Electrochemistry on-line cleaning method for heavy metal on-line monitor working electrode

A technology of working electrodes and heavy metals, which is applied in the field of electrochemical cleaning, can solve the problems of oxidation state interference, poor reproducibility of working electrodes of automatic online heavy metal monitors, and constraints on the development and application of instruments, so as to achieve good electrode reproducibility and breakthrough research and development The effect of restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

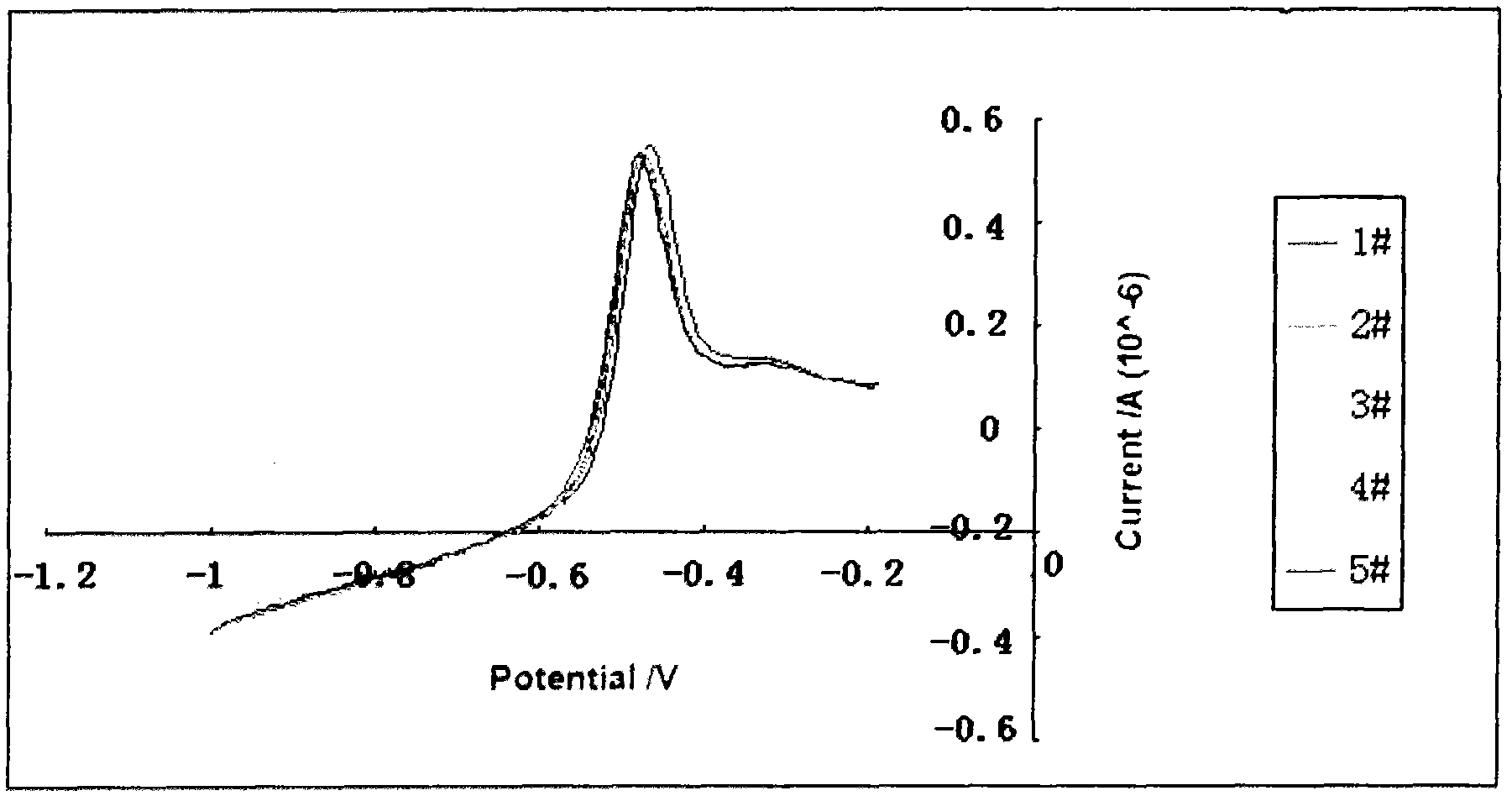

[0034] Example 1: Multiple determinations of the same water sample of lead-containing wastewater in industrial wastewater

[0035] Select an electroplating factory as the experimental site, take 5 copies of the same waste water, numbered 1, 2, 3, 4, 5# respectively, after appropriate pretreatment, and then use it.

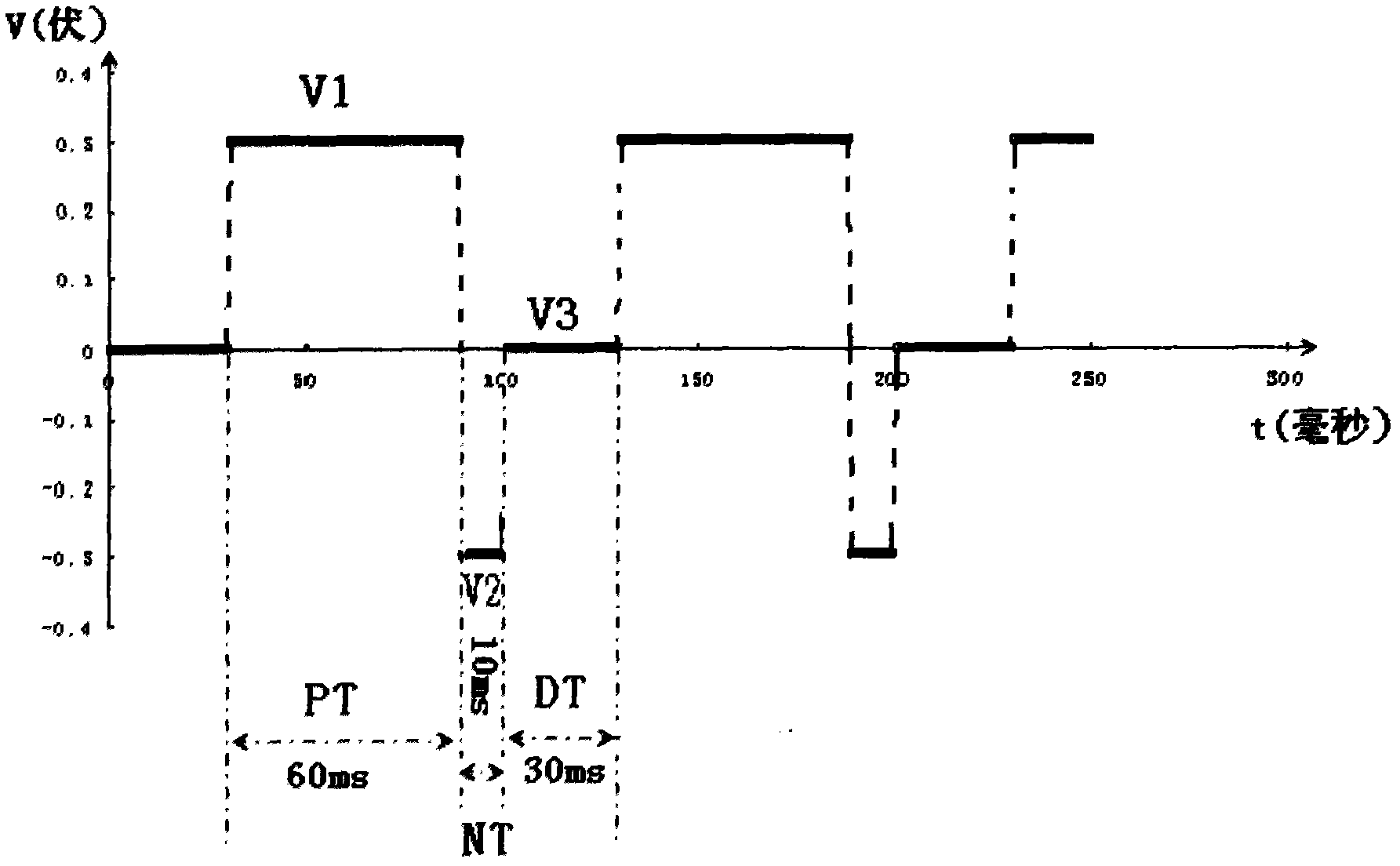

[0036] Take 1# waste water, use the heavy metal online monitor based on anodic stripping voltammetry, set the parameters, inject samples for measurement, after the measurement is completed, if figure 1 As shown, the parameters used for electrochemical cleaning are set: Potential V1 for positive potential cleaning = 0.3V, potential for negative potential cleaning V2 = -0.3V, initial potential V3 = 0V, duration of positive potential cleaning PT = 60ms, negative potential cleaning lasts The time NT=10ms, the recovery duration of the initial potential DT=30ms, and the cleaning time is 60s, that is, the number of cycles is 600 times. After setting the parameters, start...

Embodiment 2

[0037] Example 2: Multiple determinations of the same water sample of arsenic-containing wastewater in industrial wastewater

[0038] Take 5 parts of the same arsenic-containing wastewater, respectively numbered 1, 2, 3, 4, 5#, after proper pretreatment, stand by.

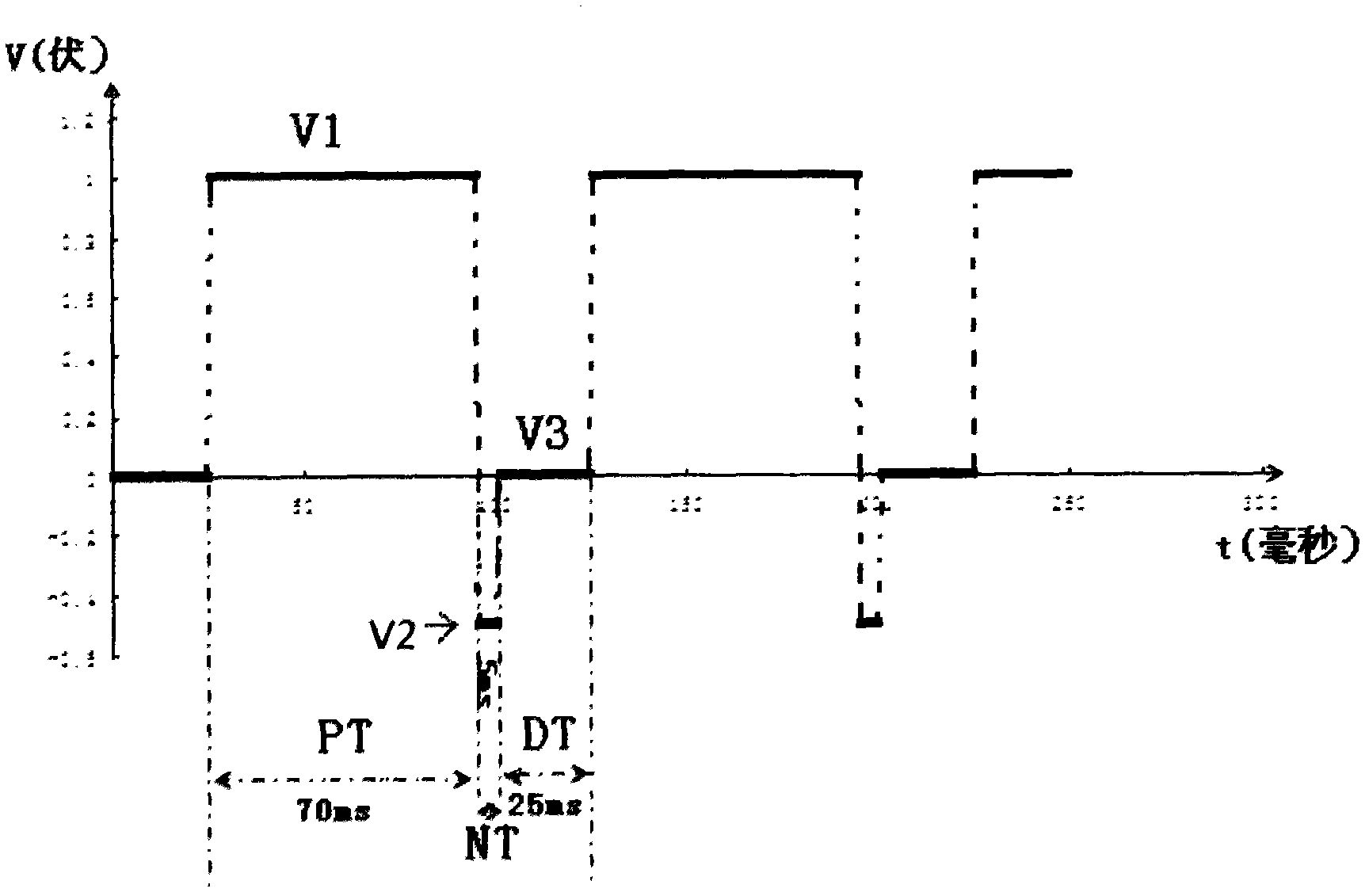

[0039] Take 1# waste water, use the heavy metal online monitor based on anodic stripping voltammetry, set the parameters, inject samples for measurement, after the measurement is completed, if figure 2 As shown, the parameters used for electrochemical cleaning are set: Potential V1 for positive potential cleaning = 1.0V, potential for negative potential cleaning V2 = -0.5V, initial potential V3 = 0V, duration of positive potential cleaning PT = 70ms, negative potential cleaning lasts The time NT=5ms, the recovery duration of the initial potential DT=25ms, and the cleaning time is 100s, that is, the number of cycles is 1000 times. After setting the parameters, start to clean the working electrode. After cleaning, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com