High-efficiency cyclone sorting preparer

A technology of preparer and cyclone, which is applied in the field of sorting equipment, can solve the problems of too long mixing process of raw coal and suspension, shortened sorting time of cyclone, and decreased sorting accuracy, so as to eliminate the phenomenon of feeding blockage , Eliminate clean coal inclusions, increase the effect of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and specific embodiments.

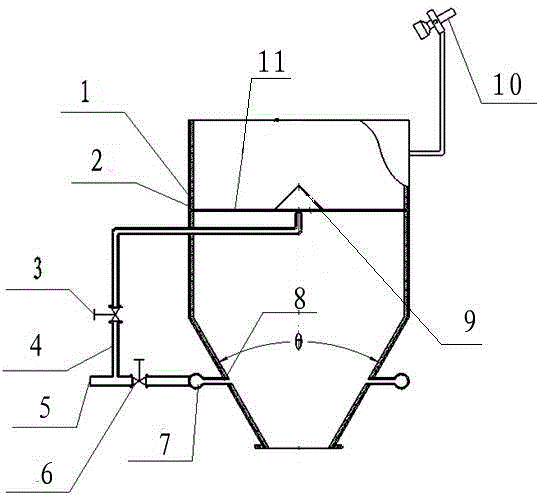

[0016] This embodiment is a high-efficiency cyclone sorting preparation device. This high-efficiency cyclone sorting preparation device consists of a feeding chute cylinder 2, an upward flow jet pipe 4, a medium inlet main pipe 5, a horizontal flow annular pipe 7, etc. composition. See the specific structure figure 1 , The feeding chute barrel 2 has a tapered structure, and the taper angle θ of the feeding chute barrel 2 is 60°-120°, which is 110° in this embodiment. The upper part of the feeding chute barrel 2 is equipped with a bracket 11, the upflow jet pipe 4 and the coal flow diffuser 9 are respectively installed on the bracket 11, wherein the upflow jet pipe 4 extends out of the feeding chute barrel 2 and is aligned with the horizontal The flow loop pipes 7 are communicated and connected. The horizontal flow annular pipe 7 and the upward flow jet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com