Online carbon deposit cleaning system for air inlet valve and combustion chamber of engine and control method

一种清洗系统、进气阀的技术,应用在发动机元件、机器/发动机、机械设备等方向,能够解决不能如愿地提高动力、影响空燃比、影响进气效果等问题,达到控制方法简单实用、提高环保性能、实现在线清洗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

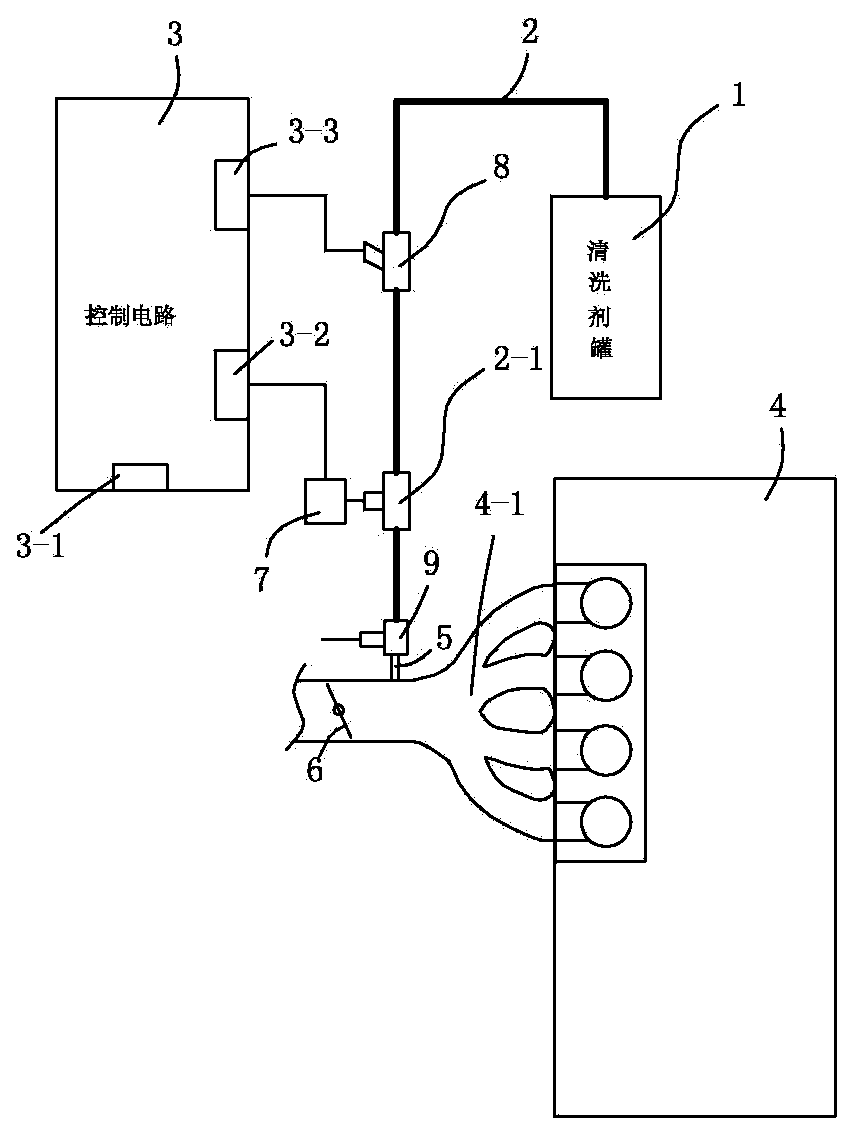

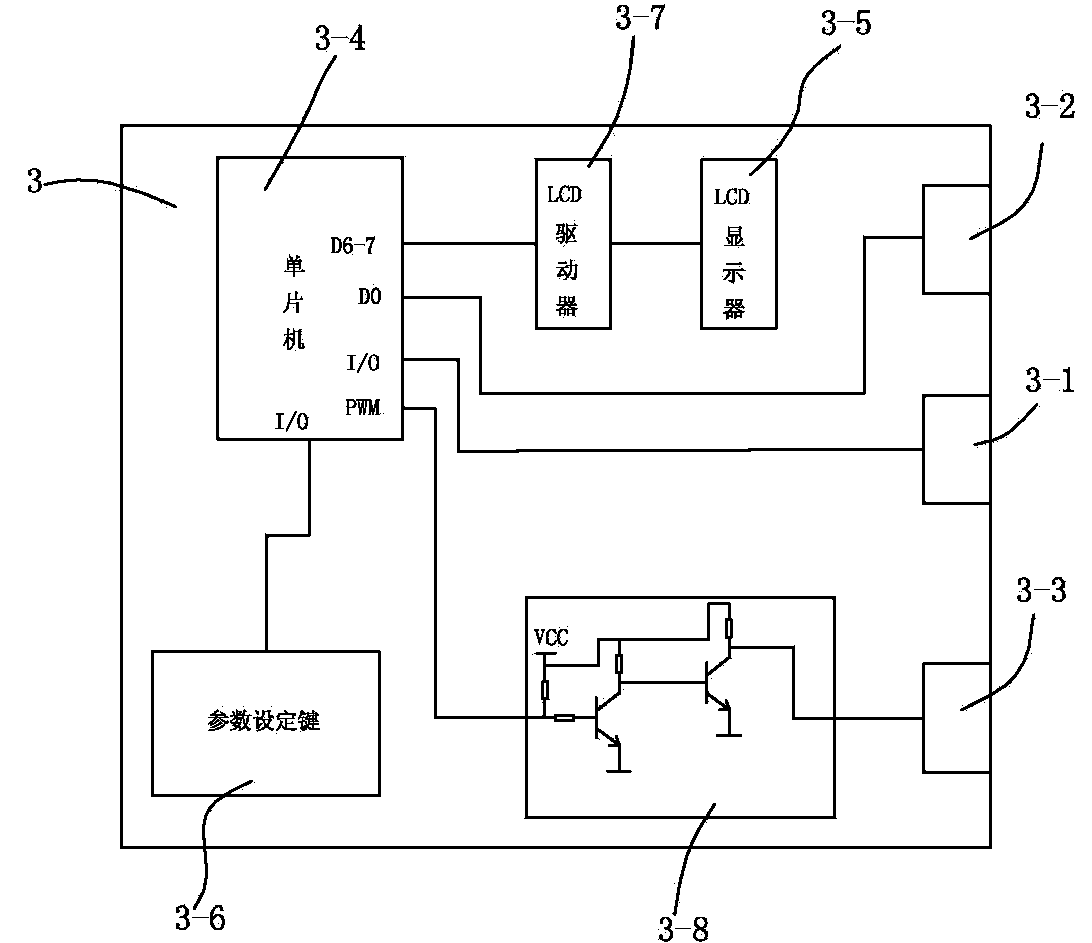

[0034] An embodiment of an engine intake valve and combustion chamber carbon deposit online cleaning system, the system is a system that can clean the intake valve and combustion chamber carbon deposits while the car is running, including a detergent tank 1 and a detergent input pipe Road 2 and control circuit 3, the intake valve cleaning agent is installed in the lotion tank, and the control circuit contains a cleaning work program, which controls the conduction and shutdown of the cleaning agent input pipeline; wherein, the control circuit A cleaning starting circuit 3-1 is arranged in the cleaning agent tank, the detergent tank is arranged on the vehicle frame in the hood of the automobile, one end of the detergent input pipeline is connected to the detergent tank, and the other end of the detergent input pipeline is connected to the engine 4 The vacuum pipeline, the vacuum pipeline is a vacuum pipeline communicated with the intake valve of the automobile engine, and a contr...

Embodiment 2

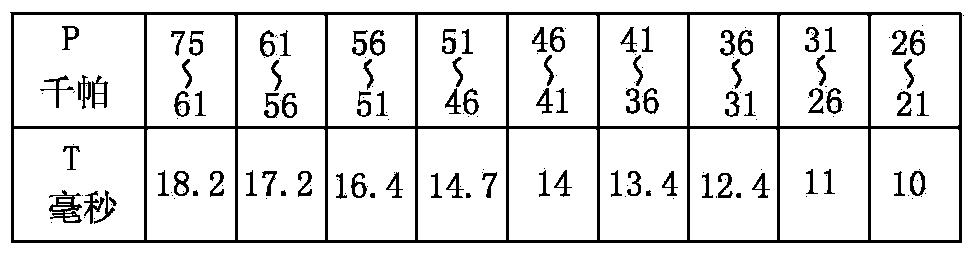

[0043] A control method for on-line cleaning of carbon deposits in engine intake valves and combustion chambers. This embodiment is based on actual

[0044] Embodiment 1 The control method of the engine intake valve and combustion chamber carbon deposition online cleaning system is a control method that can clean the intake valve and combustion chamber carbon deposits while the car is running. This embodiment is the same as Embodiment 1 Please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be used as the content of this embodiment, and will not be repeated here.

[0045] The system described in this embodiment is the second scheme system for starting the system in embodiment 1, including a detergent tank, a cleaning agent input pipeline and a control circuit. One end of the cleaning agent input pipeline is connected to the cleaning agent tank, and the cleaning agent The other end of the input pipeline is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com