Multifunctional width adjustable conveying device

A conveying device and multi-functional technology, applied in the field of cleaning equipment, can solve the problems of unfavorable continuous production, low production efficiency, increased production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

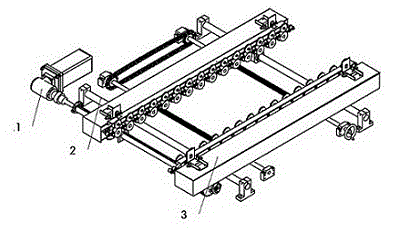

[0030] Such as figure 1 As shown, the multifunctional width-adjustable conveying device is composed of a power input device 1 , a support width adjusting device 2 , and a ball screw width adjusting device 3 .

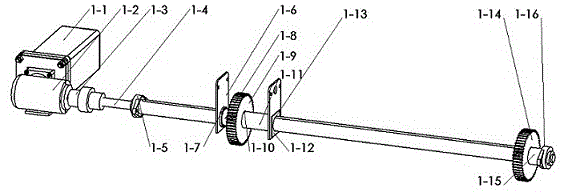

[0031] Such as figure 2As shown, the power input device 1 is composed of a motor 1-1, a motor reducer 1-2, a shaft coupling 1-3, a transmission shaft 1-4, a rhombus bearing seat 1-5, a deep groove ball bearing seat 1-6, a deep Groove ball bearing 1-7, sleeve 1-8, gear 1-9, key 1-10, sleeve 1-11, deep groove ball bearing seat 1-12, deep groove ball bearing 1-13, gear 1-14 , Sleeve 1-15, rhombus bearing seat 1-16 is formed. Rhombus bearing housing 1-5 and rhombus bearing housing 1-16 are installed on the corresponding cleaning equipment to fix the power input device, the power of motor 1-1 passes through shaft coupling 1-3, transmission shaft 1-4, key 1-10, Gears 1-9 and gears 1-14 are transmitted to the conveying guide rail pressing device, and the reciprocating moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com