Integrated multidirectional distribution valve for liquid delivery

A technology for distributing valves and liquids, applied in the field of multi-directional conversion devices for fluid conveying pipelines, can solve the problems that the residual medium in the pipeline cannot be cleaned online, the conveying medium and equipment can be polluted, and the manufacturing process of the ball valve is complicated, etc. Guarantee stability and reliability, and improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

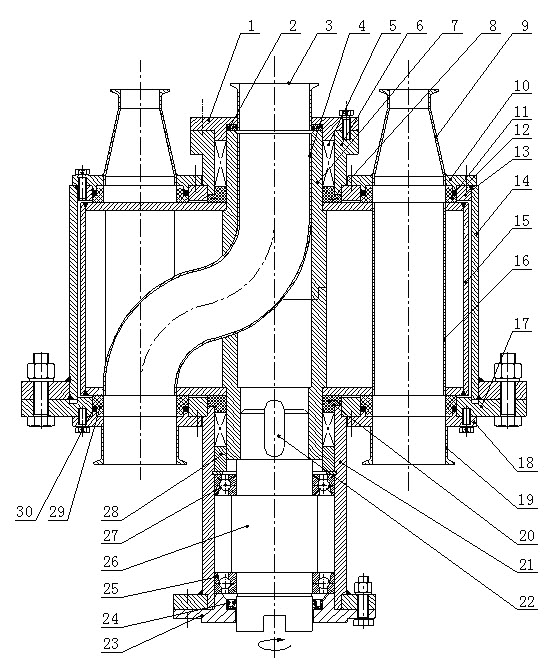

[0022] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

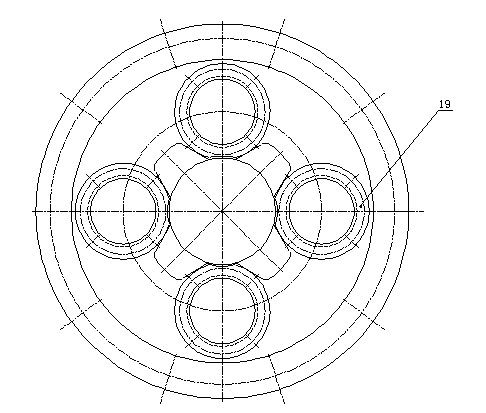

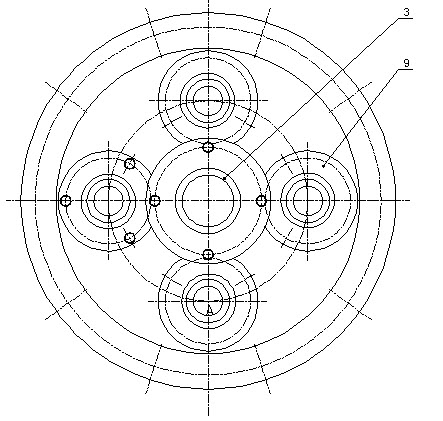

[0023] An integrated liquid delivery multi-directional distributing valve includes a valve body and a valve core. The innovation of this multi-directional distributing valve is: the valve body is composed of a housing 14 and a main end cover fixedly mounted on the lower part, the upper end surface 13 of the upper part of the housing is integrally made with the housing or welded on the upper end of the housing, the main end Cover 17 is fixed on the lower end of the cylindrical housing by bolts. A main liquid inlet 3 is fixed in the middle of the upper end surface, and the main liquid inlet is fixed in the shaft sleeve 6 fixed on the upper end surface of the valve body through the central flange 1 . 3-8 liquid outlets 19 are uniformly distributed in a ring on the main end cover, and 4 liquid outlets are provided in this embodiment....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com