenance amount and the like.

Owner:河北思莱格环境科技有限公司

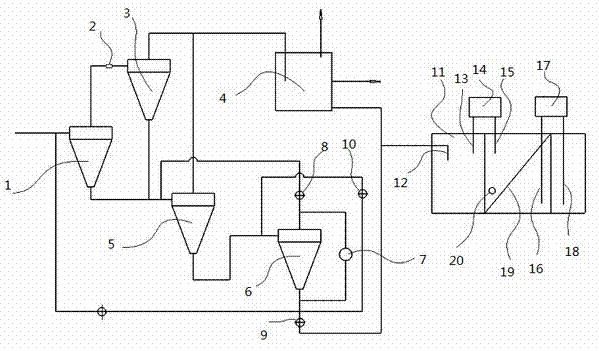

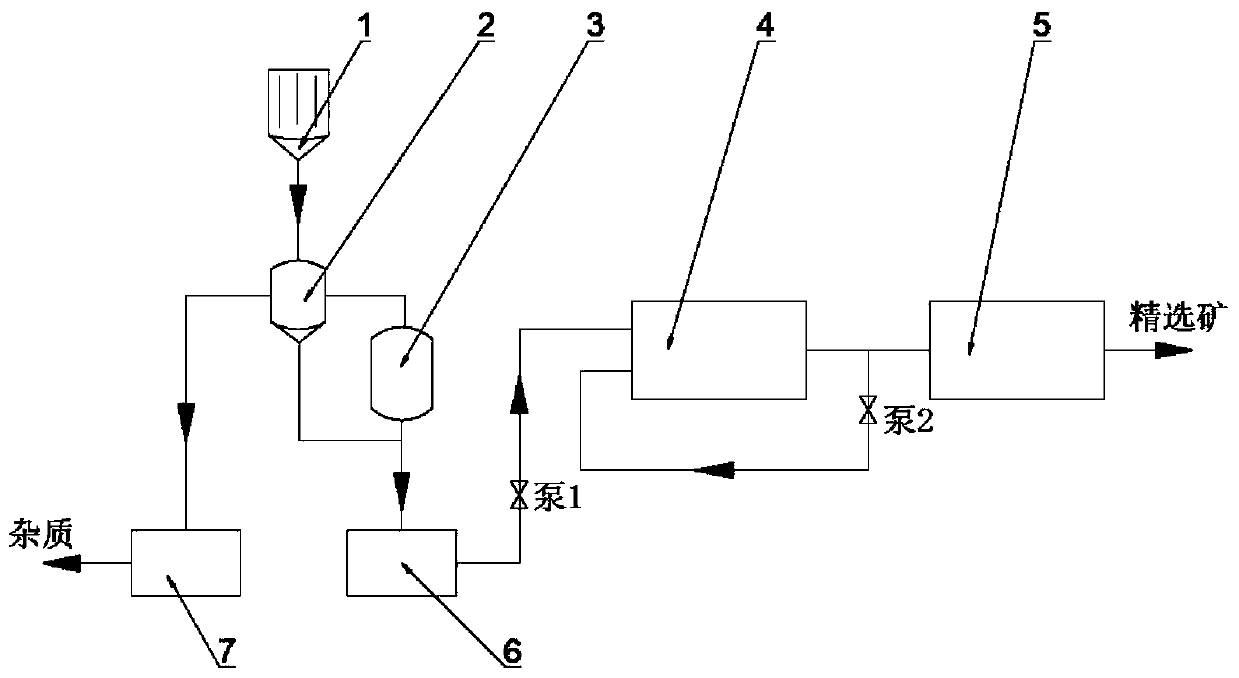

Oil-water separation method

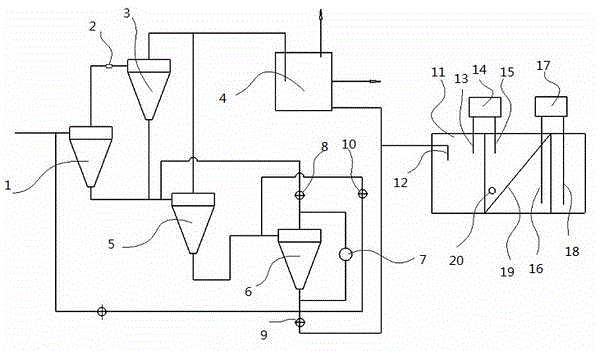

ActiveCN103830934AImprove sorting efficiencySorting is simpleLiquid separationChemistrySeparation process

The invention discloses an oil-water separation method. An oil-water separating part is used for separating an oil-water mixture into oil and intermediate water, the intermediate water enters a water processing part and is further separated into heavy impurities and water, a coarse separation hydrocyclone of the oil-water separating part is used for separating the oil-water mixture into two branches of light phase and heavy phase, and separated heavy products of the light phase are introduced into the branch of the heavy phase for enrichment, namely the separation efficiency is improved for the light phase, and the separation precision is improved for the heavy phase; for the light phase, although the separation precision is sacrificed, a part of oil runs out from the bottom flow of a first hydrocyclone, only the first hydrocyclone is used in the whole separation process of the light phase, and other hydrocyclones are not used for recleaning and return separation, and thus the separation of the light phase is extremely simple and easy to control; however, for the heavy phase, the adjustability of closed-loop return separation consisting of a second hydrocyclone and a third hydrocyclone can overcome the oil leakage defect of the light phase, and all separation errors are solved in closed-loop return separation.

Owner:SUZHOU YOUDAN INTERNET TECH CO LTD

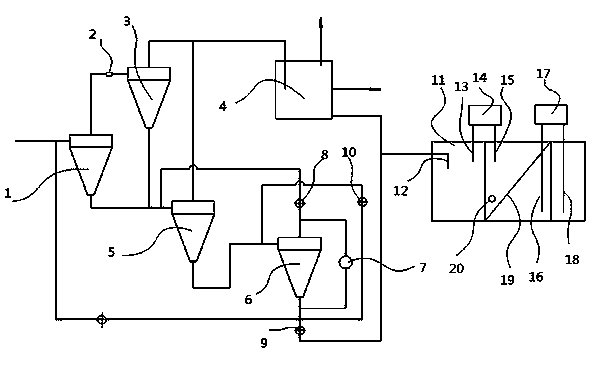

Urban domestic garbage treatment method with steps of steaming firstly and sorting secondly

ActiveCN101758067AEasy to dehydrateProne to biochemical reactionsSolid waste disposalAfter treatmentCombustion

The invention relates to an urban domestic garbage treatment method with the steps of cooking firstly and sorting secondly, which mainly comprises the following steps of: loading urban domestic garbage into a cooking kettle by using a grab bucket of a travelling crane, introducing water vapour, cooking, turning over a kettle body when the garbage easy to rot in the urban domestic garbage is cooked into slurry, pouring all the garbage into a dewatering pool, then grabbing the dewatered garbage by using the grab bucket of the travelling crane and delivering to a sorting system, wherein the sorted light garbage is used for recycling, nutritional soil is used for landscaping, heavy garbage is delivered for landfill after metal is dressed by magnetic separation, the removed sewage reaches the standard after treatment and is discharged, and methane generated in the sewage treatment process is used for combustion to produce vapour for private use. In this way, the hazard-free, reduction and reclamation treatment of the urban domestic garbage is realized.

Owner:浙江金锅环保科技有限公司

Aerobic fermentation-sorting recycling method for household garbage

PendingCN109836183ARealize full resourceRealize fully enclosed purificationClimate change adaptationMagnetic separationProcess systemsLitter

The invention discloses an aerobic fermentation-sorting recycling method for household garbage, and the aerobic fermentation-sorting recycling method comprising: spraying an aerobic fermentation promoter in the household garbage, carrying out aerobic fermentation, sorting fermented composted materials, and finally carrying out post-treatment on the sorted different materials. According to the process system disclosed by the invention, full-recycling of the household garbage is realized, totally-closed purification of the waste gas of a treatment field is realized, the wastewater is subjected to full-circulation treatment, the zero emission of the wastewater is realized, and the odor of the household garbage treatment field is eliminated; and an aerobic fermentation bin or the whole treatment field is in a semi-underground mode or even an all-underground mode, so that the situation that the garbage treatment field is dirty and smelly is completely changed.

Owner:安徽安特治废弃物资源化研究中心有限公司

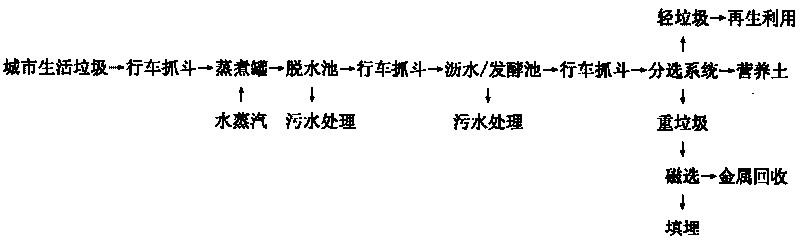

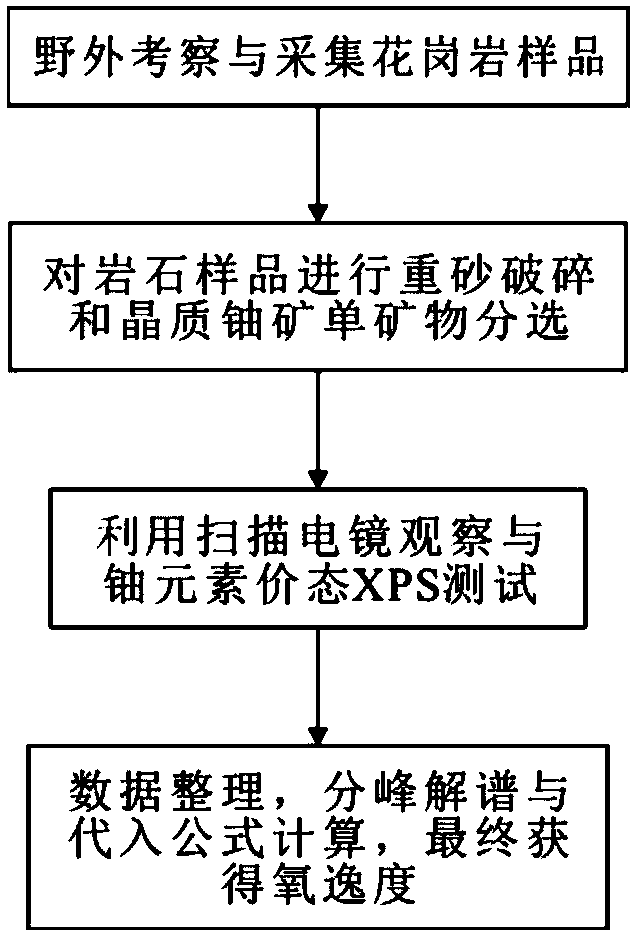

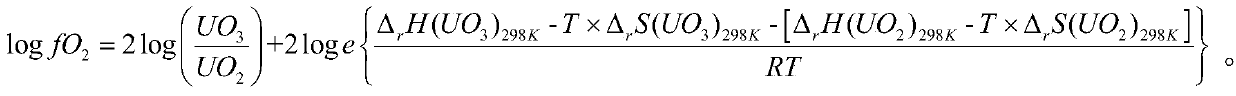

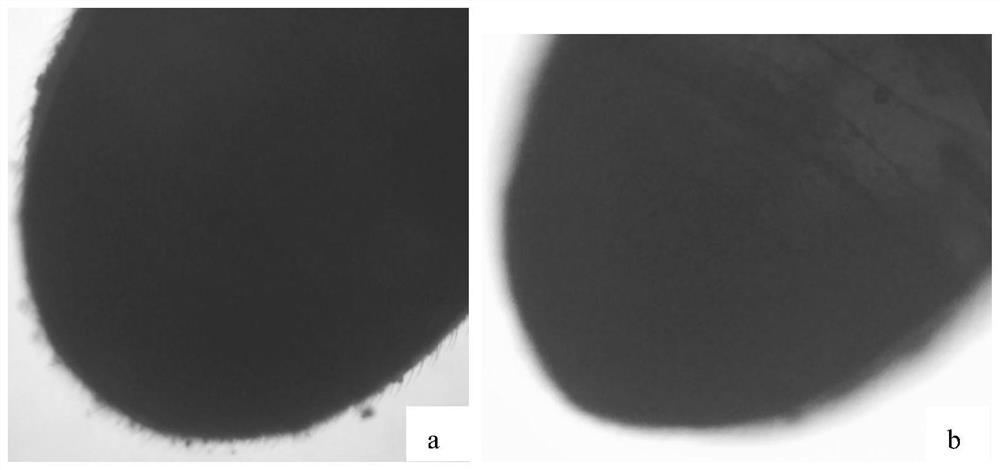

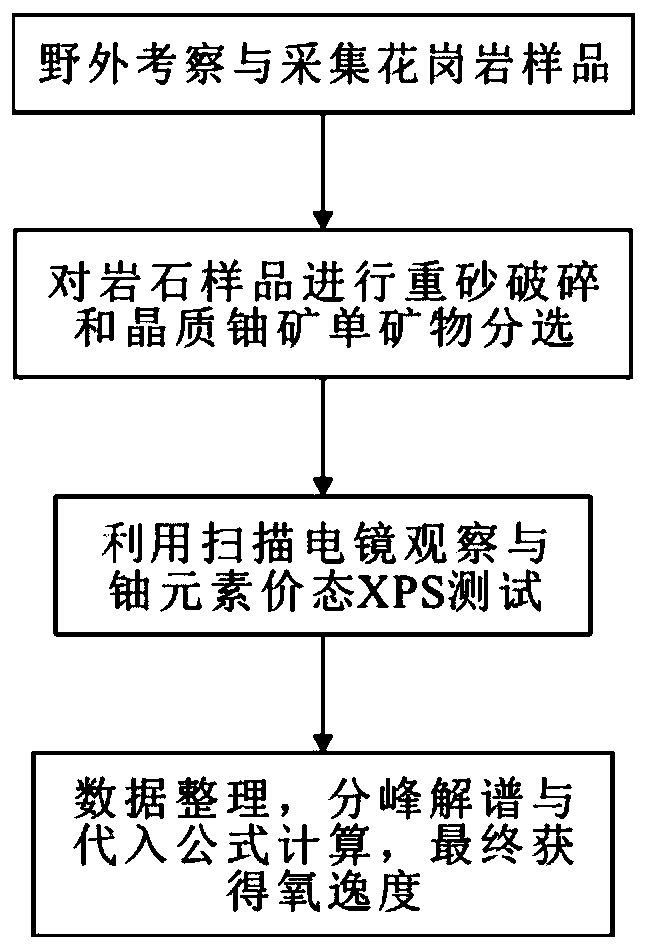

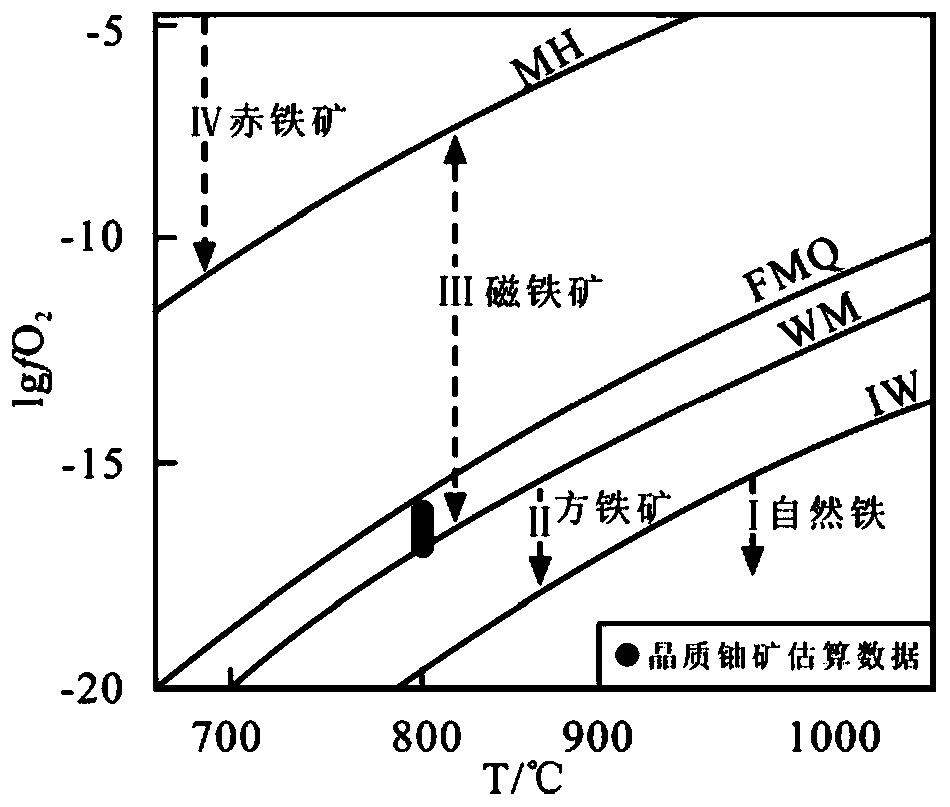

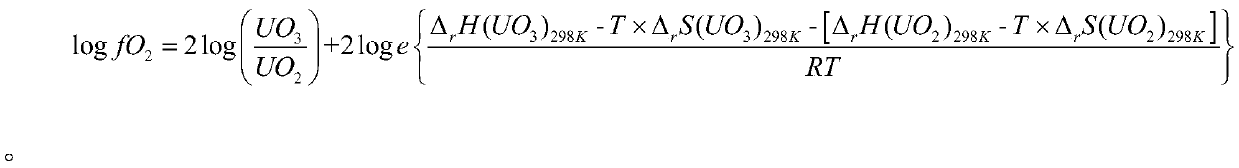

Method for calculating magmatic oxygen fugacity by utilizing uraninite in granite

ActiveCN107561241ASorting is simpleImprove the oxidation-reduction reactionEarth material testingUraninitePrill

The invention belongs to the geotechnical field and particularly discloses a method for calculating magmatic oxygen fugacity by utilizing uraninite in granite. The method comprises the following steps: step 1, acquiring a granite sample containing a uraninite auxiliary mineral; step 2, performing pretreatment and crystalline uranium ore single mineral separation on the granite sample acquired in the step 1 to obtain granite sample uraninite particles; step 3, performing scanning electron microscopy on the granite sample uraninite particles obtained in the step 2; step 4, performing uranium valence state photoelectron spectroscopy test on the granite sample uraninite particles preferably selected from the step 3 to obtain a U6+ / U4+ ratio in the uraninite; step 5, substituting the U6+ / U4+ ratio obtained by uraninite test analysis in the step 4 into an oxygen fugacity estimation formula to obtain a magmatic oxygen fugacity estimation value logfO2. The method provided by the invention is strong in operability, and can be used for testing directly with little test error.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Oil-water separation system

ActiveCN103877751ASorting is simpleOvercome the defect of running oilMultistage water/sewage treatmentLiquid separationCycloneClosed loop

The invention discloses an oil-water separation system. The oil-water separation system is provided with an oil-water separation part and a water treatment part, wherein an oil-water mixture is separated by the oil-water separation part to obtain oil and intermediate water, the intermediate water enters the water treatment part to be further separated into heavy impurities and water, a rough separation cyclone of the oil-water separation part is used for separating the oil-water mixture into a light phase branch and a heavy phase branch, a heavy product separated from the light phase is guided to the heavy phase branch to be concentrated, so that the sorting efficiency is improved relative to the light phase; the sorting precision is improved for the heavy phase; for the light phase, although the sorting precision is sacrificed, a part of oil flows out from the bottom stream of a first cyclone, but only the first cyclone is used in the entire sorting process of the light phase, no other cyclones are used for resorting and back sorting the light phase, so that the light phase can be sorted very simply and the sorting process of the light phase is easy to control; for the heavy phase, the adjustability of a closed-loop back sorting consisting of a second cyclone and a third cyclone can overcome the oil leakage defect of the light phase, and all the sorting errors are solved in the closed-loop back sorting.

Owner:SUZHOU YOUDAN INTERNET TECH CO LTD

Method for processing life garbage original-source by classification

InactiveCN1978078ASorting is simpleReduce pollutionSolid waste disposalRefuse collectionResource recovery

The present invention relates to a domestic refuse treatment method, in particular, it relates to a domestic refuse source classification treatment method. It is characterized by that the domestic refuse can be classified in the refuse collecting station, the domestic refuse can be divided into degradable organics, unrecoverable refuse and recoverable refuse, they can be respectively trated in said refuse collecting station.

Owner:朱永亮

Novel garbage sorting machine

InactiveCN104624498ASimple structureSorting is simpleGas current separationEngineeringMechanical engineering

The invention discloses a novel garbage sorting machine. The novel garbage sorting machine is capable of carrying out primary sorting on garbage according to different weights. The novel garbage sorting machine comprises a hollow-out shell body. The center of the top of the shell body is provided with a garbage inlet. A leftward inclined first material sorting board is arranged at the portion, below the garbage inlet, inside the shell. The side wall, close to the position below the left end of the first sorting board, of the shell body is provided with a first outlet. The portion, between the left end of the first sorting board and the upper edge of the first outlet, of the other end side wall of the shell body is provided with a first material sorting draught fan. An air outlet of the first material sorting draught fan faces the interior of the shell body. A second material sorting board is arranged inside the shell body and below the first outlet in a rightward inclined mode. A second outlet is arranged below the right end of the second material sorting board. The portion between the right end of the second material sorting board and the upper edge of the second outlet is provided with a second material sorting draught fan. A third outlet is arranged under the right end of the second material sorting board. A lifting cylinder is arranged at the bottom end inside the shell body. A lifting piston rod of the lifting cylinder is connected with the first material sorting board and the second sorting board in a supporting mode.

Owner:XIAN SHANGSHANG ELECTROMECHANICAL

Recovery system of accumulator plate

InactiveCN102315503BReduce pollutionNot harmful to healthSolid waste disposalWaste accumulators reclaimingParticulatesCrusher

The invention discloses a recovery system of an accumulator plate. The recovery system comprises a plate breaking part, a dust recovery part and a PM (particulate matter) recovery part, wherein the plate breaking part comprises a feed port and a machine case; a roller and a transition roller are arranged behind the feed port; the machine case is internally provided with a vibration box, a dust outlet is arranged at the upper part of the machine case and a PM outlet is arranged at the lower part of the machine case; the dust recovery part comprises a feed pipe which is communicated with the dust outlet and is connected to a dust remover; and the PM recovery part comprises a feeding pipe which is communicated with the PM outlet, and the feeding pipe is also connected with a crusher. The plates recovered by the recovery system are separated thoroughly and recovered products are refined. The recovery process generates little pollution to the environment, does not need manual operation and is not harmful to human health.

Owner:长兴巨沃机电科技有限公司

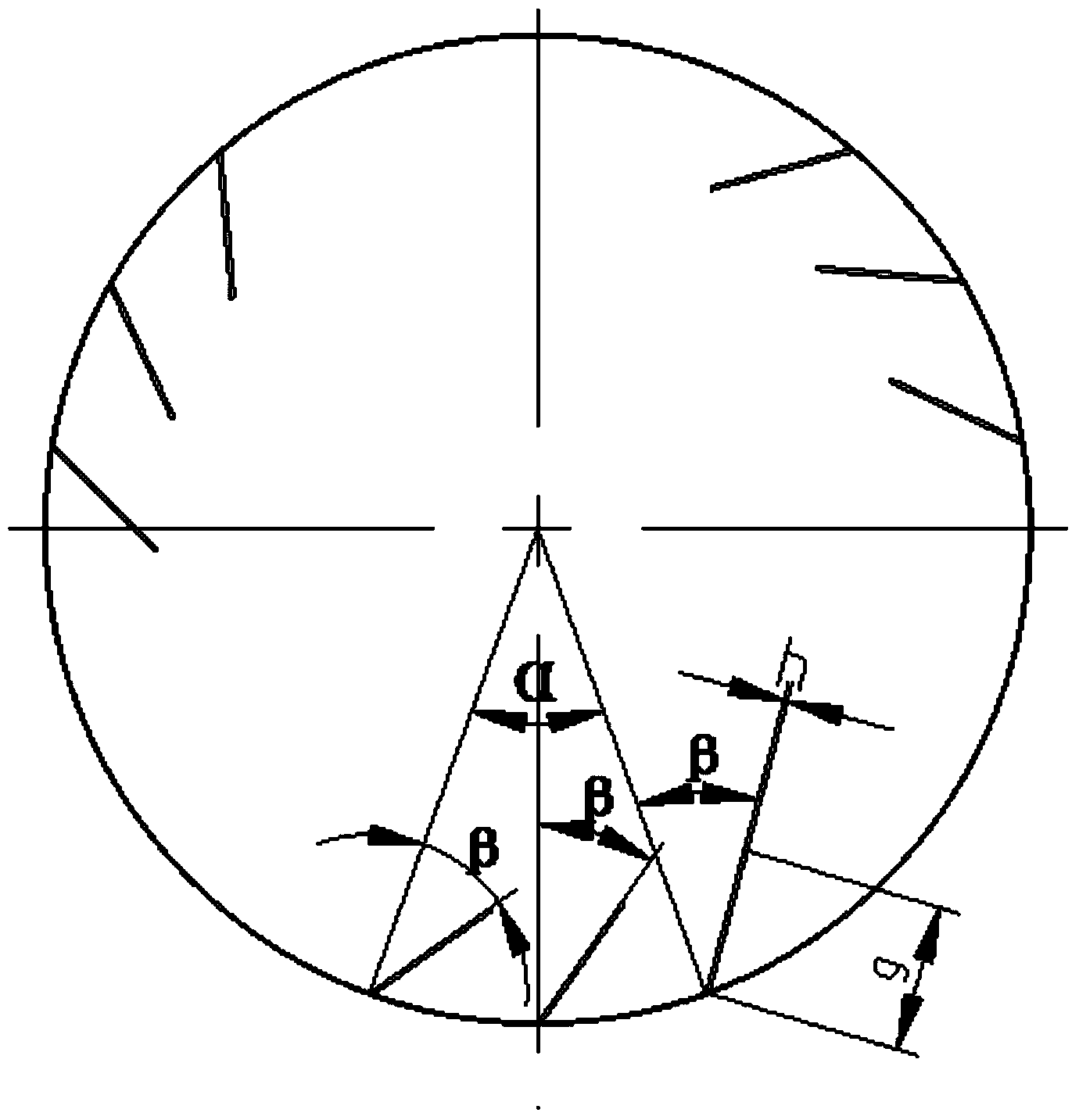

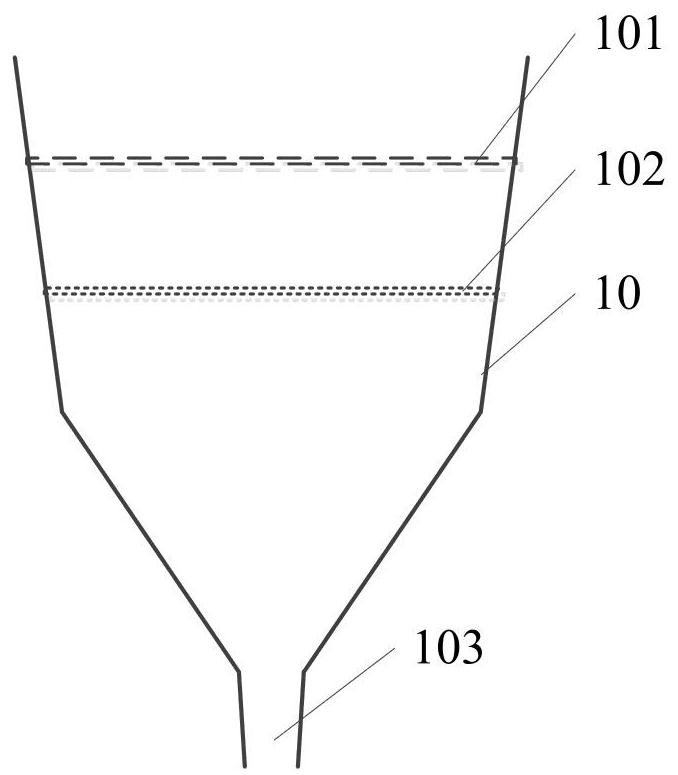

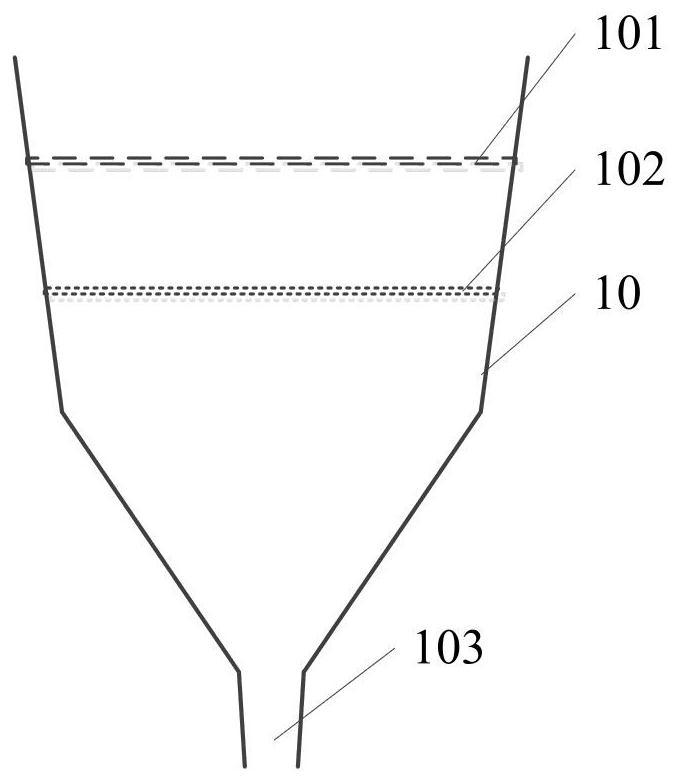

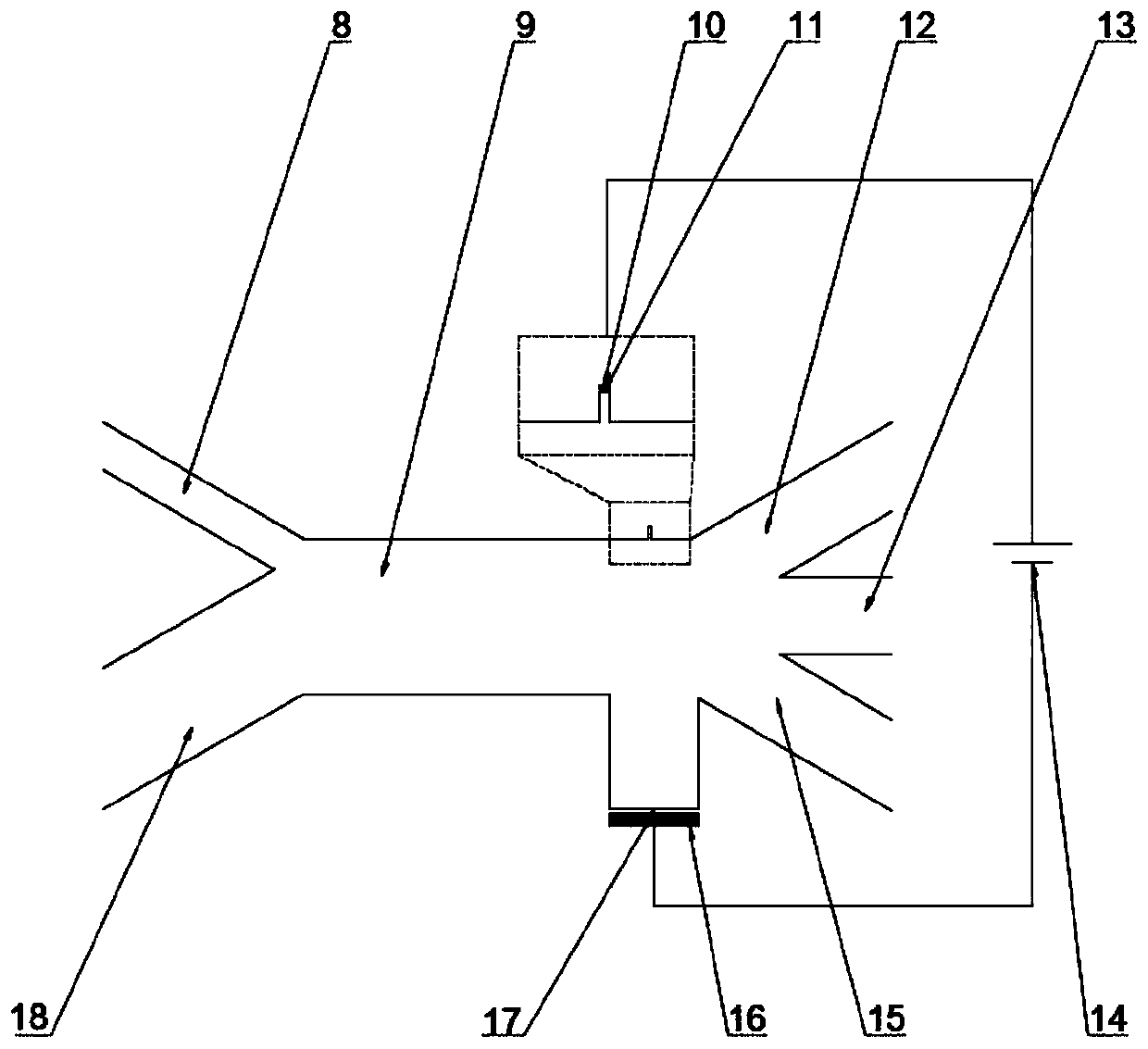

Conical pressureless fed three-product dense-medium cyclone

InactiveCN1994582AEfficient sortingSorting is simpleReversed direction vortexWet separationCycloneHigh density

The invention relates to a taper non-pressure feeding three-product heavy medium cyclone device, wherein it is formed by first-stage non-pressure feeding cyclone device and the second-stage non-pressure feeding cyclone device; the first stage device is taper cyclone device whose taper angle theta is 5-40degree, the mounting angle alpha is 25-50degree; the second stage cyclone device is cylinder one whose mounting angle beta is 5-90degree; the front end of first stage device has heavy medium suspension inlet and light product outlet while another end has mineral inlet; one end of second-stage device has heavy product outlet and another end has middle product outlet. The invention can effectively select high-density mineral, whose density is higher than 2. 0kg / l. The invention has simple process and low cost.

Owner:TANGSHAN BRANCH COAL SCI ACAD

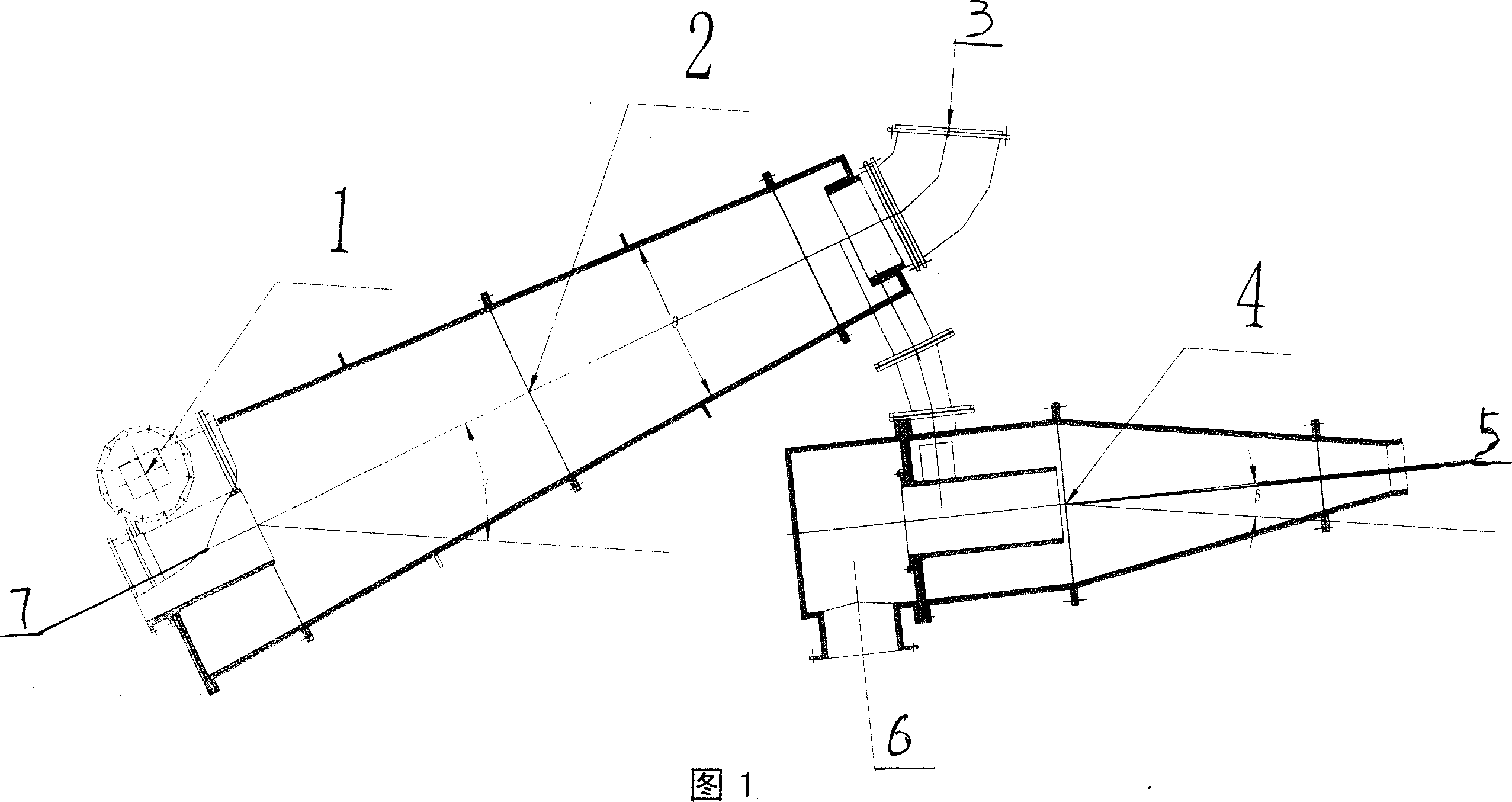

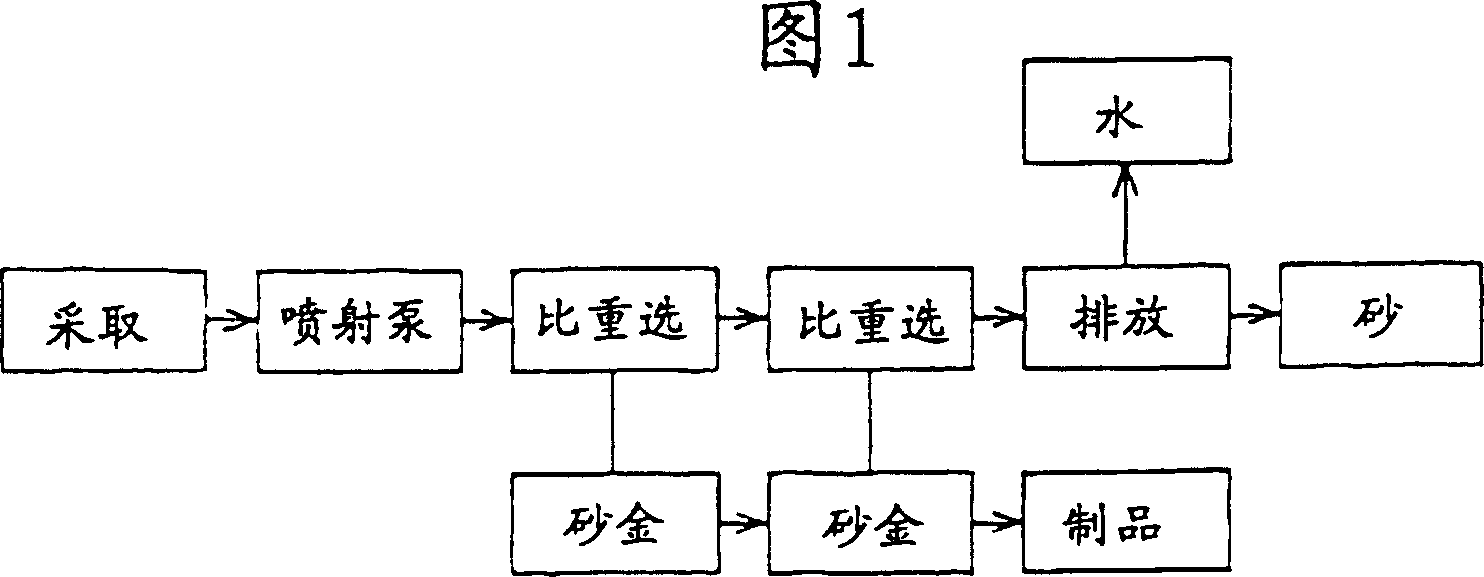

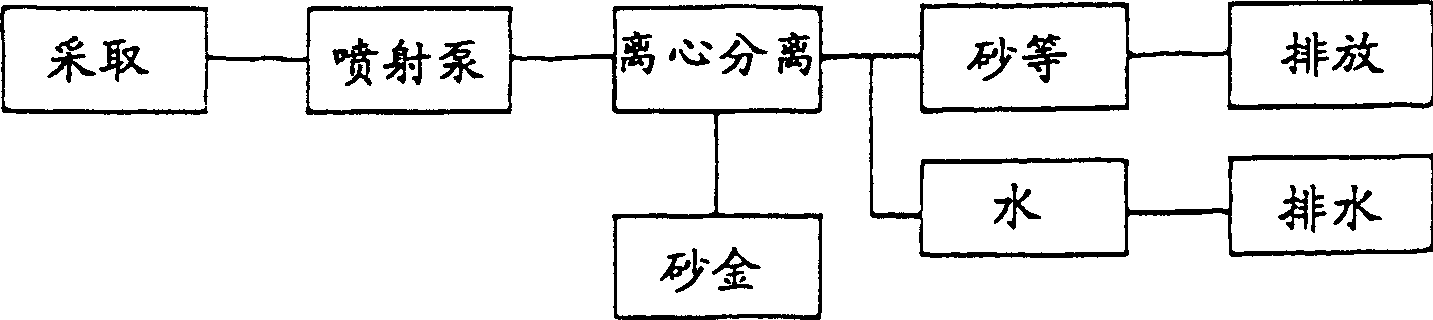

Digging and separating method for placer gold and equipment thereof

InactiveCN1204332CEfficient use ofEfficient sortingMechanical machines/dredgersMineral miningGold oreMaterials science

A placer gold separating method comprising subjecting placer gold- and gold ore-containing sand and gravel layers accumulated on the bottom of the water of a river and placer gold- and gold ore-containing sand and gravel layers formed deep in the ground to excavation or suction excavation by utilizing a water pressure difference, causing a mixture of the excavated or suction excavated placer gold- and gold ore-containing sand, gravel and water to flow horizontally by the action of a pressure fluid, and separating the placer gold and gold ores by utilizing a specific gravity difference while the mixture is flowing; and a system for this method. A placer gold mining boat used to practice this method and provided thereon with a combination of a suction excavation means, a mixture transfer means, a means for separating placer gold by utilizing a specific gravity difference, and a means for discarding the remaining mixture from which the placer gold has been separated. A placer gold separating method characterized by causing a mixture of placer gold and gold ores or pulverized gold ores and water to flow in a metallic cylinder, generating a magnetic field by a magnetic field generating means provided on an outer circumferential surface of the metallic cylinder, and magnetically depositing the placer gold in the mixture on the inner surface of the metallic cylinder, whereby the placer gold is separated.

Owner:JIPANGU

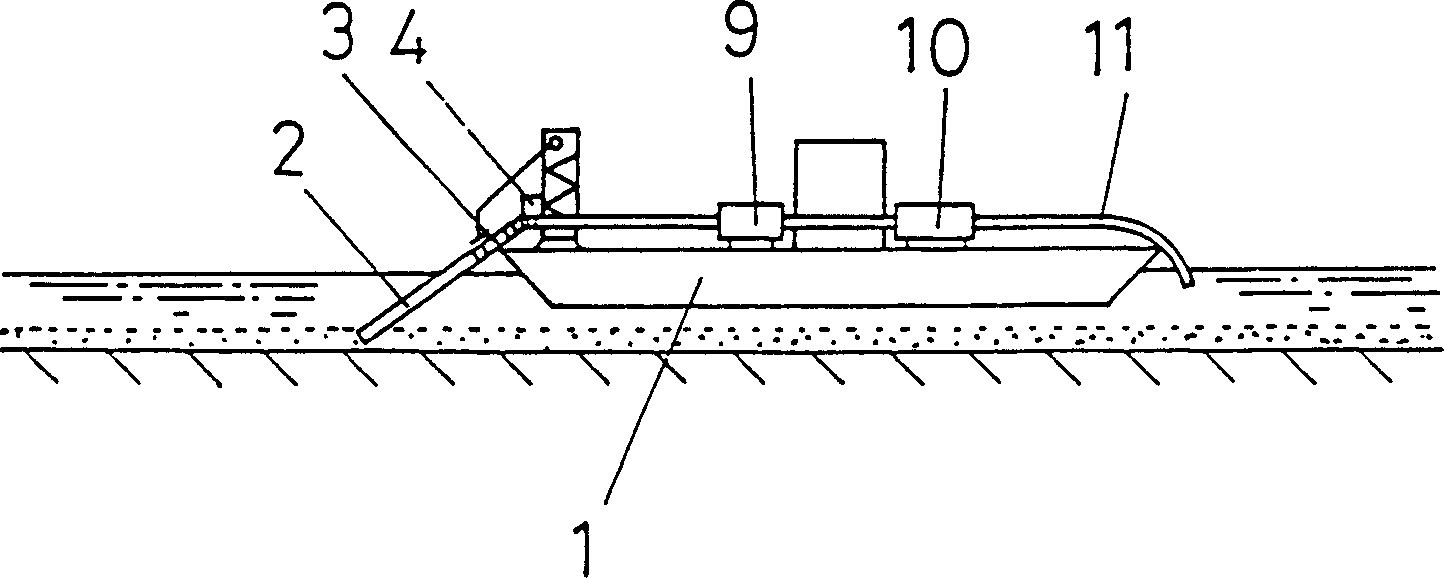

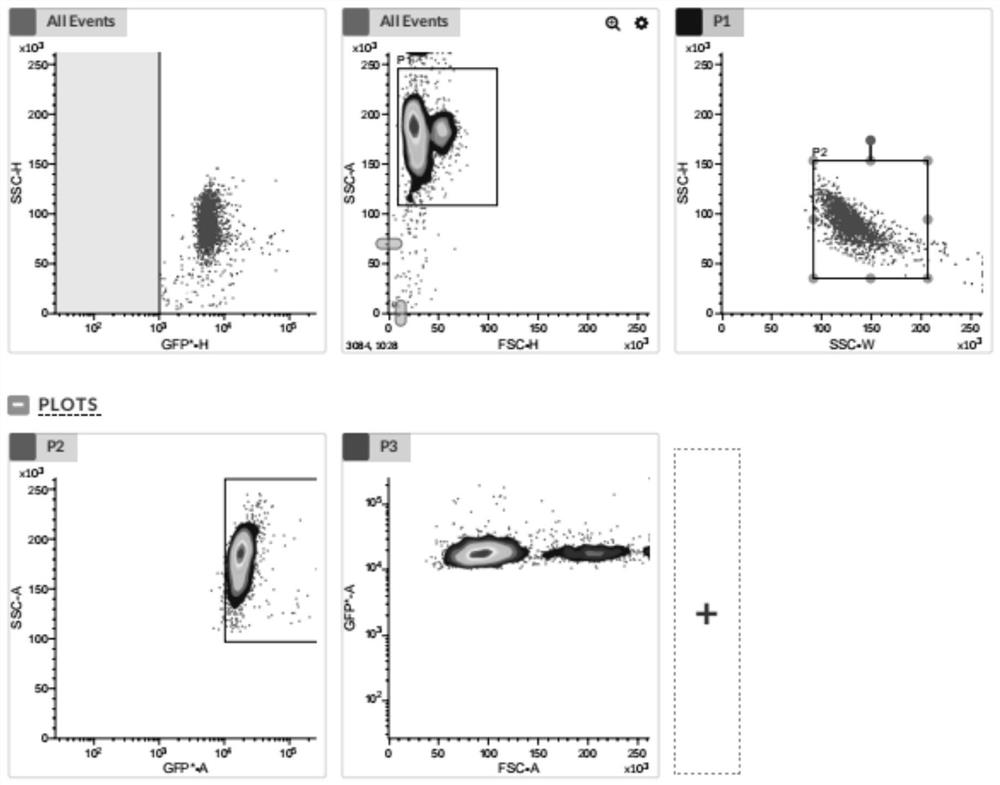

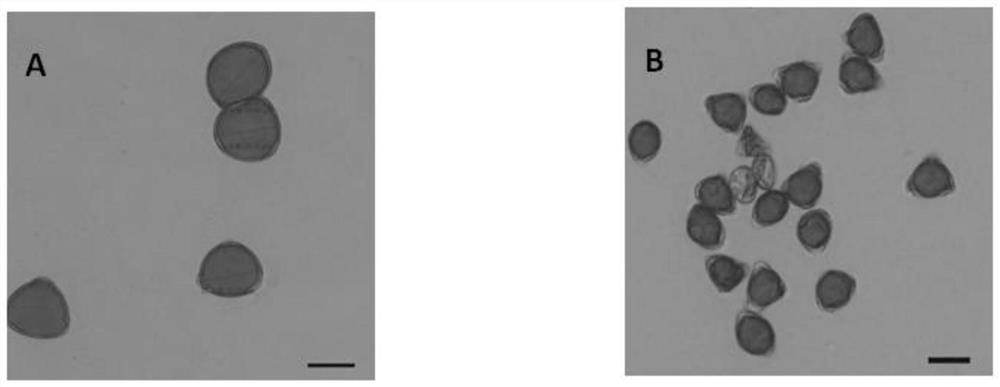

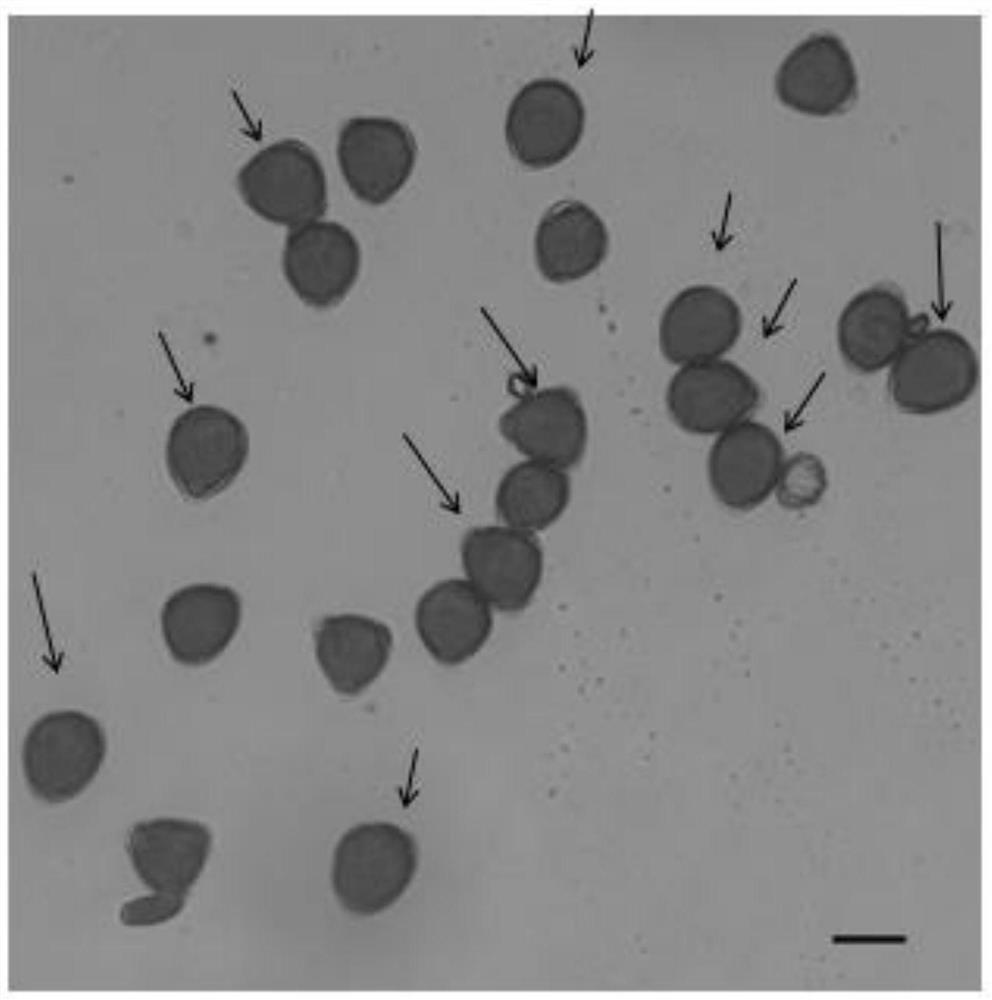

Method for sorting 2n pollen from pollen

The invention relates to a method for sorting 2n pollen from pollen. The method comprises the steps of 1, taking a pollen sample to prepare pollen suspension; and 2, sampling the pollen suspension toa flow cytometry for sorting. According to the method, the flow cytometry is applied into the 2n pollen, so that the problem that the 2n pollen sorting is low in efficiency and complicated in operation is ingeniously solved. Furthermore, in cooperation with the setting of the sorting environment temperature, humidity and parameter value of the flow cytometry, the sorting error of the flow cytometry can be reduced.

Owner:SOUTH CHINA AGRI UNIV

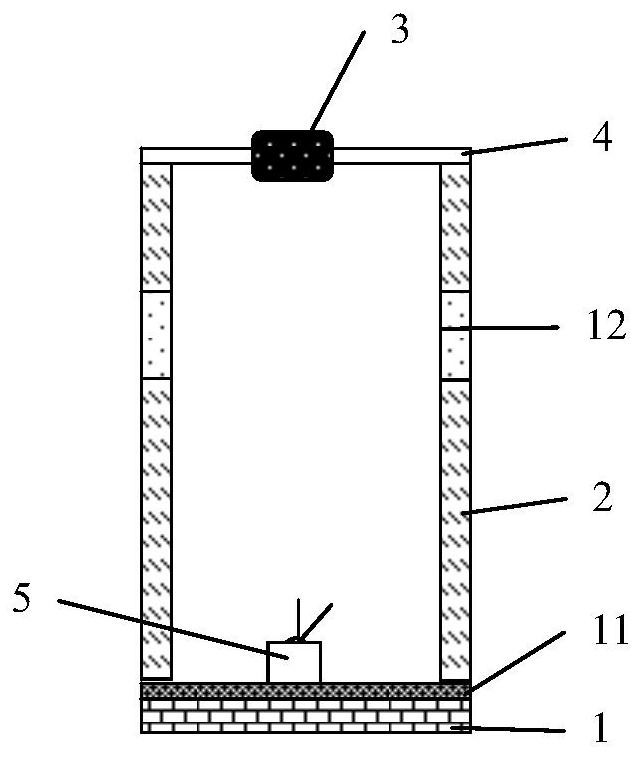

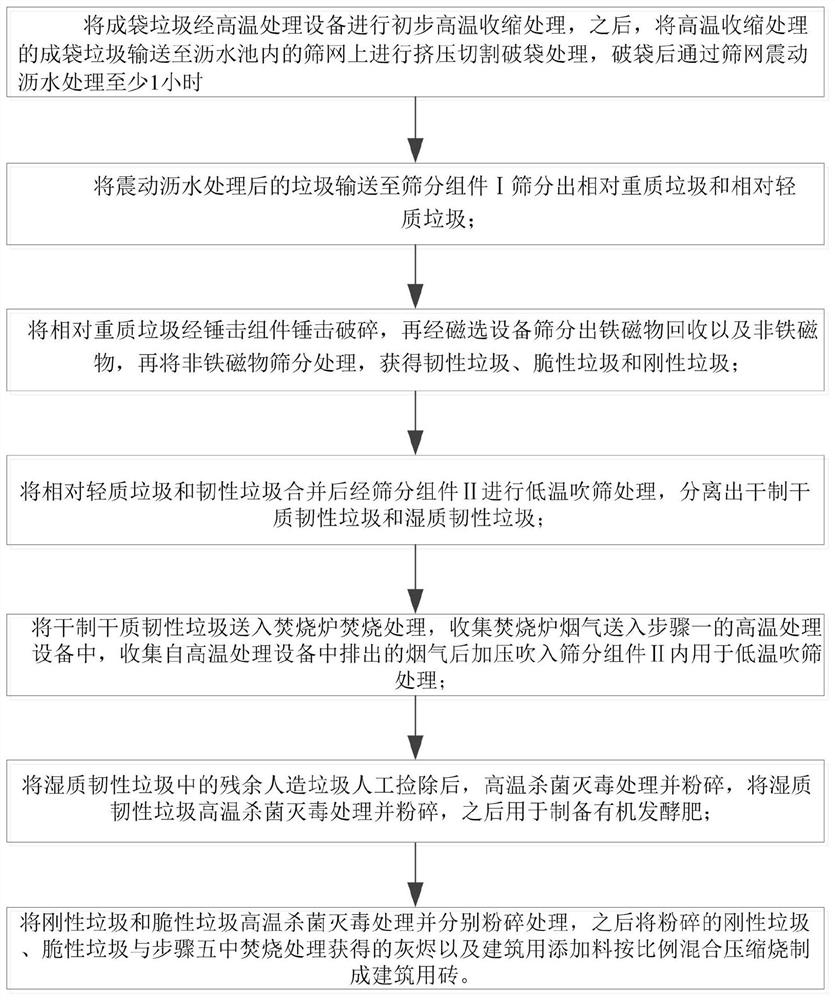

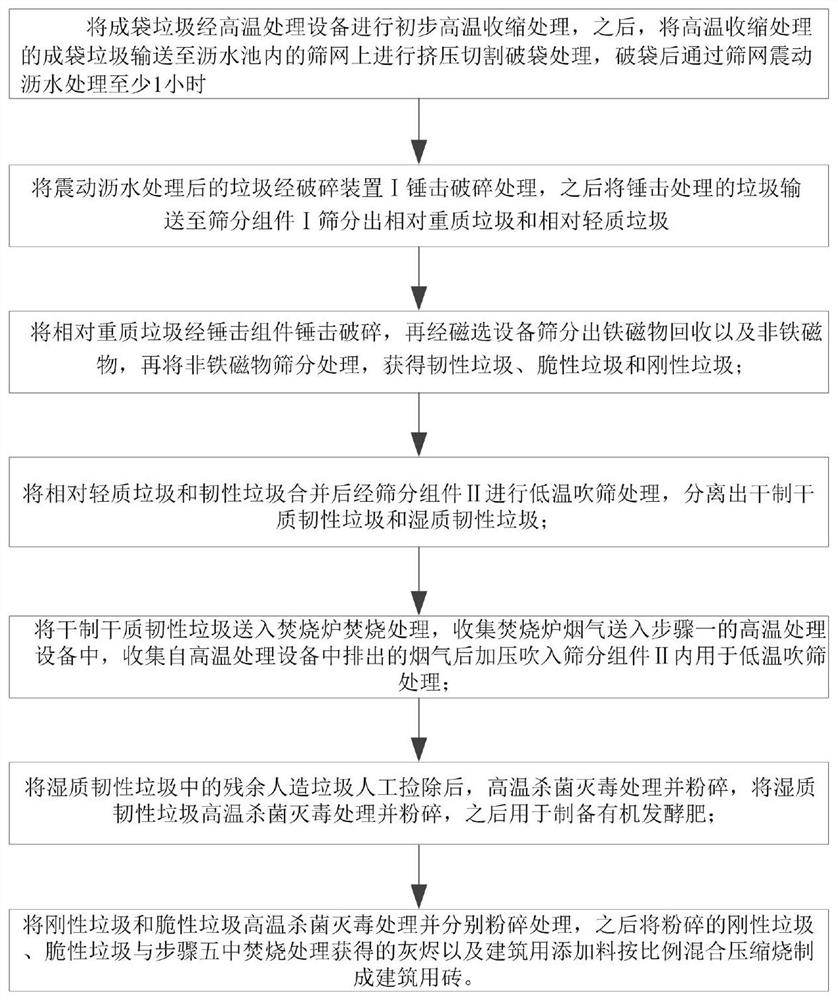

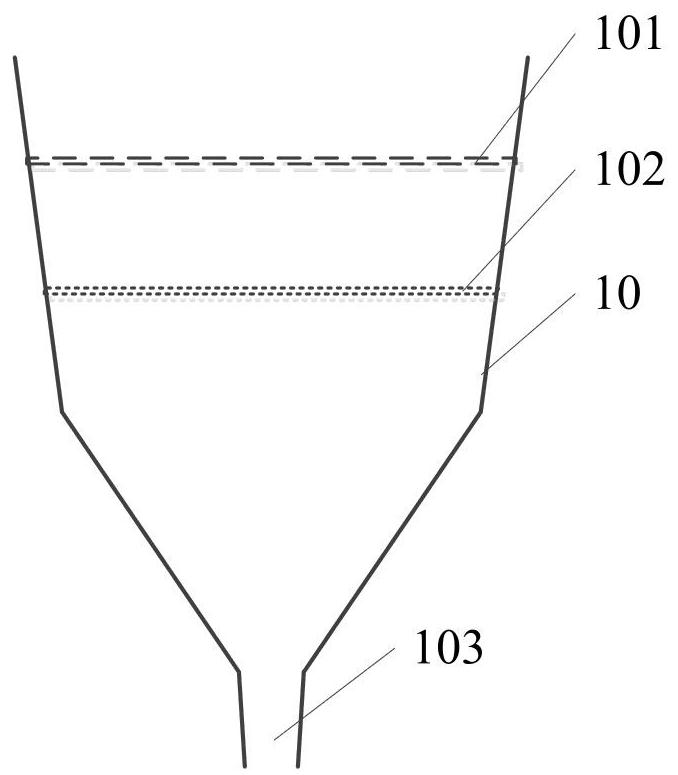

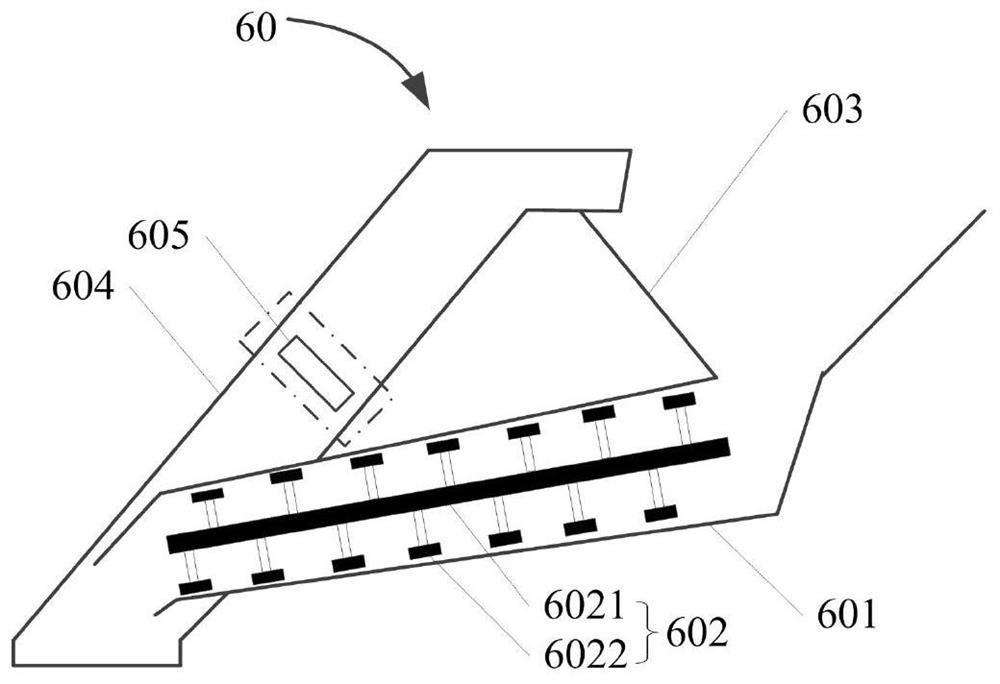

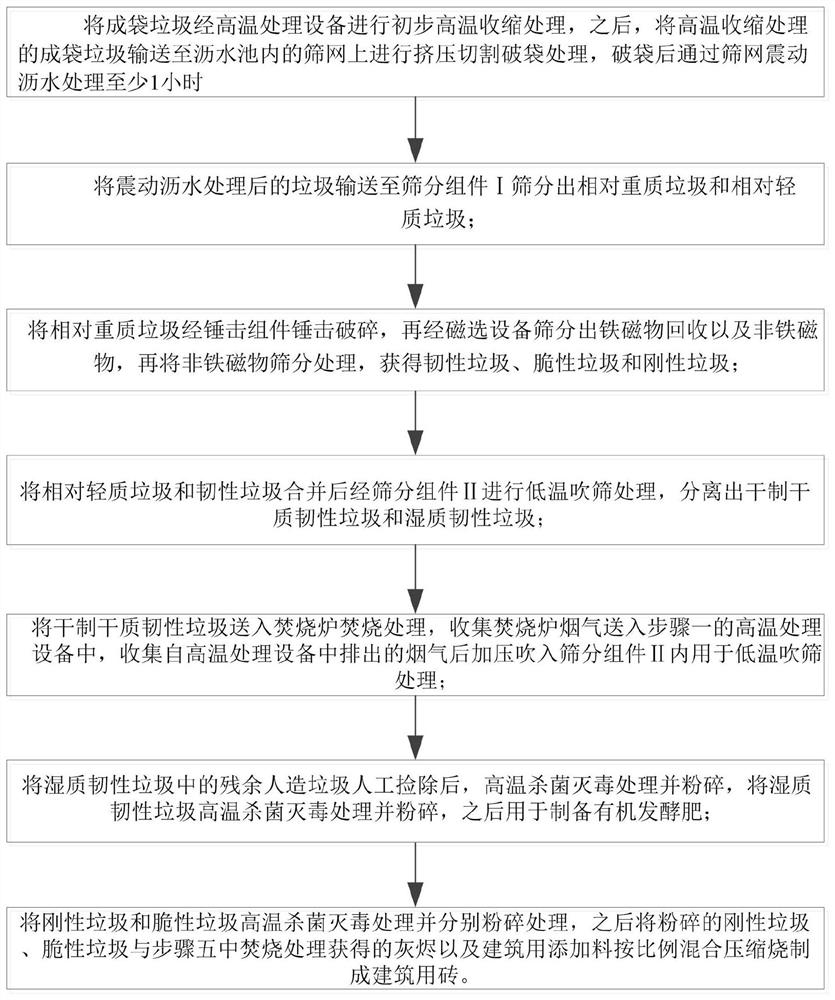

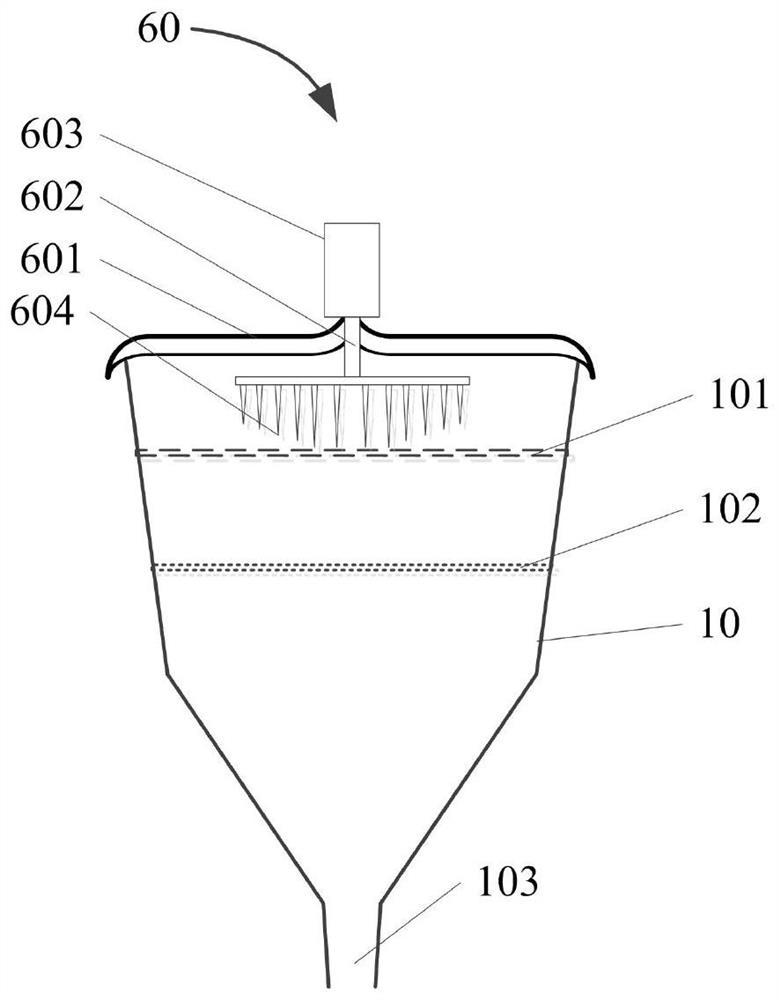

Environment-friendly and energy-saving garbage treatment method

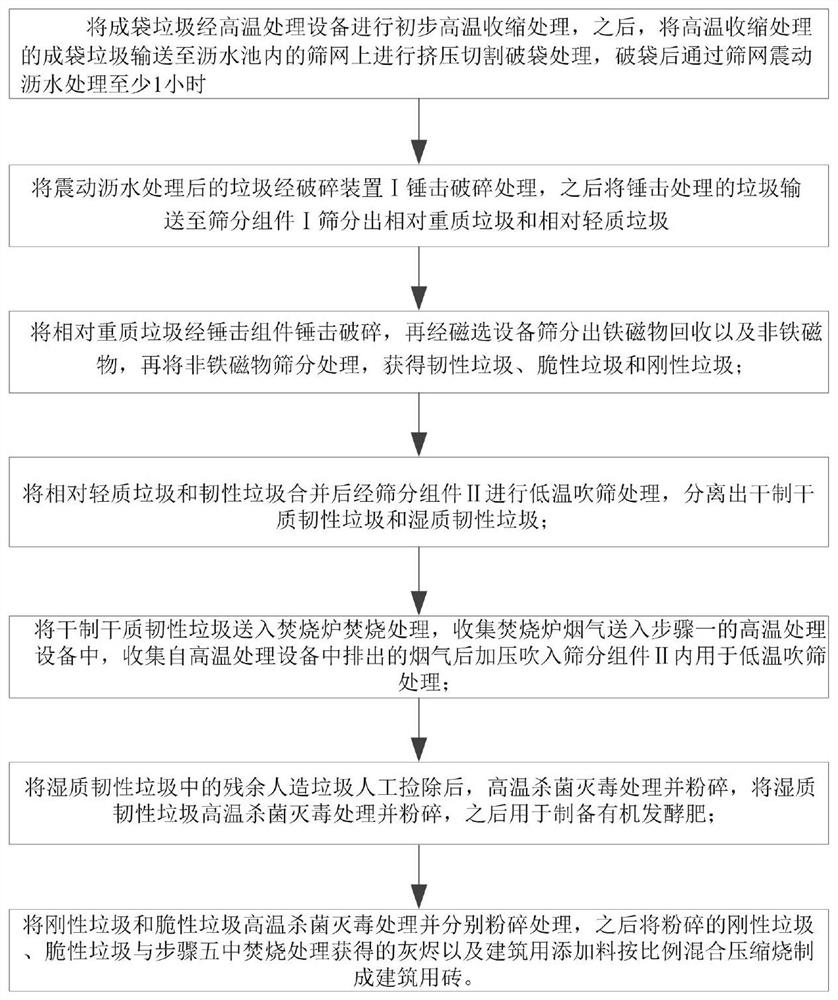

ActiveCN111872075AShort processing cycleThe classification processing effect is goodSolid waste disposalBrickRefuse Disposals

The invention relates to the technical field of resource recycling, in particular to an environment-friendly and energy-saving garbage treatment method. The method comprises the following steps that bagged garbage is subjected to primary high-temperature shrinkage treatment and then is conveyed into a draining tank to be subjected to extruding cutting bag breaking and screen vibrating draining treatment; then the garbage is subjected to hammering crushing treatment by a crushing device I to screen out the relatively heavy garbage and the relatively light garbage; the relatively heavy garbage is subjected to hammering crushing by a crushing device II to screen out ferromagnetic substances for recycling and non-ferromagnetic substances, and the non-ferromagnetic substances are screened to obtain the tough garbage, the brittle garbage and the rigid garbage; the relatively light garbage and the tough garbage are combined, and then the dry tough garbage and the wet tough garbage are separated out; the dry tough garbage is subjected to incineration treatment; the wet tough garbage is used for preparing organic fermented fertilizers; and the rigid garbage and the brittle garbage are usedfor being fired into building bricks. According to the method, the harmless treatment on the garbage is achieved, no pollution is caused to the environment in the whole process, and a sustainable circulation system is achieved.

Owner:北京净与境生态科技有限公司

A method for rapidly sorting medicinal beetle adults according to sex

ActiveCN109169533BSorting is simpleSuitable for sorting workAnimal husbandryBiotechnologyMedicinal herbs

The present invention relates to a method for rapidly sorting medicinal beetle adults according to their sex, which is characterized in that the method comprises the following steps: (1) taking a photo of the tail shape of a male medicinal beetle as a first reference photo, and obtaining a female The photo of the tail shape of the medicinal material beetle adult is as the second reference photo; Wherein, the tail shape of the medical material first shown in the first reference photo is more round than the shape shown in the second reference photo; (2) obtain to be divided The photo of the tail shape of the selected medicinal material beetle adult is used as the photo to be inspected; (3) the photo to be inspected is compared with the first reference photo and the second reference photo respectively; (4) according to the result of the comparison, the medicinal material beetle adult Sorting into male medicinal material A and female medicinal material A. By adopting the method of the invention, the male medicinal beetle adults and the female medicinal beetle adults can be sorted out simply and quickly, and it is especially suitable for sorting a large number of adults.

Owner:GUIYANG UNIV

Harmless treatment method for municipal waste

ActiveCN111872076AShort processing cycleThe classification processing effect is goodSolid waste disposalBrickIncineration

The invention relates to the technical field of resource recycling, in particular to a harmless treatment method for municipal waste. The method comprises the following steps: after bagged waste is subjected to primary high-temperature shrinkage treatment, the bagged waste is conveyed to a screen in a water draining pool for extrusion, cutting, bag breaking and screen vibration water draining treatment; relatively heavy waste and relatively light waste are screened out from the waste subjected to vibration water draining treatment; the relatively heavy waste is hammered and crushed by a hammering assembly, then ferromagnetic substances and non-ferromagnetic substances are screened out for recycling the ferromagnetic substances, and then the non-ferromagnetic substances are screened to obtain tough waste, brittle waste and rigid waste; the relatively light waste and the tough waste are combined, and then dry tough waste and wet tough waste are separated out; the dry tough waste is incinerated; the wet tough waste is used for preparing an organic fermented fertilizer; and the rigid waste and the brittle waste are used for being burned into building bricks. According to the method, harmless treatment of the waste is achieved, no pollution is caused to the environment in the whole process, and a sustainable circulation system is realized.

Owner:四川同益环境科技集团有限责任公司

Insulated dielectrophoresis ore sorting system

ActiveCN109290059BHigh purityAvoid the risks of electrolysisDielectrophoresisDispersed particle separationElectrolytic agentElectrical conductor

The invention discloses an insulating dielectrophoresis ore separation system which comprises a preprocessing storage unit, a first pump and an ore separation unit. The ore separation unit comprises an ore powder suspension liquid inlet I formed to input ore powder suspension liquid conveyed through the first pump, an electrolytic solution inlet II formed to input an electrolytic solution, a mainrunner, a current-conducting plate I and a current-conducting plate II, wherein the current-conducting plate I and the current-conducting plate II are arranged oppositely. The main runner is arrangedto converge the ore powder suspension liquid from the ore powder suspension liquid inlet I and the electrolyte solution from the electrolyte solution inlet II so that mixed liquor can be formed. The current-conducting plate I and the current-conducting plate II located on the main runner are connected with an electrode I and an electrode II correspondingly. A strong gradient electric field is formed between the current-conducting plate I and the current-conducting plate II. The electrode I and the electrode II are connected with a positive pole and a negative pole of a power source correspondingly. The mixed liquid is separated through the strong gradient electric field, thus ore powder suspension liquid selected fine is output through a fine selecting guide body ore powder suspension liquid outlet I and fine selecting non-guide body ore powder suspension liquid outlet III, and residual suspension liquid is output through a residual suspension liquid outlet II.

Owner:XI AN JIAOTONG UNIV

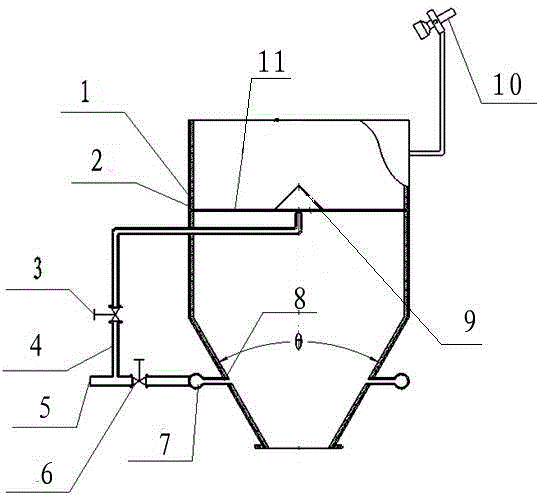

High-efficiency cyclone sorting preparer

Owner:TANGSHAN BRANCH COAL SCI ACAD +1

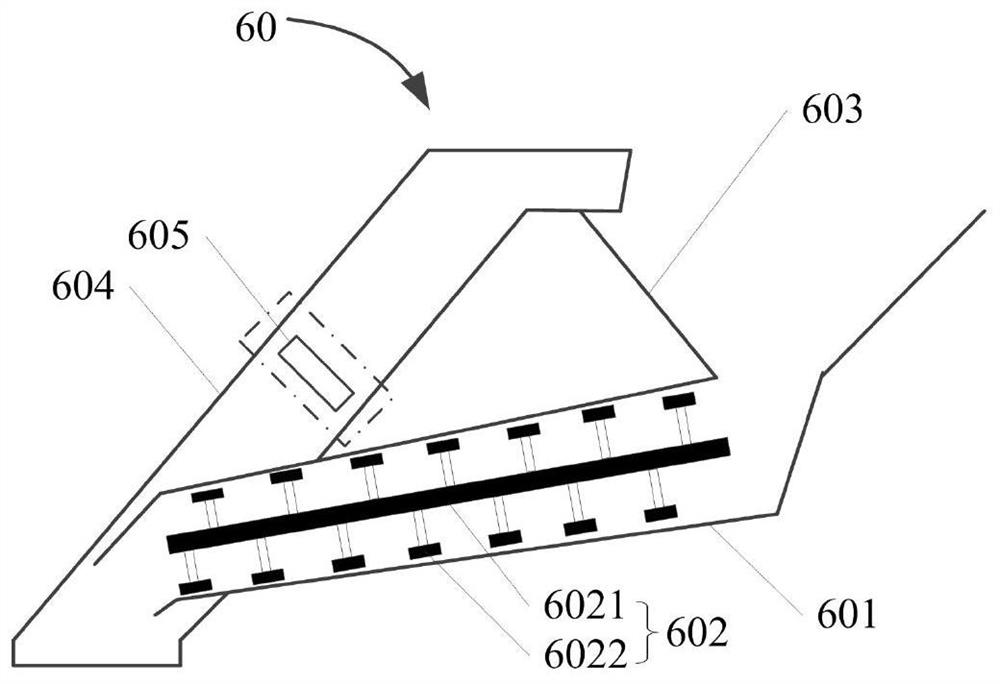

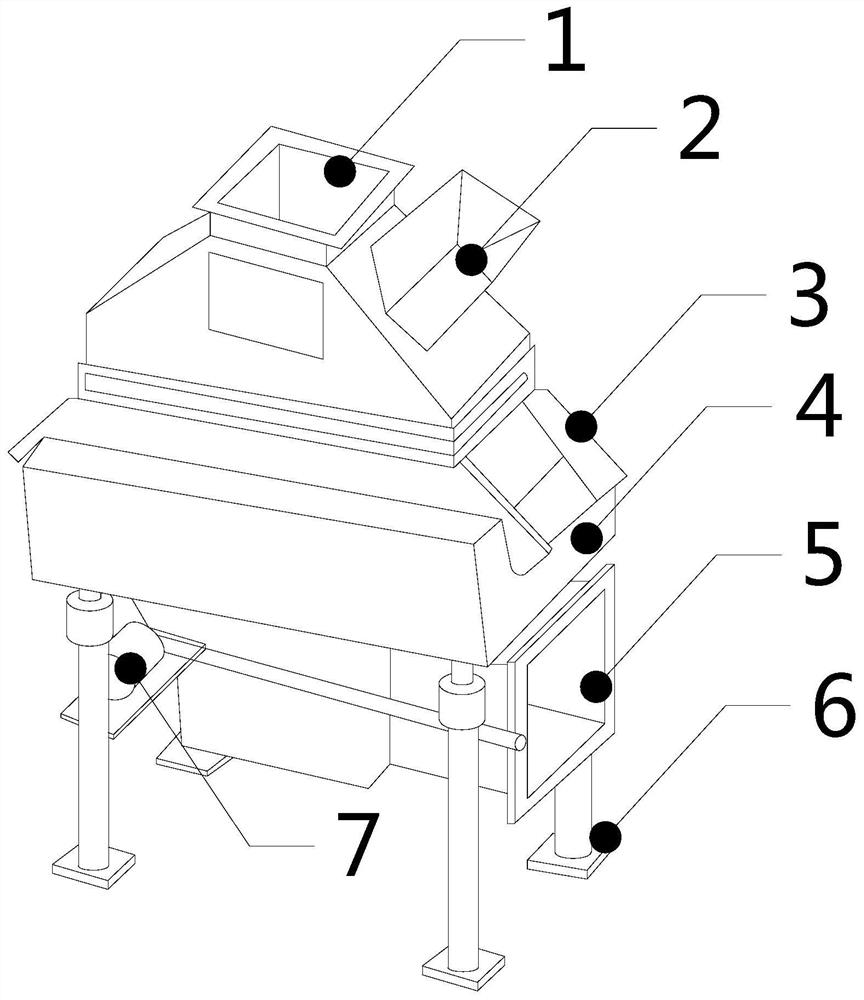

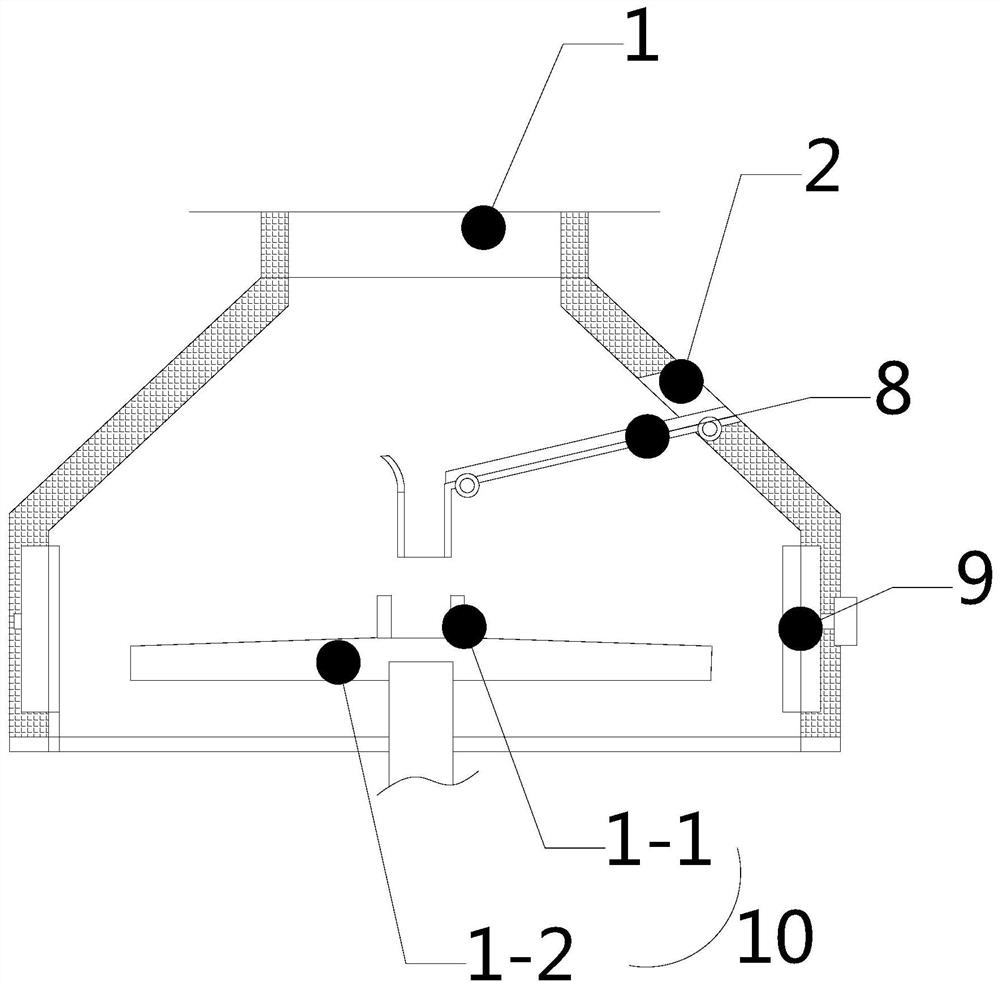

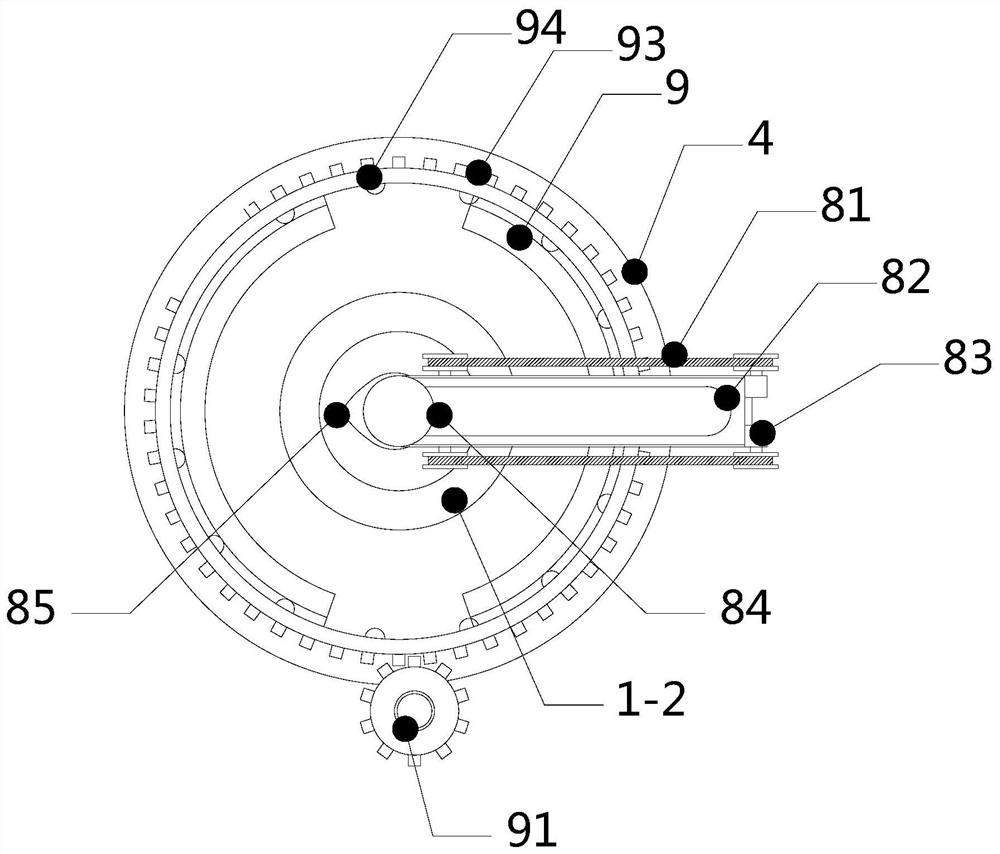

Efficient environment-friendly recycling system for valuable metals of waste circuit board

InactiveCN111744624ASpread evenlyEasy to sortGas current separationSolid waste disposalElectric machineryConstant speed

The invention discloses an efficient environment-friendly recycling system for valuable metals of a waste circuit board. The system structurally comprises a dust outlet, a feeding port, a first discharging port, a machine body, a second discharging port, supporting legs, a motor, a central feeding structure, a magnetic attraction strip and a material scattering disc, wherein the dust outlet is installed at the topmost end of the machine body, the feeding port is formed in the side surface of the machine body, and the scattering disc is arranged in the middle of the interior of the machine body. According to the system, through mutual cooperation of an inclined plate and the material scattering disc, the inclined plate rotates to gradually drive materials to slide down and fall from the discharging pipe to the center of the material scattering disc, the material scattering disc rotates to scatter the materials from the center, and the scattering is more uniform; and through the design of the discharging pipe and a material guiding ring on the same axis, the materials falling from the discharging pipe are precisely located in the material guiding ring, the materials are located in the middle of a disc, the disc is driven by the motor to rotate at a constant speed, and the materials located in the material guiding ring are uniformly spread out.

Owner:蔡彪

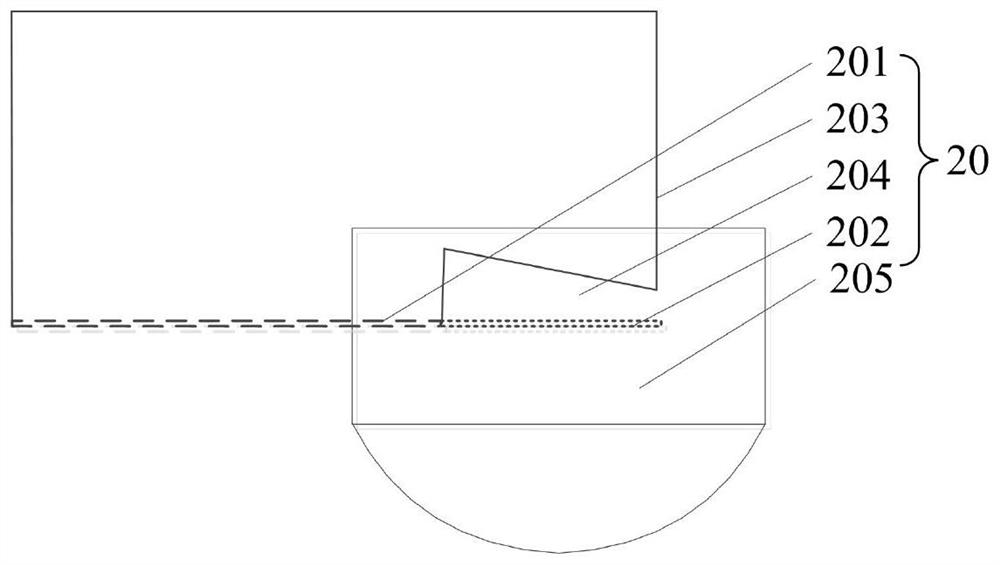

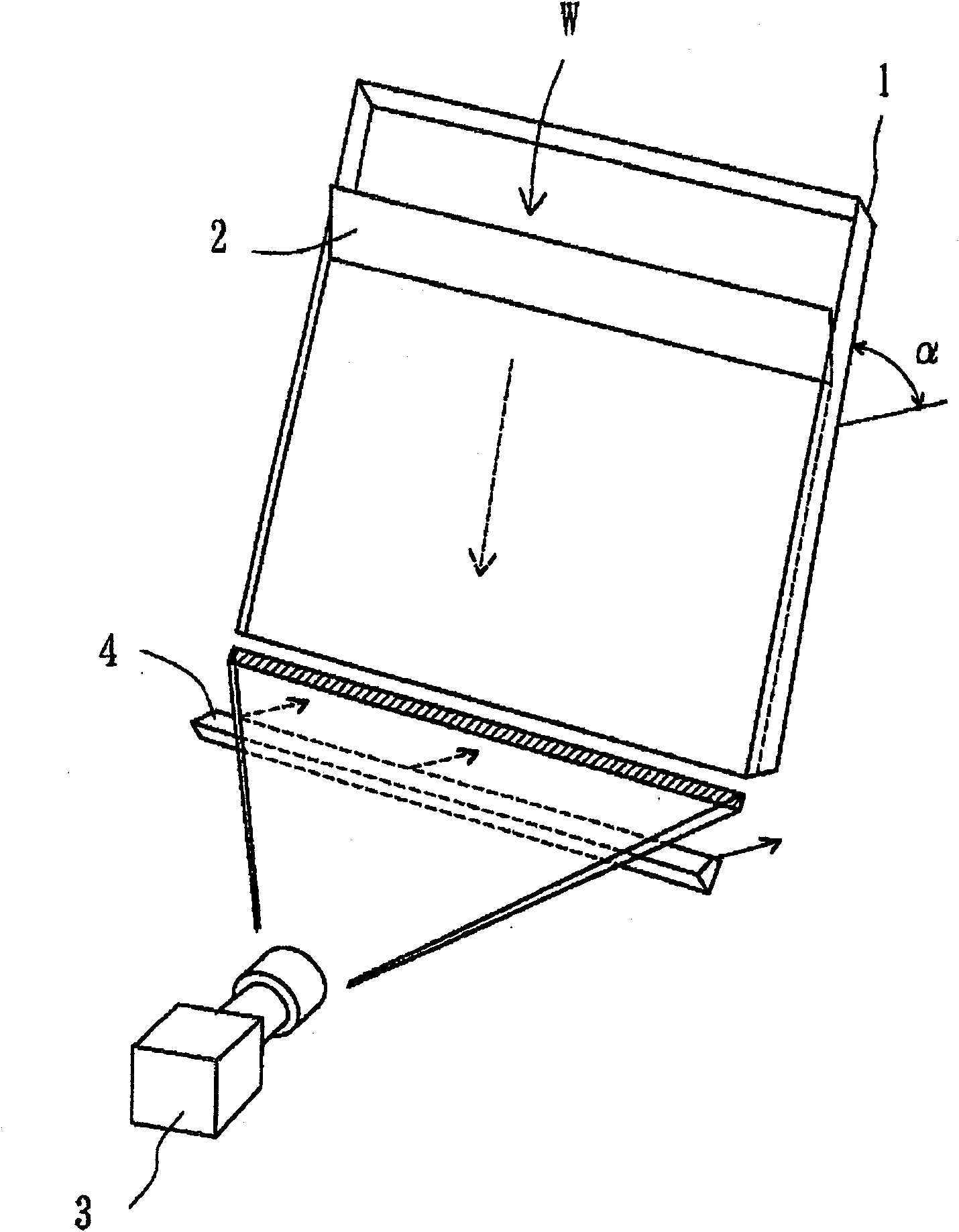

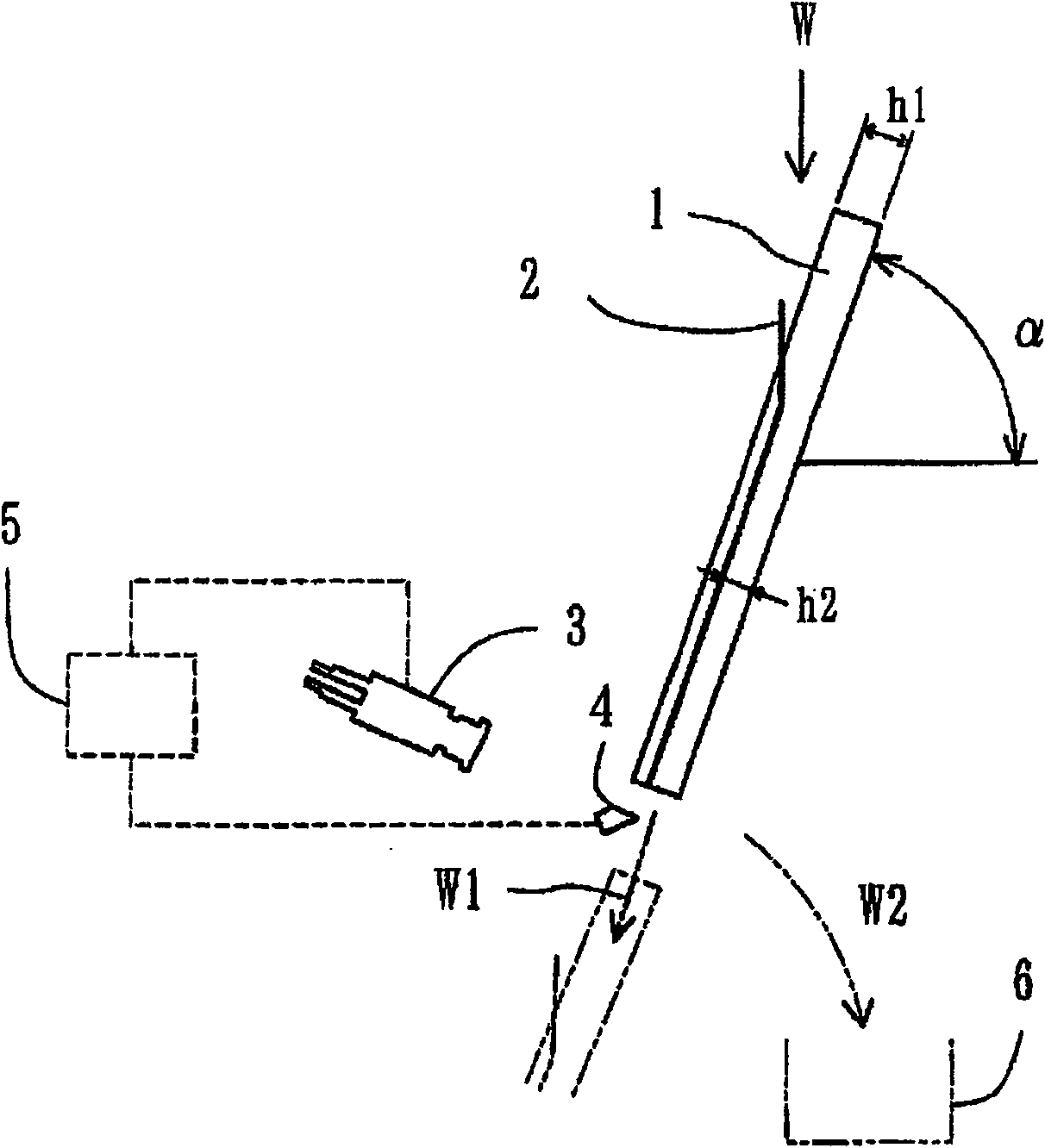

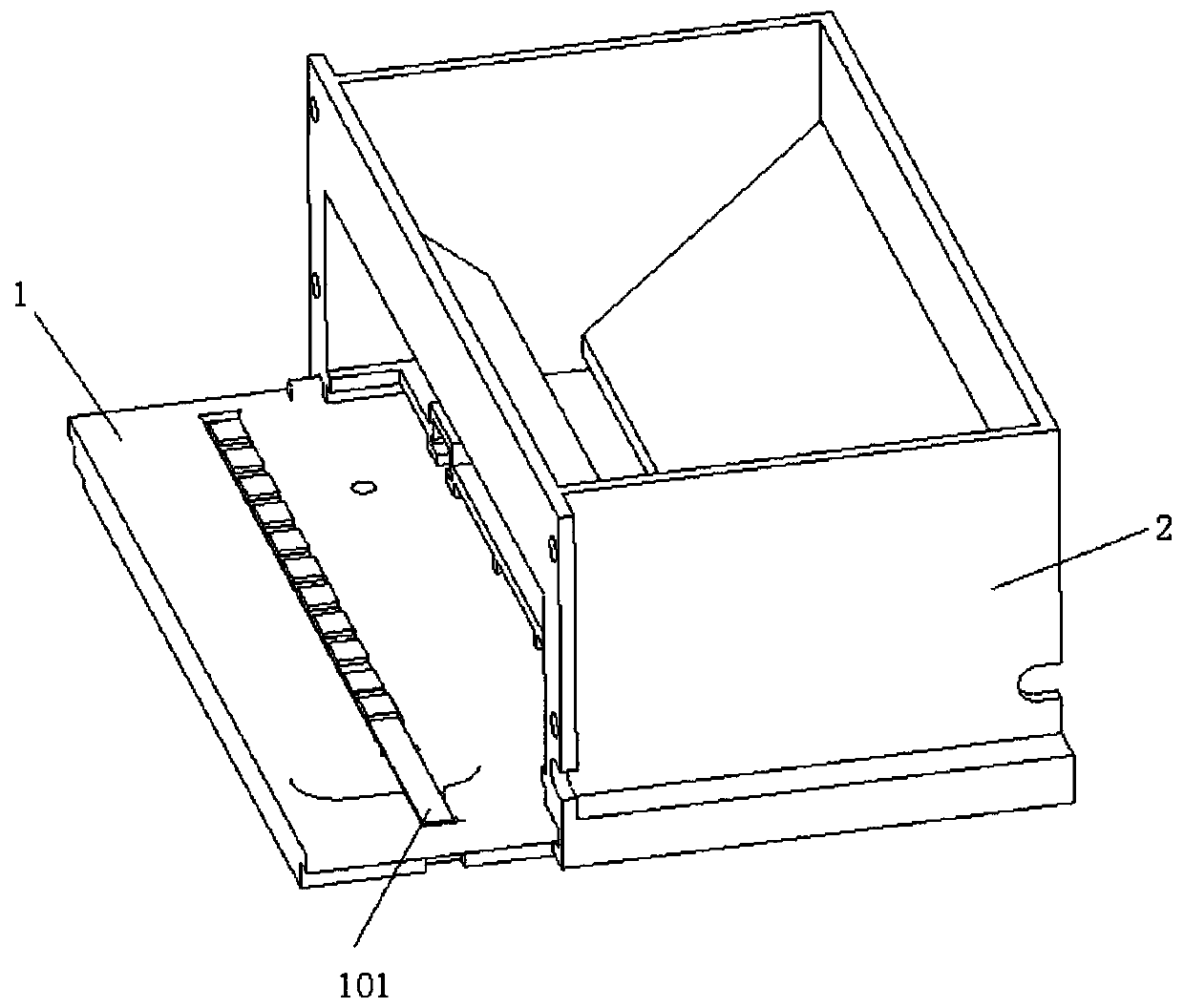

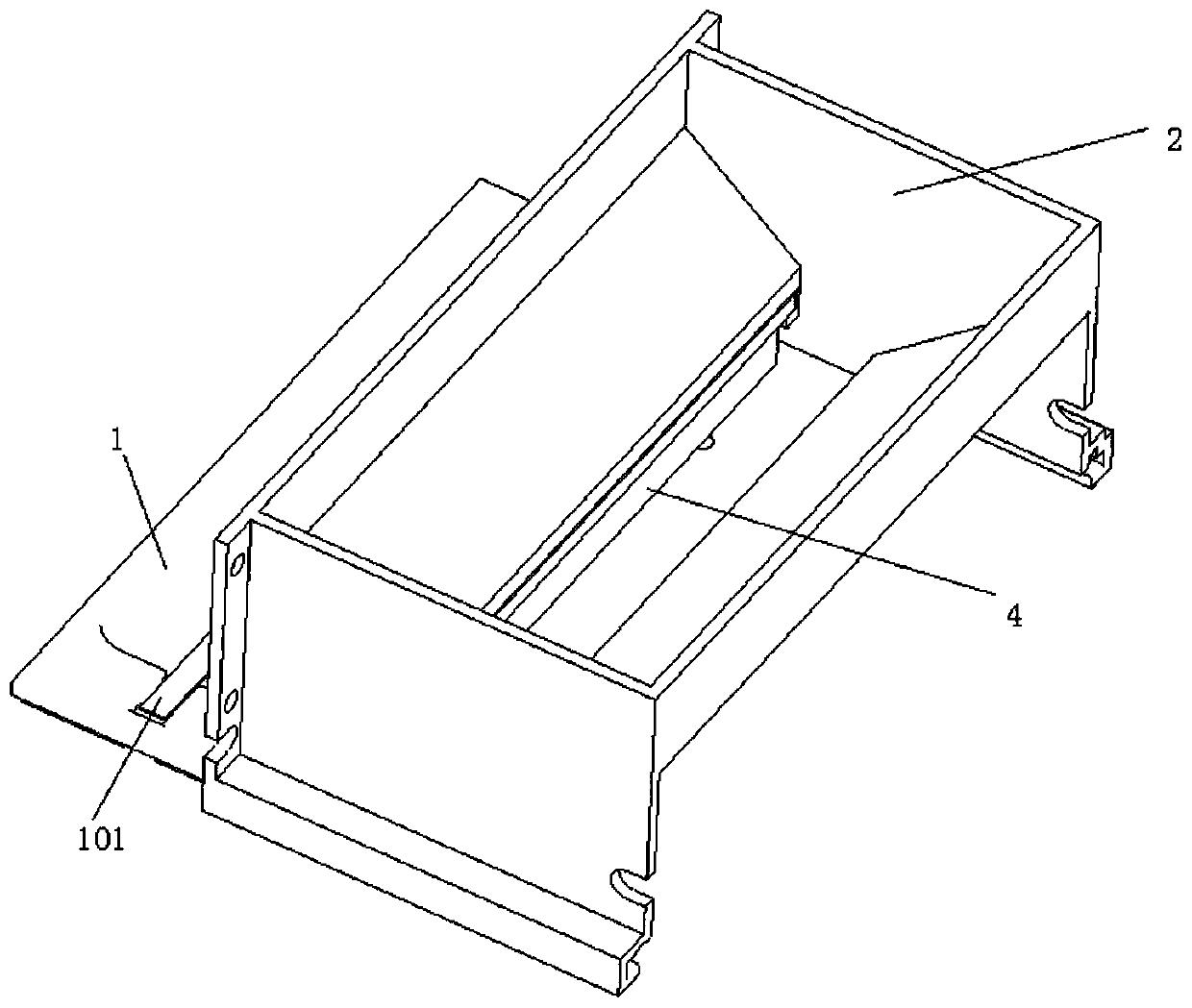

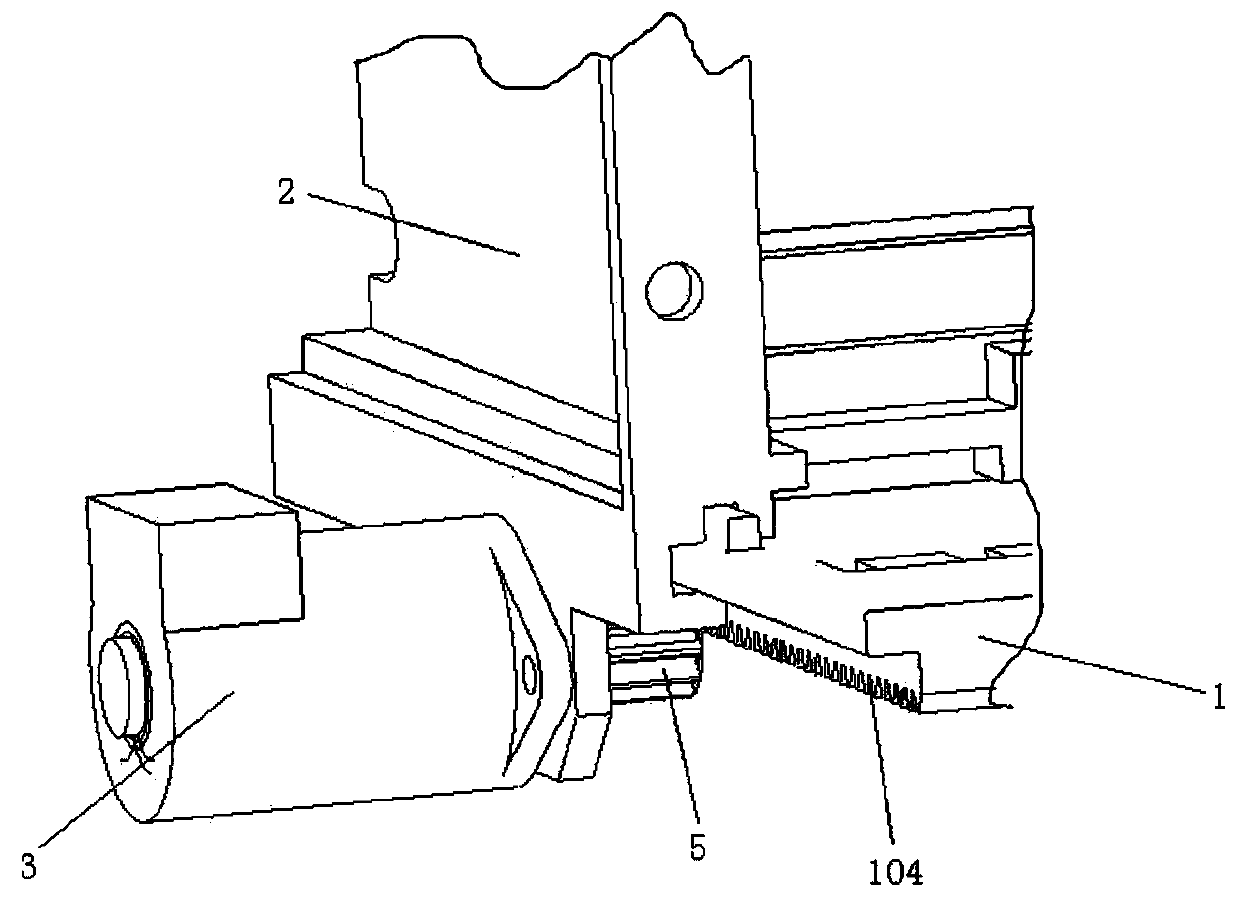

Apparatus for sorting according to colour

To provide a color sorting apparatus capable of sorting an object to be sorted which has comparatively fine and thin size and minute mass and therefore has not been able to be sorted heretofore.This color sorting apparatus for sorting an object with predetermined color from among the objects to be sorted W is equipped with a chute 1 which is installed with a tilt angle [alpha] and which makes theobject W being sliding downward bounce out in a predetermined direction, a cover 2 which is spaced a predetermined interval away from a chute surface and which covers at least a part of the chute surface, an inspection means 3 which is spaced a predetermined interval away from a chute lower end so as to be able to monitor a locus of the object W having bounced out from the chute lower end part andwhich inspects color of the object W, a determining means which is connected with the inspection means and which determines whether the object has a predetermined color based on the color of the object W obtained by the inspection means, and a separation means 4 which is spaced a predetermined interval away from the chute lower end and which blows off the object W that is determined to have the predetermined color by the determining means to allow the object W to fall along a locus different from the falling locus from the chute.

Owner:HATTORI SEISAKUSHO

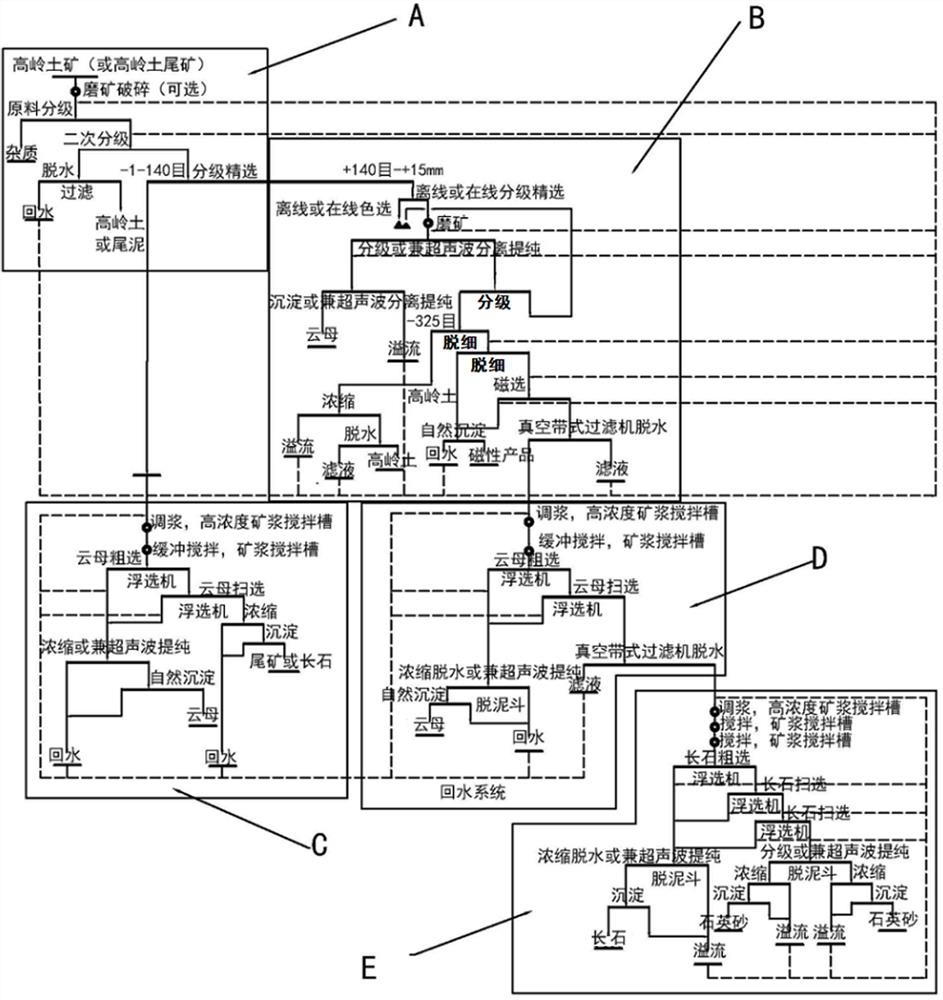

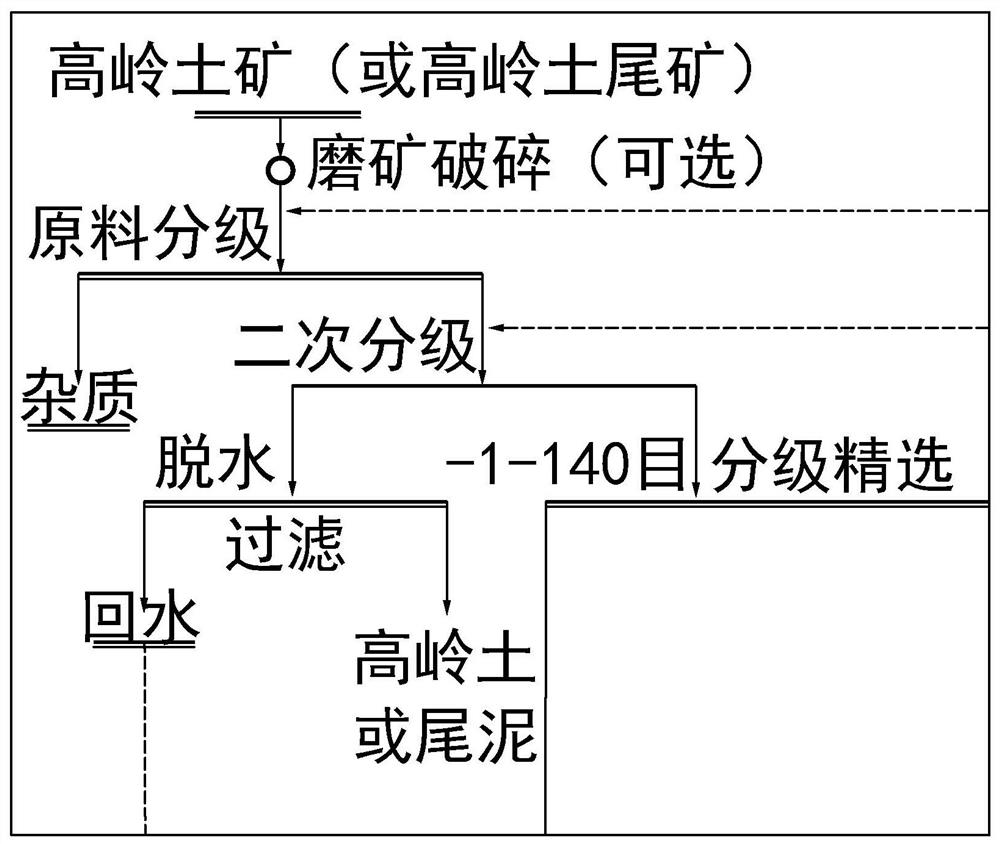

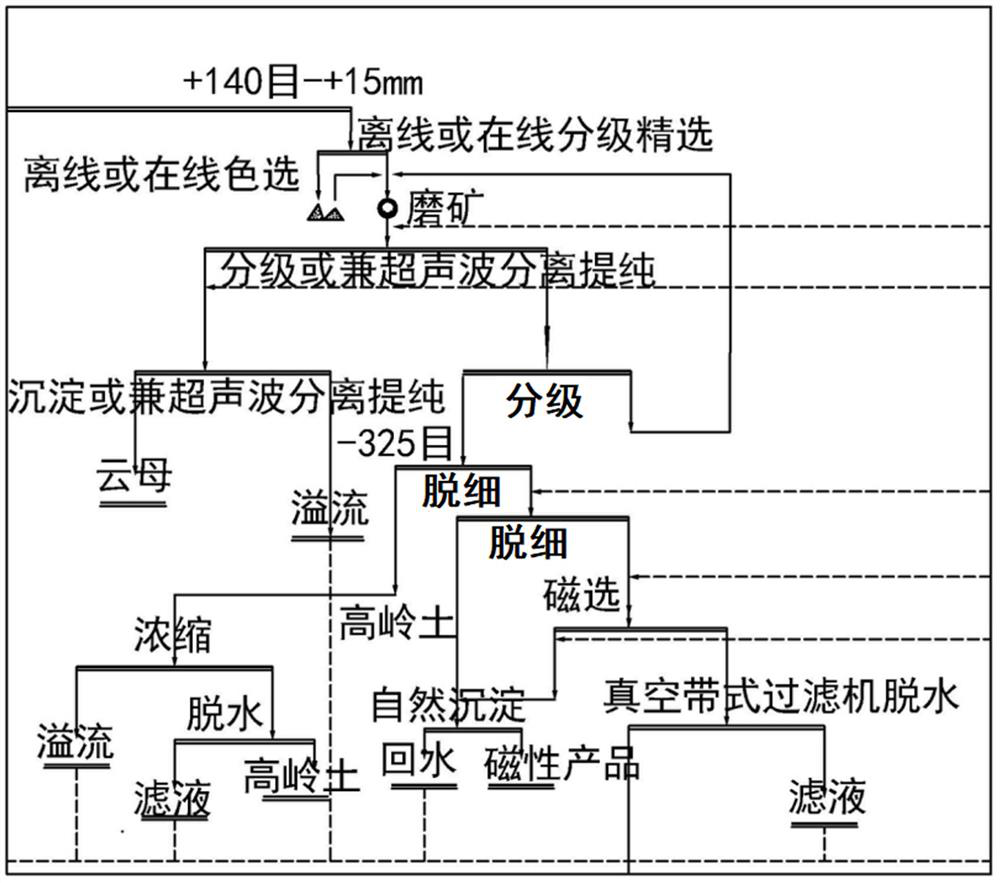

Combined mineral separation and purification method for kaolin ore or kaolin tailings

PendingCN114160300ARaise the level of value outputThe generation of solutionGlass recyclingPlastic recyclingPurification methodsKaolin clay

The invention discloses a combined mineral separation and purification method for kaolin ore or kaolin tailings. The combined mineral separation and purification method comprises one or more of a kaolin separation process, a mica separation process, a feldspar separation process, a quartz sand separation process and a magnetic product separation process. Through physical size grading, mineral separation and sorting of optical color sorting, mineral separation and sorting of flotation, mineral separation and grading and sorting of ultrasonic acoustics and the like in the mineral separation technological process, the purposes that grading is accurate, separation is sufficient, sorting is easy, the quality and purity of produced products are high, the application field is wide, and the product quality of the application field is improved are achieved. By adopting the method, the blank of extracting a high-purity material from kaolin ore (or kaolin tailings) in China can be filled, and a high-purity raw material quality foundation is laid for further deep processing of a silicon material of a product. The value output level of domestic kaolin ore (or kaolin tailings) is greatly improved, a large amount of solid waste generated by mining and mineral separation of the kaolin ore is solved, and the method is green, environmentally friendly, cyclic and energy-saving.

Owner:深圳市硕晶非金属材料技术有限公司

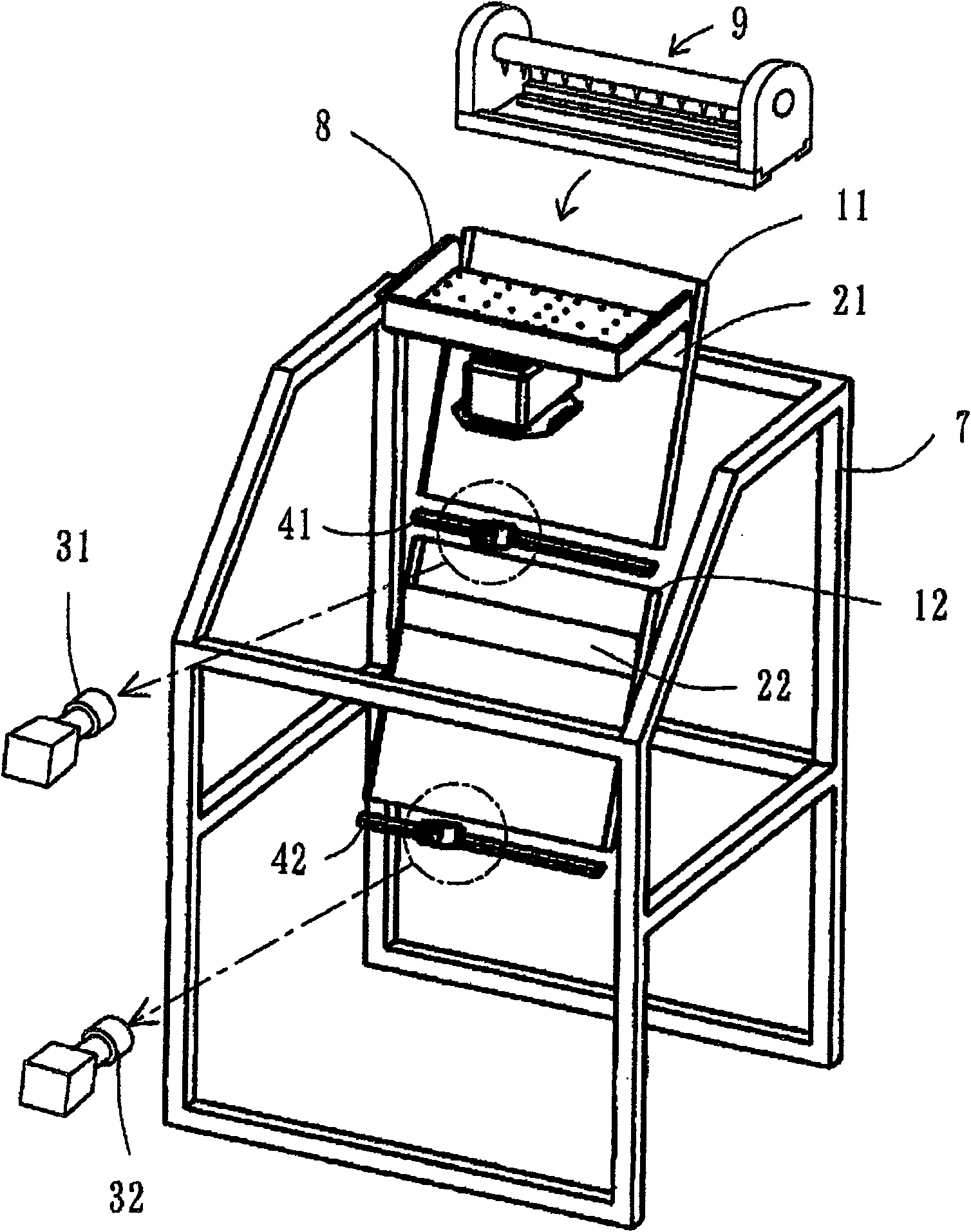

Test strip selecting mechanism

PendingCN110550334ASorting is simpleSimple structureFlat article dispensingReciprocating motionPulp and paper industry

The invention discloses a test strip selecting mechanism. The test strip selecting mechanism comprises a paper discharge bracket and a test paper containing device used for containing urine test strips. A test paper trough is formed in the surface of the paper discharge bracket. The test paper containing device comprises an inlet end and an outlet end, wherein the inlet end is arranged at the topand used for allowing the strips to enter, and the outlet end is arranged at the bottom end and is used for allowing the strips to get out. The paper discharge bracket is arranged at the bottom of thetest paper containing device and can relatively move to drive the test paper trough to do reciprocating motion at the bottom of the test paper containing device. The paper discharge bracket can closethe outlet end of the test paper containing device in the motion process. According to the test strip selecting mechanism, the structure is relatively simple, test paper sorting is easy, and the strips are not prone to being gammed; and the requirements of instruments large in batch, small in size and low in thickness can be met.

Owner:CHENGDU EMPEROR MEDICAL TECH CO LTD

A method for calculating magmatic oxygen fugacity using crystalline uranium deposits in granite

ActiveCN107561241BSorting is simpleImprove the oxidation-reduction reactionEarth material testingUraninitePrill

The invention belongs to the geotechnical field and particularly discloses a method for calculating magmatic oxygen fugacity by utilizing uraninite in granite. The method comprises the following steps: step 1, acquiring a granite sample containing a uraninite auxiliary mineral; step 2, performing pretreatment and crystalline uranium ore single mineral separation on the granite sample acquired in the step 1 to obtain granite sample uraninite particles; step 3, performing scanning electron microscopy on the granite sample uraninite particles obtained in the step 2; step 4, performing uranium valence state photoelectron spectroscopy test on the granite sample uraninite particles preferably selected from the step 3 to obtain a U6+ / U4+ ratio in the uraninite; step 5, substituting the U6+ / U4+ ratio obtained by uraninite test analysis in the step 4 into an oxygen fugacity estimation formula to obtain a magmatic oxygen fugacity estimation value logfO2. The method provided by the invention is strong in operability, and can be used for testing directly with little test error.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

A kind of oil-water separation method

ActiveCN103830934BSorting is simpleOvercome the defect of running oilLiquid separationClosed loopOil water

The invention discloses an oil-water separation method. An oil-water separating part is used for separating an oil-water mixture into oil and intermediate water, the intermediate water enters a water processing part and is further separated into heavy impurities and water, a coarse separation hydrocyclone of the oil-water separating part is used for separating the oil-water mixture into two branches of light phase and heavy phase, and separated heavy products of the light phase are introduced into the branch of the heavy phase for enrichment, namely the separation efficiency is improved for the light phase, and the separation precision is improved for the heavy phase; for the light phase, although the separation precision is sacrificed, a part of oil runs out from the bottom flow of a first hydrocyclone, only the first hydrocyclone is used in the whole separation process of the light phase, and other hydrocyclones are not used for recleaning and return separation, and thus the separation of the light phase is extremely simple and easy to control; however, for the heavy phase, the adjustability of closed-loop return separation consisting of a second hydrocyclone and a third hydrocyclone can overcome the oil leakage defect of the light phase, and all separation errors are solved in closed-loop return separation.

Owner:SUZHOU YOUDAN INTERNET TECH CO LTD

Method for sorting 2n pollen from pollen

ActiveCN110542641BSorting is simpleEfficient sortingIndividual particle analysisFlow cytometryHorticulture

The invention relates to a method for sorting 2n pollen from pollen. The method comprises the steps of 1, taking a pollen sample to prepare pollen suspension; and 2, sampling the pollen suspension toa flow cytometry for sorting. According to the method, the flow cytometry is applied into the 2n pollen, so that the problem that the 2n pollen sorting is low in efficiency and complicated in operation is ingeniously solved. Furthermore, in cooperation with the setting of the sorting environment temperature, humidity and parameter value of the flow cytometry, the sorting error of the flow cytometry can be reduced.

Owner:SOUTH CHINA AGRI UNIV

Environmentally friendly and energy-saving garbage disposal methods

The invention relates to the technical field of resource recycling, in particular to an environment-friendly and energy-saving garbage disposal method, which comprises the following steps: after preliminary high-temperature shrinkage treatment of bagged garbage, it is transported to a drain tank for extrusion, cutting, bag breaking and screen vibration draining treatment, and then The relatively heavy garbage and relatively light garbage are screened out after hammering and crushing by the crushing device I; the relatively heavy garbage is hammered and crushed by the crushing device II, and then the ferromagnetic materials and non-ferromagnetic materials are screened out, and then the ferromagnetic materials are recovered. Non-ferromagnetic materials are screened to obtain ductile waste, brittle waste and rigid waste; the relatively light waste and ductile waste are combined to separate dry ductile waste and wet ductile waste; the dry ductile waste is incinerated; the wet ductile waste is incinerated; Tough waste is used to prepare organic fermented fertilizer; rigid waste and brittle waste are used for burning into building bricks. The method of the invention realizes the harmless treatment of garbage, does not cause pollution to the environment in the whole process, and realizes a sustainable circulation system.

Owner:北京净与境生态科技有限公司

Efficient garbage sterilization, disinfection and classification treatment method

The invention relates to the technical field of resource recycling, in particular to an efficient garbage sterilization, disinfection and classification treatment method. The efficient garbage sterilization, disinfection and classification treatment method comprises the following steps that bagged garbage is conveyed to a vibrating screen arranged in a water draining tank for vibrating and water draining treatment, and meanwhile, high-temperature bag breaking and stirring equipment is also used for stirring treatment; hammering and crushing treatment is carried out on the garbage subjected tovibrating and water draining treatment, and then relatively heavy garbage and relatively light garbage are screened out; ferromagnetic substances are screened out from the relatively heavy garbage tobe recovered, non-ferromagnetic substances are screened out from the relatively heavy garbage, and then screening treatment is carried out on the non-ferromagnetic substances to obtain tough garbage,brittle garbage and rigid garbage; the relatively light garbage and the tough garbage are combined, and then dry tough garbage and wet tough garbage are separated out; incinerating treatment is carried out on the dry tough garbage; the wet tough garbage is used for preparing an organic fermented fertilizer; and the rigid garbage and the brittle garbage are used for being fired into building bricks. According to the method, harmless treatment of the garbage is achieved, no pollution is caused to the environment in the whole process, and a sustainable circulation system is achieved.

Owner:连云港徐圩环卫服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com