Method for cleaning phosphoric acid delivery pipelines

A technology for conveying pipelines and phosphoric acid, applied in the field of cleaning phosphoric acid conveying pipelines, can solve the problems of prolonged cleaning time, hidden dangers, poor operability, etc., and achieve the effects of improving cleaning efficiency, reducing labor intensity, and reducing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

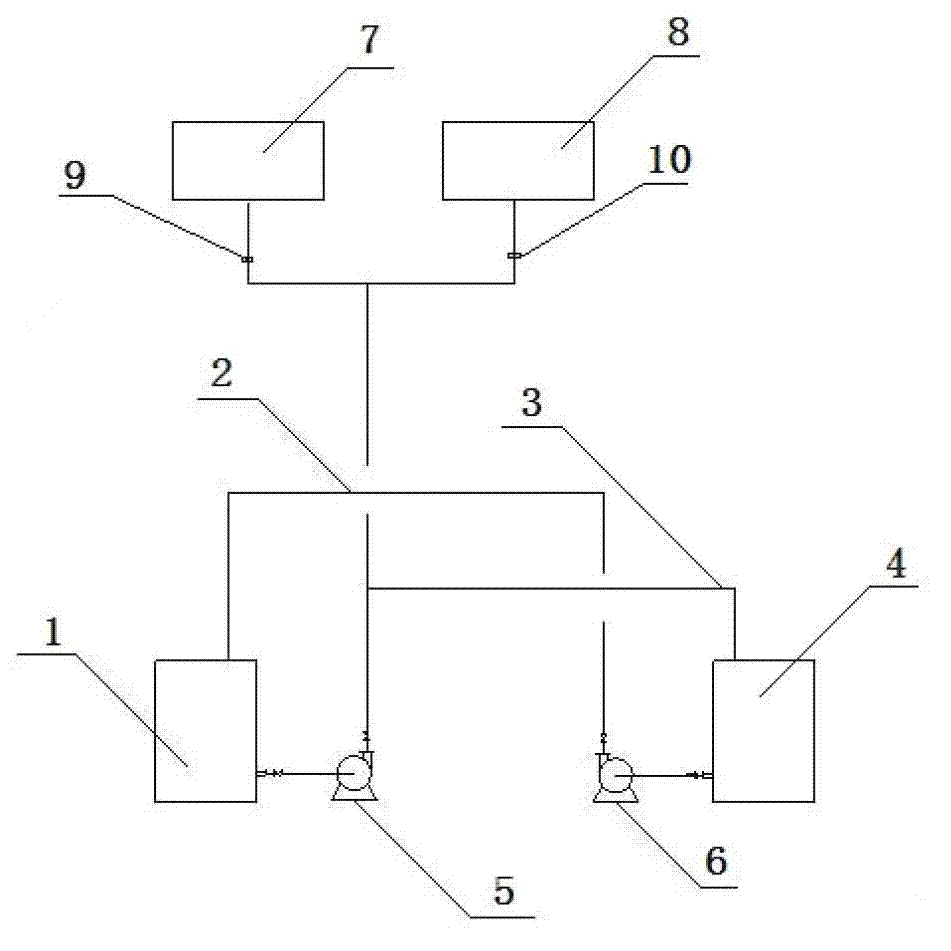

[0036] As shown in Figure 1, connect the washing liquid configuration tank 1 to be cleaned, the acid supply pipe 2, the acid supply pipe backup pipe 3, the washing liquid receiving tank 4, the liquid supply pump 5 and the liquid return pump 6 to form a circular washing system . In the cleaning solution configuration tank 1, the alkaline cleaning solution is prepared into a sodium hydroxide solution with a mass concentration of 4%, and steam is passed through to keep the temperature of the cleaning solution at 50°C. Start the liquid supply pump 6 to send the alkaline cleaning solution to the cleaning solution receiving tank 7. When the cleaning solution receiving tank 7 reaches the liquid level that can start the pump, start the liquid return pump 6, and return the cleaning solution to the cleaning solution configuration tank 1, so that The cleaning liquid circulates among the cleaning liquid configuration tank 1, the acid supply pipe 2, the cleaning liquid receiving tank 4, th...

Embodiment 2

[0039] Connect the washing liquid configuration tank 1 to be cleaned, the acid supply pipe 2, the acid supply pipe backup pipe 3, the washing liquid receiving tank 4, the liquid supply pump 5 and the liquid return pump 6 to form a circular washing system. In the cleaning solution configuration tank 1, the alkaline cleaning solution is prepared into a sodium hydroxide solution with a mass concentration of 7%, and steam is passed through to keep the temperature of the cleaning solution at 55°C. Start the liquid supply pump 6 to send the alkaline cleaning solution to the cleaning solution receiving tank 7. When the cleaning solution receiving tank 7 reaches the liquid level that can start the pump, start the liquid return pump 6, and return the cleaning solution to the cleaning solution configuration tank 1, so that The cleaning liquid circulates among the cleaning liquid configuration tank 1, the acid supply pipe 2, the cleaning liquid receiving tank 4, the acid supply pipe backu...

Embodiment 3

[0042] Connect the washing liquid configuration tank 1 to be cleaned, the acid supply pipe 2, the acid supply pipe backup pipe 3, the washing liquid receiving tank 4, the liquid supply pump 5 and the liquid return pump 6 to form a circular washing system. In the cleaning solution configuration tank 1, a sulfuric acid solution with a mass concentration of 8% was prepared, and steam was introduced to keep the temperature of the cleaning solution at 60°C. Start the liquid supply pump 6 to send the acid washing liquid to the washing liquid receiving tank 7. When the washing liquid receiving tank 7 reaches the liquid level that can start the pump, start the liquid return pump 6, and return the washing liquid to the washing liquid configuration tank 1, so that The cleaning liquid circulates among the cleaning liquid configuration tank 1, the acid supply pipe 2, the cleaning liquid receiving tank 4, the acid supply pipe backup pipe 3, and the cleaning liquid configuration tank 1. Dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com