High-solid-content engine appearance heavy greasy dirt cleaning agent and preparation method thereof

A heavy oil stain cleaning agent and engine technology, applied in the direction of detergent compounding agent, detergent composition, chemical instruments and methods, etc., can solve the problems of unsatisfactory cleaning effect, achieve the restoration of original luster, good cleaning effect, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of a high-solid engine surface heavy oil stain cleaning agent, the steps are: heating deionized water to 60-80°C, adding other raw materials, and stirring until all components are completely dissolved.

[0031] The cleaning agent involved in the present invention is prepared under the condition of 60-80°C and can be used at normal temperature. Spray this cleaner on the outer surface of the engine cylinder through a hand button spray gun, soak it naturally for 5-10 minutes, rinse with tap water to remove stubborn oil stains and carbon deposits attached to the outer surface, and restore the original luster of the engine metal surface. Steel, cast iron, aluminum, copper and other metals are non-corrosive, and the operation is simple, fast and convenient.

Embodiment 1

[0034] A high-solid-content cleaning agent for heavy oil stains on the surface of an engine, the formula of which is as follows (mass percentage):

[0035] Sodium hydroxide 2%, sodium metasilicate pentahydrate 6%, silicate stabilizer KM-309 0.6%, urea 0.5%, sodium sulfate 1.5%,

[0036] Benzotriazole 0.2%, Dodecylbenzenesulfonic Acid 2.0%, Oleic Acid 0.8%, 6501 0.5%, AEO-7 0.4%, OEP-98 0.5%,

[0037] Butyl cellosolve 4%, isopropanol 6%, deionized water as the balance.

[0038] Preparation process: heat deionized water to 70°C, add sodium hydroxide, sodium metasilicate pentahydrate, silicate stabilizer, urea, sodium sulfate, benzotriazole respectively, stir to dissolve all, and keep warm at 70°C , and then add the remaining ingredients while stirring, and obtain a light brown to brown transparent liquid after complete dissolution.

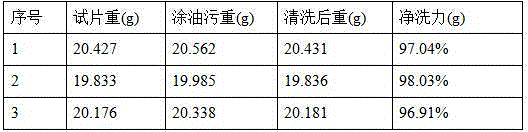

[0039] Detergency test: test according to the requirements of QB / T 2117 general water-based metal detergent

[0040] The test results are shown ...

Embodiment 2

[0061] A high-solid-content cleaning agent for heavy oil stains on the surface of an engine, the formula of which is as follows (mass percentage):

[0062] Sodium hydroxide 2%, sodium metasilicate pentahydrate 10%, silicate stabilizer KM-309 1.5%, urea 0.5%, sodium sulfate 1.5%, benzotriazole 0.5%, dodecylbenzenesulfonic acid 1.5%, oleic acid 0.8%, 6501 0.5%, AEO-7 0.4%, OEP-98 0.5%, butyl cellosolve 3%, isopropanol 5%, deionized water as the balance.

[0063] Preparation process: heat deionized water to 70°C, add sodium hydroxide, sodium metasilicate pentahydrate, silicate stabilizer, benzotriazole respectively, stir to dissolve all, keep warm at 70°C, and then stir The rest of the ingredients were added and dissolved completely to give a light brown to brown homogeneous liquid.

[0064] Detergency test: test according to the requirements of QB / T 2117 general water-based metal detergent

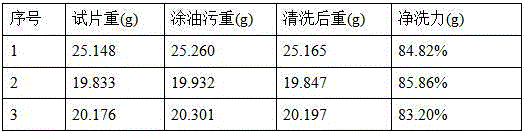

[0065] The test results are shown in the table below

[0066] table 3:

[0067] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com