Online ash removing device and heat exchanger with same

A kind of dust removal device and technology of dust remover, which is applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc., can solve the problems of inability to clean dust online, easy fouling and blockage of heat exchange tubes, etc. Low thermal resistance, flexible cleaning operation, high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, an online dust cleaning device and a heat exchanger with the online dust cleaning device according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Its specific implementation, structure, feature and effect thereof are described in detail as follows.

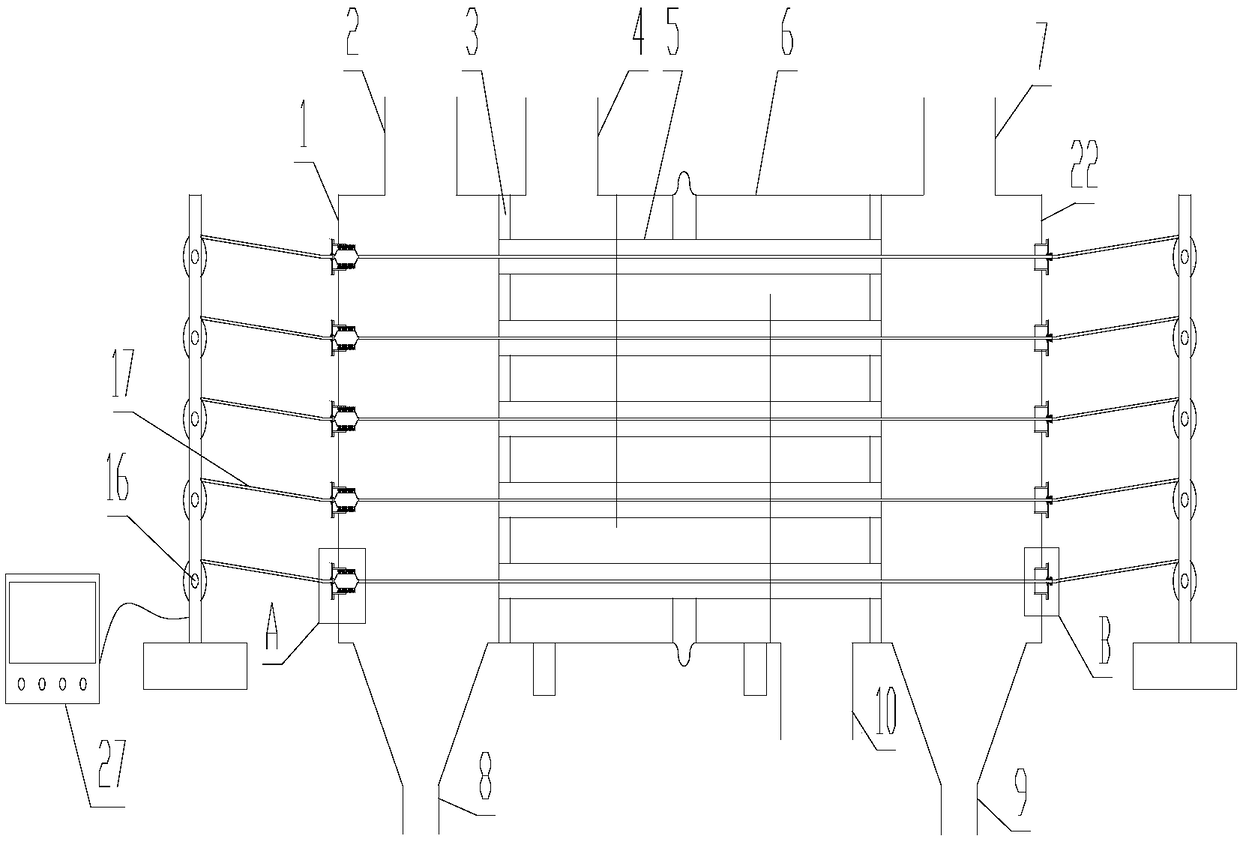

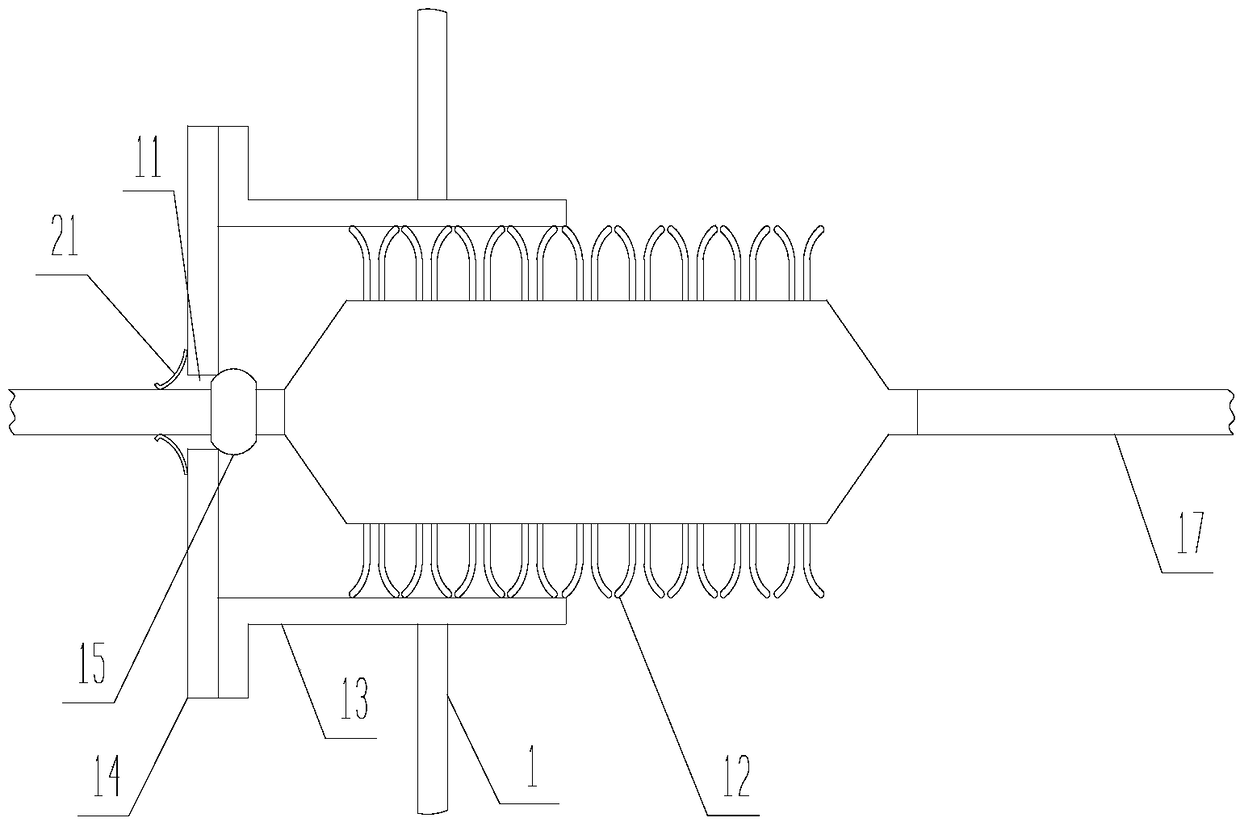

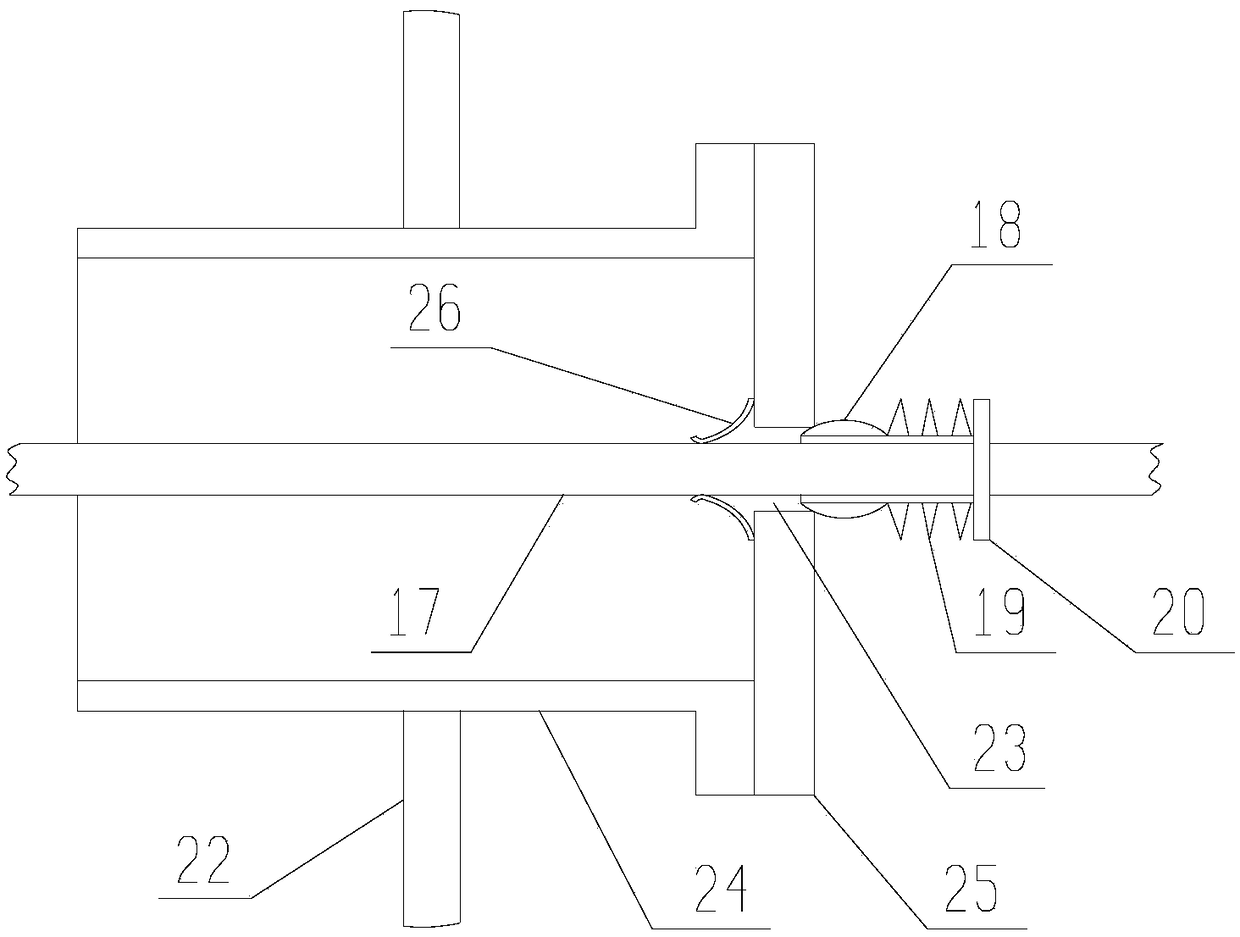

[0036] Such as figure 1 and figure 2 As shown, the online dust removal device provided by the present invention is mainly composed of a traction device 16, a wire rope 17, a dust remover 12, a front guide, a rear guide and a controller 27; On the wall of the front-end tube box 1 of the heat exchanger, the rear-end guide is fixed on the wall of the rear-end tube box 22 of the heat exchanger; the wire rope 17 passes through the front-end guide and the rear-end guide, and its two ends are respectively A traction device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com