Environment cleaning, heat extraction and dry treatment system and process for high-temperature metallurgical slag

A technology for dry processing and metallurgical slag, which is applied in heat extraction, high temperature metallurgical slag cleaning, dry processing system and process fields, can solve problems that cannot meet environmental protection, safety, energy saving, etc., and achieve the effect of avoiding explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

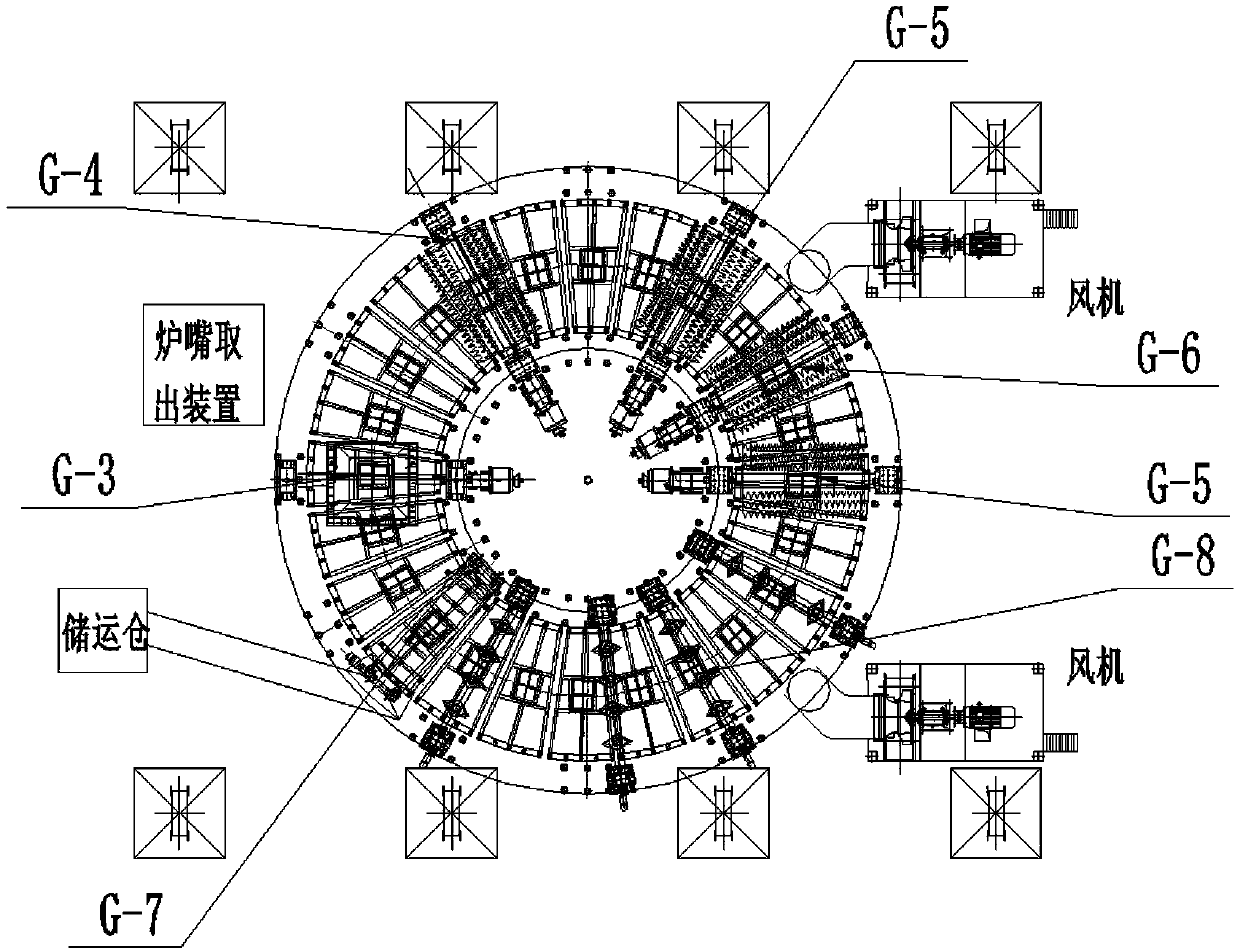

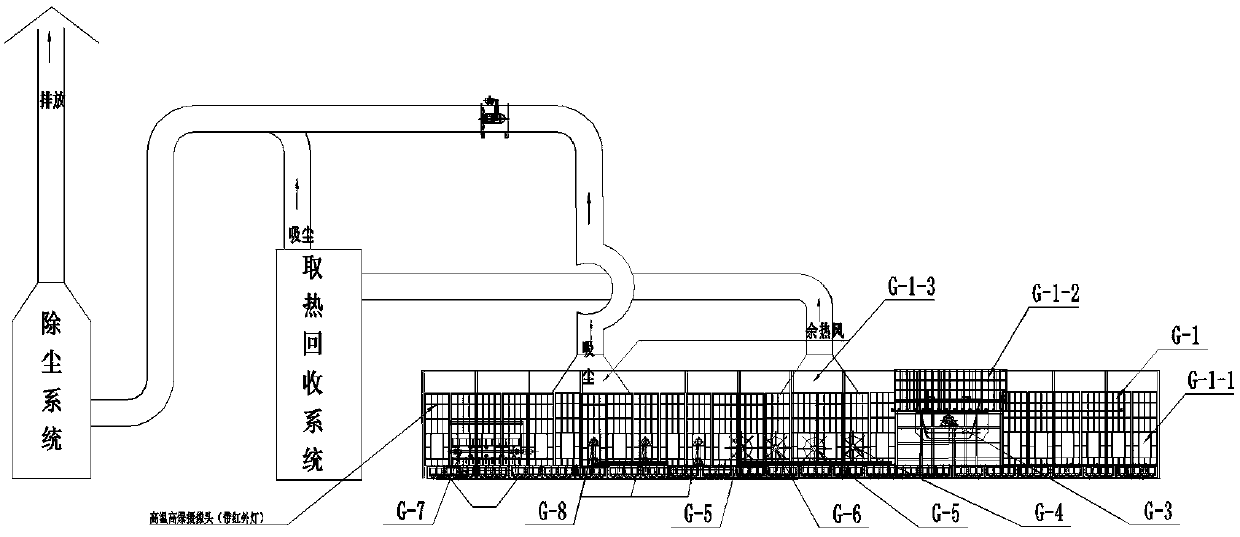

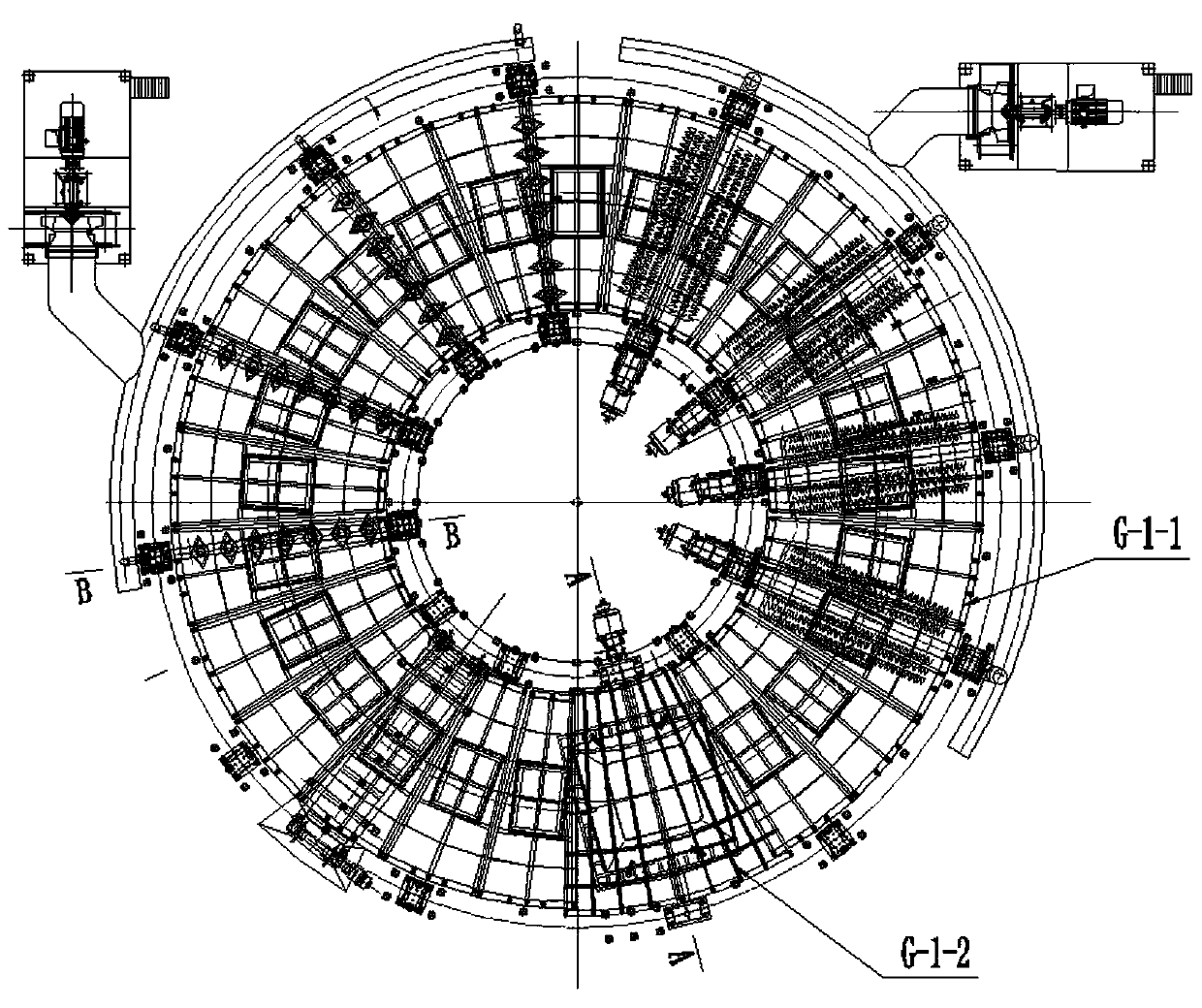

[0055] see Figure 1 to Figure 19 , a high-temperature metallurgical slag clean environment, heat extraction, dry treatment system, including sealed cabin G-1, circular rotating platform Zu G-2, slag tank tilting machine G-3, steel slag leveling machine G-4, rotating Chopper G-5, steel slag blower G-6, suspended slag scraper G-7, wind plow G-8; sealed cabin G-1 and ring-shaped rotating platform ZU G-2 pass rigid seal and flexible Sealing constitutes a closed ring-shaped tunnel-like confined space, in which the slag tank tipping machine G-3, steel slag leveling machine G-4, rotary knife cutter G-5, steel slag blowing machine G-6 are arranged in sequence, and The bearing seat and bracket are connected and fixed with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com