Recovery system of accumulator plate

A recycling system and battery technology, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of incomplete separation, harm to human health, easy to pollute the environment, etc., and achieve the refinement and crushing effect of recycled products. , the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the following, the present invention will be further described with embodiments in conjunction with the drawings.

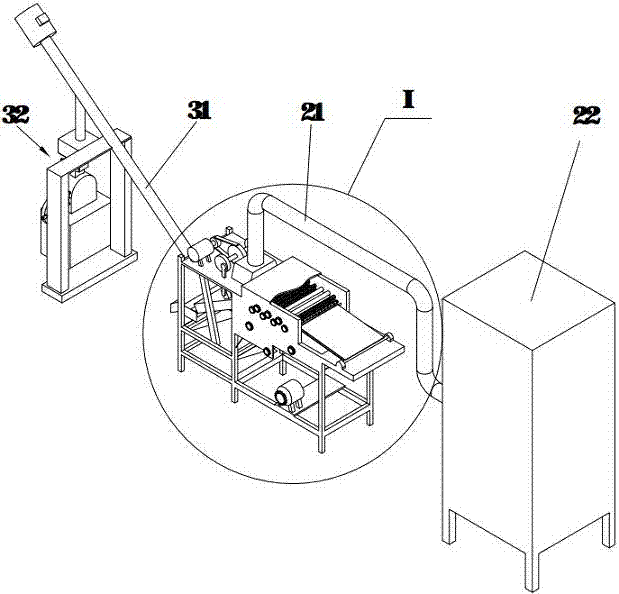

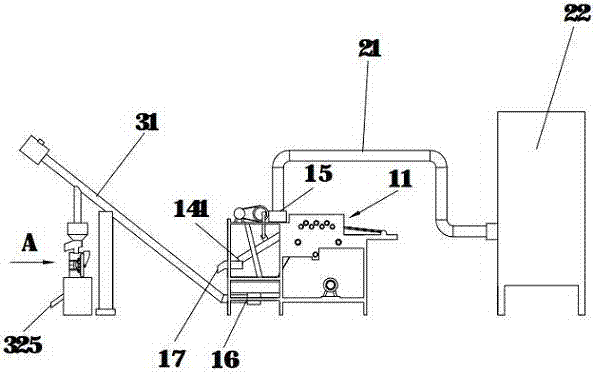

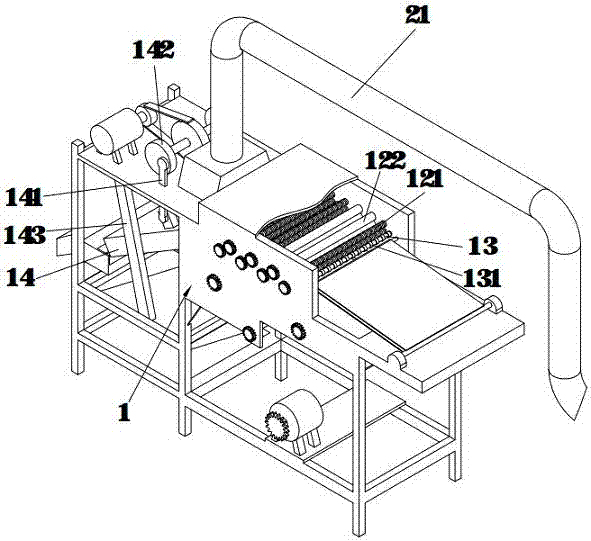

[0026] Such as Figure 1 to 5 As shown, a battery electrode plate recovery system includes a plate crushing part, a dust recovery part, and a particle recovery part. The electrode plate crushing part includes a casing 1, and the casing 1 is provided with a feed port 11, and the feed port A conveyor belt can be set before 11 to facilitate feeding. A roll and a transition roll 13 are arranged on the casing 1 behind the feed port 11, and the rolls and transition rolls 13 are spaced apart. Figure 5 The distribution relationship of the wave-shaped roll 121, the straight-shaped roll 122 and the transition roll 13 is clearly shown. The rolls include wave-shaped rolls 121 and straight-shaped rolls 122. The order of arrangement of the rolls is: one set of wave-shaped rolls 121, two sets of linear rolls 122, and three sets of wave-shaped rolls 121. Those skilled i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com