Polyamide reverse osmosis membrane and preparation method thereof

A technology of reverse osmosis membrane and polyamide, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of low water flux, limited water flux improvement, and affecting the polyamide layer, etc. The effect of streamlining, increasing water flux, and improving performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

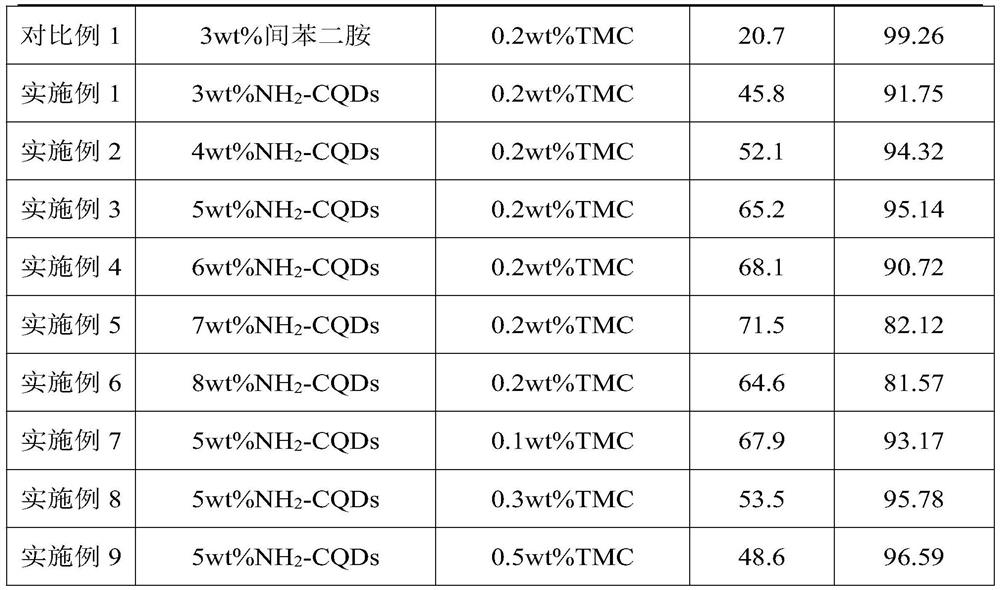

Embodiment 1

[0031] A polyamide reverse osmosis membrane, comprising a porous support membrane and a polyamide layer containing carbon quantum dots grown on the surface of the porous support membrane, the polyamide layer containing carbon quantum dots includes the following raw material components in mass percentage: amination Carbon quantum dots (abbreviated as NH 2 -CQDs), oil phase reactive monomers, oil phase solvents, acid acceptors, pH regulators and surfactants.

[0032] The oil phase reaction monomer is trimesoyl chloride (abbreviated as TMC); the oil phase solvent is n-hexane.

[0033] The pH regulator is camphorsulfonic acid and triethylamine; the surfactant is sodium dodecylsulfonate.

[0034] The size of the amidated carbon quantum dot is 1-20nm.

[0035] The thickness of the polyamide layer containing carbon quantum dots is 100-300nm.

[0036] The porous support membrane is a polysulfone porous support membrane.

[0037] A preparation method of the polyamide reverse osmosi...

Embodiment 2

[0047] The difference from Example 1 is that the mass ratio of pure water: amidated carbon quantum dots: camphorsulfonic acid: triethylamine: sodium dodecylsulfonate in step 2 is 92.59:4:2.3:1.1:0.01 , other unchanged.

Embodiment 3

[0049] The difference from Example 1 is that in the step 2, the mass ratio of pure water: amidated carbon quantum dots: camphorsulfonic acid: triethylamine: sodium dodecylsulfonate is 91.59:5:2.3:1.1:0.01 , other unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com